* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Crane Electronics

Electromagnetic compatibility wikipedia , lookup

Mechanical filter wikipedia , lookup

Three-phase electric power wikipedia , lookup

Stray voltage wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Nominal impedance wikipedia , lookup

Voltage optimisation wikipedia , lookup

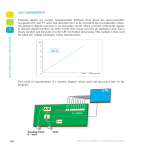

Power inverter wikipedia , lookup

Mains electricity wikipedia , lookup

Current source wikipedia , lookup

Distribution management system wikipedia , lookup

Two-port network wikipedia , lookup

Voltage regulator wikipedia , lookup

Alternating current wikipedia , lookup

Analog-to-digital converter wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Schmitt trigger wikipedia , lookup

Zobel network wikipedia , lookup

Amtrak's 25 Hz traction power system wikipedia , lookup

Integrating ADC wikipedia , lookup

HVDC converter wikipedia , lookup

Opto-isolator wikipedia , lookup

ELDEC GENERAL TECHNOLOGY HYDRO-AIRE INTERPOINT LEAR ROMEC P.L. PORTER SIGNAL TECHNOLOGY Keltec Olektron Crane Electronics Power Solutions SOLUTIONS Components (Interpoint) • • • • • • • • • Aircraft Electrical Power Cabin Fluid Management Landing Systems Sensing & Utility Systems Power Microwave Systems Electronic Manufacturing Microelectronics DC/DC Converter Application Considerations Interpoint Hybrids Interpoint has been making hybrids since 1969 and is a pioneer in DC-DC converter hybrid technology Advantages of Hybrids • Hermetically sealed (90% dry nitrogen) – protects from humidity, corrosion, contaminants, and makes converters less susceptible to arcing at high elevations • Completely enclosed, and sealed, in a metal case – reduces radiated EMI when case is grounded. • Uses printed ink resistors – increases power density and eliminates solder connections. • Uses low profile magnetics – improves vibrations • No potting material – makes the converters easier to produce, trouble shoot and provides better thermal performance. Uses bare die – better heat transfer, higher power density, reduced parasitics, lighter weight and no hardware required for attachment. ©2006 Crane Aerospace & Electronics 2 Interpoint Hybrids Cont. Hybrid Assemblies Cover Magnetic Semiconductor Wire bonds Traces / printed resistors Solder Epoxy or solder Ceramic substrate Solder Thermal epoxy ©2006 Crane Aerospace & Electronics Header (base plate) 3 Interpoint Hybrids Cont. ©2006 Crane Aerospace & Electronics 4 Reliability What can be done to insure higher reliability • Improve heat sinking. Every 25 degree C temperature rise will decrease MTBF numbers by approximately a factor of two. • Order parts with a higher screening level Consider flanged parts – a converter bolted down will stand up to shock and vibration better than a converter whose only means of attachment having their pins soldered to a PCB. Flanges also provide additional heat sinking. Non Flanged Flanged ©2006 Crane Aerospace & Electronics 5 Handling General Handling Precautions Parts should be handled carefully to protect the integrity of the compressions seals around the pins. A damaged seal, can result in loss of hermeticity. A bent pin can result in a damaged seal and a cracked substrate. If a part is dropped the seal can be compromised or the substrate could be cracked. Never cut an unsupported pin. The shock may damage the seal. A gauge block or other tool that slips over the pin, to provide support, should be used before cutting. Once a converter is soldered into a PCB the solder should have enough support to cut the pins. ©2006 Crane Aerospace & Electronics 6 Reliability Cont. Screening table from Interpoint data sheet More screening translates to higher reliability Testing options Tests performed (yes/no) ©2006 Crane Aerospace & Electronics 7 Reliability Cont. Screening table from Interpoint data sheet cont. Screening affects MTBF results Screening levels are Standard, ES, H (883), and K Standard = x MTBF hours ES = ~ 2x MTBF hours H (883) = ~ 4x MTBF hours K = ~ 16x MTBF hours ” K” screening levels have approximately16 times the MTBF hours as a Standard screening level. ©2006 Crane Aerospace & Electronics 8 Thermal Management Cont. Magnetic Semiconductors Trace Heat Sources Heat transfer Thermal epoxy or solder Ceramic substrate Solder Header Customer interface (PCB / Heat-sink) ©2006 Crane Aerospace & Electronics 9 Thermal Management Cont. The operating temperature refers to the header (base plate) temperature of the converter Heat extraction is through the header. Interpoint converters are designed to be conduction cooled. Heat generating components are thermally attached to the header, either directly mounted (magnetics), or mounted to a ceramic substrate material that has is thermally connected to the header. Steel headers are 0.050in – 0.060in (1.27mm – 1.52mm) thick providing a low thermal