* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Sepam 1000 - Schneider Electric Belgique

Ground loop (electricity) wikipedia , lookup

Telecommunications engineering wikipedia , lookup

Power engineering wikipedia , lookup

Transformer wikipedia , lookup

Mercury-arc valve wikipedia , lookup

Electrical ballast wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Power over Ethernet wikipedia , lookup

Electrical substation wikipedia , lookup

Phone connector (audio) wikipedia , lookup

Current source wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Voltage regulator wikipedia , lookup

Power electronics wikipedia , lookup

Power MOSFET wikipedia , lookup

History of electric power transmission wikipedia , lookup

Stray voltage wikipedia , lookup

Surge protector wikipedia , lookup

Ground (electricity) wikipedia , lookup

Buck converter wikipedia , lookup

Three-phase electric power wikipedia , lookup

Voltage optimisation wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Home wiring wikipedia , lookup

Opto-isolator wikipedia , lookup

Alternating current wikipedia , lookup

Mains electricity wikipedia , lookup

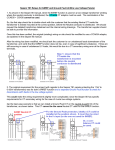

Protection and control Sepam range Sepam 1000 Installation Contents page 2 equipment identification installation of Sepam 1000 Sepam 1000 accessories supplied with Sepam 3 3 3 3 assembly and wiring dimensions and drilling assembly composition of Sepam 1000 terminal identification principle connections 4 4 4 5 5 5 connection of current inputs to 1 A or 5 A CTs 1 A or 5 A CT block and connection diagram selection of operating modes (SW1 and SW2) setting of microswitches SW1 and SW2 on EM module CCA 660 or CCA 650 connector 6 6 6 6 7 connection of current inputs to CSPs CSP connection diagram selection of operating modes (SW1 and SW2) microswitch setting chart 8 8 9 9 use of CSH 120 and CSH 200 core balance CTs CSH 120 and CSH 200 connection diagram selection of operating mode (SW1) assembly cabling 10 10 10 11 11 use of the CSH 30 interposing ring CT cabling connection to the 1 A secondary circuit connection to the 5 A secondary circuit selection of operating mode (SW1) 12 12 13 13 13 connection of voltage inputs connection of 3 VTs connection of 3 VTs (residual voltage measurement) connection of 2 VTs connection of 1 VT connection of residual voltage input selection of operating mode (SW1) 14 14 14 15 15 15 16 connection of power supply and logic inputs and outputs connection of power supply and earth connection of logic inputs and outputs selection of operating mode (SW1) 17 17 17 18 checking prior to commissioning checks microswitch setting on rear of device 19 19 19 Installation Equipment identification Installation of Sepam 1000 Sepam 1000 Each Sepam 1000 comes in a single package which contains: c Sepam, c mouting accessories, c connection accessories (connectors). The other optional accessories come in a separate package. To identify Sepam, check the label on the right side of the device which gives the product’s functional and hardware characteristics. We recommend that you follow the instructions given in this document for quick, correct installation of your Sepam 1000: c equipment identification, c assembly, c connection of current and voltage inputs, c microswitch setting, c connection of power suppply and earth, c checking prior to energizing. model equipment reference (Sepam, model and application) serial n° equipment updating label boxes reserved to the modification of the equipment ex. addition of ES1 board boxes reserved to maintenance intervention ex. replacement of EM board intervention date name of the board Example of a label on the right side of Sepam. Accessories supplied with Sepam Each Sepam comes with the following accessories. CCA 660 or CCA 650 connector (Sepam CT) (1) for connection of the CT 1 A or 5 A : c for 4 mm eye lugs, c for max 6 mm2 cable (AWG 10). CCA 608 connector 8 points. Connection of VTs: c screw terminals, c 0.6 to 2.5 mm2 wire (AWG 20 to AWG 14). CCA 604 connector 4 points. c screw terminals, c 0.6 to 2.5 mm2 wire (AWG 20 to AWG 14). 