* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download AN-9742 Device Selection Guide for Half-Bridge Welding Machine (IGBT & Diode) Summary

Electric power system wikipedia , lookup

Spark-gap transmitter wikipedia , lookup

Solar micro-inverter wikipedia , lookup

Electrical ballast wikipedia , lookup

Transformer wikipedia , lookup

Mercury-arc valve wikipedia , lookup

Power engineering wikipedia , lookup

Three-phase electric power wikipedia , lookup

Stray voltage wikipedia , lookup

History of electric power transmission wikipedia , lookup

Electrical substation wikipedia , lookup

Current source wikipedia , lookup

Transformer types wikipedia , lookup

Power inverter wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Voltage optimisation wikipedia , lookup

Surge protector wikipedia , lookup

Voltage regulator wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Mains electricity wikipedia , lookup

Semiconductor device wikipedia , lookup

Distribution management system wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Alternating current wikipedia , lookup

Power MOSFET wikipedia , lookup

Current mirror wikipedia , lookup

Opto-isolator wikipedia , lookup

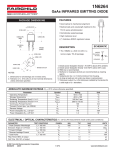

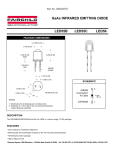

www.fairchildsemi.com AN-9742 Device Selection Guide for Half-Bridge Welding Machine (IGBT & Diode) Summary Duty Cycle of a Welding Machine Various topologies; including two SW-forward, half-bridge and full-bridge, have been used for low-voltage / highcurrent DC-ARC welding machines for system minimization and efficiency improvement. Of these topologies, halfbridge is the most commonly used for small form factor, less than 230A capacity welding machines. Compared to fullbridge topology with the same power rating, half-bridge requires more transformer wiring and higher current capacity of inverter; but requires fewer power devices. Taking a Fairchild evaluation board as the example, this article presents a device selection guide for a half-bridge welding machine application. In the welding industry; duty cycle refers to the minutes out of a 10-minute period a welder can be operated at maximum rated output without overheating or burning up the power source. For instance, a 140A welder with a 60% duty cycle must be “rested” for at least 4 minutes after 6 minutes of continuous welding at maximum rated output current 140A. Allowable Duty Cycle If actual current in use is smaller than a rated output current, the welder internal heating decreases. The welder then can be used at a higher rate than the specified duty cycle. Its allowable duty cycle can be calculated as: 2 Description of Welding Machine rated output current × duty cycle of welding machine = using output current Generally, based on the type of welding machine, the output voltage can be calculated as shown in Table 1. For example, since only 80A to 130A current would be required to weld a 3.2 welding rod, a 140A welder with a 60% duty cycle can operate for a longer time for this application. Assuming 100A is used to weld a 3.2 welding rod, actual duty cycle is more than 78.4%. Table 1. Welding Machine Output Voltage Welding Machine Output Voltage Example CO2 0.04•IAC+15 0.04•200A+15=23V TIG 0.04•IAC+10 0.04•200A+10=18V DC ARC 0.04•IAC+20 0.04•200A+20=28V Table 2. (1) Besides the actual output current, the temperature also affects the allowable duty cycle of a welding machine. Do NOT overheat