* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Study of PTCR Behavior for Wide Voltage and Ambient Temperature

Electric motor wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Power inverter wikipedia , lookup

Power engineering wikipedia , lookup

Electrical ballast wikipedia , lookup

Current source wikipedia , lookup

History of electric power transmission wikipedia , lookup

Three-phase electric power wikipedia , lookup

Schmitt trigger wikipedia , lookup

Brushed DC electric motor wikipedia , lookup

Electrical substation wikipedia , lookup

Power electronics wikipedia , lookup

Induction motor wikipedia , lookup

Distribution management system wikipedia , lookup

Buck converter wikipedia , lookup

Power MOSFET wikipedia , lookup

Voltage regulator wikipedia , lookup

Surge protector wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Opto-isolator wikipedia , lookup

Rectiverter wikipedia , lookup

Stray voltage wikipedia , lookup

Alternating current wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Stepper motor wikipedia , lookup

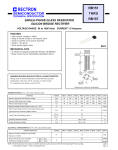

Purdue University Purdue e-Pubs International Compressor Engineering Conference School of Mechanical Engineering 1998 Study of PTCR Behavior for Wide Voltage and Ambient Temperature Variations and Optimizing the PTC Start Induction Run Motor & Overload V. K. Rao Voltas Limited Allwyn Unit Voltas Limited Follow this and additional works at: http://docs.lib.purdue.edu/icec Rao, V. K. and Unit, Allwyn, "Study of PTCR Behavior for Wide Voltage and Ambient Temperature Variations and Optimizing the PTC Start Induction Run Motor & Overload" (1998). International Compressor Engineering Conference. Paper 1271. http://docs.lib.purdue.edu/icec/1271 This document has been made available through Purdue e-Pubs, a service of the Purdue University Libraries. Please contact [email protected] for additional information. Complete proceedings may be acquired in print and on CD-ROM directly from the Ray W. Herrick Laboratories at https://engineering.purdue.edu/ Herrick/Events/orderlit.html STUDY OF PTCR BEBAVIOR FOR WIDE VOLTAGE AND AMBIENT TEMPERATURE VARIATIONS AND OPTIMIZING THE PTC START INDUCTION RUN MOTOR & OVERLOAD. AUTHOR V. Koteswara Rao ALLWYN (A unit of Voltas), Hyderabad- 500 018, India ABSTRACT Refrigerator compressor motors using PTC as starting device are in usage since years. Special care should be taken to optimize the start winding of the PTCS-IR compressor motor for wide voltage and ambient temperature range applications and also to select the proper overload protector as the characteristics ofPTC vary with both voltage and ambient temperature. This paper presents the study of PTCR behavior under a wide range of voltage and temperature . Critical values of the PTCR characteristics considered for optimizing the motor and overload protector. have to be NOMENCLATURE PTC RESISTANCE ( Ro) RESISTANCE OF PTC RESISTOR AT 25°C SWITCHING TIME (Ts) TIME TAKEN FOR PTC TO REACH ITS SWITCH TEMPERATIJRE (OR) TIME TAKEN FOR PTC TO CHANGE FROM CONDUCTING STAGE TO NONCONDUCTING STAGE RECOVERY TIME (Tr) TIME TAKEN FOR PTC TO RETURN TO TWICE THE INITIAL RESISTANCE@ 25°C AFTER SWITCHING 391 INTRO DUCTI ON The PTCR ( positive temperature coefficient resistor ) start Induction run motors used for refrigerator compressor's application are generally designed to operate in a particular range of voltage and ambient temperature. Generally the voltage range considered is ± 10% of rated voltage but for tropical conditions the voltage variation to be considered is ± 25%. Variation in the ambient temperature to be considered is from l0°C to 