impedance. While power dissipation is not uniform across the header, the temperature delta on the header should be < 1 - 2°C ©2006 Crane Aerospace & Electronics 10 Thermal Management Cont. Interpoint converter’s should be de-rated linearly from 100% at “maximum full load operating temperature” (typically 125 degrees) to 0W at “absolute maximum operating temperature” (typically 135 degrees C). Power Full load Temperature -55°C No load 125°C ©2006 Crane Aerospace & Electronics 135°C 11 Thermal Management Cont. Our converters do not have a single Tjc and do not require calculations for junction temperature. What matters is that the base plate / header does not exceed the “maximum operating temperature”. • There is no internal temperature sensing, or over-temperature shutdown circuitry, built-in to Interpoint converters. • Power dissipating components are spread out to create an even heat distribution. ©2006 Crane Aerospace & Electronics 12 EMI What is EMI? • EMI is ElectroMagnetic Interference which can be an electric field or a magnetic field. Electric fields are typically generated from voltage and magnetic fields are typically generated from currents. • Interpoint converters are completely enclosed and, when the case is grounded to earth, short electric fields to earth ground. This reduces radiated EMI significantly. Some magnetic fields can escape but are typically not a problem. The measurement of EMI is the vector sum, or difference, of CM and DM noise. EMI consists of both common mode (CM) and differential mode (DM) noise. DM noise, also known as normal mode noise, is when the currents 180 degrees out of phase between positive input and input Common. CM noise is in is typically in phase in the input lines but can have some out of phase component if the line impedances are not balanced. CM noise is measured WRT chassis. ©2006 Crane Aerospace & Electronics 13 EMI Cont. CM noise CM noise is typically generated by capacitive coupling of power components to the chassis. During switching the high dv/dt of the power components, during turn on and turn off, pump currents into the chassis through the parasitic capacitance. Internally radiated noise conducted to the chassis and input leads can also become CM noise. Ceramic Substrate Power Component Parasitic Capacitance Header/Chassis (heat sink) Chassis Connection ©2006 Crane Aerospace & Electronics 14 EMI Cont. = Switching Power Components Cp = Parasitic Capacitance ICM = CM current Typical DC/DC Converter Block Diagram Common mode currents should be bypassed back to their source. Any current that is not bypasses back to its source can take the path of the LISN and be measured. ©2006 Crane Aerospace & Electronics 15 EMI Cont. How is EMI measured A device, known as a LISN (Line Impedance Stabilization Network), is used to measure noise (pollution) in each line. It allows DC to pass and provides a path for high frequency current / voltage to be measured. EMI specs are typically concerned with high frequency noise. The high frequency takes the path of lowest impedance. Any current passing through the 50 ohm resistors (in the spectrum analyzer) will be measured. LISN 28V In 28V Out To Spectrum Analyzer Make sure when testing the unused LISN terminal is terminated with 50 ohms. To Spectrum Analyzer Two things can be done to prevent noise from being measured 1. Add a high impedance between the LISN and converter. 2. Add a low impedance to shunt current away from the LISN 28V Rtn 28V Out Rtn. Blocks high freq but allows DC current to pass Low Z allows high freq current to be measured ©2006 Crane Aerospace & Electronics 16 EMI Cont. CM Noise - No CM Filtering I x R measured by spectrum analyzer Voltage rising due to switch turning off LISN Converter Parasitic capacitance Current flow There will be some in-phase and some out-of-phase components depending on the impedances of the current paths. This shows the main switch turning off. When it turns on, the current paths will change. ©2006 Crane Aerospace & Electronics 17 EMI Cont. CM Noise - With CM Filter Lower I x R measured by spectrum analyzer LISN High Impedance Converter Parasitic capacitance Current takes path of least impedance ©2006 Crane Aerospace & Electronics 18 EMI Cont. DM Noise - No DM Filtering I x R measured by spectrum analyzer High Z (DM) T h i s Low Z (DM) LISN Converter Partial EMI filter, internal to converter, reduces ripple current but not enough to pass EMI specs ©2006 Crane Aerospace & Electronics 19 EMI cont. DM Noise - With DM Filtering Lower I x R drop measured by spectrum analyzer DM choke – High Z and lower ripple current To DC source Converter LISN Dampening network for low Q ©2006 Crane Aerospace & Electronics Added DM cap – low Z and stored charge 20 EMI Cont. • Keep power traces short and wide and overlap them with their return path. • If possible overlap Input Positive and Input Return