* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download laboratory works semiconductor electronics

Mercury-arc valve wikipedia , lookup

Spark-gap transmitter wikipedia , lookup

Ground loop (electricity) wikipedia , lookup

Ground (electricity) wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Electrical ballast wikipedia , lookup

Power engineering wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Power inverter wikipedia , lookup

Three-phase electric power wikipedia , lookup

History of electric power transmission wikipedia , lookup

Electrical substation wikipedia , lookup

Current source wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Power MOSFET wikipedia , lookup

Schmitt trigger wikipedia , lookup

Voltage regulator wikipedia , lookup

Stray voltage wikipedia , lookup

Power electronics wikipedia , lookup

Surge protector wikipedia , lookup

Alternating current wikipedia , lookup

Voltage optimisation wikipedia , lookup

Current mirror wikipedia , lookup

Buck converter wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Department of Electrical Engineering

LABORATORY WORKS

in

SEMICONDUCTOR ELECTRONICS

Valery Vodovozov and Zoja Raud

http://learnelectronics.narod.ru

Tallinn

2014

Contents

Safety warnings...................................................................................................... 3

Preliminary notes about the workflow ..................................................................... 4

Circuit preparation .............................................................................................. 4

Wiring................................................................................................................. 5

Experimentation and reporting............................................................................ 6

Job instructions ................................................................................................... 7

Work 1. Diodes................................................................................................... 7

Target............................................................................................................. 7

Lesson preparation......................................................................................... 7

Experimentation.............................................................................................. 7

Report contents .............................................................................................. 8

Optional section.............................................................................................. 8

Work 2. Transistors ............................................................................................ 9

Target............................................................................................................. 9

Lesson preparation......................................................................................... 9

Experimentation.............................................................................................. 9

Report contents ............................................................................................ 10

Optional section............................................................................................ 10

Work 3. Thyristors ............................................................................................ 11

Target........................................................................................................... 11

Lesson preparation....................................................................................... 11

Experimentation............................................................................................ 11

Report contents ............................................................................................ 12

Optional section............................................................................................ 12

Work 4. Operational amplifiers ......................................................................... 13

Target........................................................................................................... 13

Lesson preparation....................................................................................... 13

Experimentation............................................................................................ 13

Report contents ............................................................................................ 14

Optional section............................................................................................ 14

References.......................................................................................................... 14

Annexes .............................................................................................................. 15

1. Diode datasheet ........................................................................................... 15

2. Transistor datasheet..................................................................................... 15

3. Thyristor datasheet....................................................................................... 15

4. Opamp datasheet......................................................................................... 15

5. Color coding ................................................................................................. 16

6. Breadboard layout ........................................................................................ 17

2

Safety warnings

Safety warnings

This is a tutorial aid to implement laboratory works in electronics. The students are

expected to have acquired knowledge of electronic components, electrical wiring,

and electrical schematic symbols [1]. The manual complies with the curriculum and

the syllabus of the course AAR3320 “Electronics and Semiconductor Engineering”

[2], [3]. The laboratory has dangerous equipment whose voltages above 60 VDC or

30 VAC can pose a shock hazard, therefore read carefully the following safety

warnings and respect all the safety precautions.

1. Never apply the mains power if it may cause a danger or an injury. In the case of

an accident, switch off the nearest safety switch and release the sufferer from the

voltage. Thereafter call the rescue service (numbers 112 and 0112) and provide

the first aid.

2. In the case of overheating, smelling, the sparkles or electric arc between

contacts, switch off the supply immediately. Additional red safety push-button is

located on the front panel of the main laboratory switchboard. In the case of an

emergency, press this button to switch off all the lab benches. After avoiding an

emergency, pull out this push-button to restore the supply.

3. To avoid an electric shock, never switch on the supply without the instructor’s

permission, never open the covers, and do not touch with wires while the circuit is

powered.