welder machines. Feasible Welding Materials by Welding Machine Welding Machine Gas Welding Type Steel CO2 CO2 Mild, High Tensile MIG He + Ar Aluminum, SUS, Aluminum Alloy MAG Sheet Metal, Low Alloy, High Tensile DC-TIG Stainless, Mild, Copper Alloy, Nickel Alloy, Titanium Alloy, Low Alloy AC-TIG Aluminum Alloy, Magnesium Alloy, Bass Mixed TIG Light Alloy, Clad Plate DC-ARC Steel, Nonferrous Metals AC-ARC Aluminum © 2011 Fairchild Semiconductor Corporation Rev. 1.0.0 • 9/9/11 www.fairchildsemi.com AN-9742 APPLICATION NOTE Fairchild DC-ARC Welding Machine Evaluation Board Input Voltage and Frequency: 220VAC 60Hz Evaluation Board Features Output Voltage (VOUT) and Output Current (IWEL): 26VDC, 140A Input Stage: 50A Bridge Diode (600V, 50A, SquareBridge Type) Efficiency: > 80% Input Filter Stage: Designed Under Consideration of Conductive Noise and Radiation Noise Idle Power: < 4W Switching Frequency: 20KHz Figure 2 shows the main block diagram of the welding machine evaluation board. The output current and output voltage of the DC-ARC welding machine evaluation board are 26V and 140A, which constitutes a 3kW-class welding machine. Various Fairchild Semiconductor components are used to meet the design requirements. The switching frequency of the machine is 20KHz. Due to their size; the transformer and inductor are installed beside the board. An air fan is attached for cooling. Controller: PIC16F716 (8-Bit ADC and 10-Bit PWM) Inverter Stage: FGH40N60SMD (within Co-Pak Diode) Single or Parallel Output Rectifier: FFA60UP30DN * Six Units (Three Ultra-Fast Diode in Parallel) Gate Driver: Opto-Coupler for the Isolation between Switching Devices and Controller Dual Power Supply +15V, -5V for IGBT Gate Voltage AUX Power Supply: Lower Standby Consumption Green Integrated PWM IC Figure 1. Evaluation Board Figure 2. Main Block Diagram © 2011 Fairchild Semiconductor Corporation Rev. 1.0.0 • 9/9/11 www.fairchildsemi.com 2 AN-9742 APPLICATION NOTE Half-Bridge Inverter Design IGBT Selection for Welding Machine The turn ratio of the primary and secondary of the transformer in a half-bridge topology can be obtained from the equation: Among various power switching components, Insulated Gate Bipolar Transistor (IGBT) is the most suitable device for welding machines thanking for its high current handling capability and high switching speed. IGBT is a voltagecontrolled power transistor, similar to the power MOSFET in operation and construction. This device offers superior performance to the bipolar-transistors. It is the most costeffective solution for high power and wide frequency-range applications. Table 3 shows the characteristics comparison of IGBT with BJT and MOSFET. N1 = N1 = VIN ( MIN ) × DMAX 4 × B × Ae ∗ f SW (VO + VF + VI ) × N1 DMAX × VIN ( MIN ) (2) (3) where VI = VS, IWEL = output current, Id1 & Id2 = diode current (output high side & output low side). Table 3. Output voltage under no load condition is given by: Vnolaod = (VO + VF = VI ) DMAX (4) where: VO=output voltage; VF=diode drop voltage; and VI=inductor voltage drop. Transformer’s primary and secondary current can be obtained by: I1rms = N2 × IWEL × N1 1 I 2rms = × IWEL × 2 (2 × DMAX ) (5) (1 + 2 × DMAX ) (6) N2 × IWEL N1 (7) Output rectifier diode voltage and current: Vr = N2 × VIN ( MAX ) , IWEL = I d12 + I d 2 2 N1 Features BJT MOSFETS IGBT Drive Method Current Voltage Voltage Drive Circuit Complex Simple Simple Input Impedance Low High High Drive Power