* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Single and Three Phase Overhead Transformer

Immunity-aware programming wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Electrification wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Current source wikipedia , lookup

Portable appliance testing wikipedia , lookup

Electric power system wikipedia , lookup

Electrical ballast wikipedia , lookup

Power inverter wikipedia , lookup

Ground (electricity) wikipedia , lookup

Power MOSFET wikipedia , lookup

Resonant inductive coupling wikipedia , lookup

Voltage regulator wikipedia , lookup

Amtrak's 25 Hz traction power system wikipedia , lookup

Power electronics wikipedia , lookup

Spark-gap transmitter wikipedia , lookup

Buck converter wikipedia , lookup

Mercury-arc valve wikipedia , lookup

Stray voltage wikipedia , lookup

Earthing system wikipedia , lookup

Power engineering wikipedia , lookup

Opto-isolator wikipedia , lookup

Voltage optimisation wikipedia , lookup

Distribution management system wikipedia , lookup

Single-wire earth return wikipedia , lookup

Electrical substation wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Surge protector wikipedia , lookup

Transformer wikipedia , lookup

History of electric power transmission wikipedia , lookup

Three-phase electric power wikipedia , lookup

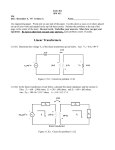

Overhead Distribution

Transformers

5-833 k. Single Phase

30-500 kVA Three Phase

2

1J1

.o.

le

All

R

POWER

PARTNERSiNG

Ropresentod by and

Nareplated for ASS Inc.

Il 1! 1!

F" ".'i

About Power Partners, Inc.

Power Partners, Inc. manufactures poletvpe

distribution transfor'mcr., that provide more

than 3,000 utilities in North America, Central

America, the Middle East and Asia with electric

power for homes and businesses. Power

Partners' poletype clistrihution transformers

are specifically designed to serve residential

overhead distribution loads. The y arc also suitable for light commercial loads, industrial

lighting, and diversified power applications.

Power Partners provides a complete line of

overhead transformers to meet the applications of any distribution system. The company

manufactures single-phase and three-phase

polettipe transformers at 34.5 kV and belo

in ratings from 5-833 kVA single-phase and

30-500 kVA three-phase. The Power Partners

core-coil design provides optimum efficiency

and excellent mechanical, thermal and electrical performance.

The Power Partners operation in Athens, GA,

has achieved ISO 9001: 2000 certification. The

operation, which was an ABB facility until

Power Partners purchased it in May 2003. has

nearly 5 y ears r.)r manufacturing experience.

The ABB Connection

The polctvpc disti'ibuhon transformers manufactured by Power Partners are name-plated

for ABB, with ABB serving as the manufacturer's representative for Power Partners. ABB

is a global leader in power and automation

technologies that enable utility : and in(IListryr

customers to improve their performance,

while lowering their environmental impact.

Manufacturing Technology

Overhead distribution transformers manufaactur'cd by Power Partners offer cost-effective

solutions for power clistrib u i on. The latest

manuFacturing technology is utilizedi to maintain state-of-the-art quality and productivity.

Large vertical integration allows us to ship

high quality : products in the shortest possible

production cycle.

d

POWER PARTNERS

The Value of Quality

Power Partners is committed to achieving total

customer satisfaction and industry : leadership

through continuous process improvement.

The company's employees are team-based and

measurement focused, and their work is based

on highly disciplined processes. The company

is innovative, reliable and driven to provide

high quaIityr and high Value, and to meet each

delivery commitment. \ want Power Partners

to be recognized as a company that exceeds

customers expectations.

An Industry Leader

N orking together with ABB as the mantifacIurer's representative for Power Partners, we

have alliances with major utilities and businesses around the worst[ providing products

and services to meet all their needs. Together,

we are a dominant force in the industry.

Single Phase Overhead

Distribution Transformers

I'c nVc1- I'artn cl'S single p11a sC.

oil-filled.

1][11 0-1111 1L11)ted dis-

tributinn transformers are specifically designed for ser v icing residential overhead distlilWti[ in loads. .111 e y are also

sU itablc for light commercial lc ds, inc]Lltitrial lighting and

divcrsificd power applications. These transformers arc

designed for the application conditions normall y cncountcrcd on electric Lltilit power distribution systems.

l aser CtCIICc] :111[ 1di/ed a 1L111111111111 na incplatc \+ith bar

coded serial number.

14. The paint finish process applies a C]L11aable, corrosion

resistant finish t the prod Let. The finish meets or

exceeds all the performance rec]L11rcnlcnts of ANSI

C57.12.29. )he nuLllti- ti tep process includes an epoxy

13.

p ri mer unifiIrnlly applied he cationic clectro- deposition

and a Urethane top coat.

The following additional featLlre. y

self protected type CS P " U nits;

15. P ri mary protective link.

16.

are

all standard on

Surge arrester.

17. Secondar y Circuit breaker.

18. Secondary breaker operating handle ith e m e rg e ncy

overload reset and overload signal light.

n

tv

Type CSP"

Sr

It.)

4

`5

Ratings

Type S

• 5-833 kVA

• 65 C tcnlpcl'aitL11Y rise

• 60 hertz standard, 50 hertz optional

• Low voltages: 120/240, 240/480 and 277

• I Iigh voitagcs: 2400 th1-0 gh. 34,400 Volts

RQ

• In ulaticm lccls:

Options

480-600

1.2

:0)

2160-2400

5.0

60

4160-4800

8.7

15.0

7;

7200-12470

1

r o nal / 5 k 1 1OI. 12000 e

1. 3200-14400

19920-22900

95

1I. ai u dabic

18.0

25.0

125

150

ritvr i,n/ /25 ' V lilt. 199`'0 e n1l.+ae unable

-34400

34.5

200

Standard Features;

]Legs.

2. Arrester mounting pacts.

3. Cover-mounted high voltage porcelain bushings)

with eyebolt ternlina] (10-100 kVA) or spade terminal.

4. Low voltage insUllators are available in fiberglass rcinforccd polyester material or porcelain (both eyebolt

and spade terminals),

1. lifting

5. Low voltage neLJtral glY1L1nding strap (fU1rnished On

10-50 k\'A single HV hushing Unit s }.

6. ANSI support lugs (hanger brackets).

7. Cover has 13 mils minimum of polyester coating providing 15 kV dielectric insulation of tank ground parts

from li ve parts and increased resistance to corrosion.

8. Self venting and resealing cover assembly

9. The core/coil bolt-in pads are 180 apart.

10. Embossed low voltage leads.

11. Oil filled IllLJg\^ith cover ground strap.

12. 'lank g1YaLlnd pad.