2 Sepam mounting lugs CCA 606 connector 6 points. c screw terminals, c 0.6 to 2.5 mm2 wire (AWG 20 to AWG 14). (1) for CS Sepams, a CCA 601 BNC/BNC cable, 4 m long, is supplied for connection to the CSP sensors. 3 Installation (1) Assembly and wiring Dimensions and drilling Drilling diagram mounting lugs 201 222 20 202 162 198 1,5 176 172 3,0 45° e = 3 mm max 205 Assembly (2) (2) c insert Sepam through the front of the cut-out. Slide it into the cut-out until the front of Sepam is in contact with the mounting plate. The 2 notches (1) at the base of the Sepam case allow it to hold by its own weight. c position the 2 lugs (2) in the holes on the top of Sepam. Tighten the threaded studs of the lugs. c make sure not to block the ventilation openings on the top and bottom of Sepam. Leave a space of at least 5 cm above and below Sepam. (1) 4 Installation Composition of Sepam 1000 slot 0 optional 1 input/ 3 output module (ES1) slot 1 power supply / 2 output module (AS’) slot 2 analog input module c Current measured by CT (EM); c Current measured by CSP sensor (EA); c Voltage (ET) ▼ ▼ ▼ EM Terminal identification principle AS' 8 7 6 5 4 3 21+ A All the Sepam 1000 connection terminals are located on the rear of the device. The Sepam 1000 modules are fitted into slots numbered 0 to 2 on the back. ES1 SW 1 SW2 SW1 The connections are identified by adding different markings. B Slot (0 to 2), connector A or B, terminal (1 to 8). example: 2 A 4 slot n° 2, connector A, terminal A. 6 5 4 3 2 1 8 7 6 5 4 3 2 1 A 4 3 2 1 B A 2 1 0 Connections All the Sepam 1000 connections are made on the removable connectors on the rear of the device. All the connectors are screw-lockable. Wiring of screw connectors: c recommended wire fitting: v Telemecanique DZ5CE0155 for 1.5 mm2, v DZ5CE0253 for 2.5 mm2. Stripped length with fitting: 17 mm, c without fitting: v stripped length: 10 to 12 mm, v maximum 2 wires per terminal. Installation 5 Connection of current inputs to 1 A or 5 A CTs The current transformer (1 A or 5 A) secondary circuits are connected to the CCA 660 or CCA 650 connector on the EM module. EM AS' ES1 8 7 6 5 4 3 21+ A This connector contains 3 core balance CT primary crossing adapters to ensure impedance matching and isolation between the 1 A or 5 A circuits and Sepam 1000. The connector may be disconnected with the power on since disconnection does not open the CT’s secondary circuit. SW 1 SW2 SW1 B 6 5 4 3 2 1 4 3 2 1 B A 2 1 A or 5 A CT block and connection diagram 8 7 6 5 4 3 2 1 A 1 0 EM B4 B1 P1 L1 B5 B2 P2 L2 L3 B6 B3 CCA 660 or CCA 650 Sepam current inputs Selection of operating modes (microswitches SW1 and SW2) 1 2 3 Sepam 1000 has several possible current input operating modes. The operating mode is selected via the microswitches on the rear of the device. They must be set before Sepam is switched on. The microswitches must be set while Sepam is de-energized. The microswitches are hidden by the CCA 660 or CCA 650 connector once it has been installed. Setting of microswitches SW1 and SW2 on the EM module (slot 2) 6 SW2 for use on the 5 A secondary circuit. SW2 SW1 SW1 for use on the 1 A SW2 secondary circuit. SW2 SW1 SW1 for measuring residual current by the sum of the currents. for measuring residual current by an interposing ring CT. Installation CCA 660 or CCA 650 Connector c Open the 2 side shields for access to the connection terminals. The shields may be removed, if necessary, to facilitate wiring. If removed, replace them after wiring. c Remove the bridging strap if necessary. The strap links terminals 1, 2 and 3. c Connect the wires using 4 mm eye lugs. The connector accommodates wires with cross sections of 1.5 to 6 mm2 (AWG 16 to AWG 10). c Close the side shields. c Plug the conector into the 9-point inlet on the rear of the device. Item B on the EM module (slot 2). c Tighten the CT connector fastening screws on the rear of Sepam. N.B. To disconnect the current inputs with the system on line, never disconnect the wires; unplug the CT connector from the rear of Sepam. Installation 7 