High Low Low Switching Speed Slow(µs) Fast(ns) Middle Operating Frequency Low Fast (less than 1MHz) Middle S.O.A Narrow Wide Wide Saturation Voltage Low High Low Power losses of an IGBT include conduction loss and switching loss. The conduction loss is determined by IGBT’s Vce(sat) value and the duty rate. The switching loss is determined by turn-on and turn-off action during IGBT’s switching transient. For IGBTs, there are technical trade-off characteristics between the Vce(sat) and the switching loss. If Vce(sat) is high, switching loss becomes low and vice versa. Therefore, the designer should select an IGBT based on the system configuration and its switching frequency. The total loss of an IGBT can be expressed as: Current running through the IGBT and secondary-side rectifier diode can be calculated by: IGBT Current : I D = Device Characteristics Comparison (8) Total 1 Pulse Switching Switching Conduction Loss = X + (9) Loss Loss (EON + EOFF) Frequency (VCS(SAT) X IC X Duty) © 2011 Fairchild Semiconductor Corporation Rev. 1.0.0 • 9/9/11 www.fairchildsemi.com 3 AN-9742 APPLICATION NOTE Figure 3 curves show the characteristics comparison between PT IGBT and field-stop IGBT. PT IGBT has NTC temperature characteristic: as temperature rises, Vce(sat) decreases. Field-stop IGBT has PTC temperature characteristic: as temperature rises, Vce(sat) increases. Therefore, PT IGBT with NTC characteristic is more suitable for the application where IGBT is operated solely. However, if parallel operation of IGBTs is required for current sharing, field-stop IGBT with PTC characteristic would be more appropriate. FGH40N60SMD FGH40N60UFD FGH40N60SFD HGTG20N60A4D 70 Collector Current, Ic[A] 2.0 Total Switching Loss[Eon+Eoff], Ets[mJ] 80 The following figures show that the switching loss becomes the dominant factor over conduction loss in 25kHz and above switching frequency area. 60 Tc=25deg.C 50 Vge=15V 1.5 Tc=25deg.C Tc=125deg.C 1.0 0.5 Test Condition : Vcc=400V, Rg=10 ohm, Vge=15V 0.0 10 40 20 30 40 Collector Current, Ic[A] 30 Figure 5. Total Switching Loss Ets vs. Collector Current IC 20 10 250 0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 Total power loss of IGBT, Pd [W] 0.0 Collector-Emitter Voltage, Vce(sat)[V] Figure 3. HGTG20N60A4D(PT) vs. FGH40N60UFD/SFD (Field-Stop Gen1) 80 FGH40N60SMD FGH40N60UFD FGH40N60SFD HGTG20N60A4D 70 Collector Current, Ic[A] FGH40N60SMD FGH40N60UFD FGH40N60SFD HGTG20N60A4D 60 Tc=125deg.C Vge=15V 50 200 FGH40N60SMD FGH40N60UFD FGH40N60SFD HGTG20N60A4D s los er w po Vcc=400V, Rg=10 ohm, tal 150 Vge=15V, Ic=40A, Tc=125deg.C To Test Condition : 100 ing itch Sw 50 E n+ Eo [ s los ] off Conduction loss 0 20.0k 40 40.0k 60.0k 80.0k 100.0k Switching Frequency, Fsw[KHz] 30 Figure 6. Total Power Loss of IGBT Pd vs. Switching Frequency 20 The gate resistor is also very critical to the switching loss. High gate resistance results in high switching loss. On the other hand, high gate resistance improves EMI performance as the di/dt is lower during the switching transient. A properly selected gate resistor should minimize the switching loss without sacrificing system EMI performance. 