traces. Overlap Vout with Output Common. Overlap a clock signal with its return signal. If traces can not be overlapped keep them as close together as possible - minimize the loop. Overlapping traces means one trace runs on one side or the board and the return path for that trace runs on the other side of the board directly above or below it. This included Sync and Sync return. • Keeping traces short will help reduce radiated noise. • Keeping traces wide will add capacitance when overlapping. Wide traces will also have a slight affect on reducing inductance (although inductance can be good in some cases). • When possible, ground the converter’s case to earth ground to minimize radiated noise. ©2006 Crane Aerospace & Electronics 21 EMI Cont. Keep a low inductance / resistive path between filter chassis and converter chassis to allow the CM noise can take the path of the CM filter caps (internal to the external filter) to get back to the converter. Filter converter 6 1 4 2 3 5 7 C4 ??? CM current Low impedance needed Keep filter and converter as close together as possible and connect chassis to earth ground to reduce radiation. ©2006 Crane Aerospace & Electronics 22 EMI Filters Cont. Try and keep power flow in a straight line. The EMI filtering section should be in a noise free environment. Placing the EMI, or input section, by the output, or any other noise source, may allow the noise to couple to the input and be measured. Loops (no overlapping) Filter To LISN Non Ideal Layout Converter Long, thin, traces Load Coupled noise is not filtered Ideal Lay-out • Short traces • Wide traces Vin Filter Converter Load • Straight flow • Over-lapping traces • Good chassis connections Good chassis connections between filter, converter, and chassis (earth ground) ©2006 Crane Aerospace & Electronics 23 EMI Filters Cont. Capitalize on the Parasitics If parasitics are not considered, a balun (CM choke) will act as a short to DM currents and act as a high impedance to CM currents. If using a balun consider segment winding a choke vs. bifilar winding. The poor coupling will create DM inductance (leakage inductance) free. The diagrams below show a segment wound versus a bifilar wound CM choke. Bifilar wound. Low DM inductance and more likely to have a short between the 2 wires Segment wound. Free DM inductance (good) and less likely to have a short between the 2 wires +28V +28V Rtn. Loose coupling between +28V and +28V Rtn. ©2006 Crane Aerospace & Electronics Good coupling between +28V and +28V Rtn. 24 EMI Filters Cont. Measuring leakage inductance of a CM choke Short the two Finish ends of the inductor (28V Out to Return Out) Measure between the two start ends of the inductor (28V In to Return In) The measured value will be the influence of both windings in series as seen by the DM noise. Measure between both start leads Short both finish leads ©2006 Crane Aerospace & Electronics 25 EMI Filters Cont. Choosing a filter • Size the filter for the maximum steady state current at the lowest input voltage. Maximum converter current = PoutMax / (VinMin x efficiency). For multiple converters add their currents. • Surge currents during start up are typically not a concern. • Check converter and filter data sheets for recommended filter / converter combinations. From FMCE-1528 data sheet ©2006 Crane Aerospace & Electronics 26 EMI Filters Cont. • When using more than one converter with an EMI filter consider syncing converters to eliminate beat frequencies. Beat frequencies typically occur at frequencies below most EMI specs but not always. • If using an external DM capacitor between a converter and filter consider adding a damping resistor in series with the cap. Modeling results to insure a low Q is recommended. • For modeling purposes, filter schematics are typically available in our data sheets. Converter input filter schematics and EMI filter schematics can be obtained through Interpoint applications department. Schematic from FME28-461 data sheet ©2006 Crane Aerospace & Electronics 27 Output Filtering • For reducing DM output noise add DM capacitance at the output. Adding caps close to output pins of converter can will keep currents local and help prevent conducted noise from becoming radiated noise. Adding them at the load will clean up the noise where it counts. • For greater noise reduction add an inductor to make an LC filter. Modeling is recommended to verify a low Q. Don’t forget to incorporate load capacitance into your model. • A higher C, and lower L, will decrease the Q of an external filter (Good). The leakage inductance from a CM choke will typically provide enough DM inductance to provide excellent results. An inductor can compromise output load transient performance (bad). ©2006 Crane Aerospace & Electronics 28 Output Filtering Cont. A higher C can improve output load transient performance (good) as long as it does not decrease