Connection of current inputs to CSPs The CSP sensors are connected by prefabricated coaxial cables, part no. CCA 601 (4 m long) which are to be ordered with the CSP sensors. The cables are fitted with 2 BNC type connectors. The cables are plugged into: c Sepam 1000, in the BNC inlets on the rear of the device, identified L1, L2 and L3, on the EA modules (slot 2), c the CSP sensors, in the BNC outlet on each sensor. CSP connection diagram CCA 601 cable The CCA 601 cable shielding is earthed naturally by the connection to Sepam 1000’s BNC inlets. Do not earth by any other means. EA The CSP sensors should be earthed via the earthing screw on the side of the device. L1 P1 L2 P2 L3 1 2 3 ECA L1 P1 P2 CCA 601 cable CSP sensor Detailed view of a connection. CCA 601 cable. 8 Installation Selection of operating modes (microswitches SW1 and SW2) The operating mode is selected by setting the microswitches on the rear of the device. They must be set before Sepam 1000 is switched on, while it is de-energized. Set microswitches SW1 and SW2 on the EA module (slot 2) in accordance with the chart opposite. They are to be set according to: c the CSP model used (30 A-300 A, 160 A-1600 A, 500 A-2500 A), c the rated current of the protected system, c the residual current measurement method (sum or core balance CT). N.B. When the rated current of the electrical system to be protected does not appear in the chart, choose the column that corresponds to the current rating immediately above. Microswitch setting chart SW2 setting 30 36 45 60 75 90 120 150 180 225 300 160 192 240 320 400 480 640 800 960 1200 1600 500 600 750 1000 1250 1500 2000 2500 SW2: for selection of the phase current range 01 01 01 01 01 01 01 01 01 01 01 SW1 setting SW1 : residual current measured by the sum of the phase currents 01 01 01 01 01 01 01 01 01 01 01 01 01 01 01 SW1: residual current measured by core balance CT 01 01 01 01 01 01 01 CSP sensor 31-10 : 30-300 A. CSP sensor 33-10 : 160-1600 A. CSP sensor 34-10 : 500-2500 A. Example of microswitch setting This example indicates the microswitch setting in the following case: c system rated current: 160 A. c CSP sensor used: 160-1600 A model. c residual current measured by the sum of the 3 phase currents. 01 1 phase 1 6 7 phase 2 SW2 12 13 phase 3 18 CCA 601 cable. 1 SW1 2 Installation 9 Use of CSH 120 and CSH 200 core balance CTs The only difference between the CSH 120 and CSH 200 core balance CTs is their inner diameter (120 mm and 200 mm). Due to their low voltage isolation, they may only be used on cables. CSH 120 and CSH 200 connection diagram To measure residual current up to 20 A, connect the core balance CT to the “2A rating” input. To measure residual current up to 300 A, connect the core balance CT to the “30A rating” input. P1 EA/EM A S2 A4 A3 A2 A1 REF 30 A rating 2 A rating c.b. CT S1 P2 1 2 3 P1 S2 CSH core balance CT S1 P2 earthed metallic cable shielding 1 2 3 Cable shield earthing. Selection of operating mode (SW1 microswitches) Set the corresponding Sepam 1000 microswitches. The microswitches concerned (SW1) are found on the EM or EA module (slot 2). Refer to the chapter entitled “connection of current inputs”, “selection of operating modes”. SW1 Setting for measuring residual current via a core balance CT. 10 Installation Assembly Assembly on MV cables. Assembly on mounting plate Group the MV cable (or cables) in the middle of the core balance CT. Use non-conductive binding to hold the cable. Remember to insert the 3 medium voltage cable shielding earthing cable through the core balance CT. Cabling The CSH 120 or CSH 200 core balance CT is connected to the CCA 606 6-point connector (item B) on the current input module. Recommended cable: c sheathed, shielded cable, c min. cable cross-section 0.93 mm2 (AWG 18), c resistance per unit length < 100 milli ohms/m, c min. dielectric strength: 1000 V. Connect the connection cable shielding in the shortest manner possible to the Sepam 1000 2 A 4 terminal. Flatten the connection cable shielding against the metal frames of the cubicle. The cable shielding is