10 0 0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 Collector-Emitter Voltage, Vce(sat)[V] Figure 4. FGH40N60SMD (Field-Stop Gen2) Reduction of conduction loss and total device cost with better thermal performance would be the advantage of the parallel operation of IGBTs. However, for such kind application, the following must be considered: Using high-temperature PTC characteristic IGBT Using gate resistor with ≤1% tolerance for each IGBT Proper gate PCB layout for symmetrical current paths Identical heat sink size and airflow for each IGBT Same threshold voltage and saturation voltage characteristics © 2011 Fairchild Semiconductor Corporation Rev. 1.0.0 • 9/9/11 www.fairchildsemi.com 4 AN-9742 APPLICATION NOTE Below are the IGBT turn-off characteristics measurements with JIG testing. Under the same conditions, FS Planar Gen2 IGBT FGH40N60SMD shows faster switching characteristic, lower Vce(sat), and tremendously lower turn-off loss compared to previous technology devices - PT and FS Planar Gen1 IGBT. Figure 9 and Figure 10 show the IGBT operation waveforms of the evaluation board with R-load and welding load. These waveforms reveal that welding load consumes three times the current that R-load consumes. Therefore, it is important to select IGBT with suitable Icm parameter to avoid saturation at peak-current condition. 1.0 FGH40N60SMD FGH40N60UFD FGH40N60SFD HGTG20N60A4D Switching Loss, Eoff[mJ] 0.8 Tc=25deg.C Tc=125deg.C 0.6 0.4 Test Condition : Vcc=400V, Ic=40A, Vge=15V 0.2 5 10 15 20 25 30 Gate Resistance, Rg[ohm] Figure 9. R-Load Test at IOUT=14A Figure 7. Turn-Off Loss EO vs. Gate Resistance Rg 16 Switching loss, Eoff / A[uJ] Tc=25deg.C FGH40N60UFD 12 HGTG20N60A4D FGH40N60SFD FGH40N60SMD 8 1.6 1.8 2.0 2.2 2.4 Collector-Emitter Voltage, Vce(sat)[V] Figure 10. Welding-Load Test at 3.2 Pie Welding Rod Figure 8. Turn-Off Loss EOFF vs. Collector-Emitter Vce(sat) © 2011 Fairchild Semiconductor Corporation Rev. 1.0.0 • 9/9/11 www.fairchildsemi.com 5 AN-9742 APPLICATION NOTE Figure 11 through Figure 16 show turn-off switching loss EOFF measurement with welding load and R-load. Due to the leakage inductance and capacitor element, there is huge difference in EOFF measurement compared with the JIG test result. The EOFF of FGH40N60SMD shows the lowest loss from the test. Figure 11. EOFF Comparison Under R-Load (FGH40N60SMD) Figure 12. EOFF Comparison Under R-Load (FGH40N60UFD) Figure 13. EOFF Comparison Under R-Load (FGH40N60SFD) Figure 14. EOFF Comparison Under Welding Load (FGH40N60SMD) Figure 15. EOFF Comparison Under Welding Load (FGH40N60UFD) Figure 16. EOFF Comparison Under Welding Load (FGH40N60SFD) © 2011 Fairchild Semiconductor Corporation Rev. 1.0.0 • 9/9/11 www.fairchildsemi.com 6 AN-9742 APPLICATION NOTE Rectifier Diode for Welding Machine Qrr = Fairchild Semiconductor provides five kinds of diodes that cater to different applications. Diodes with lower Vf, Irr, and Trr characteristics are ideal for welding applications; however, the common P_N theory dictates that the lower the Vf, the longer the Trr and vice versa. A designer chooses a diode with a trade-off point where Vf and Trr benefit the system efficiency the most. The following figures show performance comparisons for 600V/8A diodes from each Fairchild Semiconductor diode technology. 