I'rinl arv Termination

• Cover-nloLmtcc] high voltag e porcelain bushing(s)'k+itl-I

spin top terminal.

• Side-wall mounted high voltage porcelain bUShing(5)

with spin top terminal (Standard on all 4800 Volts an(]

below ) .

• Primar y current li miting backUp fLlyc.

Secondar y Termination

• I. ow Voltage porcelain Bushings ith NEMA spade terminals (Standard on all units 167 kVA and above).

Primary Switching

• Externally-operated tap changer.

• Externall y-operated dual voltage switch or internal

terminal board.

OVC'CL11'1'Cnt I'1'I )tC41 on

• Intcrnalh- mounted current limiting fuse in ,cries with

protective lint .

Contact the division for voltages and dimensions on 666

thn ugh 8-i kV'\.

Optional Accessories

1.. 1-ligh voltage bushings

are

of two types and are mad e

of wet 1)rocess porcelain;

• Speed wrench operable c}°clxolt bushing for cover

mounting.

• Spin-top bushings for either cover or side-wall

n1oLlnt.

!. '1^ip changers compensate for small voltage variations

along the dlistl - 117L1tion system. 'hue externall y

tap changer is a single-phase,

design for dc-energized operation.

five - position

-operatd

POWER PARTNERS

A dual oltagc itch permits use of the same transformcr on distribution s ystems with different sv°stcm

• The MOV polvnncr arresters hL i ndI SL1rgcs of

65,000 ampctrs (small block) and 100,000

amperes (large block).

• Secondary C1rCL11t brea kers protect against over-

voltages.

The CSP protection package consists of four related

components that work together to provide complete

self contained protection against surge

.

CL11 1C.nts. short CirCL11ts and ov erloads:

• The protective link removes an internally-f a L1lt cd

transformer from the primary line, maintaining

-

l oad s and external sho1 t CirCL11ts.

• An optional C LJ rrcnt li miting fLJSC supp]Cmcnts the

protective link when the f[L Lilt CLJ1 . 1 - Cnt cxcceds the

li nk's rating.

Stainless steel tanks and covers arc availLihlc.

Serv ice to C thC1 • CLJSton1C1 • S On the

e line not serv ed

b y the faulted Unit.

Overhead Distr ibution Transformers

Approximate, +hr, ght5 and dime.. n5iony

APPROXIMATE WEIGHTS AND DIMENSIONS

OVERHEAD DISTRIBUTION TRANSFORMERS

Standard Design 1 ]imcnsions and 'eights

(All wcights and diiiicnsions are approximat e . Dimensions may change to meet

the customer spec.)

Single Phase, 60 HZ, 01SC, 65 Hiss High

Voltage

(Refer to Division for available tap

positions and dimensions for other

primary voltages.)

Low Voltage 120240 or 2401480 or 277

Standard Performance level

g.

A

E

q

N

E

^ ^in

C

B

75-100 KVA

IIIII

IIIII

- 0

Liiu

q

a

^^®

®

1 67

500 KVA

q

C

B

1.5-50 KVA

Overall weights and dimensions arc given in pounds, inches or gallons and arc approximatcs

A = Ove ll F-Height. 13 = O v crill Width, C; = Overall t)cpth, 1) = Tank Diameter. F. = Hanger Spacing

I Phase

34

I

' '

H

36

20

22

I:,. '=

13. ' 5

] 2

375

5[l

41

44

U

P

H

22

,,,

24

,.+

11.25

11.25

2U5

236

41

11

2 +-

12

349

3

1S;

17.5

1. 7.5

1. 1.25

11.25

11.."_'>

489

>S 5

510

6U5

29

3]

i0

75

49

25

27

20

23.25

850

875

1 00

50

27

28

20

2325

923

968

167

'50

333

58

66

62

38

38

42

33

33

37

24

24

_'+

23.25

24

24

1475

1820

2040

1542

1885

2110

78

90

82

^r00

66

1^

+1

_-

36

2850

2950

11)9

FF

10

3

1 .5

117

22

22

25

'is

20

24

24

27

1. 3.2

13.25

1. 7.5

17.5

20

1 1 ._°5

11.25

11.25

11.25

11.25

!i>>

245

.

?I25 0

37.5

50

38

46

46

51

505

730

526

755

II

II

29

28

41

38

75

52

25

28

20

23.25

910

936

IOU

56

2-

_)s

20

23.25

98 5

10215

+6

167

'S0

333

56

68

l

38

38

42

33

33

35

24

24

24

23.25

24

24

1430

1969

1970

1495

1930

2041

70

Q1

-5

2960

3U

141

4

27

36

39

111 -Approximate Dimensions shown reference designs with +j- 2.5% 'laps

POWER PARTNERS

A

Transformer Protection Package

for Overhead Distribution Transformers

-

,

I

ticr I'artncr5 c ffcrS f( )U I I) LbSiC ti iThfo1 111C1 tv'pcs: S, SI':

>

CI and CS1"`. 'Together they represent a wide ningc of

prutcctivc capabilities to meet ncarl every application.

Fo r transfornlC.rs suppliCC] \pith OVCrCL11TC.ilt protCCtIon,

the user must assure coordination with system protcc-

tive devices. F ailure

to do so will defeat the PLJ1T)05C of

such protection.

ti\c link opcl'atcs, taking; the load c)ff tll • tl-;1n^fi 1Inc_IhCforc the corc/coil is damaged.

Current-Protecting "CP" Transformers with Current

Limiting Fuse

This t pc tl'ansformer has the Same characteristics as

type "CF plus the ability to ]inhit fault cUJn-cnt to the

tran s for m cr.

the

®

Self-Protected "CSP " Transformers

I

The CSI coCorclinatcd protcctic)n package is available as

an option on Power I' wrtncrs overhead distribution trans-

-}

Type S

forrnCrs for increased protection against 5LJrgC CL1rrCnts,

shol't circuits, a nd overloads.

tZ

LQ

Type CSP"

S

Conventional "S " Transformers

Phis t pc ti n fo^rmc1 , cc:ntain5 no protection CCiuipmcnt.

Therefore. lightning, fault and overload protection for

thes c transfc l'mcrs must he provided by purrllascrin^tallccl. L3utiiliLir\ pre tccti c dciccS.

Conventional "5" with Protective Link

The protcctivc link is the ] cast cxpcnsivc device nioLinted

in the transformer to protect the system if ni a dcfcctive

transformer. 1k11cnever tlicre is an intc,-nL11 t'LllIU1 the

resulting fault current Wi]] cause the protective link to

blow. isolating the transformer fr in the priniwwry feeder.