the BW of the converter too much. To keep from interacting with the converter’s control loop, external output LC filters should have their resonant frequencies greater than 100KHz, or be well damped. When using an external output LC filter, with a converter that has remote sensing, always sense before the output choke. Sensing after the output choke will add two poles to the compensation and could make the converter unstable. All high frequency caps should have low ESR/ESL. A larger value, low frequency cap, and damping resistor, can take care resonance if an inductor is used as part of the filter. • Consider using different value caps. Smaller value caps typically work better at high frequency and larger value caps work better at low frequency. A 2.2uF, a 0.1uF and a 0.01uF cap in parallel may provide better noise attenuation than a 4.7uF cap. ©2006 Crane Aerospace & Electronics 29 Output Filtering Cont. • Layout rules for EMI also apply for output noise. • With typical measuring techniques CM noise can show up as DM noise. A CM choke, and CM capacitors, can greatly reduce the apparent DM noise (CM noise). • Bypassing CM noise from Output Common to chassis with ceramic caps will reduce CM noise. Having a ceramic cap from Input Common to chassis will help re-direct some of the currents back to the primary if that is where it belongs. Make sure isolation specs are not being violated because of this. If designing a CM filter consider segment winding the balun (CM choke) to take advantage of the free DM inductance (leakage inductance). Modeling • The next few pages show results from making slight adjustments to a damping resistor of an output filter. It affects the Q and the attenuation of the output noise. Changes in any component can produce similar results. • Modeling is highly recommended for optimization. ©2006 Crane Aerospace & Electronics 30 Output Filtering Cont. Modeling a filter L1 will want to interact with the larger 33uF cap which can be dampened by a resistor (R3). The damping resistor is so small that it does not burn much of energy in L1. This results in a high Q. High Q Damping resistor (variable) ©2006 Crane Aerospace & Electronics 31 Output Filtering Cont. Modeling a filter Here the damping resistor (R3) is too large and the 33uF cap is affectively not in circuit. The result is a high Q. High Q Damping resistor (variable) ©2006 Crane Aerospace & Electronics 32 Output Filtering Cont. Modeling a filter Here the damping resistor is small enough to allow the 33uF cap to interact with L1 yet big enough to burn the energy in L1. This results in a low Q (desirable) and the attenuation has not suffered. Low Q (good) Damping resistor (variable) ©2006 Crane Aerospace & Electronics 33 Output Filtering Cont. Before and After results of a MTR2805S (full load) using a filter similar to the one shown in the previous slide, and an optimized layout. The inductor was a segment wound CM inductor to achieve a leakage inductance of around 1.5uH. In addition a CM cap was connected from Output Common to Chassis. Most of the 4mVpp noise shown here is not real as the scope shows 3mV without the converter on. Before After Scope set to 20MHz BW. Use barrel of scope probe for measurement App note ©2006 Crane Aerospace & Electronics 34 Line Transients • A line transient is a fast, dynamic, change in input voltage. • The change in line voltage can be within the converter’s normal operating range or out of its normal operating range. • When operating out of the normal operating range a maximum value, and time, is imposed. • The specified transient value is the maximum input voltage not a value added to the 28V bus. A 50V transient means the input will see 50V not 50V on top of 28V. Excerpt from data sheet Normal operating range Transient (outside normal Operating range) Transient within normal Operating range Imposed time ©2006 Crane Aerospace & Electronics 35 Synchronization Usage The Sync feature allows adjustment of the converter’s switching frequency by an external clock. • Noise injected into the sync input can adversely affect converter performance so place close attention to layout and recommendations for unused sync pins. Applications include - Concentration of the noise generated by several converters into a narrower band. - Shifting the noise away from sensitive frequencies of a system. - Eliminating beat frequencies from parallel converter operation. No sum or difference frequencies are present. Low frequency noise is not attenuated significantly by an EMI filter. ©2006 Crane Aerospace & Electronics 36 Synchronization Usage Customer’s System +28V Converter 1 Filter Sync out Sync in +28V Rtn Do not connect Sync Return to Input Common of an EMI filter. High frequency currents run through the filter (noise) and the CM inductor can have several volts (noise) across it. ©2006 Crane Aerospace & Electronics 37 Synchronization