grounded in Sepam 1000. Do not ground the cable by any other means. Maximum resistance of Sepam connection wiring Installation rating used max. resistance 30 A 4Ω 2A 10 Ω 11 Use of the CSH 30 interposing ring CT The CSH 30 interposing ring CT should be used when residual current is measured by a current transformer with a secondary circuit (1 A or 5 A). It acts as an interface between the current transformer and the Sepam 1000 residual current input. The CSH 30 interposing ring CT is mounted on a symmetric DIN rail. It may also be mounted on the plate by means of the mounting holes on the base. Cabling The secondary winding of the CSH 30 is connected to the CCA 606 connector. Cable to be used: c sheathed, shielded cable, c min. cable cross-section 0.93 mm2 (AWG 18) (max. 2.5 mm2), c resistance per unit length < 100 mΩ/m, c min. dielectric strength: 1000V. Connect the CSH 30 interposing ring CT connection cable shielding in the shortest manner possible to the 2 A 4 terminal. Flatten the cable against the metal frames of the cubicle. The connection cable shielding is grounded in Sepam 1000. Do not ground the cable by any other means. The CSH 30 interposing ring CT must be installed close to the Sepam (Sepam CSH 30 link less than 2 m long). 12 Installation Connection to 1 A secondary circuit 5 turns EA/EM REF 30 A rating 2 A rating c.b. CT A4 A3 A2 A1 2 P1 S1 P1 1 P2 S2 P2 CSH 30 interposing ring CT 1A c.b. CT 1 2 3 c plug into the CCA 606 connector. c wind the transformer seconday wire 5 times around the CSH 30 interposing ring CT. Connection to 5 A secondary circuit 1 turn EA/EM REF 30 A rating 2 A rating c.b. CT A4 A3 A2 A1 2 P1 S1 P1 1 P2 S2 P2 CSH 30 interposing ring CT 5A c.b. CT 1 2 3 c plug into the CCA 606 connector. c wind the transformer secondary wire once around the CSH 30 interposing ring CT. Selection of operating modes (SW1 microswitches) SW1 Setting for measuring residual current by an interposing ring CT. Installation Set the SW1 microswitches, referring to the chapter entitled “connection of current inputs”, in the “selection of operating modes” section. 13 Connection of voltage inputs This concerns types of Sepam 1000s that have voltage inputs. ET AS' ES1 Type TX. 8 7 6 5 4 3 21+ A Phase and residual voltage transformers (VTs) are connected to the CCA 606 6-point connector on the ET module. Sepam 1000 can function with 1, 2 or 3 VTs. Residual voltage can be measured by two methods: c calculated by Sepam 1000 based on the phase voltages, c wired directly to Sepam 1000 from a transformer with open delta-star windings. SW 1 SW 1 B 6 5 4 3 2 1 4 3 2 1 B A 2 Connection of 3 VTs 1 This arrangement doesn't allow for residual voltage measurement by the sum of the 3 phase voltages. 3 8 7 6 5 4 3 2 1 A 1 0 2 P2 S1 S2 A6 A5 A4 A3 A2 A1 ET U21 U32 SW1 or P1 microswitch setting voltage inputs Connection of 3 VTs (measurement of residual voltage) 1 2 3 This arrangement is used for Sepam 1000 to measure phase-to-phase voltages U21 and U32 and to calculate residual voltage based on the VT secondary voltages. It requires the use of 3 VTs with the primary between phase and earth. Terminals 1 and 6 must be strapped in order for Sepam to calculate residual voltage. P1 P2 S1 S2 A6 A5 A4 A3 A2 A1 ET U21 U32 SW1 microswitch setting voltage inputs 14 Installation Connection of 2 VTs 1 This arrangement does not allow residual voltage to be measured by the sum of the 3 phase voltages. 3 2 P2 S1 S2 A6 A5 A4 A3 A2 A1 ET U21 U32 SW1 or P1 microswitch setting voltage inputs Connection of 1 VT 1 This arrangement does not allow residual voltage to be measured by the sum of the 3 phase voltages. 