2.6 2.4 Stealth 2.2 Hyperfast2 VF [V] The figures below show the performance of diodes used in single and parallel configuration. Although the reverse recovery loss increases, Vf is reduced with parallelized diodes and better thermal performance can be expected. Designer caution is required for parallel diode application to ensure that the air flow does not cause unbalanced current conditions, as the Vf of diode tends to decrease when the temperature rises. Ulrafast Hyperfast Hyperfast2 Stealth Stealth2 Stealth2 Hyperfast 2.0 (10) Generally, the rectifier diode of welding machine has higher conduction loss than reverse recovery loss. Therefore, the diode VF value is more critical for a welding application. For this reason, ultra-fast diode FFA60UP30DN (30A dual diode) is used for this evaluation board. Three diodes are used in parallel for each tap of transformer to lower the VF. FCS Rectifier Diode Vf vs Qrr, 600V 8A 2.8 1 × I rr × t rr 2 Tc=25deg.C 1.8 Diode I-V charateristic 100 1.6 Tc=25deg.C Tc=125deg.C Ultrafast 1.4 80 IF, Forward Current [A] 1.2 1.0 0 20 40 60 80 Qrr [nC] Figure 17. VF vs. Qrr Trade-Off FSC Rectifier performance @ 600V, 8A 10 Ultrafast Hyperfast Hyperfast2 Stealth Stealth2 Tc=125deg.C 8 6 4 IF [A] 2 60 40 FFA60UP30DN-Dual 20 FFA60UP30DN-single 0 0.0 0 0.6 1.2 1.8 VF, Forward Voltage [V] -2 -4 Figure 20. Diode I-V Characteristic -6 -8 FFA60UP30DN Qrr charateristic -10 360 -12 -80.0n -40.0n 0.0 40.0n 80.0n 120.0n VR = 150V IF = 30A Single Dual 160.0n Stored Recovery charge Qrr [nC] Time [sec] Figure 18. Reverse Recovery Performance 300 Tc=125deg.C 240 180 120 60 Tc=25deg.C 0 100 200 300 400 500 di/dt [ A/us] Figure 21. Stored Recovery Charge Qrr vs. Diode Current Slop di/dt Figure 19. Test Circuit and Waveforms © 2011 Fairchild Semiconductor Corporation Rev. 1.0.0 • 9/9/11 www.fairchildsemi.com 7 AN-9742 APPLICATION NOTE Figure 22 shows the diode switching loss when the board is operating at 20KHz. The conduction loss is about 336µJ, while the reverse recovery loss is only about 4µJ. Figure 24. UIS Test Circuit Figure 22. Diode Conduction Loss During Welding Figure 25. FFA60UP30DN Immunity Capability Blocking Capacitor For half-bridge topology; if the two series DC bank capacitors or the turn-on time of IGBTs are not matched, DC flux occurs in the transformer. The accumulated DC flux eventually drives transformer into saturation. The IGBTs can be destroyed by sharply increased current due to the saturated transformer. To block the DC flux in the transformer core, a small DC blocking capacitor is placed in series with the transformer primary. The value of the DC blocking capacitor is given by: Figure 23. Diode Reverse Recovery Loss During Welding Cblocking = Avalanche occurs in a diode with sudden current increase when the voltage across a diode exceeds the specified Vr value. Here, the area (Vr(AVL)*Isa) that diode does not fail is called avalanche energy and the equation is: 1 Vr ( AVL ) ] EAVL = × L × Isa 2 × [ 2 (Vr ( AVL ) − VDD) D max× ID ∆VP × Fsw (12) where ∆VP is the permissible droop in primary voltage due to the DC blocking capacitor. Below is the waveform of the transformer primary current. The current abruptly rise due to the saturated transformer caused by DC bias. (11) ∴ Q1 = IGBT ( BV ces ) > DUT (Vr ( AVL )) Avalanche energy is occurred by the second output inductor, as shown in the equation. The immunity capability is proportional to the inductance. The inductance of a welding machine is generally designed as small value as several µH, and diode immunity capability value becomes an important factor for choosing a device. Avalanche can occur in the secondary-side rectifier of a welding machine; especially when the welding work is completed and the reverse pass occurs by inductor. Immunity capability is measured using a circuit as shown in Figure 24 with the graph in Figure 25 showing avalanche energy test result waveform. © 