50°C. This wide variation of voltage and ambients calls for special care to be taken while designing the PTC start Induction run motors and selecting the overloa d Otherwise the reliability of compressors gets adversely affected.. When the voltage is varying the switching and recovery times of PTC vary. Also, the ambient variations cause some variations in the switching and recovery times of PTC. Specific characteristics of PTC are largely governed by the combined effect of voltage and ambient temperatures. A perfect match of motor overload and PTC as a combination works reliably on the refrigerator at different combinations of voltage and ambient temperatures. Experim entation Different sets of experiments are conducted to detennine the effect of voltage and ambient temperatures individually and in combination on the characteristics ofPTC. Simulation of approximate start winding resistance and inductance in series with the PTC to evaluate the behavior at different voltages at constant ambient temperature is done. The same set-up is used for evaluating the behavior of PTC at different ambient temperatures at constant voltage. Then simulating the different combinations of voltages and ambients the PTC switching and recovery time's characteristics are recorded. Storage Oscilloscope is used for recording the characteristics of PTCR in the experiments. The observations of experiments are listed in table 1. 0. Considering the critical characteristics of PTCR two motors 118th HP and 116th HP are designed with optimized start winding for refrigerator applications and also selected the overload protector to suit PTCR behavior. These compressors fitted in refrigerators are tested for startability at 4 3oc ambient after 392 pulldown to prove the matclring of PTCR and motor design and also compared with the RSIR motor with electromagnetic relay. Refrigerators are also tested for power interruption & locked rotor tests at different voltages to see the matching of overload protector. The observations of experiments are listed in table 2.0. Description of results As shown in the fig.1 the switching time of PTCR varies with the ambient temperature and voltages. The combined effect is that at -1 ooc & 160 Volts the switching time is maximmn of 2.4 seconds and at 80°C & 260 Volts it is minimum of0.385 seconds. · As shown in fig.2 the recovery time of PTCR varies with the ambient temperature and voltages. The maximum recovery time that PTCR takes is another important characteristic of PTCR to be considered for optimizing the start winding and overload. In this case the maximum ambient temperature ofPTCR considered is 80°C because the shell temperature of compressor when running in high ambients like 43°C I 50°C will be about 85°C to 90°C. The maximum recovery time of 185 seconds recorded is at 80°C & 260 Volts and the minimmn of 42 seconds at -10°C & 160 Volts. Analysis The minimum switching time of0.385 seconds will become only critical if the motor is not acheiving the stable condition before this time. The motor is designed to acheive the stable condition before this minimum switching time. The maximum recovery time obtained from the experiment (table.1.0 & :fig.2) is 185 seconds at 80°C ambient & 260 Volts. The resistance of the PTC after 185 seconds is the recovery resistance. Therefore recovery resistance is considered for calculating the starting torque and optimized the start winding to give required starting torque at 260 Volts. The minimum restarting time allowing the system to balance is generally taken as 3 minutes, which is more than the minimum recovery time of 42 seconds recorded at -1 ooc & 160 Volts. However