4. Enable free access to the feeder board, lab bench, emergency switches, and all

the devices, which are adjusted during the experimentation. All equipment and

appliances should be well visible and their displacement or pulling down from the

table should be avoided.

5. When assembling the circuits, connect no more than two conductors to one

terminal or socket. To change the circuit, switch off the power.

6. Before energizing the lab bench, make sure that all devices and measuring

instruments are suitable for operation throughout the voltage and current ranges

provided by this manual. Do not run the circuits over the rated voltages and

currents and do not allow their overloading. Do not use equipment if it looks

damaged or operates abnormally.

7. It is prohibited to lean and sit, to hang clothes, to place bags, cases etc. on the

workplaces, to leave and to enter the laboratory without the instructor’s

permission, to eat, drink and smoke in the laboratory, to touch the devices not

needed for the given work, and to implement the experiments alone.

3

Preliminary notes

Preliminary notes about the workflow

Circuit preparation

1. Every student should implement the mandatory part of the works and may employ

the optional part given in small print in this tutorial aid.

2. Prepare for a work beforehand. Using the annexes of this manual, find the data

of the studied semiconductor devices, resistors, and the breadboard layout.

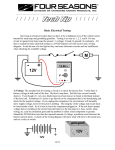

3. Basing on the schemes shown in Fig. 1, develop the principal circuit diagram for

experimentation. Each circuit includes a studied semiconductor device and

voltage dividers. Restrict the supply voltage Us = 10 V and set its polarity

accordingly the component data. Limit the power consumption of every part P ≤

1 W. Calculate the buffer resistors R1 to limit the current through a component.

Connecting a semiconductor without such resistors is a sure-fire way to kill it! To

adjust the voltage U2 across the component, apply the potentiometers R2 of 1 kΩ

or 10 kΩ. Therefore,

R1 ≥ max { Us / Imax; Us2 / P }

P1 ≥ Us2 / R1

I1 ≤ Us / R1

R1

VD

IA

UAC

R2

RLED

Us

LED

R1B

R2B

R1C

R1G

IC

IB

VT

UBE

UCE

R2C

R2C

Us

R1A

IG

IA

VS

UGC UAC

R2A

Us

Fig. 1. Basic schemes for experimentation

4. Add a circuit to indicate whether the scheme is energised using a LED and a

resistor:

RLED ≥ (Us – ∆ULED) / ILED

PLED ≥ ILED2⋅RLED

5. To estimate the voltages and currents, supplement your circuit with meters. Use

the digital multimeter or a voltmeter to measure the voltage across two leads. To

this aim, place the positive terminal on the lead with higher voltage (if known) and

the negative terminal on the lead with a lower voltage. A digital multimeter can be

used as an ammeter to determine the current flow through a wire or electrical

component. This measurement is accomplished by placing the multimeter or the

ammeter in series with the wire that the current is flowing through. Draw expected

characteristics.

4

Preliminary notes

Wiring

1. Develop the wiring diagram. Every workplace is accomplished with a breadboard,

a board with a studied device, a power supply, and measuring devices.

Converting the principal circuit to a wiring diagram, example of which is shown in

Fig. 2, is not straightforward because the arrangement of components will look

quite different from the principal circuit.

Power supply

Measuring

devices

– Us +

Coloured

safety wires

PA

Bread board

Sockets

Bus strips

Board of the

studied

device

VD

LED

RLED

R1

DO NOT COPY

PV

Components

Jumper wires

Clip rows

R2

Clip columns

Fig. 2. Example of a wiring diagram

2. Place the resistors, potentiometers, and LED on the breadboard layout. Use the

clip rows for the parts those thin leads do not exceed 0,6 mm in diameter and the

clip columns at the foot of the breadboard for the potentiometers and resistors

with thicker leads.

3. Link the components routing the jumper wires around the parts, not over them

thus making changing the components easier when needed. Wire the red positive

supply socket of the breadboard with a red bus strip and the black negative

supply socket with a black bus strip. Do not insert the component leads to the bus

5

Preliminary notes

strips; instead, use the jumper wires to wire the bus strips with the leads pushed

into the clips.