Usage Customer’s System +28V Converter 1 Filter Sync out +28V Rtn Sync in • Here we have the Sync Return line going directly to the converter’s Input Common as desirable. The problem is now you have shorted out the CM choke in the external filter and the high current on the +28V Return line will want to return through the Sync Return Trace – not good. ©2006 Crane Aerospace & Electronics 38 Synchronization Usage Cont. Two converters & filter (recommended connections) Power (noise) Customer’s System +28V Converter 1 Filter Sync in +28V Rtn Sync out Overlap traces to reduce EMI Overlap traces to reduce EMI Wind transformer with good coupling (bifilar) to reduce leakage inductance Connections made directly to pins of converter Converter 2 Sync in Power traces (noisy) Overlap traces to reduce EMI Dedicated traces (clean) ©2006 Crane Aerospace & Electronics 39 Synchronization Usage Cont. • The application of the Sync signal can cause an output voltage transient. It is recommended to apply sync while the converter is Inhibited, then release Inhibit. • If the converter can not be Inhibited, have the initial Sync signal transition be negative (i.e. from 5V to 0V). This has been shown to reduce output transients due to the application of the Sync. Do not deviate from the recommended sync range or the converter may be damaged. If the recommended range is from 500kHz to 600kHz a value of 200kHz may saturate magnetics and damage a converter. More benign deviations may cause the converters to run hot. If the Sync signal is not being used see data sheet recommendations for unused pins. Typically, if unused, the Sync pin is connected to Input Common. Although the converter will most likely run fine when floating following the “unused pin recommendations” makes the Sync signal less susceptible to noise. • See data sheet for recommended amplitudes, duty cycles and frequency ranges. App note ©2006 Crane Aerospace & Electronics 40 Inhibit Usage Cont. Primary Inhibit circuit used on many Interpoint converters Inhibit External circuitry Inhibit should be open circuit for enable, and connected to Input Common for Primary Inhibit or to Output Common for Secondary Inhibit (check data sheets for recommendations). An internal pull-up is present, no external pull-up is needed, or recommended. Do not apply voltage to the Inhibit pin. ©2006 Crane Aerospace & Electronics 41 Inhibit Usage Cont. Transitions should be very fast. Do not use capacitors on the Inhibit pin to delay the rise. • When using a common connection to inhibit several converters each inhibit may need to be isolated with a diode. Some converters already have internal isolation diodes. Check with Interpoint Applications if in doubt. App note ©2006 Crane Aerospace & Electronics 42 Current Limit • Interpoint converters have current limit points that are typically 115% to 125% of full load. Check data sheet to be sure. Interpoint converters typically have a constant current, current limit. As current tries to increase past the current limit point the output of the converter drops sharply. Output drops at current limit point full load 120% of full load Vout • Iout ©2006 Crane Aerospace & Electronics 43 Current Limit Cont. Short Circuit Protection Short circuit protection is current limit with any output shorted. The output will limit its current by causing the output voltage to drop. The output voltage, at the pins of the convert, will be equal to Iout x Rout. Rout is the resistance seen by the output pins of the converter and Iout is current limit value. Example Current limit = 10A Rout = 0.02ohms (trace resistance and short resistance) Vout = 0.2V (10A x 0.02 ohms) • It is good practice to heat sink for worst case power dissipation. This is may be during short circuit. ©2006 Crane Aerospace & Electronics 44 Input Impedance Input filters should have low impedance Source impedance is the total impedance looking from converter input pins into the DC source, including the DC source. Source impedance includes PCB traces, external filters, inrush protection, DC source and anything else in between. Don’t forget to consider dynamic impedances (inductors, capacitors) The total source impedance must be lower than the input impedance of the converter or the converter can oscillate causing damage to the converter. • A dc-dc converter has a negative input impedance which means that as input voltage decreases, input current increases. This is the opposite of a resistive load and at low frequencies the input current will be 180 degrees out of phase from the input voltage ©2006 Crane Aerospace & Electronics 45 Input Impedance cont. With a converter Pout stays constant and the input impedance increases proportionally to Vin2 Zin vs. Vin 80 70 60 Vi n2 /2 0W Low input voltage (high input current) translates to low converter input impedance. Compare the graph of Zin to Iin. 50 40 Zi n The