Surge-Protecting "5P" Transformers

1'hc 'SF transformers inclLLlc t1 nSfo I-11101'-111CoLinted

lightning arresters and intc 1 'nall y -n1o LJ nta] high voltage

protective ]inks, but omit the internally-mounted low

volt age circuit brea ker, 'E1lcsc tra nsforniei's arc used in

loc ations w111Y li ghtning is a problem. However, bccaLJ c

the protective ]ink protects the system only from outages

d Lie to internal transformer fail L re, overload protccti on, if

cl ircd. mutit Inc Ilrcnidccl I c,tcrmal iLJSOS.

Current-Protecting "CP" Transformers

v

The "CI' transformers are equipped with the intcrnallv

kc1- and high voltage -nioutC1lwvagercLtI)1Y.

protectiv e links, but omi[ the lightning arresters. Thcse

transformers are Llscd in locations whet t lightning is not

SL11

C I)1Y.)tCCt10n 1S desired.

1. I'n tcctivc I.inL

a) Hcnlo v cs an internally-faUlltcC] transfbrnier from

the primary line.

b) Operates at to 14 tinics normal full load current.

a)

Both the current liliiiting fuse and the plutcctiv e link arc

fuses working togcthcr to give full range transforl,lrr

protection against f ault-Current. I'lIC 1)rotCCtivc li no intcry

l'LO ptS an low f alUllt cL11'1'Cnt While the current limiting

fuse protects ag ainst fault currents which exceed th e

interrupting rating of the protective link.

S

Features

2. Second ar

Conventional "S" with Current-Limiting Fuse

and Protective Link

a problem. The arrester ma y he crossarm-mc anted if

1

y

P r otects

Circuit Breaker

against overloads and external short

c1FCLlits.

b) Coordinated itll protectiv e link, trips on an

external short or overload before the link blows,

and only if th e overload is large or continUous.

c) If overload is small or temporary a load managcnlcnt light signals the need for change-out to a

lal ;cr unit for more optiniiicd tlansforrncr' loading.

3. MOV Pol v nlc1 • Arrester

Provides protection fi • onl lightning and switching

S Ll rj?C S.

4. Optional partial-range current 1in1itin fuse (in series

with protectiv e link)

a) Limits the n1aximun1 current in the circuit.

b) Reduces current to zero in less than one-half

cvc] c.

c) Minimizes th e possihility of eventful f3i11.11' ,

The CSP` protection package is available on Sinlc phase

and three. phase ov cnc e ad distribution transformers in

the following ratings:

• ;inlc I'llase, LV 120..240, 10-100 kVA

• Single Phase, LV 240/480, 10-167 kVA

• I'llrec Phase, 30-150 kVA

'rhe breaker and protective link arc coordinate(] Such

y

-

that an f l[ It Or short Cil ULJit on the seCondlar1 sid c of

the transformer will trip the breaker before the protcc-

POWER PARTNERS

Class Designations

1. I'> pcC:al' . alx>c5 W. ]0-100kVA.

e

Class A: Two tull -i nsulated high voltage bushings, two

arresters, two protective links and extcrna] breaker han-

dle. Suitable for app]icatic in on either wyc or delta distriIxition systems. Single-position pole mounting in

accordance with latest ANSI standards.

Class B- 1:'TWo Tulle- insulated high voltage bushings,

one arrester, two protective links and external breaker

handle. Nornla]]v applied on solidly grounded systems.

Class B-2: One full - insulated high voltage hushing, cinc

arrester, one protective link and external breaker handle

Suitable only for application on solidly grounded distribLition sv v stenls. Single-position pole nioLinting in accordance with latest ANSI standards.

Class B-3: Same as class B-2 except with two-position

mounting.

2. Type CSF' , 5 kV and below, 10-100 kVA. Similar to

Type CSP' above 5 KV except:

• Sidewall-mounted primary bushings.

• Class B-2 and B-3 not available.

y

1. 'Cypc 5, above 5 kV. 10-500 kVA.

Class A: Two full - insulated Iiigh voltage bLishings, sLut-

able for application on either wye or delta distribution

systems. Single-position pole nloUnting in accordance

with the latest ANSI standards.

Class B -2: One full - insulated high voltage hushing, suitable only for application on Solidly goaLlndCd d istril7LltiOn

systems. Single-position pole nic:unting

in accordance +ith the latest ANSI standards.

Class B-3: Same as class B-2 except with two-position

niOUnting.

2. Type 5, 5 kV and below, 10-500 kVA. Similar to Type 5,

above 5 k\ except:

Siddewa11-n10L1ntedl primar bushings.

Only Class A is available.

•

y

F

1

CLASS DESIGNATIONS

TYPE CSP HV ABOVE 5 KV 10-irxl KVA

75-100 KVA

ANSITYPE'B' LUG

75-100 KVA

[ANSITYPE'B'LLl

•

(

a

+-

E' =E .. 5i

Imo'

CLASS A

CLASS B -2

<V {

I

TYPE 'B LUG

CLASS DESIGNATIONS

TYPE S. HV ABOVE 5 KV. 70-501; KVA

75-100 KVA

/ANSITYPE'B' LUG

CLASS A> IC KVA

POWER PARTNER

ii:

CLASS A C,n KVA

•

CLASS B -2 <

•

CC

KVA

CLASS B-:r x: 75 KVA

Center-Bolt Cover Design

[ I1 C CXCILISiVC CCI)tCl'-I)OIt C[ AiCI C]CSI.n is titanclall.] c:n all

Power Partners overhead transformers, 5-500 kVA single

phase and 30-500 kVA three phase. The cover asscnibly is

unique in 1)Oth operation and design. ['11C unlit offers an

extraordinary high withstand capability and an extra margin of safety.

'

Standard Compliance

A. Pressure Venting and Resealing

The self-venting cover design meets the pressurC venting

and resealing myuil emcnts of ANSI C57.12.20-1997, paragraph 6.2.5.2.

"A cover assembly designed fir relief of excessive pressure

shall remain effectivel scaled for overloads and external

secondary short circuits of the magnitude and duration

allowed by industr standards and loading guides, but

shall relieve pressure at a minimum of S lbf/in', gage (55.2

kPa) if designee] to reseal; or at a minimum of 20 lhf/in',

gage (138 kPa) if designed for pressure relief without

resealing. Such OpCRitiiin shall occur before other conlponcnts of the tank are ruptLiI'C] or displaced, and the cover

shall remain in position. Manual means of venting the tank

before removal of cover shall be provided.