4. Apply the blue and green sockets to wire the emitter and collector of the

transistor board or the anode and cathode of the diode and thyristor boards. Use

the yellow socket to wire the control leads (base, gate).

5. Connect also the external board of a studied device, the supply, the measuring

devices, and the signal generators (if required) to these sockets.

Experimentation and reporting

1. Assemble the circuit accordingly the wiring diagram by pushing the component

leads to the breadboard clips. Keep the jumper wires on the board flat, so that the

board does not look cluttered.

2. Provide the link-up of the breadboard with the board of a studied device and the

measuring devices using the coloured cord set of special safety wires belonging

to the workplace outfit. Choose the red wires for the positive polarity and the black

ones for the negative polarity.

3. Before experimentation, check all the connections carefully. Make sure that

semiconductor devices are the correct way round and no leads are touching

(unless they connect to the same block).

4. When selecting the measuring range of the meters, ensure that the maximum is

above the expected reading anticipated. Selection of a high range prevents the

meter overloading. When the range of the value to be measured is unknown, set

the highest possible range or, wherever possible, choose autoranging.

5. Adjust the supply voltage to about 10 V and then turn off the power with the

pushbutton. After that, connect the breadboard to the positive (red) and negative

(black) terminals of the power supply and press the pushbutton to test the circuit.

If your circuit does not work, deenergize the breadboard and very carefully recheck every connection against the circuit diagram.

6. In experimentation, change the voltages by potentiometers and measure voltages

and currents. Any overvoltage, overcurrent, and overheating are prohibited!

During the measuring you can optimise the meter range for the best reading. If

possible, enable all the leading digits to not read zero, and in this way the

greatest number of significant digits can be read.

7. Before changing functions or experiments, power off the breadboard. Never

perform resistance or continuity measurements on live circuits!

8. At the end of experimentation, submit the protocols and other results to the

instructor. After instructor’s permission, take off the circuit, switch off and return

the measuring devices and equipment onto their places, and leave the workplace

in order.

9. Every student must prepare and defend the personal report about every work.

The report includes the title sheet, protocols, tables of experiments, calculations,

diagrams, and conclusions. In conclusions, evaluate compliance of the results

with the theoretical aspects and valid standards, and expediency of the used

methods. Pay attention to the differences of the results obtained, experimental

errors, mistaken measurement readings, and their reasons.

6

Diodes

Job instructions

Work 1. Diodes

Target

Making the simple diode circuits and acquainting with diode characteristics.

Lesson preparation

1. Using Annex 1 in this manual, find the LED and the diode data: their types,

maximum forward currents IF max, maximum reverse voltages UR max, and forward

voltage drops ∆UF.

2. Familiarise with the available power source, its voltage Us max, and current Is max.

3. Develop the LED circuit indicating whether the breadboard is energised.

4. Develop the circuit and wiring diagrams to explore the forward volt-ampere

characteristic of a studied diode. Calculate and place a voltage divider between

the power supply and the diode to protect the circuit from overloading. Choose

the potentiometer of 1 kΩ or 10 kΩ and the buffer resistor to this aim.

5. Provide the circuit link-up with:

• dc voltmeter PV to measure the diode forward voltage UF and reverse

voltage UR

• dc ammeter PA to measure the diode forward current IF and reverse

current IR

and find out the data of the available measuring devices: their types, measuring

limits, and maximum measured values.

6. Sketch an expected volt-ampere characteristic and diode voltage waveforms.

Experimentation

1. Familiarise with a LED:

•

Wire the red (positive) supply socket of the breadboard with a red bus strip

and the black (negative) socket with a black bus strip.

•

In the first breadboard row, assemble the circuit for indication whether the

breadboard is energised by inserting the current-limiting resistor and the LED

to the clips, putting them together, and linking to the bus strips.

