* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download ADXL202 - Senior Design

Index of electronics articles wikipedia , lookup

Telecommunication wikipedia , lookup

Schmitt trigger wikipedia , lookup

Power MOSFET wikipedia , lookup

Analog-to-digital converter wikipedia , lookup

Wien bridge oscillator wikipedia , lookup

Operational amplifier wikipedia , lookup

Tektronix analog oscilloscopes wikipedia , lookup

UniPro protocol stack wikipedia , lookup

Radio transmitter design wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Transistor–transistor logic wikipedia , lookup

Integrating ADC wikipedia , lookup

Audio power wikipedia , lookup

Current mirror wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Power electronics wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Rectiverter wikipedia , lookup

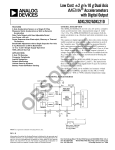

MICROCART Sensors – Acceleration, MicroGyro, Instrumentation Amplifiers UPDATED: 12/00/99 BY: Chris Holand? ADXL202 Its assumed that the ADXL202 will work for this sensor application. The maximum acceleration that the ADXL202 will read is 2g. It is possible that this might be exceeded by the helicopter vibration. Consequently, all readings should be checked for over range values. If they occur, the ADXL202 can be replaced with the ADXL210 which reads a maximum acceleration of 10g. When implementing the ADXL202 data into the control system, a compromise must be made in determining a value to use for calculation of the tilt angle. Referring to the data sheet, you will see that the sensitivity of the ADXL202 changes with the tilt angle. For angles less than ±30°, the change is very small and average value could be used with out introducing a large error. For the rate damping part of the control system, the primary concern is not necessarily with the exact angle of tilt, but with the change in tilt. A 0.1µF capacitor is required for power supply decoupling with 100Ω in supply line for additional decoupling. Equation for -3dB bandwidth: F3dB 1 5F = (2)(32k)C(x,y) C(x, y) Where C is the value of the capacitance used on both analog outputs. From table 1 in the data sheet, a value of 0.47µF gives a -3dB of 10Hz. For MicroCART, the low bandwidth will filter out any vibrations that have a frequency higher than 10Hz. This takes care of a lot of problems that could occur due to vibration. The bandwidth of the ADXL202 is 0.01Hz to 5 kHz. If 10Hz bandwidth doesn’t eliminate vibration, then the bandwidth of the ADXL202 can be lowered to near DC levels. Even for analog operation, the DCM period must be set by Rset resistor. Any value between 500kΩ and 2MΩ will work. For this project a 1.3MΩ resistor will be used. It should be noted that the device itself has noise with characteristics of white Gaussian noise that contributes equally to all frequencies. The noise is proportional to the square root of the bandwidth of the accelerometer and is described by the following equation: 500g Noise(rms) BW 1.5 Hz It should be noted from this equation that the noise decreases as the bandwidth decreases. For more detailed information about noise, consult the data sheets. Figure 1 shows the schematic for tilt sensing. The diagram does not give the orientation the accelerometer must be in for two axis tilt sensing. This can be determined from the data sheet easily. Capacitor CDC and resistor Rf is for power supply decoupling and RSET is used to set the DCM period which isn't used, but must have a value. Table 2 has a list of the values used in the schematic. Figure 1. Schematic for ADXL202. Component Value CYfilt=CXfilt 0.47µF CDC 0.1µF RSET 1.3MΩ Rf 100Ω Table 2. List of component values for figure 1. The sensitivity of the ADXL202 relative to the supply voltage is given by the following equation: ADXL202 Sensitivity = (60mV Vs ) g At a power supply of +5V, Vdd, results in 300mV/g. For future reference in the document, the sensitivity will be as: 300mV 1g 300V g 100mg mg The zero g offset is found from the following equation: Zero g Offset = VDD 2 Again at the power supply voltage of +5V, Vdd, the zero g offset is +2.5 V. From figure 14 of the ADXL202/ADXL210 spec sheets, you can see that the output varies slightly due to different orientations. A valid assumption is that the ADXL202 will not have to measure angles more than ±30°. This makes the variation negligible. For the following calculations, it’ll be assumed that the ADXL202 will measure angles of ±45°. This will represent the extreme for determining the sensitivity of the output relative to a degree change in tilt. Again from figure 14, the output will change by 12.2 mg/degree tilt. This will result in a change of: 300V 12.2mg 3.66mV mg per degree tilt per degree tilt If the instrumentation amplifiers have an offset voltage on the order of 100µV, they will not introduce any significant error. With a sensitivity of 300mV/g, the ADXL202 will have an output