to enable the compressor to start at 160 Volts after system balancing time and 80°C PTC ambient, motor is designed to produce required minimum starting torque at 160 Volts taking the PTC recovery resistance into considerations (not PTC resistance). Therefore the compressor starts between any voltage from 160 Volts to 260 Volts after 3 minutes at any ambient between -10°C to 50°C. 393 The overload characteristics are nmed to reset only after 185 seconds (maximum recovery time obtained from experiments) so that the compressor (PTC) will be ready for starting between any voltage ranging from 160 Volts to 260 Volts, after tripping in case of power interruptions in pulldown test or after ultimate trip. CONCLUSION The compressors are made with new design motors of 1/8 hp & 1/6 hp. Tests on appliance are conducted with PTC and Overload . Appliance tests for low voltage running, startability and high voltage running,startability are conducted. Reliability tests under extreme conditions are also conducted. The performance of these compressors is found satisfactory in all above tests for the variation of voltages from 160 to 260 Volts and ambient temperatures from l0°C to 50°C. Depending on the PTCR behavior for different voltage and ambient variation. The maximum recovery time obtained from similar experiments the motor start winding and overload can be optimized. ACKNOWLEDGEMENTS 1) M/s Annapuma Electronics , Hyderabad, India 2) M/s Siemens, New Dellii, India 3) M/s Texas Instruments, Singapore REFERENCES 1. Robert F Blaha " The PTC Resistor ". 21st Electronic Components Conference, 1971. 2. Veinott, C. G. "Theory and Design of Small Induction Motors"_ Mc.GrawHill publications, 1979. 3. William R Hoffmeyer. ~~A Motor designer looks at Positive Temperature Co-efficient Resistors". General Electric Company. 394 PTCR SWITCHING TIME RECOVERY TIME CHARACTERISTICS AT DIFFERENT VOLTAGES AND AMBIENTS VOLTAGE SWITCIDNG TIME=11ILLI-SECONDS RECOVERY TIME (SECONDS) -10°C 10°C 25°C 5ooc 1 sooc -10°C l0°C 25°C 50°C 80°C 160 42 50 I 2400 2110 1937 1500/ 935 81 104 144 230 1200 1092 890 600\ 480 48 60 89 117 170 260 960 813 685 500/ 385 52 65 99 134 185 TABLE 1.0 STARTABILITY TESTS ON REFRIGERATOR RELAY RESTART TIME (SECS) VOLTS\TIME 60 120 150 180 160 NS OK OK OK 170 OK OK OK OK ELECTRO 180 OK OK OK OK MAGNET 190 OK OK OK OK -IC 200 OK OK OK OK RELAY 220 OK OK OK OK 230 OK OK OK OK 250 OK OK OK OK 260 OK OK OK OK PTCR RELAY NS NS NS NS NS NS NS NS NS 160 170 180 190 200 220 230 250 260 NS NS NS NS NS OK OK OK OK TABLE2.0 OK:COMPRESSORSTARTED NS : COMPRESSOR NOT-STARTED 395 NS OK OK OK OK OK OK OK OK OK OK OK OK OK OK OK OK OK PTCR AMBIENT TEMP VS SWITCHING TIME CURVE AT DIFFERENT VOLTAGES 00. 2500 Q z 0 \,.) 2000 '"•" 00 ~ ~ ::2 1500 -+- 160 VOLTS ~ --230VOLTS ......,....260VOLTS - ::2 '"" 1000 f-4 -=~ 500 ~ ··;,c'·· .. .. . ~ 0 -I0°C -~ ·:.. ·. I0°C 50°C 25°C 800C AMBIENT TEMPERATURE FIG. 1 PTCR AMBIENT TEMP VS RECOVERY TIME CURVE AT DIFFERENT VOLTAGES zoo~~--~--~~~~~~~----~~~ 180+;;~~~~:~;~~~;;~.;,.;;~+-~-~~;.~.~.;,~¥,~~~~.;~;,0·:~+~,;<:;;·<:~·~'~''·~·+····'··~~ 00. 1604~•o4~~;0;UL;,;,::;f~0~~~~~~,.;;,~~;~;.;~:~~·~+~~~;~,;~~~~;~;~,~~·~r~<l ~140~)2.~;;~;~d~:~;.~..c•••;,,~;~~.;;~~;~~~)l.~,""0;;~,.;;~;,;,;~;""~~~'~'~"·~'~'74 0120~·>.:..:;";.::;c,c:c.,;o;.;;;,;.c;,,;,.~c:~:c ...•..cc.c,~:.,~ .. ,.•..,,.•. +,~~••0 ::... ~ ~ 00.}00~,~~~;~~.,o;.; __ ,.~~~~;~··~"';,;;~;;~.;;~;-~•+0~;~~~ ~ 80 -~~;~;_,~~;.,;",;''·"''··~""·'··'·'·''•'·'··'·'""""'"""~:;;~,.;;;;.,:._;;~;:..~;;e.;,;;,;__,,;;,;,;";';,"''''•'"~"·.:.:l ::2 '"" 60 ~ 40 20 0 -10°C 10°C 50°C 25°C AMBIENT TE:MPERATURE FIG.2 396 80°C -+-160 VOLTS -D-230VOLTS ._...,_260VOLTS