•

Adjust the power supply voltage to 10 V. Connect it to the breadboard sockets.

Self-examine and ask an instructor to examine the assembled circuit.

•

Power on the supply and ensure the LED beams. Then, power off the supply

and ensure the LED dims. If a fault occurs in any instant, deenergize the

breadboard immediately, examine the circuit and eliminate errors.

2. Tune the potentiometer:

•

Put together the current-limiting resistor and the potentiometer and link to the

bus strips. Wire the potentiometer slider with the blue socket and the negative

(black) bus strip with the green socket.

7

Diodes

•

Choose the measuring devices and assign their ranges and terminals for

wiring. Connect the voltmeter across the blue and green sockets. Selfexamine and ask an instructor to examine the assembled circuit.

•

Power on the supply. Turn the potentiometer knob and find its positions that

correspond to the maximum and minimum voltages. Assign the minimum

voltage and then power off the supply.

3. Estimate the forward volt-ampere characteristic:

•

Assemble the desired circuit, self-examine and ask the instructor to check it.

•

Power on the supply. Turn the potentiometer smoothly until the maximum

supply voltage or the diode permissible current is achieved. At every step,

measure the diode voltage and current, fill the measured values in the

protocol, and plot the diagram.

•

Restore the minimum voltage and power off the supply.

4. Following the instructor’s permission, switch off the devices, take off the circuit,

and introduce proper order at the workplace.

Report contents

1. Wiring diagram of the experimental setup with specification of the components.

2. Circuit diagram of the experimental setup.

3. Calculation of the resistors.

4. Tables of the observed data.

5. Scaled diagrams of the experimental volt-ampere characteristic.

6. Estimation of the knee voltage and the forward voltage drop ∆UF in the upper

point of the volt-ampere characteristic.

7. Conclusions regarding estimation, comparison and explanation of the expected

and obtained results.

8. Signed protocol.

Optional section

1. Design and assemble the circuit to estimate the reverse volt-ampere characteristic, repeat

experimentation, and include the table and the characteristic obtained to your report.

2. Using a signal generator and an oscilloscope, develop and assemble the circuit to trace the diode

voltage waveform and employ experimentation in the given point of the volt-ampere characteristic.

3. Calculate the diode power dissipation at the maximal anode current and prove your result with

simulation.

4. Design the circuit whose supply voltage exceeds the diode breakdown (Us > UR max), calculate the

voltage divider, and prove your design with simulation.

5. Design the rectifier circuit which load voltages and currents exceed the diode ratings (ULOAD >

UR max, ILOAD > IF max), and prove your design with simulation.

8

Transistors

Work 2. Transistors

Target

Making the simple transistor circuits and acquainting with input and output

characteristics of a transistor in the common emitter mode of operation.

Lesson preparation

1. Using Annex 2, find the transistor data: type, permissible collector-emitter voltage

UCE max, base voltage UBE max, collector current IC max, power dissipation Pmax, beta

gain β, and frequency fmax. Calculate an expected base current IB max.

2. Familiarise with the available power source, its voltage Us max, and current Is max.

3. Develop the wiring and circuit diagrams to study an input characteristic IB(UBE) at

zero collector-emitter voltage UCE and an output characteristic IC(UCE) at different

base currents IB of a transistor in the common emitter mode of operation.

Consider the pnp or npn transistor structure to set the proper supply polarity.

Calculate and place a voltage divider between the power supply and the base

circuit to bias and protect the base. Calculate and place another divider between

the power supply and the collector circuit to protect the collector. Choose the

potentiometers of 1 kΩ or 10 kΩ in these dividers.

4. Provide the circuit link-up with:

• dc voltmeters PV to measure the transistor collector-emitter voltage UCE

and base voltage UBE

• dc ammeters PA to measure the transistor collector current IC and base

current IB

and find the data of the available measuring devices: their types, measuring

limits, and maximum measured values.

