* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download OILTAP® R Technical Data (TD 115/02)

Multidimensional empirical mode decomposition wikipedia , lookup

Electrical substation wikipedia , lookup

Ground (electricity) wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Electrical ballast wikipedia , lookup

Current source wikipedia , lookup

Transformer wikipedia , lookup

History of electric power transmission wikipedia , lookup

Three-phase electric power wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Buck converter wikipedia , lookup

Crossbar switch wikipedia , lookup

Opto-isolator wikipedia , lookup

Rectiverter wikipedia , lookup

Alternating current wikipedia , lookup

Voltage optimisation wikipedia , lookup

Distribution management system wikipedia , lookup

Stray voltage wikipedia , lookup

Switched-mode power supply wikipedia , lookup

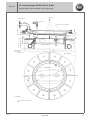

www.reinhausen.com On-load tap-changer OILTAP® R Technical Data TD 115 2 TD 115/02 115/02/01/0 Table of Contents Table of Contents 1 2 General .................................................................................................................................................................................................................. 4 1.1 1.2 4 6 Technical Data ................................................................................................................................................................................................... 15 2.1 2.2 2.3 3 Summary of the technical data ....................................................................................................................................................... Survey ....................................................................................................................................................................................................... Rated through-current (Iu), rated step voltage (Ui) and step capacity (PStN) ................................................................ 15 Contact life ............................................................................................................................................................................................. 17 Rated withstand voltages of the internal insulation ................................................................................................................ 17 Appendix – dimensional and installation drawings .......................................................................................................................... 20 NOTE These technical data are intended for the calculator and designer of the transformer. These type-specific data are only valid in connection with the information contained in the general section (TD 61) since this section contains important information on such subjects as potential connection, leakage inductance, current division, and so on. Dimensional drawings and connection diagrams are subject to change without prior notice. Drawings submitted during bidding and ordering are always binding. Since the on-load tap-changer is delivered to the specifications of the transformer manufacturer, the transformer manufacturer is responsible for selecting the correct properties of the on-load tap-changer so that the requirements of the transformer are met. 115/02/01/0 TD 115/02 3 1 General 1 General 1.1 Summary of the technical data R I 1201 R I 2002 R I 24023) R I 3003 1 1 1 1 1200 1200 2000 2400 3000 Rated short-time withstand current (in kA) 15 15 24 24 30 Rated short-circuit duration (in s) 3 3 3 3 3 Rated peak withstand current (in kA) 37.5 37.5 60 60 75 Max. rated step voltage Uim (in V)1) 4000 4000 4000 4000 3000 Step capacity (PStN) (in kVA) 3000 30002) 44002) 60003) 6000 On-load tap-changer R III 1200 Y Number of poles and application 3 (neutral point) Max. rated throughcurrent Ium (in A) Rated frequency (in Hz) Operating positions 50 to 60 Without change-over selector: max. of 18 With change-over selector: max. of 35 Rated insulation level 72.5 123 170 2459) 300 3627) Highest operating voltage Ub (phase-phase) on diverter switch (in kV) 55 79 145 170 245 3008) Rated lightning impulse withstand voltage (in kV, 1.2 I 50) 350 550 750 950 1050 1175 850 950 460 510 Highest voltage for equipment Um (in kV)5) Rated switching impulse withstand voltage (in kV) AC withstand voltage (in kV, 50 Hz, 1 min.) 140 230 Rated withstand voltages of internal insulation 325 395 see table 3 Oil compartment Pressure-proof up to 0.3 bar continuous difference pressure (test pressure 0.6 bar), head and cover of the on-load tap-changer are vacuum-proof. Oil suction pipe Installed as standard (for details, see BA 18) Temperature range The on-load tap-changer