input impedance of a DC converter is equal to Vin2/ Pin. = 30 Zin 20 10 0 0 ©2006 Crane Aerospace & Electronics 10 20 30 40 46 Input Impedance cont. Consider more than just steady state impedances Consider converter Input impedance during application of a slow rising input voltage bus. The converter may turn on at a low voltage (~14V) and the converter’s input impedance will be lower than at nominal line voltage. When the converter turns on the output voltage rises very fast. The fast rise of output voltage will charge any internal output filter capacitance, and load capacitance. There can also be overshoot during turn on. This rise in output voltage can create higher Pout than steady state. • Where possible, reduce input DM inductance and increase input DM capacitance. - DM capacitance decreases impedance seen by the converter - DM inductance increases impedance seen by the converter - Q is proportional to the square root of L/C (low L, hi C decrease Q) App note ©2006 Crane Aerospace & Electronics 47 Input impedance continued Cont. Vin Vout Fast rising input voltage Rising Vout charges output filter caps Iin Steady state current (0.5A / div) Turn on of MTR2805D (10V span voltage with 11.8 ohm load – less than ½ load) A mercury switch was used to apply an instantaneous voltage to the input of a MTR. The fast rising output voltage creates a surge current into the output filter capacitor. This is reflected back as input current. Adding load capacitance will increase this surge current. After the output filter capacitor is fully charged the converter operates in steady state and the input current can easily be calculated. ©2006 Crane Aerospace & Electronics 48 Input impedance continued Cont. Vin Slow rising input voltage Vout Low-line-drop-out PWM momentarily throttles back due to overshoot Iin High input current due to low line operation Steady state current (0.5A / div) Turn on of MTR2805D (10V span voltage with 11.8 ohm load – less than ½ load) DC source comes up slowly and high current is demanded at low input voltages. The output rises slowly, with input voltage, due to the duty cycle being maxed out at low input voltage (low-line-drop-out). Slow rise in output voltage does not create high currents into output filter capacitor. The output overshoots and causes the converter’s PWM to momentarily turn off until the output voltage drops to the regulation level. ©2006 Crane Aerospace & Electronics 49 Using the Span voltage Interpoint’s dual converters can be used as dual outputs or a single output. When used as a single output this is referred to as the “span voltage” Example If a 12V dual is configured as a positive 24V output, the negative output would be used as Output Common, and the positive output would be used as the +24V output. Output Common of the converter would be left floating. If a12V dual is configured as a negative 24V output the positive output would be used as Output Common and the negative output would be used as the -24V output. Output Common of the converter would be left floating. D2 L3 D2 +24V L3 +12V D3 +12V D3 C1 Rtn. C1 N/C Rtn. C2 N/C C2 D4 D1 System RTN D4 L4 -12V D1 System RTN Float Output Common and use as +24V L4 -12V -24V Float Output Common and use as -24V ©2006 Crane Aerospace & Electronics 50 Using the Span voltage Cont. Capacitance when using a span voltage • When using a dual configured as a single output, the span voltage is capable of half the load capacitance of each output. Example If a 12V dual has a maximum capacitive rating of 100uF on each output, the total capacitance for the span voltage would be ½ the max capacitance for each output or 50uF. An easy way to visualize this is to break the output common connection and the caps are in series which halves their value. converter Load converter Load pos_max 100uF neg_max 100uF = ©2006 Crane Aerospace & Electronics Max_load_cap 50uF 51 Maximum Output Capacitance Load capacitance above maximum rating • Adding output capacitance typically increases the output rise time. On some models it may cause output overshoot at turn on if the capacitance is significant. • Adding output capacitance can also reduce the converter’s BW making it a little more sluggish to load transients. • The maximum output capacitance values range from 10uF(MHF+2812D and MHF+2815D) to 5000uF. • Too large of value can interfere with control loop and can cause undesired operation. The SMDs, if available, list the maximums capacitance for Interpoint converters. All new data sheets will have this information. ©2006 Crane Aerospace & Electronics 52 Load Balance • Load balance only pertains to dual converters (not all) and the auxiliary outputs of triple converters. • Typical load balances are 10% / 90%, 20% / 80%, 30% / 70%. • When deviating from the load balance spec the negative output can be out of regulation. Example Assume a 20% / 80% load balance spec and