2011 Fairchild Semiconductor Corporation Rev. 1.0.0 • 9/9/11 Figure 26. IGBT Saturation Current www.fairchildsemi.com 8 AN-9742 APPLICATION NOTE Figure 27. Zoom of IGBT Saturation Current Figure 28. PWM Convert 40KHz to 20KHz Power Supply Structure and Design MOSFET integrated IC FSMG0465R is used for power supply. Its simple peripheral circuit and 66KHz switching frequency reduce the PCB and transformer size. In addition, the efficiency of power has been maximized by the minimization of idling power that can be achieved from low power consumption in Standby Mode (<1W at 230VAC input at 0.5W load). There are transformer type and SMPS type for the substitute power supply. SMPS type, compared to linear transformer type, has stable output power over the influence of input serge, sag, and noise; and minimal design of size and weight is possible. In addition, transformer type has a fixed input voltage, whereas SMPS has a wide input voltage range of 80VAC~264VAC, which can be used for free voltage welding machine without additional operation. However, it is necessary to consider counter measures for noise as the switching noise may affect main inverter. For further information about Fairchild Power Switches (FPS™), refer to the application note AN-4150 found at: http://www.fairchildsemi.com/an/AN/AN-4150.pdf. Gate Driver Design A transformer, opto-coupler, or HVIC can be used for a gate driver. Necessary supply voltages for different gate drivers are listed as: HVIC Driver: +15V, 0V (High and Low Gate), + 24V, 0V (Output Detect), +5V, 0V (Controller) Otpo-Coupler Driver : +15V, 0V, -5V (High-Side Gate), +15V, 0V, -5V (Low-Side Gate), +24V, 0V (Output Detect), +5V, 0V (Controller) Pulse Transformer: +24V, 0V (Output Detect), +5V, 0V (Controller) The opto-coupler and transformer provide isolation between the control circuit and IGBTs. However, a transformer may cause half bridge cross-conduction due to the offset voltage of gate-pulse dead-time stage. Through an by integrated high-voltage MOSFET, the HVIC provides isolations between the control circuit and the high-side IGBT. This does not work with negative supply voltage. A negative supply voltage is necessary for HVIC during a fast commutation in a half-bridge topology to prevent dv/dt shoot-through. The shoot-through is linked to a fast voltage variation across one of the two IGBTs. A current flowing through collector-emitter capacitor can bring the gate voltage of an IGBT, when turned off, to rise due to Miller effect and obtain a cross conduction into the leg. Controller Design The evaluation board uses PIC16f716 for the control circuits. PIC16f716 controller consists of four ports of 8-bit AD converter and one port PWM timer with 9-bit, 40KHz resolution. To generate two PWM pulses from one PWM signal, a D flip-flop and an AND gate are used to divide the 40KHz PWM into 20KHz PWM pulse (see Figure 28). R2 +5V R3 1k C2 104 17 18 +5V R19 330 RA0/AN0 C12 104 RA1/AN1 2 RB3 9 3 +5V 2 Temp VR3 5k +5V 3 2 1 +5V C19 C20 C21 C22 C23 104 104 104 104 104 R6 1K R11 MCLR/VPP RB7 2 Temp R8 C4 104 ZD! 1 RB6 1N4099 D5 RB5 2 10k J2 Output C5 104 RA3/AN3/VREF RB4 R9 1k 1N4937 RB0/INT 2 1 LVD 7 8 4 1 C6 R10 1K RB1 RB2 RA4/TOCKI 3 2 6 2 C15 104 7409 8 6 Gate1_1 5 4 gate1_2 3 3 2n3904d/ON 7474 C13 470P -15V +5V R20 330 C9 22P 330 R12 330 R13 330 +15V U6 2 PS2501 8 6 3 U4B 5 4 Q1 4 R18 1K 12 C16 104 Gate2_1 gate2_2 6 5 11 7409 R14 330 R15 330 R16 330 2n3904d/ON -15V C14 470P 10 6 