OILTAP® R can be operated in the rated load range with oil temperatures of -25 °C to +105 °C. Table 1 a 4 TD 115/02 115/02/01/0 1 General On-load tap-changer Weight (in kg) ca. Displacement volume (in dm3) ca. R III 1200 Y R I 1201 R I 2002 R I 2402 R I 3003 525 360 4454) 445 525 with changeover selector 595 (7704)) 410 (5004)) 505 (6404)) 505 (6404)) 595 (7804)) 72.5 kV 289 (3674)) 274 (3534)) 280 (3604)) 280 (3604)) 286 (3674)) 123 kV 314 (3924)) 299 (3764)) 305 (3844)) 305 (3844)) 311 (3924)) 170 kV 334 (4124)) 319 (3964)) 325 (4044)) 325 (4044)) 331 (4124)) 245 kV 354 (4324)) 339 (4164)) 345 (4244)) 345 (4244)) 351 (4324)) 369 (4464)) 374 (4534)) 374 (4534)) 380 (4614)) without changeover selector 300 kV Oil filling quantity VS and minimum volume DV6) of the diverter switch oil compartment 72.5 kV 168 123 kV 188 170 kV 203 245 kV 218 300 kV 240 Table 1 b Notes for tables 1a and 1b: 1) The maximum rated step voltage may be exceeded by 10% due to overexcitation of the transformer if the step capacity is limited to its rated value. 2) Higher step capacities available as special design 3) Forced current division by two parallel winding branches required 4) Applies to tap selector size E 5) In accordance with VDE 0111, part 1: R.m.s. value of the phase-phase voltage for which a piece of equipment is rated for its insulation 6) Minimum volume of oil conservator for oil temperature ϑ = –30 °C ... +100 °C: DV = 0,1 VS + 4 (dm3) 7) On request 8) Oil filter unit 0F 100 (combi-filter) required, UbST > 300 kV on request 9) Rated withstand voltages comply with IEC 60214: 1989; unrestricted tests possible up to 1050 kV 1.2|50 or 460 kV, 50 Hz, 1 min. 115/02/01/0 TD 115/02 5 1 General 1.2 Survey 8997470E_01 Fig. 1a 6 Survey of the on-load tap-changer designs (no. of poles, change-over selector, and installation lengths) TD 115/02 115/02/01/0 1 General 8997470E_02 Fig. 1b 115/02/01/0 Survey of the on-load tap-changer designs (no. of poles, change-over selector, and installation lengths) TD 115/02 7 1 General Survey of the basic connection diagrams (figures 2a, 2b, 2c) with designation of the tap selector contact terminals in accordance with MR standards. This contact terminal designation corresponds to the specifications in the on-load tap-changer dimensional drawings. Fig. 2a excerpt from 8906164E_1 8 TD 115/02 115/02/01/0 1 General Fig. 2b 8906164D_2 115/02/01/0 TD 115/02 9 1 General Fig. 2c 8906164D_3 10 TD 115/02 115/02/01/0 1 General Examples of connection diagrams (contact designation in acc. w. MR standards) Fig. 3 Example: On-load tap-changer R III 1200 Y–C/D, basic connection diagram 10 19 1 W 115/02/01/0 TD 115/02 11 1 General Fig. 4 Example: On-load tap-changer R III 1200 Y–E, basic connection diagram 14 27 1 G 12 TD 115/02 115/02/01/0 1 General Fig. 5 Example: On-load tap-changer R I 2002–C/D, basic connection diagram 18 35 1 W 115/02/01/0 TD 115/02 13 1 General Fig. 6 Example: On-load tap-changer R I 3003–C/D, basic connection diagram 18 35 1 W 14 TD 115/02 115/02/01/0 2 Technical Data 2 Technical Data 2.1 Rated through-current (Iu), rated step voltage (Ui) and step capacity (PStN) On-loadR III 1200 Y tap-changer Iu (A) 700 R I 1201 1200 700 R I 2002 R I 2003 (Special design) R I 24021) R I 3003 1200 1070 2000 1300 2000 1400 2400 2000 3000 Ui (V) 4000 2500 4000 2500 4000 2200 4000 3000 4000 2500 3000 2000 PStN (kVA) 2800 3000 2800 3000 4280 4400 5200 6000 5600 6000 6000 6000 Table 2 Rated through-currents (Iu), related rated step voltages (Ui) and step capacities (PStN), at highest and lowest rated step voltage of the step capacity curve (see fig. 7 and fig. 8) 1) R I 2402 with forced current division by two parallel winding branches Note: Fig. 7 Step capacities (rated step voltages Ui, rated throughcurrents Iu) for on-load tap-changer R III 1200 Y, R I 1201, R I 1202 CAUTION: Only applies to network service. When used for industrial transformers, please contact us. 8997510E 115/02/01/0 TD 115/02 15 2 Technical Data 8997510E Fig. 8 Step capacities (rated step voltages Ui, rated through-currents Iu) for on-load tap-changer R I 2002, R I 2003 (= special design), R I 2402, R I 3003. Note: 1) R I 2402 with forced current division by two parallel winding branches. CAUTION: Only applies to network service. When used for industrial transformers, please contact us. 16 TD 115/02 115/02/01/0 2 Technical Data 2.2 Contact life The mean expected contact life of the arcing diverter switch contacts can be estimated based on the relative load (Iu / Ium) as shown in figure 9. Since actual contact life in individual cases depends on many influencing factors while in service, only estimations can be given (not applicable to constant current service). The inspection regulations must be observed. Fig. 9 115/02/01/0 