5. Sketch expected input and output characteristics and voltage waveforms.

Experimentation

1. Select the measuring devices and assign the required measuring ranges and

sockets for wiring. Adjust the supply voltage to 10 V.

2. Find the positions of the potentiometer knobs that correspond to the maximum

and minimum voltages and set the minimum voltages on their sliders.

3. Assemble the desired circuit to estimate the input characteristic IB(UBE) at an open

collector. Self-examine and ask an instructor to examine your circuit.

4. Power on the base supply and ensure the circuit operates properly. If the fault

occurs, power off the breadboard immediately, examine the circuit and eliminate

errors.

5. To build the input characteristic, increase smoothly UBE by turning the base

potentiometer knob until the maximum base voltage UBE or current IB max is

achieved. At every step, measure the base voltage UBE and current IB, fill the

measured values in the protocol, and plot the graph. Afterwards, remove the base

voltage and the breadboard supply.

9

Transistors

6. Assemble the desired circuit to estimate the output characteristics IC(UCE), selfexamine and ask the instructor to examine it also.

7. Using the selected resistor values, calculate the expected saturation current IC sat

and cutoff voltage UCE cutoff.

8. To build an output characteristic, keep the base current IB far below the IB max and

increase smoothly UCE until the cutoff voltage UCE cutoff is achieved or the collector

current IC reaches the saturation level IC sat. At every step, measure IC, write

down IB, UCE and IC to the protocol, and plot the graph.

9. Following the instructor’s permission, switch off the devices, take off the circuit,

and introduce proper order in the workplace.

Report contents

1. Wiring diagram of the experimental setup with specification of the components.

2. Circuit diagram of the experimental setup.

3. Calculation of voltage dividers and an expected base current.

4. Tables of the observed data (UBE, IB) at an open collector and (UCE, IC) at given IB.

5. Scaled diagrams of the experimental input and output characteristics.

6. Estimation of the cutoff voltage (UBE cutoff) and saturation current (IC sat), load line,

operating point at observed IB, beta and alpha gains, as well as the differential

input and output resistances at the operating point.

7. Conclusions regarding estimation, comparison and explanation of the expected

and obtained results.

8. Signed protocol.

Optional section

1. Find an output characteristic at the maximal base current and include to the report the table and

the characteristic obtained, load line, operating point at observed IB, beta and alpha gains, as well

as the differential input and output resistances at the operating point.

2. Estimate an input characteristic at IC > 0. To this aim, keep IC < IC max and increase smoothly UBE

until the permissible base voltage UBE or current IB max of the transistor is achieved. At every step,

measure the base voltage UBE and current IB, fill the measured values in the protocol, and plot the

graph.

3. Using a signal generator and an oscilloscope, develop and employ the circuit to trace the base

and collector voltage waveforms in the given point of the output characteristic.

4. Design an employ an additional experiment to demonstrate the non-linear modes of the transistor

operation and prove your result with simulation.

5. Calculate the transistor input and output voltage drops at the operating point of the highest current

gain and prove your result with simulation.

6. Calculate the transistor input and output power dissipation rates at the operating point of the

highest power dissipation and prove your result with simulation.

10

Thyristors

Work 3. Thyristors

Target

Making the simple thyristor circuits and acquainting with input and output

characteristics of a thyristor.

Lesson preparation

1. Using Annex 3, find the thyristor data: type, maximum forward current IF max,

forward voltage UF max, reverse voltage UR max, gate voltage UG max, and gate

current IG max.

2. Familiarise with the available power source, its voltage Us max, and current Is max.

3. Develop the circuit and wiring diagrams to study the input characteristic IG(UGC) at

an open anode and output characteristic IF(UF) of a thyristor. Calculate and set a

voltage divider between the power supply and the gate circuit to protect the power

source and the gate from overloading. Calculate and set another voltage divider

between the power supply and the anode/cathode circuit to protect the thyristor.

