* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download 1. experimenting with agilent-vee measuring mosfet characteristics

Mains electricity wikipedia , lookup

Flip-flop (electronics) wikipedia , lookup

Multidimensional empirical mode decomposition wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Linear time-invariant theory wikipedia , lookup

Two-port network wikipedia , lookup

Schmitt trigger wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Lumped element model wikipedia , lookup

Switched-mode power supply wikipedia , lookup

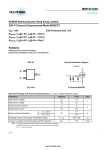

1. EXPERIMENTING WITH AGILENT-VEE MEASURING MOSFET CHARACTERISTICS I. INTRODUCTION 1. Objectives Metal-Oxide-Semiconductor Field-Effect Transistor (MOSFET) is the most widely used electronic device in digital integrated circuits. Physical operation, characteristics and circuit applications of the MOSFET are extensively covered in textbooks on microelectronic circuits and devices. In order to observe the characteristics (ID vs. VDS and VGS) of a MOSFET in detail, a curve-tracer, which is an expensive equipment, is needed. In this experiment, this characterization will be performed by using a power supply and a multimeter, which are controlled by Agilent-Vee, a visual programming language. This experiment has two objectives; i. analyzing the current-voltage characteristics of enhancement type MOSFETs (to check if the textbooks tell the truth) and ii. gaining experience in using Agilent-Vee. 2. Equipment: KEYSIGHT E3631A Power Supply AGILENT 34461A Digital Multimeter Agilent-Vee Software PC with GP-IB Capability 3. Prerequisites: Familiarity with the basic principles of MOSFET operation and a preliminary instruction on Agilent-Vee. II. PRELIMINARY WORK 1. Read the sections 4.1 (Characteristics of the MOS Capasitor), 4.2 (The NMOS Transistor), 4.3 (PMOS Transistors) and 4.4 (MOSFET Circuit Symbols) from the textbook Microelectronic Circuit Design by Jaeger & Blalock 2. Read the “EXPERIMENT”(part III). III. EXPERIMENT We will characterize the MOSFETs in the CD4007 MOS array chip. The chip includes 3 nchannel and 3 p-channel enhancement mode MOSFETs as shown in Figure 1.1. The substrate for the n-devices should be connected to VSS. Figure 1.1 - Schematic of CD4007 MOSFET array Constructing the circuit for ID vs. VDS measurement In order to obtain the drain current vs. VDS and VGS characteristics of a MOSFET, both drain and gate voltages must be swept. We will use the +6V and +25V outputs of the KEYSIGHT 3631A power supply (under PC control) for this purpose. The outputs of the power supply will be controlled by the software Agilent-Vee. First turn off the power supply and construct the circuit given in Figure 1.2. Pin 4 of CD4007 (VD) is connected to +25V output of the power supply through the multimeter AGILENT 34461A in current measuring mode. Connect pin 3 (VG) to +6V output of the power supply. Connect pin 7 to ground to bias the bulks of the devices. Constructing the circuit for ID vs. VDS measurement 1. Turn on the power supply (Do not turn the output on yet) and start Agilent-Vee on the computer. 2. From the menu bar select I/O → Instrument Manager. Click on hpeE3631A as Create IVI-COM Driver Object Figure 1.2 – Circuit for ID vs. VDS measurement 3. Double click on the title bar of the driver, enter “VDS” as the title and click OK. 4. We will use another KEYSIGHT E3631A Driver to control the +6V (VG) output of the power supply. Place another KEYSIGHT E3631A Driver in the work area by selecting I/O → Instrument Manager → hpeE3631A → Create IVI-COM Driver object Driver. 5. Double click on the title bar of the driver, enter “VDS” as the title and click OK. 6. Double click on the “VDS” to add an operation then click on Create Instance and click OK. 7. Double click on the “VDS” to add an operation then click on Initialize, from the dialog box choose reset parameter as False. 8. Click on Configure Terminals Voltage, name it as output2 choose voltage level as variable and create input terminal then click OK. 9. Double click on “VDS” and click close then OK. 10. Double click on second hpe3631A, enter “VGS” as the title and create instance to add an operation. 11. Double click on “VGS” to initialize, choose reset parameter as False. 12. Double click to add an operation, from the Outputs→Item→Applyvoltagecurrent, determine the current level as “1” name it as output1 choose voltage as variable and select create input terminal then click OK. 13. Then double click to add an operation on “VGS” and close it. Click OK. 14. Click on instrument manager to replace ag3461a multimeter driver to study area. Be careful about to choose it as Create IVI-COM Driver. Name it as multimeter from the title bar on the left side of the screen. 15. Double click to add an operation on multimeter driver, then create instance, double click on initialize 16. Double click to add an operation again and choose DCCurrent→Measure, determine the range as “0,01” and determine the resolution as “1E-6”. 