* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Compensation Made Easy: Advances in Designing with Digital

Power engineering wikipedia , lookup

Signal-flow graph wikipedia , lookup

Opto-isolator wikipedia , lookup

Mains electricity wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Spectral density wikipedia , lookup

Chirp spectrum wikipedia , lookup

Three-phase electric power wikipedia , lookup

Control theory wikipedia , lookup

Audio power wikipedia , lookup

Alternating current wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Utility frequency wikipedia , lookup

Oscilloscope history wikipedia , lookup

Power electronics wikipedia , lookup

PID controller wikipedia , lookup

Mathematics of radio engineering wikipedia , lookup

Rectiverter wikipedia , lookup

Analog-to-digital converter wikipedia , lookup

Regenerative circuit wikipedia , lookup

Time-to-digital converter wikipedia , lookup

Phase-locked loop wikipedia , lookup

Control system wikipedia , lookup

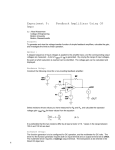

Utilizing a Digital PWM Controller to Monitor the Health of a Power Supply Mark Hagen Systems Engineer Digital Power Group Texas Instruments 13 Oct 2008 CEME 1 A Digitally Controlled Power Supply Power Stage iL Vin L RCS CCS + V RLoad out - C2 + - Gate drivers C1 isense divider network Digital PWM Controller + u[n] d[n] digital Compensator ramp counter Vref current ADC e[n] error ADC verr + supervising CPU R1 Vref DAC vsense EAmp R2 serial I/O Reasons to go digital Cp to host Programmable start/stop sequencing. (Programmable start/stop delay and voltage ramp rates.) Monitoring of system power and health metrics of the circuit. Ease of adjusting the loop compensation. PC design tool does the math Can be tailored to the system late in the process since it is defined by serial bus commands instead of by RC components. 13 Oct 2008 CEME 2 Start/Stop Sequence PMBus Standard supports sequencing commands Digital controller operation TON_DELAY TON_RISE TRACKING_MODE Delay timed digitally. Track desired ramp under closed loop control by slewing Vref setpoint DAC ramp rate defined by TON_RISE & VOUT_COMMAND rail#2 tracks rail#3 Vout follows digitally defined ramp May want separate loop compensation for start/stop ramps Operating modes: Start/stop ramp 13 Oct 2008 CEME Regulate Light load 3 Digitally Monitored Parameters VIN (scaled input voltage) IIN (requires dedicated current sense circuit) Shunt resistor: 4-terminal, low TCR type. Current sense amplifier: INA13x, INA19x, INA21x, etc. "READ_IN" PMBus command VOUT PMBus provides for a separate measure of Vout from the control loop voltage sense. IOUT Either shunt sense circuit like Iin or Inductor DCR sense. Amplifier typically internal to controller or driver IC. Temperature Ambient temperature measured at controller. Component temperature at each controlled power stage. duty cycle "READ_DUTY_CYCLE" PMBus command Combined with Vin and Iout measure, forms a efficiency/circuit-health metric. 13 Oct 2008 CEME 4 Power Supply as a Feedback Controlled System Power Stage iL Vin L RCS CCS C2 + - Gate drivers C1 + V RLoad out - isense divider network Digital PWM Controller d[n] digital Compensator - System consists of + u[n] ramp counter Vref current ADC e[n] error ADC supervising CPU verr + R1 Vref DAC vsense EAmp Cp R2 serial I/O Plant (Power stage) to host Sensor network (voltage divider) Setpoint reference (Vref. Typically a DAC in digital PWM controllers.) Error amplifier (fast ADC) Compensator (digital filter) Pulse width modulator (fast digital counter) Delay elements (account for phase loss due to the time it takes to calculate and apply the control effort) 13 Oct 2008 CEME 5 G ( s) u[n] G Delay 2 G Plant Modeling the Loop Vout Vsense G Div Example with analog summing junction H(s) KPWM d[n] G Delay 1 Open-loop gain Closed-loop gain where 13 Oct 