Choose the potentiometers of 1 kΩ or 10 kΩ in these dividers.

4. Provide the circuit link-up with:

• dc voltmeters PV to measure the gate voltage UGC and thyristor voltage UF

• dc ammeters PA to measure the gate current IG and the thyristor current IF

and find the data of the available measuring devices: names, measuring limits,

and maximum measured values.

5. Sketch expected input and output characteristics and voltage waveforms.

Experimentation

1. Select the measuring devices and assign the required measuring ranges and

sockets for wiring. Adjust the supply voltage to 10 V.

2. Find the positions of the potentiometers that correspond to the maximum and

minimum voltages and set the minimum voltages on their outputs.

3. Assemble the desired circuit to estimate the input characteristic IG(UGC) at the

open anode circuit. Self-examine and ask an instructor to examine the circuit.

4. Power on the supply source and ensure the circuit operates properly. If the fault

occurs, power off the lab bench immediately, examine the circuit and eliminate

errors.

5. To estimate an input characteristic, increase smoothly the gate voltage by the

gate potentiometer until the accessible gate current or maximum gate voltage is

achieved. At every step, measure the gate voltage and current, fill the measured

values in the protocol, and plot the graph. Afterwards, remove the gate voltage

and the breadboard supply.

6. Assemble the desired circuit to estimate the output characteristic IF(UF), selfexamine and ask an instructor to check it. Make sure the gate voltage is zero.

7. To build the output characteristic, set the maximum accessible thyristor voltage

UF and increase smoothly the gate voltage until the thyristor opens (i.e. until UF

11

Thyristors

drops and the anode current appears). Since the thyristor is open, remove the

gate voltage and make sure the anode current continues to flow.

8. Then, decrease the thyristor voltage accurately and, at every step, measure the

thyristor voltage and current, fill the measured values in the protocol, and plot the

graph. Fix the hold point, i.e. the last non-zero point of this graph.

9. Following the instructor’s permission, switch off the devices, take off the circuit,

and introduce proper order in the workplace.

Report contents

1. Wiring diagram of the experimental setup with specification of the components.

2. Circuit diagram of the experimental setup.

3. Calculation of voltage dividers.

4. Tables of the observed data UGC, IG and UF, IF.

5. Scaled diagrams of the experimental input and output characteristics.

6. Estimation of the hold voltage and hold current as well as the forward voltage

drop ∆UF in the upper point of the output diagram.

7. Conclusions regarding estimation, comparison and explanation of the expected

and obtained results.

8. Signed protocol.

Optional section

1. Find experimentally the gate currents to open the thyristor at a couple of other UF voltages and

build the firing diagram IG(UF).

2. Using a signal generator and an oscilloscope, develop and employ the circuit to trace a voltage

waveform UF(t) in the given point of the output diagram.

3. Assemble the circuit and plot the forward and reverse characteristics of the closed thyristor without

the gate control.

4. Calculate the thyristor input and output impedances, prove your calculation with simulation, and

explain their differences.

5. Calculate the thyristor input and output voltage drop at the highest current and prove your result

with simulation.

6. Calculate the thyristor input and output power dissipations at the highest current and prove your

result with simulation.

12

Annexes

Work 4. Operational amplifiers

Target

Acquainting with amplitude and phase frequency responses and voltage waveforms

of a non-inverting voltage amplifier with negative feedback built on the operational

amplifier (opamp).

Lesson preparation

1. Using Fig 3 and Annex 4, find the opamp data: type, supply voltage, open-loop

voltage gain, slew rate, gain-bandwidth product, and input impedance. Acquire

with the tuning knobs and plugs of the test board. Locate the output potentiometer

R1, the feedback potentiometer R2, the input potentiometer R3, the signal inputs

1, 2, and the output 3.

R3

+Us

+

−

R2

R1

DO NOT COPY

Fig. 3. Circuit to study an opamp

2. Familiarise with the available power and signal sources: their names, voltage

shapes, maximum voltage Us max, and maximum current Is max.