KHW 579-4 Expected mean contact life under average load n – Number of operations Iu – Rated through-current Ium – Max. rated through-current TD 115/02 17 2 Technical Data 2.3 Rated withstand voltages of the internal insulation Fig. 10 shows diagrams of the voltage stress present on the tap winding of the three primary basic connections of threepole on-load tap-changers and single-pole on-load tap-changers. When selecting the on-load tap-changer, a check must be made to determine whether the highest stress on the tap selector does not exceed the related rated withstand voltages. With reversing switch Without change-over selector With coarse tap selector in (+) - position With coarse tap selector in (-) - position CAUTION Adhere to the maximum rated lightning impulse withstand voltage stress on a0 in mid-position. 8997560M a0 = Between preselected and selected tapping on the diverter switch a1 = Between tap selector contacts of the winding of one tap position (connected or not) a = Between beginning and end of a tapped winding and, with coarse tap winding, between beginning and end of a coarse tap winding. Note for coarse tapping arrangement in (-) -position of the change-over selector: When stressed with impulse voltage, the permissible withstand voltage „a“ must be adhered to between the end of a coarse tap winding connected with the K tap selector contact and the tap selector contact at the end of the tapped winding of the same phase. b = Between the tap selector contacts of different phases and between change-over selector contacts of different phases, which are connected with the beginning/end of a tapped winding or with a tap selector contact. f = Between diverter switch terminal and ground Additional for coarse tapping arrangement in (+) - position of the change-over selector: c1 = From one (-) -change-over selector contact to terminal of the same phase. c2 = Between (-) -change-over selector contacts of different phases Fig. 10 18 Rated withstand voltages TD 115/02 115/02/01/0 2 Technical Data Insulation distances Note: Tap selector size D1) kV 1.2I50 kV, 50 Hz, 1 min Tap selector size E kV 1.2I50 kV, 50 Hz, 1 min Ub £ 72.5 kV: 140 kV 1.2I50; 30 kV, 50 Hz, 1 min / Ub >72.5 kV: 80 kV 1.2I50; 3 x USt a0 Table 3 Tap selector size C kV 1.2I50 kV, 50 Hz, 1 min a1 150 30 150 30 150 30 a 400 85 5002) 110 670 180 b3) 400 100 5002) 150 670 180 c1 550 180 590 210 820 250 c23) 550 195 590 225 820 280 Rated 1) 2) 3) withstand voltages (in kV) of the internal insulation of the tap selector Tap selectors in accordance with basic connection diagrams 10 09 1 W, 12 11 1 W, 14 13 1 W are designed as 18 09 1 W, 18 11 1 W, 18 13 1 W. Tap selectors in accordance with basic connection diagrams 16 15 1 W and 18 17 1 W are not possible. Higher values up to 550 kV on request Omitted for on-load tap-changers R I 1201, R I 2002/2402, R I 3003 The tap selector size (ID letters C, D, E) characterizes the internal insulation of the tap selector whose rated withstand voltages must be adjusted to the requirements of the transformer winding. The permissible maximum service voltage along the individual tap selector paths is half the AC withstand voltages listed in table 3. 115/02/01/0 TD 115/02 19 3 Appendix 3 Appendix Dimensional drawings On-load tap-changer OILTAP® R III 1200 Y, tap selector size C/D, E ...................................................................................... 896722, 897867 On-load tap-changer OILTAP® R I 1201, tap selector size C/D, E ........................................................................................... 899753, 899401 On-load tap-changer OILTAP® R I 2002, tap selector size C/D, E ........................................................................................... 896721, 897866 On-load tap-changer OILTAP® R I 2402, tap selector size C/D, E ........................................................................................... 897490, 897864 On-load tap-changer OILTAP® R I 3003, tap selector size C/D, E ........................................................................................... 896720, 897865 Tap selector and change-over selector terminal contacts, tap selector size E ...................................................................................... 897868 Installation drawings Tap selector size C/D ................................................................................................................................................................................................ 896705 Tap selector size E ..................................................................................................................................................................................................... 