2008 CEME KAFE KEADC KNLR GCLA GDelay1 KPWM GDelay2 GPlant GDiv = = = = = = = = = G CLA KNLR e[n] K EADC K AFE Ve + Vr K DAC ref v Sense H s G s v error v Sense H s G s ref 1 H s G s analog front end gain in V/V error ADC gain in LSB/volt Nonlinear boost gain Control-law accelerator (digital compensator) gain Total sampling and CLA computational delay PWM gain in duty/LSB On-time and any delay to multiple power stages driving Vout Transfer function from d to Vout of the power stage Divider network transfer function in V/V 6 Loop Stability Criteria G(s) u[n] G Delay 2 G Plant Vout Vsense G Div H(s) KPWM d[n] G Delay 1 G CLA KNLR e[n] K EADC K AFE Ve + Vr K DAC ref The frequency response is derived from the average model of the power stage Open-loop gain = H(f)•G(f) Stability criteria (same as analog control) Phase margin: Phase distance from 180º at the frequency where gain = 0 dB want 45º to 65º Gain margin: Gain at frequency where phase = 180º want > 6 dB 13 Oct 2008 CEME GM PM 7 G(s) Power-Stage Model u[n] G Delay 2 G Plant Vout Vsense G Div H(s) KPWM G Delay 1 G CLA KNLR e[n] K EADC Ve K AFE + Vr K DAC ref A (discrete) time model is needed to get accurate estimates of transient performance and stability Define continuous-time state equations (states are iL and vC) L + vout Cq x Dq Vg – Convert to discrete-time difference equations RL Vg x A q x Bq Vg and ˆ 1] and ˆ x[n ˆ 1] d[n x[n] ˆ vˆout [n] Cx[n] d[n] iL R esr R + vc – c(t) DPWM G(z) C Hvo H=1 eADC vref Design software such as Spice or the Fusion Digital Designer integrates difference equations for each interval to simulate the power stage 13 Oct 2008 CEME 8 Define the Plant (power stage) Resulting transfer function for the plant Enter component parameter values Gain elements Vin and duty (from Vout) Series elements L, DCR, RDS(on) Parallel elements C, ESR, ESL Lump like components together 13 Oct 2008 CEME 9 G(s) u[n] Divider-Network Model G Delay 2 G Plant Vout Vsense G Div H(s) KPWM G CLA K NLR e[n] K EADC KAFE Ve + Vr K DAC ref GDiv(f ) Vout Set RC lowpass corner frequency at 35% to 45% of error-ADC sample frequency. Continuous model R2 R1Czs 1 K Div G Div s K Div R1 R2 K Div R1 Cz Cp s 1 G Delay 1 Divider scales Vout to error-ADC input range. With Cp, forms anti-alias low-pass for error-ADC. d[n] R1 Cz Vsense R2 Cp Digital power-design software creates a discrete model from continuous circuit description. Apply discrete transform to continuous model evaluated at each error-ADC sample time 13 Oct 2008 CEME 10 Define the divider network Set the divider gain (attenuation) Set nominal Vout at ~75% of error-ADC dynamic range headroom for margining, over-voltage detection. Communicated to device by PMBus commands VOUT_SCALE_LOOP VOUT_SCALE_MONITOR Define capacitors to set pole (or zero) Good idea to roll off high frequency at 70% to 90% of Nyquist frequency. (35% tp 45% of switching frequency.) 13 Oct 2008 CEME 11 G(s) Model the Compensator u[n] G Delay 2 G Plant Vout Vsense G Div H(s) POL applications require 2nd-order compensation d[n] G Delay 1 G CLA K NLR e[n] Two zeros and a pole at zero Hz This is a classical PID controller (Proportional, Integral, Derivative) Discrete form: duty(z) b z 2 b z b G CLA z e(z) 01 11 z 1 21 K EADC KAFE Ve + Vr K DAC 2 zeros pole at origin Additional poles improve effect of error-voltage quantization by smoothing the 2 zeros CLA output: duty(z) b01z 2 b11z b21 G CLA z KPWM e(z) z 2 a11z a 21 2 poles To model in discrete time, the design software evaluates the compensator difference equation: d(z) b01 b11z 1 b21z 2 1 a11z 1 a 21z 2 e(z) d n b01e n b11e n 1 b21e n 2 a11d n 1 a 21d n 2 13 Oct 2008 CEME 12 ref Types of Compensator Realizations Numerator 2nd-order table look-up (UCD9112) d[n] d z K 0 z2 K1z K 2 e z z 1 K0N ... K1N ... K2N ... K01 K00 K11 K10 K21 K20 z –1 e[n] z –1 d[n – 1] z –1 e[n – 2] Direct-form digital