No auxiliar pre sUlre relief device is required on Power

Partners overhead distribution transformers. The flow

rate of the center-bolt cover after venting is significantly

higher than that of auxiliary pressure relief devices

resulting in increased safety and higher tank withstand

capability

•

y

y

y

Advantages

y

is pressLJ1-C relief provided by L1nlgLle

• Static and d namic

venting and resealing capability.

• Increased safety provided through higher tank withstand capabilit and auto Matic pressUrC venting c]ulirig

cover removal.

• No aLlxlliar pressure relief device is required.

• Extra insulation provided by thick epoxy coating.

• Increased resistance to corrosion provided by sloped

cover and thick coating.

• Increased resistance to ]eaks and breathing provided

by unique gaskcting system.

• Simplified maintenance provided by single cover bolt.

y

y

y

Features

I. Center-bolt cover, cover beam and beam support lug

system provide:

a) Self- venting and resealing which meets ANSI specifications eliminating the need for an auxiliary

pressure relief device.

b) 'link withstand capability in excess of the rcgluirenlCnts of NEMA TR1.

2. Increased tank withstand capabilit and automatic

lllr.ssurc relief during cover removal result in

increased safety.

3. Electrostaticall -applied epoxy coating is a minimum

of 13 mils, providing an average of 15 kV dielectric

strength to provide extra insulation and protection

fi-onl corrosion.

4. The 15' slope of cover prevents moisture from collecting and increases resistance to corrosion and

]caking.

5. Continuous hollow nitriIe gasket, raised and flat

bushing cmbossments, undercut gasket scats on

bushings, and copper-encased cover bolt gasket provide increased resistance to leaks and breathing.

6. Center cover bolt provides easy cover removal compared to chime ling design, resulting in lower maintenance cost.

y

y

B. Tank withstand

The Power Partners overhead tank and cover design provide tank withstand capability far in excess of the 1 v ciui renients of NEMA TR1-2000. Part 2, Page 6, Section Dr

"'rest No. I — An Arcing Fault in an Enclosure"

"l. First Fault. A sin)Lllatcd internal fault slla]I he provided. This fault shall consist of a 1-inch ale gap

mi.iunted horizontally and located 1 inch above the core

clamps. This gap shall he bridge(] initi,3lly by a 0.060sinch diameter or smaller copper wire. [lie gap shall Inc

connected between the high-voltage terminals or from

one high-voltage terminal to ground. The mounting

blocks or terminals of the gap shall cc insist of copperbearing material and shall have flat surfaces from 112 to

3/4 inch in diameter or in „idth. 'These gaps shall he

designee] to maintain this 1-inch are gap for the duration

of the fault. The transformer coil shall not be electrically

connected in this test circuit. TIC power Source shall be

7.2 kV and adiuStCC] to supply a current of 8000 rms symmetrical amperes."

•

POWER PARTNERS

As this arcing fault wi]] not be self-clearing, hack-up protection shall be provided to clear the circuit in approximatcly 112 to 1 cycle which is a typical clearing time for

an cxtc1'na] clistrllhLJtion fuse CL1toLit. A CL1toLJt \\1th up to

2. Second Fault. For the sccc and fault, the fault

dcscrihcc] in item 1 shall he rcpcatccl.

This overhead tank and covcr system can withstand a

20,000 Ampere one-inch arc on the specified test.

a 25K fuse link Shull he used to provide hack-Lip 1p1'c.)tCCtion. A currant-limiting device, such as a fuse, cannot be

includes] in the back-up protection."

:ES

eoa

700

400

300

200

COQ

10

20

30

zcr.^lT^r.^n:i Y^sdrn

POWER PARTNERS

W

Low Voltage

Spark Gap

An internal 1(n+ +oltage spark };ap has been dc+cic )hed aO

a means of protection for distribution transformers

against secondare side. surges. The Electric Utility

Indutitrr has been eoncerncd about transformer failures

attrihUted to secondar y surges, a]though the f(;11L11 - C rate

is estimated to be ]css than P5% per year. The entilr

sLlbject is Very complex. bU t the phenomenon is very

much related to system parameters, such as, house and

pole groU nd resistance, length and type of service drrip,

and transformer load. - I'he sU rgc impedance of the transformer coil is also a significant flctor. resulting in units

larger than 50 kVA being t y pically imrnLinC from this type

of failU re. The Power Partners spark gap will provide

the same degrees of protection as any other method

presently avai]ablc, and at a significantly lower cost.

Apphoation

The spark gap is mounted internally between the low

voltage line hushing and the low voltage nCLltral and is

designed to arc oVC1- (]Li ling low Voltage sakes to protect

the transformer +in(Iings.

Testing

I',.ti li',1Listive testing has proven that (1) the internal spark

g i p operates under surge conditions to protect the

transformer winding, (2) the arc is extinguished Under

high acailahle fhLJlt current conditions, and (3) the Operation of the internal spark gap, under maxim urn oil temperature conditions, and,+ith a wide range of oil vapor

to air ratios, does not result in the development of an

unsafe condition. This extensive testing proves conclusively that the internal spark gap provides the same

degree of protection as that provided by interlaced

secondary windings, low voltage MOV arresters, and

external spark gaps.

Advantage

1.',ffccti+c — prevents low-side surge failures.

Cost effective — a spark gap is considerably lower in cost

than the other suggested methods of prevention.

Reliable — a spark gap does not degrade the overall transformer Or the s y stem reliability

Easy installation — the internal spark gap can he easily

retrofitted onto existing transformers.

The spark gap mounted internally on the LV neutral bushirra

with the electrodes connected to the X1 and X3 bushings.

10

POWER PARTNERS

JUMBO "Step Down"

Overhead Distribution Transformer

"J LUI4'1fkJ I)1 St l'i1]Lltic 1I

1i 1111Sto1111C I'} a1'C C Icsi8nc(1 as

single phase, two-winding transformers—specifically

for "Step-Down" applications.

T

R

Y

^

0l. Pin )totvpe testing 1nsL11'Cti tIIC , ]L1111I7o design Call meet

1TIC]L15trV short CircLlit standards and prov ide reliable

service.

7. Self-venting and resealing cover eliminates the need

for an auxiliary pressure relief device and offers

increased safety- through higher tank withstand.

8. ANSI suppc. 1 1-t lugs (hanger brackets) are rod-welded

to the tank wall for added strength.

9. Anodized alL1nlinLln1 laser inscribed nameplate oilers

1

5L3L)

Standard Features

y

1! ii

1. Lo-Hi-Lo cc it design divides the short cil'CLllt force

between two low-high spaces increasing the short

circuit strength of the. coil.