17. Double click to add an operation then click close. 18. Select Flow → Repeat → For Range from the menu bar and place it to the left of VDS. Connect the output pin of the “For Range” object to the “voltage” input of “VDS”. Arrange the range from 0 to 6 with 0,25 step. 19. Change the title name as “vd” 20. Select Flow → Repeat → For Range from the menu bar again and place it to the left of VGS. Connect the output pin of the “For Range” object to the “voltage” input of the hpeE3631A Driver. Arrange the range from 2 to 5 with “1” step. 21. Change the title name as “vg”. 22. Select Flow → Delay. Place the ”Delay” object in the work area. Set the delay to 0.25 sec. 23. Connect the output pin of the “For Range” object controlling VDS to the sequence input pin of the “Delay” object. 24. Connect the sequence output pin of the “Delay” object to the sequence input of the AGILENT 34461A Driver. 25. Select Display → X vs. Y Plot. Place the “X vs. Y Plot” object in the work area. Click on it to Add Terminal→Control Input→Auto scale 26. Connect the data output of the “For Range” object controlling VDS to the first input terminal from the top of the “X vs. Y Plot” object. 27. Connect the “return” output of the AGILENT 34461A Driver to the second input of the “X vs. Y Plot” object. Connect the sequence output pin of the “For Range” object controlling VGS to the “Autoscale” (third) input of the “X vs. Y Plot” object. 28. Save the program on the desktop under the name “mosidvds”. 29. Run the program and wait until it is completed Your arrangement and run program should look like the following figure: Figure 1.3 – Agilent-Vee setup for ID vs. VDS characteristics Measuring ID vs. VDS characteristics 30. Observe the characteristics on the “X vs. Y Plot” object. 31. For each curve corresponding to a different VGS in the range 2.5-5V, locate the point where the current is saturated and record VGD at this point (use the marker on the X vs. Y plot). Estimate the threshold voltage of the MOSFET. 32. Now change the upper limit of the “For Range” object controlling VDS to 0.5 and the step to 0.05. Change the lower limit of the “For Range” object controlling VGS to 3V, upper limit to 6V and the step to 1V. 33. Run the program and observe the current-voltage characteristics. What is the operation region of the MOSFET now? 34. The drain current of a MOSFET in the triode region can be expressed as 𝐼𝐷 = 𝐾𝑛 [(𝑉𝐺𝑆 − 𝑉𝑇 )𝑉𝐷𝑆 − 2 𝑉𝐷𝑆 2 ] Use the threshold voltage value you estimated above, ignore KnVDS2 term in the above expression and determine and record Kn from the slope of the ID vs. VDS characteristics for each curve corresponding to a different VGS. Which Kn value is the most precise one? Explain your reasoning. Constructing the Agilent-Vee program for ID vs. VGS characteristic In this part of the experiment, we will measure the ID vs. VGS characteristic of the MOSFET under constant VDS (5V) by modifying the program constructed above 35. From the menu bar select I/O → Instrument Manager. Click on hpeE3631A as Create IVI-COM Driver Object 36. Double click on the title bar of the driver, enter “VGS” as the title and click OK. 37. Double click on the “VGS” to add an operation then click on Create Instance and click OK. 38. Double click on the “VGS” to add an operation then click on Initialize, from the dialog box choose reset parameter as False. 39. Click on Configure Terminals Voltage, name it as output2 choose voltage level as variable and create input terminal then click OK. 40. Double click on “VGS” and click close then OK. 41. Click on instrument manager to replace ag3461a multimeter driver to study area. Be careful about to choose it as Create IVI-COM Driver. 42. Double click to add an operation on ag3461a driver, then create instance, double click on initialize 43. Double click to add an operation again and choose DCCurrent→Measure, determine the range as “0,01” and determine the resolution as “1E-6”. 44. Double click to add an operation then click close. 45. Select Flow → Repeat → For Range from the menu bar and place it to the left of VGS. Connect the output pin of the “For Range” object to the “voltage” input of “VGS”. Arrange the range from 0 to 6 with 0,25 step. 46. Select Flow → Delay. Place the ”Delay” object in the work area. Set the delay to 0.25 sec. 47. Connect the output pin of the “For Range” object controlling VGS to the sequence input pin of the “Delay” object. 48. Connect the sequence output pin of the “Delay” object to the sequence input of the AGILENT 34461A Driver. 49. Select Data → Build data → Coord from the menu bar and place it to the work area. Connect the “return” output pin of multimeter to the “YData” input pin of “Build Coord” object. 