filter (UCD9240) d z e z Numerator b0 z 2 b1z b2 d[n] a1 PID-form digital filter (conceptual) d z e z KP KI Denominator z 2 a1z a 2 z –1 e[n] Denominator z z 1 KD z 1 z KP KI KD z 2 b0 z –1 z –1 e[n – 1] d[n – 1] z –1 a2 d[n – 2] e[n – 2] b2 b1 KP dP[n] e[n] Kl K P 1 K I 2K D z K P K D dl[n] KD z 2 1 z d[n] Proportional Integral z –1 dD[n] z –1 Derivative e[n – 1] 13 Oct 2008 CEME z –1 13 G(s) u[n] Choosing the Compensation G Delay 2 G Plant Vout Vsense G Div H(s) KPWM d[n] G Delay 1 G CLA K NLR e[n] K EADC KAFE Ve + Vr K DAC ref Choose continuous time parameters to shape the Bode-plot loop gain to achieve desired phase and gain margin DC gain KDC Zeros ωz1 ωz2 Poles: origin, ωp2 s s s2 s 1 1 1 2 d s or K r r Q K DC z1 z2 DC e s s s2 s s 1 p2 p2 Then transform the continuous-time polynomial in s to a discrete-time polynomial in z. This is typically done by the design software TI Fusion Digital Power Designer performs the transformation by: 1. Apply the bilinear transformation by substituting s into the above polynomial: 2. Then solve for discrete-time polynomial coefficients: 13 Oct 2008 CEME d z e z z 1 s 2Fs z 1 b0 z 2 b1z b2 z 2 a1z a 2 14 Define the compensation Center zeros on 2nd order plant pole Spreading the zeros either side of the plant pole improves the output impedance of the system In above example I reduced the 2nd order zero frequency a bit to buy some phase margin. Define the compensator poles Integrator function defines 1st pole at the origin. Set 2nd pole above 0 dB cross-over to increase gain margin. 13 Oct 2008 CEME 15 Effect of locating zeros perfect cancellation Perfectly canceling plant 2nd order pole does not result is lowest possible closed loop output impedance Results in increased load transient settle time. 13 Oct 2008 CEME 16 Effect of locating zeros, cont. zeros spread Spreading zeros minimizes output impedance Lower output impedance improves load transient settle time. 13 Oct 2008 CEME 17 Adding Nonlinear gain to the compensation Strictly linear compensation flat gain Transient response 13 Oct 2008 CEME 18 Adding Nonlinear gain to the compensation Reduce gain for quiescent cond. where verror near 0. gain high for transient, gain low at around zero. Improves steady state voltage, peak error reduced. 13 Oct 2008 CEME 19 Nonlinear Boost Scope traces with and without nonlinear boost 1.3 1.2 Uniform gain of 1X Gain boosted 3X for |verr | > 5 Gain boosted 4X for |verr | > 5 130.5 mV 108.1 mV 5.2 mV 5.0 mV 88.4 mV 5.0 mV no boost 1.15 Vout (V) Parameter Peak-toPeak Output Excursion RMS Error During Quiescent Operation rms pk-pk 1.25 1.1 3X boost 1.05 1 4X boost 0.95 0.9 load current 0.85 0.8 0 200 400 600 800 1000 Time (µs) 13 Oct 2008 CEME 20 System Identification (Transfer Function) Digital PWM controllers offer the opportunity to identify the system dynamics (System-ID) by measuring the transfer function of the system in situ (in place). No external test equipment No auxiliary circuits or probes To do this we need to: From this response, calculate the open loop gain Generate an excitation signal Inject that signal at a summing junction Capture the response of the system to the excitation From the open loop gain determine key performance metrics of bandwidth, gain margin and phase margin. For a digitally controlled system the logical location to make the measurement is just before or just after the digital compensator. 