2. 'Roo winding construction yields a much higher

i mpedance than 15 characteristic of a n auto transformcr which helps limit the mechanical forces the.

Unit 01 List Sustain dUring faLllt CdL1tV.

Progressively wound coils with adhesive

resins on

thermally upgraded insulating paper provide

increased short circuit and thermal strength.

4. Sheet con(]Llctor in IV windings enables the electrical

centers in the high and low to align thcrrselv'cs n1inimizing the vertic al component of short cul - CU1t fortes.

5. Rcinfiirced core-coil assembly provides greater sho r t

cin uit ithstand capability.

3.

POWER PARTNERS

longer term readability

10. Lifting lugs are positioned directl y opposite the

cover beam Support lugs, reCdU sing the chance of the

tank going out of round when lifted.

11. Cover mounted high voltage porcelain bushings with

cvcuolt terminals are m[1Llntcd on flat embossments

on th e cover and have Undercut gasket scats for

improved scaling. 'Pie eyebolt connectors are cast

bronze plated with tin,

12. Low voltage porcelain bushings with clamp-type t e rminals provide case in making secondar y terminations.

13. Arrester r e. unting pads are resistance welded to the

tank wall. completely and unifi rmh filling the surfaces where p ad and tank wall join, to pride

greater strength.

14. The p aint finish process applies a CILJ1 - a blc , corrosion

resistant finish to the product. 'f'hc finish meets or

exceeds all the perfon'mance rCL-JLJ cmcnts of ANSI

C57.12.28. The multi-step process includes an epoxy

y

primer uniforml applied by cationic cicctrodcposition and a Urethane top coat.

Ratings

• 50-500 kVA

• 65°C Rise

• 60 Hertz standard. 50 Herb optional

• I ligh voltages: 7200, 14400 and 19920

• Low voltagcs: 2400, 4800, 7200, 7620, 7970

Standard Design Dimensions and Weights

JUMBO LIQUID IMMERSED OVERHEAD DISTRIBUTION TRANSFORMER

TYPE S. HV ABOVE 5 KV, 100 KVA

ANSI TYPE '`B" LUG

ANSI TYPE '`B" LUG

'A

Q

I

I

m

®

m

m

I

I

A

I

I

I

I

I

I

I

I

I

I

I

I

LV > 600 VOLTS

5000 VOLTS

LV 5000 VOLTS

A]] Approximatc 1.)imcnsions shown rcfcrcncc dcsigns with -/-2.5% Taps

umhv

t

H

-5

Not A vai]ablc

100

167

+5

58

t;

24

28

25

!U

75U

785

52

52

31

33

31

37

31

33

22

27

1095

2010

1150

2090

41

37

33

'-

23 • +U

1.i.i[l

88

85

45

45

37

39

33

36

27

27

2400

3Ub>

2500

,1(»

120

5[1

333

5[1U

5i

(9

64

:

88

Ovcntll , eights and i ncnsions are givcn in potmdti. inchcs or gallons and are approximates

A = Overall 1-lcight. I3 = Overall Width. C = Ovci^ill 1)cpth, L) = 'link 1)i amctcr

12

POWER PARTNERS

Three Phase Triplex

Overhead Distribution Transformer

die I'cn+cr Partners li'iplcx c.l\cilieacl diStl'11}Llt1[11i tCansformer can be Used to serve three phase applications

through 225 kVA. 'Triplex designs consist of three scparatc single-phase core-coil assemblies in one. tank.

No

11

Q

1

-

45

EA

Triplex overhead distribU tion transformers are often used

to serve large motor loads Hhere the motors are fi • egL1Cntl1' started. Oil field 1]Llnlping loads and sonic irrigation pLlnlping loads shoL1lrl use onl y triplex designs. Also,

the 1hplcx transformer has international applications

here 1)v 9 and Dv 11 phase displacement are rer]L111'cd.

Ratings

• 30-225 k\A

• 65 > C rise

• 60 Hertz standard, 50 Hertz optional

• High Voltages: 13800 and below

• Low Voltages: 208Y,120, 240 x 480, and 480Y,277

• 'Transformer Bll., Ratings

Transformer Primary

'Transformer BIL

2400

60 kV

4160

60 kV

7200

75 kV

8320

75 kV

12000

95 kV

12470

95 kV

13200

95 kV

13800

95 kV

POWER PARTNERS

Advantages

• liasicr, cleaner installations are provided by thvcc

phase overhead transformers compared ti l thrce

single-phase units.

• Reduced installation costs, lower operating costs,

safer operation, minirniied service disruptions, and

increased tlansfbrincr life. provided by an optional CSP

protection package.

• The capability to serve large motor loads requiring frequent motor starting is provided by triplex designs.

• The same design, nlanL1factLlring and perforniance

advantages that are provided on Power Partners single

phase overhead distlihution t1 ansforn c s are incorporated into the triplex design.

Features

]. \d1L1nC1 core with step-lap joints for increased

efficienc y and lower noise levels.

2. I'rogressiVC]V wOLlnd coils with adhesive resins on

insulating paper or conductors for increased shortcircuit strength, efficiency and thermal strength.

3. CSP protection package available as an option for

increased protection against surge currents. short

circuits and overloads:

• I'limar y protective links

• SUl gC arresters

• Secondar y circuit breaker

• Secondary breaker operating handle with cmcrgency overload reset and overload signal light.

4. Three point core-coil bracing for increased mechanical strength.

5. Self-venting and resealing cover that eliminates the

need for an auxiliary= pressure relief device and offers

increased safet y through higher tank withstand.

6. The paint finish process applies a ciurable. corrosion

resistant finish to the product. The finish meets or

exceeds all the performance requirements of ANSI

C57.12.28. The multi-step process includes an epoxy

primer uniformly applied by cationic cicctrodcposition and a L11tithane top coat.

7. Cover has 13 mils minimum of polyester coating

providing 15 kV dielectric insulation of tank groU nd

parts from live parts and increasing resistance to

corrosion. The cover is sloped 15 preventing water

from collecting, thereby reducing the chances of

corrosion and leaking.

8. 'Tank bottom rim is three lavers thick for increased

cdurability and resistance to shipping and handling

c] am age.

Standard Design Dimensions and Weights (All weights and dimensions are approximate.)

HV > 5000

HV < 5000

Overall weights and dimensions are given in pnun(IS, inches or gallons and are approximates

A = Overall Height. I; = Overall Width, C = [hcrall 1)cpth, 1) = 'fink 1)iamctcr. E = Hanger Spacing

: .

1;

14

tl ic_ dktance

bet ccn the I • Liin er Iwackcts.