3 2 P2 S1 S2 A6 A5 A4 A3 A2 A1 ET U21 U32 SW1 or P1 microswitch setting voltage inputs Connection of the residual current input 1 2 3 This arrangement is used to connect the residual voltage measured outside Sepam 1000 via a transformer with open delta-star windings. The connection is made on terminals A1 and A2 of the 6-point connector. P1 P2 S1 S2 A6 A5 A4 A3 A2 A1 ET U21 U32 V0 SW1 microswitch setting voltage inputs Installation 15 Connection of voltage inputs (cont’d) Selection of operating mode (SW1 microswitches) ET The voltage input conection subassembly has 2 microswitches (2) that must be set according to the connection diagram being used. The microswitch setting is indicated in each of the preceding connection diagrams. The microswitches must be set before Sepam 1000 is switched on, while it is de-energized. SW 1 AS' 8 7 6 5 4 3 21+ A SW 1 B 6 5 4 3 2 1 2 16 8 7 6 5 4 3 2 1 A 4 3 2 1 B A ES1 1 0 Installation Connection of power supply and inputs and outputs Connection of power supply and earth EM AS' 8 7 6 5 4 3 21+ A The Sepam 1000 power supply is connected to the CCA 604 4-point terminal block on the AS’ module situated on the rear of the device. The power supply input is protected against accidental polarity inversion. ES1 SW 1 SW2 SW1 B The Sepam 1000 chassis must be earthed via the grounding screw situated on the AS’ module. 6 5 4 3 2 1 Use a braid or cable fitted with a 4 mm eye lug. The eye lug fastening screw is already mounted on Sepam when it is delivered. (Should the screw be lost, never replace it by a screw longer than 8 mm). 4 3 2 1 B A Connection of logic inputs and outputs 8 7 6 5 4 3 2 1 A 2 1 0 EM AS' ES1 8 7 6 5 4 3 21+ A The logic information is connected to the CCA 608 and 604 connectors on the AS’ and ES1 modules. SW 1 SW2 SW1 B 6 5 4 3 2 1 4 3 2 1 B A 2 Cabling should be in accordance with the diagram for your application.. 8 7 6 5 4 3 2 1 A 0 1 ES1 0A AUX 2 AS' 1A +1 -2 TRIP 8 7 6 5 01 02 AUX 1 04 4 3 05 2 1 As' module 3 4 07 AUX 4 08 1B Installation AUX 3 4 3 03 1 2 06 INPUT 5 6 7 8 ES1 module 17 Connection of power supply and logic inputs and outputs (cont’d) Selection of operating modes (SW1 microswitches) The ES1 module has 2 SW1 microswitches that must be set to determine the logic input operating mode. EM The microswitches must be set before Sepam is switched on, while it is de-energized. ES1 AS' 8 7 6 5 4 3 21+ A SW 1 SW2 SW1 B 6 5 4 3 2 1 4 3 2 1 B A 2 01 SW1 8 7 6 5 4 3 2 1 A 1 0 status guar. 1 status guar. 6.0 Vdc 4.2 Vac 14.0 Vdc 10.0 Vac setting to be used for 24 to 30 Vdc supply voltages 25.4 Vdc 33.6 Vdc 18.0 Vac 23.8 Vac setting to be used for 48 to 250 Vdc or 100 to 240 Vac supply voltages 01 SW1 18 0 Installation Checking prior to commissioning Checks EM These operations should be carried out before Sepam 1000 is energized. Supply voltage Ensure that the cubicle auxiliary power supply has the same operating voltage as Sepam 1000. It is indicated on the rear of the device, beside the power supply connector, by a point in the box corresponding to voltage. AS' 8 7 6 5 4 3 21+ A ES1 SW 1 SW2 SW1 Earthing Check that the Sepam 1000 chassis is earthed by the grounding nut situated on the AS’ module. Check that the screw has been tightened. Connectors Check that all the connectors on the rear of the device are correctly plugged in and screw-locked. B 6 5 4 3 2 1 4 3 2 1 B A 2 Microswitch setting on rear of device 8 7 6 5 4 3 2 1 A 1 0 Check that the microswitches used to set the Sepam 1000 operating mode and calibrations are correctly set (pushed to the limit on the left or right so as to avoid random setting). The settings are given in the chapters related to the connection of the different inputs. c “connection of current inputs to 1 A or 5 A CTs”, c “connection of voltage inputs”, c “connection of logic inputs and outputs”, the microswitches must be set while Sepam is de-energized. If the microswitches are incorrectly set, the measurements supplied by Sepam will be erroneous and the protections will not trip at the required set points. Installation 19 Schneider Electric SA Postal address F-38050 Grenoble cedex 9 Tel: 33 (0)4 76 57 60 60 Telex: merge 320842 F http://www.schneider-electric.com Rcs Nanterre B 954 503 439 3140744A-D ART.75728 As standards, specifications and designs change from time to time, please ask for confirmation of the information given in this publication. This document has been printed on ecological paper. Publishing: Schneider Electric SA Design, production: Idra Printing: 02 / 1998