13 Oct 2008 CEME 21 Possible Measurement Locations Given the following basic system equations: u' G(s) power stage y Gu u d x2 y' d Hc c e x1 digital controller PWM ADC u y x2 H(z) d c digital compensator ery x1 e - The closed loop response at each node is: r Inject a sinewave at r, x1 or x2 Measure response at node y, e, c, d or u Solve for GH 13 Oct 2008 CEME GH GH G r x1 x2 1 GH 1 GH 1 GH H H 1 u r x1 x2 1 GH 1 GH 1 GH H H GH d r x1 x2 1 GH 1 GH 1 GH 1 1 G c r x1 x2 1 GH 1 GH 1 GH 1 GH G e r x1 x2 1 GH 1 GH 1 GH y 22 Calculate the open-loop gain from the closedloop response Solution of G(f)H(f) for various injection and measurement nodes: Loop gain G(f)H(f) r inject at: x1 x2 Measure response at: y y ry y x1 y Hy x2 Hy u d c e H r 1 u H r 1 d r 1 c r 1 e H x1 1 u H x1 1 d x1 1 c x1 1 e x2 1 u d x2 d Hc x 2 Hc e x2 e Note that the formula for calculating open loop gain contains the compensator gain H(f) if the system is excited before the compensator and measured after, or vice-a-versa. This is not a big problem since a digital compensator is completely deterministic. Its frequency response can be calculated as: (for a 2nd order compensator) b0 z 2 b1 z b2 H f meas 2 Ts is the compensator sample period z a1 z a 2 z exp j 2πf meas Ts cos2πf meas Ts j sin 2πf meas Ts 13 Oct 2008 CEME 23 Type of Excitation to use for System-ID # of frequencies per measurement Needed dynamic range Needed memory (RAM) Max meas. interval Measurement signal to noise sinewave white noise 1 narrow (few bits) 2 words 1 M samples* high N/2 wide (many bits) 1k words or more limited by available memory medium Accurate Fast * 12 bit samples, 32 bit accumulator 13 Oct 2008 CEME 24 Sinewave Generation Use table look-up technique Digital controllers such as the UCD9240 or TMS320C2801, have a build-in sinewave table in ROM. For each sample, step through the table with a step size defined as step N tableLen Fmeas Fsamplerate then generate the excitation signal as: phase = phase + step; index = phase >> PHASE2INDEX; sine_signal = sine_table(index); // use MSB bits for sine table index // lookup excitation signal value in table When the end of the table is reached, wrap to the beginning of the table by subtracting the table length from the index. By maintaining the fractional part of the table index and rounding to determine the table entry, very high frequency resolution can be obtained. 13 Oct 2008 CEME 25 Response Measurement The definition of a Discrete Fourier Transform (DFT) is: N 1 K k v n e j 2πnk / N n0 k k v n cos 2 n j sin 2 n N N n 0 This says that we can calculate the real and imaginary magnitudes of the kth harmonic of a signal by multiplying that signal by a sine and cosine sequence and summing. Since we've already generated a sinewave to inject into the loop as the excitation signal, the response measurement is simply: N 1 cosSum += d*Xcos; sinSum -= d*Xsin; // // // // Accumulate cosine sum for measurement node d Accumulate sine sum for measurement node d (Note that since a sine is shifted by π/2 from a cosine, the cosine sequence is easily generated by adding an offset to the sine table index of 1/4 the table length.) 13 Oct 2008 CEME 26 Example Calculation of G(f)H(f) Inject at r measure at d u' G(s) power stage y' digital controller PWM ADC y d H(z) e digital compensator r x CPU xcos z-1 cosSum xsin z-1 sinSum serial bus to host • Return cosSum and sinSum for each injected excitation frequency. Calculate open loop gain as follows: N Gainopenloop G f H f X cos r 2 H f 1 hr f jhi f 1 d cosSum j sinSum • Where Xcos is the base to peak amplitude of the excitation and N is the # samples the response is summed over. • Then plot magnitude and phase of G(f)H(f) to determine phase margin, gain margin and bandwidth. 13 Oct 2008 CEME 27 Practical Auto-ID measurements Windowing The definition for the DFT produces the response just at harmonic frequencies. These frequencies produce an integer number of cycles in the measurement interval. At other frequencies you need to do something to reduce "leakage". 1. 2. Window the measurement data. A raised cosine or triangle window are popular options. Modify the measurement interval so that an integer number of cycles are measured. (What we implemented.) Settling 13 Oct 2008 CEME We want just the forced response, so the controller needs to wait some number of samples for the natural response to decay. 