897873 Additional drawings On-load tap-changer head .................................................................................................................................................................................... 893899 On-load tap-changer cover with mounting flange for pressure relief valve ........................................................................................ 895168 Versions of the on-load tap-changer head, swiveling range of gear unit ............................................................................................. 896703 Special design for installation in bell-type tanks ........................................................................................................................................... 896762 Horizontal drive shaft, tap selector size C/D, E .............................................................................................................................. 896708, 897872 Jumpers for parallel connection of tap selector terminal contacts for on-load tap-changer OILTAP® R I 2002, R I 3003, selector size C/D, E ................................................................................................................................................................ 896706, 898713 Tap selector bottom, shielding, tap selector size C/D .................................................................................................................................... 896702 Tap selector bottom, tap selector size E ............................................................................................................................................................ 897869 Tie-in resistors, tap selector size C/D .............................................................................................................................. 896707, 898124 - 898135 Potential switch, tap selector size C/D, E ......................................................................................................................................... 898136, 898614 Additional drawings for on-load tap-changer ................................................................................................................................................ 898826 20 TD 115/02 115/02/01/0 8967227E 115/02/01/0 On-load tap-changer OILTAP® R R III 1200 - C/D, dimension drawing TD 115/02 21 8978677E 22 On-load tap-changer OILTAP® R R III 1200 - E, dimension drawing TD 115/02 115/02/01/0 8997530E 115/02/01/0 On-load tap-changer OILTAP® R R I 1201 - C/D, dimension drawing TD 115/02 23 8994011E 24 On-load tap-changer OILTAP® R R I 1201 - E, dimension drawing TD 115/02 115/02/01/0 8967218E 115/02/01/0 On-load tap-changer OILTAP® R R I 2002 - C/D, dimension drawing TD 115/02 25 8978666E 26 On-load tap-changer OILTAP® R R I 2002 - E, dimension drawing TD 115/02 115/02/01/0 8974905E 115/02/01/0 On-load tap-changer OILTAP® R R I 2402 - C/D, with forced current division with two parallel winding branches, dimension drawing TD 115/02 27 8978646E 28 On-load tap-changer OILTAP® R R I 2402 - E, with forced current division with two parallel winding branches, dimension drawing TD 115/02 115/02/01/0 8967208E 115/02/01/0 On-load tap-changer OILTAP® R R I 3003 - C/D, dimension drawing TD 115/02 29 8978657E 30 On-load tap-changer OILTAP® R R I 3003 - E, dimension drawing TD 115/02 115/02/01/0 8978683E 115/02/01/0 On-load tap-changer OILTAP® R Tap selector size E, tap selector and change-over selector terminal contacts TD 115/02 31 8967056E 32 On-load tap-changer OILTAP® R Tap selector size C/D, installation drawing TD 115/02 115/02/01/0 8978733E 115/02/01/0 On-load tap-changer OILTAP® R Tap selector size E, installation drawing TD 115/02 33 893899AE 34 On-load tap-changer OILTAP® MS, M, R, RM On-load tap-changer head, centric drive TD 115/02 115/02/01/0 8951685E 115/02/01/0 On-load tap-changer OILTAP® MS, M, R, RM With flange for pressure relief valve TD 115/02 35 8967034E 36 On-load tap-changer OILTAP® R Versions of the on-load tap-changer head, swiveling range and drive direction of the gear unit TD 115/02 115/02/01/0 8967627E On-load tap-changer OILTAP® MS, M, R, RM Special design for installation in bell-type tank Lifting device O-Ring 44.2 - 5,7 Suction pipe Drilling hole in sectional plane Transformer cover O-Ring Level traverse Guiding ring with Um = 170 kV, 245 kV, 300 kV Supporting flange Level traverse Z = Guiding pin Drive side of the tap selector 115/02/01/0 TD 115/02 37 8967087E 38 On-load tap-changer OILTAP® MS, M, R, RM Horizontal drive shaft (limit dimensions) Tap selector size C/D, centric drive TD 115/02 115/02/01/0 8978723E 115/02/01/0 On-load tap-changer OILTAP® R Horizontal drive shaft (limit dimensions) Tap selector size E, centric drive TD 115/02 