50. Select Data → Collector from the menu bar and place it to the right of the “Build Coord” object. Connect “Coord” data output pin of the “Build Coord” object to the “Data” input pin of “Collector” object. Connect the sequence output pin of “For Range” object controlling VGS to the “XEQ” input pin of “Collector” object. 51. The drain current of a MOSFET in saturation is expressed as 𝐼𝐷 = 𝐾𝑛 2 (𝑉𝐺𝑆 − 𝑉𝑇 )2 We will fit this expression to the measured data by using Kn and VT as fitting parameters. This process will yield reliable values for Kn and VT. A regression object will perform the fitting function. The above equation can be expressed as 𝐾𝑛 𝐾𝑛 2 𝑉𝐺𝑆 − 𝐾𝑛 𝑉𝑇 𝑉𝐺𝑆 + 𝑉 2 2 𝑇 Select Device → Regression. Place it in the work area. Choose “Fit Type” as polynomial (“Poly”), and “Order” as 2. 𝐼𝐷 = 52. Select Display → XY Trace and place the trace in the work area. “Add a data input terminal the trace. Create an “Autoscale” control terminal and connect this terminal to the sequence output pin of the “For Range” object. Connect the “array” output pin of the “Collector” object to the second input pin of the “XY Trace” object. ID vs. VGS data will be entered to the object through the second input terminal. 53. Connect “Array” data output pin of the “Collector” object to “Point List” data input pin of “Regression” object. In order to check the accuracy of the above expression and fitting, we will also plot the fitted data on the “XY Trace” object and compare the resulting curve with the experimental one. In order to do this, connect “Fitted Data” output pin of the “Regression” object to the first input pin of the “XY Trace” object. 54. Coefficients provided by the regression object after fitting will provide information on Kn and VT. C2 will yield the value of Kn/2 and C1 will represent -KnVT. Once Kn is determined from C2, VT can be found by dividing C1 by -Kn. In order to do this, select Device → Formula. Place two “Formula” objects in the work area. Enter “a[1]” into one of the objects and “a[2]” into the other. 55. Select Device → Formula. Place the “Formula” object next to the other “Formula” objects. Select Add Terminal → Data Input. Connect the data output pins of “a[1]” and “a[2]”. “Formula” objects to the “A” and “B” input pins of this “Formula” object, respectively. Enter (-A/(2*B)) as the formula. 56. Select Display → Alphanumeric. Place the object near “Formula” objects. Change the title to VT. 57. Connect the “Result” output pin of “Formula” object containing (-A/(2*B)) to the data input pin of Alphanumeric Display VT. Get one more “Alphanumeric Display” object, and change the title of the object to Kn. Connect the “Result” output pin of a[2] “Formula” object to the “A” input of a new “Formula” object. Connect “Result” output pin of this “Formula” object to the data input pin of Alphanumeric Display Kn. 58. Save the program to the same directory under the name “mosidvgs”. 59. Your arrangement should look like to the setup given in Figure 1.4. Figure 1.4 – Agilent-Vee setup for ID vs. VGS characteristics Measuring ID vs. VDS characteristics 60. Run the program constructed above. Compare the results of fitting and the experimental data. Is there a good agreement? If not, explain the reason for discrepancy. 61. Now, change the lower limit for the “For Range” object to 0.8 and run the program again. Do you have a much better agreement now? Why? 62. Compare the set of Kn and VT values found at this step with that estimated from the ID vs. VDS characteristics. Which one is more accurate? Explain your reasoning. 63. Now, increase the order to 3 in the regression object and connect an “Alphanumeric Display” to the “Coeffs” output of the “Regression” object. Run the program and observe the coefficients calculated. Compare the magnitude of C3 with the other coefficients. Is the expression, ID=(Kn/2)*(VGS-VT)2, reliable enough for estimating the drain current of a MOSFET in saturation? Explain your reasoning. EXPERIMENTING WITH MEASURING MOSFET CHARACTERISTICS NAMES: 1. 2. SECTION: Measuring ID vs. VDS characteristics VGS (V) ID VDS VGD 2.5 3 3.5 4 4.5 5 1. Threshold voltage of the MOSFET: 2. What is the operation region of the MOSFET when you change the limits and steps of “For Range”: 3. Kn values: VGS (V) Kn 3 4 5 6 4. Which Kn value is the most precise one? Why? Measuring ID vs. VGS characteristics 5. Compare the results of the fitting and the experimental data. Is there a good agreement? If not, explain the reason for discrepancy: 6. Do you have a much better agreement when you change the lower limit for the “For Range” object? Why? 7. Compare the set of Kn and VT values found at this step with that estimated from the ID vs. VDS characteristics. Which one is more accurate? Explain your reasoning. 8. Coefficients: C0: C1: C2: C3: 9. Compare the magnitude of C3 with the other coefficients: 10. Is the expression, ID=Kn(VGS-VT)2, reliable enough for estimating the drain current of MOSFET in saturation? Explain your reasoning.