28 Power Stage Transfer Function The compensation in a digital PWM controller is deterministic No gain or offset error Poles and zeros concisely defined. So divide measured loop gain by known compensator TF. Then use this measured response instead of modeled plant to choose compensation. Note that the measured TF is more damped than the modeled TF. Measurement takes into account losses not included in plant model. Losses show up as effective increase in resistance, which adds damping. 13 Oct 2008 CEME 29 Monitor power system health DC/low frequency measurements Vin, Iin Iout, Vout Temperature of each power stage AC measurements Automatic Identification of the system transfer function Use linear (average) model of the plant to estimate component values Look for a change in monitored parameter Use statistical process control techniques to decide if it has changed. 13 Oct 2008 CEME 30 Statistical Process Control Many techniques Mean & Range charts Mean & Sigma charts Key concepts Average a set (sample) of measurements. This guarantees normally distributed measurement error based on central limit theorem. Compare sample average to a confidence interval to decide if the mean has changed. 13 Oct 2008 CEME 31 Confidence Interval Givenk z where σ is the expected population standard deviation, 2 n n is the sample size and z is the probability that the sample mean is 2 within the confidence interval. Then the interval is k, k Example During product development μ, σ of open loop bandwidth were found to be to be μ = 55.0 kHz σ = 0.750 kHz. Last 4 measurements of BW using Auto-ID are 56, 58, 53, 55 kHz.x = 55.5 kHz z for 90% confidence is 1.96 2So confidence interval is [ 54.2650, 55.7350] Therefore we can say with 95% confidence that the mean has not changed. 13 Oct 2008 CEME double sided sigma (zα/2) probability (%) event ppm 1.00 68.26 317k 1.65 90.00 100k 1.96 95.00 50k 2.00 95.44 45.6k 2.58 99.00 10k 3.00 99.73 2.7k 3.09 99.98 2.0k 3.29 99.99 1.0k 3.48 500 3.89 100 4.00 63.6 5.00 0.6 6.00 2 ppb 32 "Health" metrics Transfer function based measures open loop bandwidth, phase margin, gain margin Power stage Q Compare to expected values Don't have to measure full frequency range. One freq may be sufficient. Lossy components cause Q to be reduced. Input power vs. output power efficiency =v IN i IN Average duty cycle (see next slide). vOUT i L Temperature Power stage balance UCD9240 allows closed loop control of temperature balance Power stage vs ambient (measured at controller IC.) 13 Oct 2008 CEME 33 Average Duty Cycle vOUT Then D VIN FET switchs D VIN VOUT iL Monitor RS and compare to SPC control limits L1 CC RS V Rs i L D OUT VIN RS RLoad RS RLOAD RC 40 39.5 duty in % Capture duty cycle at output of digital compensator. At DC RLoad RSW(LOSS) RDS(ON) RDCR 39 38.5 38 37.5 25 series resistance in mOhms 0 5 10 15 20 inductor current in Amps 20 15 10 5 25 13 Oct 2008 CEME 30 35 duty in % 40 45 34 Conclusion Digital PWM Controllers now offer: Programmable start/stop sequencing. Ability to Monitor power and health metrics. Power stage voltages and currents Temperature Duty cycle Complete control of compensation gain, zeros and poles. In situ measurement of system dynamics. Enables measurement at other than the lab bench. (For instance, on factory floor or installed in end equipment.) Use monitored parameters to assist in predicting failure Apply statistical confidence limits to decide if the parameter has changed. If a mean shift is indicated, issue a warning to the host system. Design tools for Digital Power: Pull together sequencing, monitoring and control configuration in one place. Allow sophisticated, accurate frequency and time simulation of the target system. Automatic System Identification of the power supply dynamics. Automatic tuning of the loop compensation. 13 Oct 2008 CEME 35