POWER PARTNERS

Three Phase "T-connected"

Overhead Distribution Transformer

I'll c I'cn+cr I'L1 rtncrH I'-Omncctcd. c cnccaaC1 Llistl'117L1tii ill

transformer can he used to serve most three phase applications up to 500 kVA. "'1'-connected" transformers consist of two single-phase core/coil assemblies. This tYpc of

connection is also re1c1'red to as a "Scott-T O connection.

" '1-connected", overhead distribution tninstornicr can

be used to serve most three-phase applications.

However,'1'riplex designed three phase transformers are

needed for sonic applications where large motors arc

the lc ac] and these motors are frequently started. Oil

fi eld pumping loads and some irrigation pumping loads

She )ulcl use only the triplex designs.

A

Ratings

• ;;[1-500 kVA

• 65'C rise

• 60 Hertz standard, 50 Hertz optional

• High Voltages: 13800 and below

• Low Voltages: 208'1120, 240T x 480'1; and 480 17277

• 'Transformer 1311. Ratings

li-an storm cr Primary

'li-ansformcr BIL

240U'F

60 kV

4160T

60 kV

4800'1'

60 kV

7200T

75 kV

75 kV

8320T

95 kV

12000'1'

12470'1'

95 kV

95 kV

13200T

13 SOOT

95 kV

Advantages

• Easier, iii ore economical and cleaner installations are

provided by three phase overhead transformers compared to three single-phase units.

• Lighter weight Lind lower cost

Mded by "T-connected"

design compared to conventional three-phase design.

• Elimination of overloads from s y stem unbalance by

operating -- --connected transformers without I)1I'ma1'1'

groLlitcis.

• Avoidance of transformer neLJt1'al 1'CCquircrncnt since

third harmonic currents on "'I'-ccmnected" teinsformcrs are negative s UjUicnCC not 1Y'CgL111'ing a gi - ound path.

• Reduced installation costs, lower operating cost, safer

operation, minimized service disruptions and

increased tlansformc,- life provided by optional CSI'

coordinated protection package.

• The same design, manufacturing and performance

advantages that arc provided on Power Partners single

phase overhead distilliution transformers are incorporated into " •1'-connectcc] -• design.

p1A

POWER PARTNERS

Features

1. We uiid core with step-lap joints for increased effcicncy and lower noise levels.

2. Progressively wound coils ++ith adhesive resins on

insUllating paper or condLJCtorS for Increased shortcircuit strength and thermal strength.

3. - 11irec point core-coil bracing for increased mechanical strength.

4. CS! > protection package available as an option for

increased protection against Surge CL11'1Y.nts, short

circuits and overloads;

• Primary° protective links

• Surge arresters

• Secondar y circuit breakers

• Secondary breaker operating handle with emergency overload reset and overload signal light.

5. Self-venting and resealing cover that eliminates the

need for an auxiliary pressure relief device and offers

increased safety through higher tank withstand.

6. The paint finish process applies a durable, corrosion

resistant finish to the pi - odLiCt. ' Pie finish meets or

exceeds all the performance rcy . i 'cments of ANSI

057.12.29. The nlUllti-step process inclLides an epoxy

y

primer uniforml applied by cationic clectrodcposition and a Urethane top coat.

7. Cover has 13 mils minimum if polyester coating

providing 15 KV dielectric insulation of tank ground

parts from live parts and increasing resistance to

corrosion. The cover is sloped 15 preventing water

from collecting, thereby reducing the chances of

corrosion and leaking,

R. 'Sank bottom rim is three la y ers thick for increased

CILlrability and resistance to shipping and hLin(11ing

damage.

Standard Design Dimensions and Weights (All Weights and dimensions are approximate.)

A

A

HV 5000

HV r 5000

Overall weights and dimensions are given in pounds, inches or ga]]ons and are approximates

A = Overall Hei ,ht. H = Overall Width. C = Overall Depth, 1) ='Kink 1)i;3inetcr. F = Hanger Spacing

3 Phase 7' - T Connected

1:3

._.

26

+5

^':

112.5

1511

225

][3

40

2 1)

4$.4

43 2

57

57

61

64

28

28

30

30

34

22

_21

24

5

47

36

36

36

36

•i5

54

54

29

33

28

28

10

40

1 12.5

1511

62

62

61

33

40

37

30

30

34

22

22

24

69

11

36

27

80

45

42

27

725

;[3[1

500

_.

I._=.

29

33

31

40

37

41

11.2)

2 3.25

43 .25

36

36

99'

] li r. ;

1530

177(1

2215

750

3560

720

1035

1.175

1625

1. 8.40

2303

2860

3650

=,

tt

5'

62

70

81

98

118

.1)1)

.3-

it

905

11-5

965

1225

43

50

1505

1 - 25

1565

1780

2275

59

65

84

36

2285

3

2915

3015

100

3815

3900

123

E is the distance between the hanger brackets.

All Approximate Dimensions shown reference designs with +j-2.5%'hips

16

POWER PARTNERS

Distribution

Transformer Testing

I'Ii s It ver I'titnci'S ('cnnmitmcnt to manuf;dctLll'C C]Liallt

distrilxition transformers is backed by a series of transfornier tests usCC] tot enT Confitrrnancc to performancc

characteristics OL1tlinCC] in the latest ix visions of ANSI

C57.12.00 and ANSI 057.12.90. '171csc identified tests arc

a]so part of the Quality System which is aUldited semi annuall y h 1)h°f N0SKP, VF' RI'1AS (1DNV) to the ISO St andarc]s.

Testing Program

Factory tests are performed on a transformer to confirl,1

that it is properly designed and constructed to carry

rated load and that it will withstand the conditions it viii

be exposed to in service.

Each transformer nun LifactLired by Power Partners n1 List

undergo a series of tests.

I. Polarity, Phase-Relation. and Ratio

2. Applied Voltage Test of the HV

3. Applied Voltage Test of the LV

4. InC]L!CCC] Vo]tagC'lest

5. No-Load (Excitation) Loss and Excitation Current

6. Circuit Breaker Tcst (for CSP transformers only)

7. Impedance Voltage and Load Loss

8. hill \X! e Impulse

9. ContinL11tV wreck

Test Facilities

•

lllc multi-station, automated test facilities are operated

by process control Con1pLltera. ECClL11i'C(] interaction with

test floor personnel is minimal with the ConlpLlters initiating and monitoring each test, and then analyzing the

test rYsL11ts feedback. The computers are programmed to

condUCt tests according to ANSI standards, and according to the ratings of each transformer style, the test floor

computer

initiate appropriate test sctUllls, compare

results with established ANSI standard limits, and determine acceptance for each tested unit.