3 G1 Cont+ PC1 PC817 105 Q CLK Q Q2 R17 1K 13 +5V VR2 5k D 1 GND 2 1 R7 1K 4 U3A 5 X1 20Mhz 15 C8 22P 560 U2A U5 2 PS2501 16 5 J1 OSC2/CLKOUT R4 36k R5 C3 104 Current Limit TH RA2/AN2 OSC1/CLKIN J1 1 1 VR1 5k BD1 +5V +5V +5V +5V +5V 4 14 C11 10uF/10V C10 104 PRE D4 1N4937 C1 22uF/10V R1 10 ohm/3W PIC16C711 C LR D3 1N4937 U1 1 2 1 +5V D2 1N4937 VD D J3 CT +15V +5V 27k D1 1N4937 G2 Cont- RD1 SD G3 PWR Y1 WLD RD2 ERR C7 104 Figure 29. Controller Schematic © 2011 Fairchild Semiconductor Corporation Rev. 1.0.0 • 9/9/11 www.fairchildsemi.com 9 AN-9742 APPLICATION NOTE ICG = dv/ dt × CCG Q I CG = G CG × dV / dt Vge = Rg × ICG Figure 34. Opto-Driver Gate Waveform Figure 30. Effect on dv/dt to VGE DC Reactor Design DC reactor helps stabilize arc current during welding operation. As DC reactance grows, specter occurs smaller. On the contrary, if the mobility of arc is lowered and the LDC value gets too large, it is harder to create an arc. Therefore, an appropriate reactor choice is necessary. If considering VOPEN as output no-load voltage, VWEL and IWEL as rated output voltage or current; the maximum LDC value can be obtained from the equation: : LDC ≤ Figure 31. Effect on dV/dt to Gate Wave − R × tR IWEL In(1 − × R) Vopen (13) Based on the above considerations, an opto-coupler is used for this welding machine evaluation board. Figure 32 and Figure 33 present the gate waveforms captured with different types of gate drivers. It is clear the opto-coupler is the best choice for this welding application. where R is the equivalent resistance of welding load and Tr is the rising time of the output current from 0 to the rated current. Once the maximum LDC value is obtained; the optimum LDC value can be finalized through testing. Figure 32. HVIC Gate Waveform Figure 35. Soft-Start During Welding Operating Figure 33. Transformer Gate Waveform © 2011 Fairchild Semiconductor Corporation Rev. 1.0.0 • 9/9/11 Figure 36. Welding Operating www.fairchildsemi.com 10 AN-9742 APPLICATION NOTE When to chose an IGBT, its Vce(sat), Eoff turn-off loss, gate driver resistor, and Icm characteristics are the critical factors that require a designer’s careful attention. Conclusion Better performance is expected for a DC-ARC welding machine when the inverter devices are selected properly based on the inverter topology and its switching frequency. This article presents a power device selection guide for a half-bridge welding machine application. For the secondary -side rectifier diodes, it is important to determine which is the dominant factor, Vf or reverse recovery loss, based on system switching frequency. The evaluation board uses three ultra-fast diodes (FFA60UP30DN) in parallel for each tap of the transformer to lower the Vf and therefore the conduction loss. References [1] Aspandiar, Raiyo, “Voids in Solder Joints,” SMTA Northwest Chapter Meeting, September 21, 2005, Intel® Corporation. [2] Bryant, Keith, “Investigating Voids,” Circuits Assembly, June 2004. [3] Comley, David, et al, “The QFN: Smaller, Faster, and Less Expensive,” Chip Scale Review.com, August / September 2002. [4] Englemaier, Werner, “Voids in solder joints-reliability,” Global SMT & Package, December 2005. [5] IPC Solder Products Value Council, “Round Robin Testing and Analysis of Lead Free Solder Pastes with Alloys of Tin, Silver, and Copper,” 2005. [6] IPC-A-610-D, “Acceptance of Electronic Assemblies,” February 2005. [7] IPC J-STD-001D, “Requirements for Soldered