39 8967066E 40 On-load tap-changer OILTAP® R R I 2002, R I 3003, tap selector size C/D Jumpers for parallel connection of tap selector terminal contacts TD 115/02 115/02/01/0 8987131E 115/02/01/0 On-load tap-changer OILTAP® R R I 2002, R I 3003, tap selector size E Jumpers for parallel connection of tap selector terminal contacts TD 115/02 41 8967028E On-load tap-changerOILTAP® R Tap selector size C/D, tap selector bottom shown with the lowest parts connected to the voltage, standard design without grading ring, special design with grading ring 42 TD 115/02 115/02/01/0 8978695E 115/02/01/0 On-load tap-changer OILTAP® R Tap selector size E, tap selector bottom shows lowest parts connected to voltage TD 115/02 43 8967078E 44 On-load tap-changer OILTAP® R Tap selector size C/D, principal arrangement of potential switch and tie-in resistors TD 115/02 115/02/01/0 8981242M 115/02/01/0 On-load tap-changer OILTAP® R Tie-in resistor cylinder R I to WP, tap selector size C/D, Um = 72.5 kV to 300 kV, 2 x 14 to 2 x 18 resistors TD 115/02 45 8981252M 46 On-load tap-changer OILTAP® R Tie-in resistor cylinder R I to WP, tap selector size C/D, Um = 72.5 kV to 300 kV, 2 x 3, 2 x 5, to 2 x 13 resistors TD 115/02 115/02/01/0 8981262M 115/02/01/0 On-load tap-changer OILTAP® R Tie-in resistor cylinder R I to WP, tap selector size C/D, Um = 72.5 kV to 300 kV, 2 x 4, 2 x 6 to 2 x 12 resistors TD 115/02 47 8981272M 48 On-load tap-changer OILTAP® R Tie-in resistor cylinder R I to WP, tap selector size C/D, Um = 72.5 kV to 300 kV, 3 to 26 resistors TD 115/02 115/02/01/0 8981282M 115/02/01/0 On-load tap-changer OILTAP® R Tie-in resistor cylinder R I to WR, tap selector size C/D, Um = 72.5 kV to 300 kV, 2 x 14 to 2 x 18 resistors TD 115/02 49 8981292M 50 On-load tap-changer OILTAP® R Tie-in resistor cylinder R I to WR, tap selector size C/D, Um = 72.5 kV to 300 kV, 2 x 3, 2 x 5, to 2 x 13 resistors TD 115/02 115/02/01/0 8981302M 115/02/01/0 On-load tap-changer OILTAP® R Tie-in resistor cylinder R I to WR, tap selector size C/D, Um = 72.5 kV to 300 kV, 2 x 4, 2 x 6, to 2 x 12 resistors TD 115/02 51 8981312M 52 On-load tap-changer OILTAP® R Tie-in resistor cylinder R I to WR, tap selector size C/D, Um = 72.5 kV to 300 kV, 3 to 26 resistors TD 115/02 115/02/01/0 8981322M 115/02/01/0 On-load tap-changer OILTAP® R Tie-in resistor cylinder R III 1200 WP, tap selector size C/D, Um = 72.5 kV to 245 kV, 3 x 2 to 3 x 7 resistors TD 115/02 53 8981332M 54 On-load tap-changer OILTAP® R Tie-in resistor cylinder R III 1200 WP, tap selector size C/D, Um = 72.5 kV to 245 kV, 3 x 8 to 3 x 10 resistors TD 115/02 115/02/01/0 8981342M 115/02/01/0 On-load tap-changer OILTAP® R Tie-in resistor cylinder R III 1200 WR, tap selector size C/D, Um = 72.5 kV to 245 kV, 3 x 2 to 3 x 8 resistors TD 115/02 55 8981352M 56 On-load tap-changer OILTAP® R Tie-in resistor cylinder R III 1200 WR, tap selector size C/D, Um = 72.5 kV to 245 kV, 3 x 9 to 3 x 11 resistors TD 115/02 115/02/01/0 8981362M 115/02/01/0 On-load tap-changer OILTAP® R Potential switch R III 1200 WS, R I to WS, tap selector size C/D, Um = 72.5 kV to 300 kV TD 115/02 57 8986142M 58 On-load tap-changer OILTAP® R Potential switch R III 1200 WS, R I to WS, tap selector size E, Um = 72.5 kV to 300 kV TD 115/02 115/02/01/0 8988261E On-load tap-changer OILTAP® R Additional drawings for on-load tap-changer Basic connection diagrams .............................................................. 890616 Tap selector and change-over selector terminal contacts, tap selector size E................................................................................ 897868 Tap selector bottom, shielding, tap selector size C/D ........................................................................... 896702 Tap selector bottom, tap selector size E ...................................... 897869 Versions of the on-load tap-changer head ................................ 896703 Horizontal drive shaft, tap selector size C/D .............................. 896708 Horizontal drive shaft, tap selector size E ................................... 897872 Installation drawing, tap selector size C/D ................................. 896705 Installation drawing, tap selector size E ...................................... 897873 On-load tap-changer head .............................................................. 893899 115/02/01/0 TD 115/02 59 www.reinhausen.com © Maschinenfabrik Reinhausen GmbH Falkensteinstrasse 8 93059 Regensburg, Germany Phone +49 941 40 90-0 Fax +49 941 40 90-111 E-Mail [email protected] Please note: The data in our publications may differ from the data of the devices delivered. We reserve the right to make changes without notice. TD 115/02 en • 0903/1000 • 115/02/01/0 • F0019601 • Printed in Germany