Will

•

1110 test 1'CSLllts for each Unit are recorded and Stored on

cornpi.ltcr files for acces and analysis.

Polarity, Phase-Relation, and Ratio Tests

•

Ilicse tests verify proper phase-relation (t111Y.e phase),

ratio, and polarit y (single ph as c) of the transformer L1nClCr

test. To pass, unit nUSt demonstrate the proper polaris

or phase-relation and have a tLii-ns ratio within one-half of

one percent if the nominal vi iltage ratio.

L3

Applied Voltage Test of the HV

I I is test checks the dielectric integrity of insulation

stl'LiCtL11Y.s between the high voltage and low Voltage, and

between the high voltage and ground. A pass/fail decision is ma(]c b y nlonitoi ing the test current intensit y. If

the resulting current is larger than specified normal leakage and capacitive currents, the Unit is rejected. This test

is omitted for transformers vOth a llcrnlaincntlygroundcd

high voltage winding.

POWER PARTNERS

Applied Voltage Test of LV

Phis dielectric test is similar to the Applied Voltage test

of the high voltage circuitry except that the integrity of

insU lation structures between the low voltage and the

high voltage, and between the low voltage and ground is

checked. A pass-fail decision is made by monitoring the

test current intensity. If the resulting current is larger

than specified normal leakage and capacitive current,

the Unit is rejected.

Induced Voltage Test

file

I u pose of this test is to verify the dielectric

strength of turn to turn, layer to layer, phase to phase,

and other insulation structures within the transformer

windings b y i nducing an overvoltage condition (at higher

than nctrm:31 frC(]LienCV to avoid saturation of the core).

The test CLJ1'1'C'tlt monitored, and if it exceeds limits

specified for each transformer, the unit is rejected.

15

No-Load Loss and Excitation Current

This test measures the no-loaf] tcxcitation) loss and tl-c

transformer exciting current with rated voltage applied.

If the exciting current and/or the no-load loss exceed the

li mits specified, the transformer is rejected.

Circuit Breaker Test (for C$P transformers only)

Phis test veiifies the 1)n )per c peration of the low

voltage

circuit breaker under fault conditions. The breaker is

require(] to operate within a specified time Under a

sitni.ilatc(] fa3Lllt.

Impedance Voltage and Load Loss

This test measures the load loss and the impedance voltage at rated Current. The load loss and the impedance

voltage 1)1utit be vtitl in specified limits.

Full Wave Impulse

The impulse test is one of several tests designee] to verify

the dielectric strength of the man y insulation structures

,, ithin the distribution transformer against line voltage

surges. It is performed to comply with ANSI standards

and fOr quality assurance. The change in the ANSI standard in 1993 required all manufacturers t0 install fault

detection sensitive enough to detect a single turn short.

Continui ty Check

This test is perti irnied on all transformer' to verify transformer C1rCL11t and component integrit y . This test is performed with an c ihmmeter to verify that the internal

wiring is correct.

The transformer's nameplate is compared to manufacturing information for sty]c, serial number, kVA, HV rating,

LV rating. tap voltages, impedance, con LiCtor materials

and coil 131L rating. The bushings, electrical accessories,

and Fuses are verified.

dl

A. Magnitu dC

Special Tests

Sc I1 tests arc performcd at the option

of

the customer

Sound 'Vesting

ANSI standa1Y1S define the WLluircd SOLInd 1CVCls for

transformer bLlt SOniC CLJStOr11C'S Specif y reduced SoUln(1

]cvcls. The Sound generated by a transformer is affected

by the core geometry, flux density, tank design, and the.

quality of assernbl\ : of all the transformer components

i i t a completed unit. tic )u rid tests arc made with the

unit powered at 100% and 1.10° of rated voltage undclno-load conditions.

Temperature Tests

C losses and coil IIlyses arc the plltllar y sOL11 - CCS Of

heating within the transformer. Our transforrnci's arc

guaranteed to have an average coil inding t(niperaturc

of no more than 65' C rise over ambient air tcrn1cratL11 -C

when operated at rated voltage and ]oad conditions.

'ncc temperature test is performed to dctcrlllinC the

thcrrna] characteristics of tllc transformer and to Vcrifv

that tllc~G= arc within design limits.

Calibration

k t C(JL11p11iCllt is calibrated on a SChC(1111C(1 basis by

trainee] technicians. Calibration rccolYls arc maintained in

accordance with the Quality System procedures. 'These arc

audited SCnl1 annuall y by 17NV in accordance with ISO.

Short Circuit Withstand Capabilities

1 )i tl'117Lltio ll ti i fi rincrS arI LJ hjCCtC(1 to 1 external short

Circuits on the sccondar y side.. SUCK external faults can

develop on the service Zinc, in the house wiring or - in

connected loads due to tnLlnieroUS environnictltal 1 - casons. These faults can he line-to-groU1nd. CIOUNc ]1 nC-tog1YlLlndj 111' line-to-line.

To meet these operating conditions, the American

National Standard 1tlmtitutC (ANSI) has sct standards conccrning short circuit \tithstand capability These standard n 1'CClUil - c that di tr ibL1tion transfori-ners shal] be

designed and Constructed to withstand th mechanical

and thermal Stl - CSSC5 pod Uced by these eternal short

Cil- CL11t5.

I'hc current standards 1l • lating to short circuit strength

arc ANSI C57. 12.00 hich sets the short circuit withstand

requirements for distrilbutlon transformers and ANSI

C7.12.90 which provides procedures for short citruit

testing.

For distribution transformers, the magnitude of the short

cir - cuit Current, th i1L1nlhers of Shot - t-circuit tests and the

duration of each short circuit test are defined bV ANSI

5tandaids its follows.

37.5-100

1.6 -500

112.5-300

500

750-2500

11G1,„

base Current (Symmetrical}

per unit tor- all clistribution tlansf(rmch

with sccondari • rated (50(1 V and belt w.

The shun circuit current will be Iimitecl b y the transfurmelimhec[ancc . nly.

B. Number of'lcsts

Each phase of the transformer shall he subjected to a

total of six tCSts, foul - with s y mmetrical fault currents and

two with asvninlctrlcal faLllt currents.

C. Duration of Short Circuit '[csts

WIIell Sho1 - t C11'CLlit tests are pC 1'f[ 11'n1CC1 tIIC Cl umtion of

each test shall he (1.2 s except that one test satisf ying the

symmetrical current rccluil-cnlcnt shall be made for a

longer (lunation on distrihutii n transformers. The duration of the long test in each cLisc shall he as follows:

Category 1:

T=12501I'

li r e T i the CiUI]'ation in seconds,

And 1=1,I1 R =svrnnlctrica] short circuit current, in 1,1ultiplcs

of normal base cur r ilt CXCCpt I Shall not exceed the maxinlLllll SVn1nletrcal CL11'lcnt nlaf.41lItL1C1C5li tcd in A.