Electrical and Electronic Assemblies.” [8] IPC-SM-7525A, “Stencil Design Guidelines,” May 2000. [9] JEDEC, JESD22-B102D, “Solderability,” VA, Sept. 2004. [10] Syed, Ahmer, et al, “Board-Level Assembly and Reliability Considerations for QFN Type Packages,” Amkor Technology, Inc., Chandler, AZ. Related Resources FGH40N60SMD — 600V, 40A Field Stop IGBT FFA60UP30DN — 300V Ultrafast Recovery Power Rectifier FSGM0465R — SMPS Power Switch, 4A, 650V (Green) Appendix — Circuit Diagrams C23 R6 10 102 + BUS Z1 FGH40N60SMD ZD1 1N4744 BD1 C54 1uF M275V 1 4 + - 1 C1 400V 560uF RV3 20D431K C2 400V 560uF GBP5006 ZD3 1N4744 ZD6 1N4744 L6 GND2 FAN 2 R3 10/3W ZD4 1N4733 10/3W FGA60UP30DN 630V Z4 FGA40N60SMD ZD8 1N4744 ZD9 1N4733 R9 T1 1 Gate2 R8 D3 CT1 C61 R4 4.7k ZD7 1N4733 R7 4.7k C50 10uF 630V Gate1 Z3 FGA40N60SMD Gate2 RV1 20D431K 1 10/3W GND1 3 LF1R FILTER C62 472M R1 R2 4.7k ZD2 1N4733 5 D7 FGA60UP30DN 6 3 2 RV2 20D431K C55 472M P11 1 Z2 FGA40N60SMD Gate1 1 P3 1 L5 P10 JF3250G 4 L4 52uH 8 D16 C51 10uF 630V R39 C24 10/3W 10 + Output FGA60UP30DN TRANSFORMER CT 102 C52 10nF 630V R5 4.7k D17 - BUS D18 D19 FGA60UP30DN FGA60UP30DN C53 10nF 630V FGA60UP30DN - Output Figure 37. Main Circuit © 2011 Fairchild Semiconductor Corporation Rev. 1.0.0 • 9/9/11 www.fairchildsemi.com 11 AN-9742 APPLICATION NOTE C209 102 R211 10 D203 T101 EER3940S L1 10uH +15v 9 MBRF10H100 C223 470uF 35V 1 C224 470uF 35V 10 R212 C208 3.3nF 630V R207 43K/1W 3 R208 2 BD201 5D-9 LF201 30mH + - C222 470uF 35V L2 10uH -15V U201 6 R201 1M/1W 2KBP06M3N25 C211102 R21310 7 D205 FGM0465R L3 10uH 1 Drain 15+v Vstr 8 12 MBRF10H100 C203 400V 100uF R203 150K 4 FB D201 3 Vcc 2 AC220V N PC1 Q201 2N2222 C205 33nF 100V C217 470uF 35V C218 470uF 35V D206 L4 10uH -15V ZD201 1N4745A 1 C204 R205 47nF 1K 1K 2 14 2 R204 C220 470uF 35V GND2 C212 102 1W 5 R209 100 ohm/0.5W 2 250V 2A C219 470uF 35V 13 R210 R214 10 UF4004 1 C202 275Vac 100nF 1N4007 1k R202 270K 1 3 C201 275Vac 100nF 4 GND NTC F201 C211 470uF 35V MBRF10H100 NTC1 AC220V H TNR 10D471k GND1 C210 10 D204 102 11 D202 R206 75K C206 100nF MBRF10H100 C207 47uF 50V R215 10 15 D38 1N4744 C213 D207102 L5 1 5v 4.9uH MBRF10H100 C215 470uF 10V 16 XY C216 1000uF 10V gnd 4.7nF/1KV R216 R219 1 4 620 2 3 3 1 R218 C214 18K 47nF R220 8K 2 U202 TL431 8K R217 1.2k PC2 817 Figure 38. Auxiliary Power Supply Figure 39. Controller DISCLAIMER FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER NOTICE TO ANY PRODUCTS HEREIN TO IMPROVE RELIABILITY, FUNCTION, OR DESIGN. FAIRCHILD DOES NOT ASSUME ANY LIABILITY ARISING OUT OF THE APPLICATION OR USE OF ANY PRODUCT OR CIRCUIT DESCRIBED HEREIN; NEITHER DOES IT CONVEY ANY LICENSE UNDER ITS PATENT RIGHTS, NOR THE RIGHTS OF OTHERS. LIFE SUPPORT POLICY FAIRCHILD’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD SEMICONDUCTOR CORPORATION. As used herein: 1. Life support devices or systems are devices or systems which, (a) are intended for surgical implant into the body, or (b) support or sustain life, or (c) whose failure to perform when properly used in accordance with instructions for use provided in the labeling, can be reasonably expected to result in significant injury to the user. © 2011 Fairchild Semiconductor Corporation Rev. 1.0.0 • 9/9/11 2. A critical component is any component of a life support device or system whose failure to perform can be reasonably expected to cause the failure of the life support device or system, or to affect its safety or effectiveness. www.fairchildsemi.com 12