that varies from 2.5±300mV. Hence, the instrumentation amplifiers will need gain. Using the extreme of ±45° again, the output of the ADXL202 will vary ±0.707g. This results in a variance of: 300mV 0.707g 212.1mV g Using an amplification of 5 V/V: 212.1 mV5 V V 1.0605 V Therefore the range of measuring voltages will be: 2.5 1.0605 V = 1.440,3.561 V Angular Velocity Sensing MicroGyro The MicroGyros will read a maximum angular velocity of ±150 deg/sec. The sensitivity is 1.11mV/deg/sec. The analog output is defined as: Vout1,2 Vg1,g2 Vref where Vref is 1.225 V and Vg1,g2 is an output that changes according to applied rotation. Since no movement implies a zero output, Vg1,Vg2 equals Vref in this condition. Over the full range of the sensor: deg mV 150 1.11 166.5 mV deg sec sec According to the data sheet, single ended measurement cannot be made of Vg1 or Vg2 outputs. The measurement of output has to be take as the difference as stated before. Hence, the difference will result in an net output of: 166.5 mV Using an amplification of 5 V/V: 166.5 mV 5 V V 832.5 mV Figure 2 shows the schematic for the MicroGyro. The following is a listing of the pin number and the corresponding name for the pin. The capacitor CBC is for decoupling the power supply. 1. 2. 3. 4. 5. 6. 7. 8. 9. Vref1 Vg1 Gnd Vdd Vref2 Vg2 Wake Temp NC - No Connection Figure 2. Schematic for MicroGryo. Note that the wake pin needs to be high in order for the device to function. The optional temperature sensor pin is not used in this diagram. Instrumentation Amplifiers AD623 The basic circuit for use with the AD623 instrumentation amplifier is shown in figure 3. Its possible for op amps to rectify RF signals which shows up as a DC offset. This design is taken from the data sheets and has the specific benefit of attenuating any RF interference. Table 2 has a list of the components of the corresponding value. The resistor RG sets the gain at 5 V. Component C1=C2 C3 CS1 CS2 RG R1=R2 Value 1000pF 0.047µF 0.033µF 0.01µF 24.9kΩ 4.02kΩ Table 2. List of component values for figure 3. All resistors should be 1% or better metal film units. All the capacitors need to be 5% or better. These components need to be precise as possible otherwise the benefits of using this circuit design and precision instrumentation amplifier are wasted. Figure 3. Schematic for the instrumentation amplifier AD623. Vss is connect to Gnd for connection to the ADXL202, but the MicroGyros require Vss to be connection to a negative power supply in order to allow the output to swing negative. This in amp is rail to rail on operation of a single supply only, hence leave room between the maximum negative voltage needed for output and the negative power supply. Analog/Digital Conversion Here is some general information that needs to be considered when choosing the A/D converter. The sensitivity of the ADXL202 was determined to be 300 µV/g and the MicroGyro is 1.11mV/deg/sec. In both cases a gain of 5 V/V was used. This results in new sensitivity of 1.5 mV/mg and 5.55 mV/deg/sec for the ADXL202 and the MicroGyro respectively. In the worst case, the ADXL202 changes 12.2mg/degree, hence the output will change: 1.5 mV mg 12.2 mg degree 18.3 mV degree This is the worst case for sensitivity of the ADXL202. Therefore, the MicroGyro is the limiting factor in choosing the resolution of the A/D converter. Use of a 10 bit A/D converter over 0 to 5 V would result in the following resolution: 5V 5V 4.88 mV 210 1024 Since 4.88 mV < 5.55mV for the MicroGyro, 10 bits of resolution is sufficient for the A/D converter. General Notes All sensors and amplifiers need to be decoupled from the power supply. If possible, a separate supply and ground should be used for the analog devices. This help minimize the digital noise. Both the ADXL202 and the MicroGyro have an offset voltage that needs to be determined and compensated for. Data sheets for both devices have information for how to go about doing this. Temperature compensation is something that can be considered for the MicroGyro. References Data sheets are available from the Analog Devices web site for the ADXL202 and the AD623 (http://www.analog.com). Information for the MicroGyros is also available at their web site (http://www.gyration.com). I have also found the following references useful about helicopter flight, control systems, and general information: The Helicopter by John Fay, ISU call number TL 716 F35 1976 C.2, this was an easy read about helicopters, but had good general information Foundations of Helicopter Flight, by Newman, ISU call number TL716 N39 1994b Helicopter Performance, Stability, and Control, ISU call number TL716.P725 1986 The Art and Science of Helicopter Flight, I don't have the call number, but I think this was the best book overall. It does a very good job of explaining Automatic Flight Control Systems (AFCS) Automatic Flight Control, ISU call number TL 589.4 P34 1993