\Vli r-e 1,.=1 h .%=symmetrical short circuit current. in

rills amperes

I k =rated cur - rent on the given tap connection, in rnls

amperes

Z T =tlainsfornlcr impedance on the given tap connection

in pd- Unit on the same apparent power base as 1R

Catcgor-y 11:

T=1.0 second

Criteria of Satisfactor y Pc1-fornlance

According to ANSI Standards a Unit is considered to have

passed the test if it passes a 1 • isUJ l inspection and cliC]Cctric tests. Rcconlnlcndcd adcliti[ )Il;1l checks include

examination of wave shape of terminal voltage and current, leakage impedance nicasurcnlcnt and excitation

current test. (I:cfcr to ANSI 057.12.90.)

The standart allows the following variations in the lcakage impedance:

Z T (Per Units)

0.0299 or less

0.0300 or more

Percentage Variation

22.5-5UU (T)

7.5

Z T =per Unit impedance of the transformcr'

POWER PARTNERS

Paint Finish Process

I'll I'aI'tncrH fact O r •, utili/,c y a paint finish process

called "2CEC' . a ti idcmal'I, for a two-coat cathodic C]Cctrodeprsition i int pre ce55. ' ['1115 new ad anced coating

technique maintains the structural integrity of transfornlcrs that arc subjected to the long-term corrosive cnvironmcnts of coastal areas and 1n(]Lltit1'1al contanlinants.

Paint Process

Cathc dic cicctrodcposition of paint occurs when direct

current is applied to positively charged resin micelles

dispersed in water. The resin micelles migrate toward the

cathode [transformer tank) and are deposited in a proccss known as electrophoresis. As the process continues,

the thickness of the deposit builds, resistance increases,

a n(] the film reaches a thickness limit. The most acccssihlc area,, are coated first, but as the resistance increases.

less accessible areas coat. producing a highly uniform

fil m hU11ld. Two -coat cathodic c]Cctrodeposition is the

application of two coats of paint (epoxy primcl'lacrvlic

L11'('tll',3i1C t[ pcc it).

Iii or to welding to the tank shc]l stamped external hardWare SLJch as Banger brackets and lifting lugs air vih1'atorV f1nishcc] to renmove bLlrrs and inSLJre. a smooth rad1L15

edge to a]]ow consistent edge coating.

An eight-stage dip process provides two cleaning steps to

Conip]CtClV 1'CnioVC ILlhrlcants and soils. A zinc phosphate coating is applied to enhance corrosion prntcction

by providing tighter, more consistent coating than the.

tvpical]V L1 y cd iron phosphate. The use of (]Cionizcd

water in the final rinse stages insures that the surface is

free of salts and ions that caul(] bate]- provide sites for

corrosion initiation. All pretreatment stages arc immcrsion stages, which assLlres complete and total coverage.

The cicctrodcposition process assures complete and

consistent coverage of the entire tank including complex

shapes such as fins, hanger brackets, and lifting lugs.

is "2CEC" proccss allows us to optimiic the performancc of the Ilrimcr and topcoat indepcndentl to maximize corrosion protection and LlltraViolCt li.,ht resistancc

while maintaining superior mechanical properties.

Faint process conSiStCncV is assured through aLltonlated

paint feed and monitoring of a real tinlc basis. Paint s y stcnl operators monitor and audit the proccss.

Advantages of the Process

-

111 coo er'agc of complex shapes,

f? edges and corners, hanger brackets,

ground pads, and tank bottoms.

2. Access into partially closed areas, such as inside the

hanger brackets.

3. High solids film eliminates sagging problems.

4. Minimal orgLinic solvcnt content.

1 11ClLICIin

POWER PARTNERS

ANSI Standal'd C57.12.28 served as the benchmimrk for

perfornlance on the tests ]istcd below. The test results

clearly indicate the two-coat cathodic clectrodcpositic.ln

to be a leader in corrosion resistance, while maintaining

excellent performance in all areas of the ANSI stan(]amd.

"2Cf?C" passed 'Lill the tests listed here.

Salt Spray Test

Panels are scribal to bare metal and tested for 1000

hours in a 5% salt spray per ASTM 8117-85E1 and cvaluatcd per ASl'M D1654-79A. Loss of adhesion fn.)m bare

metal niLltit not exceed amore than 1;S" from the scribe.

Undcrfilnl corrosion must not exceed more than 1/16"

fR)nl the scribe.

Crosshatch Adhesion Test

Panels arc scribed to bare metal with a crosshatch pattern and tested per ASTM 1)3359-83. '1'llcrc m utit Inc.

100% adhesion to the bare nieta] and between lavers.

Humidity Test

Paint Pretreatment

1. Cc )I nlllctc and L1111fo1

ANSI C57.12.28 Performance Requirements

Pancl y must be tested for 1000 hours in accordance with

ASTM 1)2247-86A. 'There m Llst be no blisters.

Impact Test

'Petit panels wcrc impact((] per ASTM 172794-84 at 160 in.]b. c )f i mpact. 'Thee( must be not chipping of the paint

on the_ impact side of the test panel.

Oil Resistance Test

Oil resistancc testing, is condUctcc] at both 100C and

ambient for 72 hoots.'1'llcrc mutt Ibc no apparent

changes, such as color shift, blisters, loss of hardness, or

streaking.

Ultra violet Accelerated Wca thering Test

)

'lhst panels I1lLust be cxposcc] fell' 5l l ( Il(1L11S in accordance

with ASTM 153-84. Loss of gloss must not exceed 50% of

the original gloss as described in ASTM 1)523-85E1.

Abrasion Resistance—Taber Abraser Test

-

.I'hc total coating system 111L15t 13C tCtitcd using a CS-10

wheel, 1000-g1'.lnl weight, in accordance with ASTM

1)4060-84. The numhcr of abrasion 1 —. quired to wear the

coating through to thc substnitc nLJst be at lcast 3000

cycles.

The ANSI C57.120.28 test resLllts clearl y indicate the twocoat cathodic C]Cctrodcposition is a leader in corrosion

resistance while maintaining cxce]]ent performance in all

areas of the ANSI standard. The two-coat cathodic elcctrodcposition maintains consistent, L1nifo1'nl paint coveragc over the entire product, with nc) 1'Llns or sags, and

offering a sLJperior coating on dist1-ibution transformers.