a full rated power of 10W (sum of both outputs). At full load one output can supply 8W while the complimentary output can supply 2W. If one output is 8W and the other output is 1W the spec would be violated. At 50% of full rated power (5W) one output could provide 4W if the complimentary output were at 1W or greater. If the complimentary output went to 0.8W while the other output was set to 4W the spec would be violated. ©2006 Crane Aerospace & Electronics 53 Accessing SMDs - DSCC website Standard Microcircuit Drawings, also known as SMDs, are data sheets provided by the Defense Supply Center Columbus (DSCC) in their format. They include parameters, and conditions, that may not be included on a Interpoint data sheet. Shown to the right are three pages of an 18 page MSA2805S SMD ©2006 Crane Aerospace & Electronics 54 Accessing SMDs - DSCC website Cont. Enter www.dscc.dla.mil into browser and hit enter At the bottom of the home page click on “Standard Microcircuit Cross-Reference” Below shows the screen that should appear and how to access the desired part. In this case it is the MSA2805S Select Vendor PN Select Contains Type in part number Click go ©2006 Crane Aerospace & Electronics 55 Application Notes Application Notes Interpoint has many application notes related to DC-DC converters and filters. These have a wealth of information that may make the difference between a successful or an unsuccessful design regardless of whose converters are used. They user friendly, easy-to-read and in an easy-to-understand format. A list of our app notes are provided below. We hope to increase this list soon. DC/DC Terminology - Provides a glossary of terms used in the industry - Allows for a better understanding of parameters used in Interpoint’s data sheets. Designing with a Distributed Power Architecture - Explains the benefits of using a Distributed Power Architecture - Explains some of the issues when working with DC-DC converters. EMI Compliance Statement - Discusses some of the requirements of Mil-Std-461C - Addresses which of these requirements Interpoint converters typically meet EMI Conducted Interference - Explains what EMI is and how it is generated - Provides a tutorial on the design of EMI filters - Explains what can be done to reduce EMI - Contains precautions such as what happens with an un-dampened filter. - Explains and cautions about Input impedance issues. ©2006 Crane Aerospace & Electronics 56 Application Notes Cont. Inhibit & Synchronization - Provides an overview of Interpoint’s Inhibit and Sync circuits including circuit diagrams - Provides “Do(s)” and “Don’t(s)” when using Inhibit or Sync - Addresses the use with multiple converters - Provides Lay-out precautions Inrush Current - Provides an overview of the causes of Inrush current - Explains what can be done to reduce Inrush currents - Explains input impedance issues and provides precaution - Provides a schematic of a circuit that can be used to reduce Inrush currents Mechanical Mounting, Vibration and Shock - Addresses the handling, including the cutting of pins, of Interpoint converters - Touches some thermal issues - Addresses vibration and shock Measurement and Filtering of Output Noise - Explains sources of noise - Explains differences between CM noise and DM noise - Provides measuring techniques - Provides solutions for reducing CM and DM noise - Provides precautions ©2006 Crane Aerospace & Electronics 57 Application Notes Cont. Thermal Management - Explains how to calculate power dissipation (source of heat) - Explains convection, conduction, and radiation - Provide a basic understanding of thermal issues including calculations. - Explains thermal impedances of Interpoint converters Transient Suppression - Briefly touches some transient specs - Provides some solutions, including schematics, and outlines limitations - Provides precautions such as damping and impedance imbalances Link to app notes http://www.interpoint.com/resources/application_notes ©2006 Crane Aerospace & Electronics 58 Application Assistance Interpoint has a dedicated applications department whose sole purpose is helping customers. Application Goals Respond to customers within 24 hours. We can usually be reached immediately by phone. Provide customers with the answers they need to move forward. Encourage all questions from the customer and make them feel all their questions are welcome and important Always encourage customers to follow up if they are not satisfied with the answers Provide the best service in the industry! Application Engineers Wayne Brown (425) 895-4016 [email protected] Dennis Koo (425) 895-3002 [email protected] ©2006 Crane Aerospace & Electronics 59 Aircraft Electrical Power Cabin Fluid Management Landing Systems Sensing & Utility Systems Power Microwave Systems Electronic Manufacturing Microelectronics www.craneae.com ©2006 Crane Aerospace & Electronics 61