3. Develop the circuit diagram to study amplitude and phase frequency responses

and voltage waveforms of a non-inverting voltage amplifier with negative

feedback built on the base of an opamp. Provide the circuit link-up with the power

source, signal generator on the input (1), and oscilloscope on the input (2) and

output (3) of the amplifier.

4. Draw expected frequency responses and voltage waveforms of the voltage

amplifier.

Experimentation

1. Assemble the desired circuit to estimate the input and output waveforms. Selfexamine the assembled circuit and ask the instructor to examine it.

2. Switch on the power source and set the voltage of 10 V. Ensure the circuit

operates properly. If the fault occurs in any instant, power off the lab bench

immediately, examine the circuit and eliminate errors.

3. Switch on the signal generator and the oscilloscope. Set the sinusoidal waveform

of the signal generator with the frequency of 100 Hz and attenuation of 50 dB

(50 − 300 mV).

13

Annexes

4. Set the given feedback level and tune the maximum output sinusoidal signal of

the amplifier using the input and output potentiometers. Measure the input peakto-peak signal value Upk-pk in and write down it to the protocol.

5. Measure the output signal peak-to-peak value Upk-pk out and the time shift φ [µs]

between input and output waveforms; write down them to the protocol.

6. Smoothly increasing frequency f [MHz], make 3−5 measurements in each of the

three frequency bands − Hz, kHz, MHz (10−20 points altogether) − and repeat

item 5 at every step.

7. Following the instructor’s permission, power off the devices, take off the circuit,

and introduce proper order in the workplace.

Report contents

1. Circuit diagram of the experimental setup, with specification of the components.

2. Calculation example of the voltage amplification factor Ku [p.u.], Ku [dB] and the

phase shift φ [rad].

3. Table of the observed and calculated data at the given input (Upk-pk in) and

feedback signals: f [MHz], Upk-pk out [V], φ [µs] and φ [rad], Ku [p.u.] and Ku [dB].

4. Scaled diagrams of the amplitude

Ku [dB] (f [MHz]) and φ [rad] (f [MHz]).

and

phase

frequency

responses

5. Bandwidth estimation.

6. Input and output voltage waveforms at the cutoff frequencies.

7. Conclusions regarding estimation, comparison and explanation of the expected

and obtained results.

8. Signed protocol.

Optional section

1. Set another feedback level and repeat the abovementioned items 4 to 6. Build the graph of the

bandwidth dependence upon the feedback fraction.

2. Set another signal shape and repeat the items 4 to 6. Build the graph of the bandwidth

dependence upon the signal shape.

3. Define experimentally the frequency and voltage bands in which the opamp is a linear device.

Build the input and output voltage waveforms of the non-linear opamp operation.

References

1. Vodovozov, V., Jansikene, R., Electronic Engineering, Tallinn: TUT, 2006, 148 p.

2. Vodovozov, V., Jansikene, R., Elektroonika ja Jõupooljuhttehnika (Tõlge inglise

keelde), Tallinn: TTÜ, 2008, 140 lk.

3. Vodovozov, V. Introduction to Electronic Engineering, Available at:

http://bookboon.com/int/student/electro/introduction-to-electronic-engineering

14

Annexes

Annexes

1. Diode datasheet

Quantity

АЛ102А

АЛ336Б

5

2

2,8

10

2

2,0

Forward current IF max, mA

Reverse voltage UR max, V

Forward voltage drop ∆UF, V

Pinouts

C

C

A

A

Д206

(1N360)

100

100

0,5

C

A

BAV21

1N4148

NTE177

250

200

1,0

150

75

1,0

250

150

1,0

C

A

C

A

C

A

2. Transistor datasheet

Quantity

Structure

Collector-emitter voltage UCE max, V

Base-emitter voltage UBE max, V

Collector current IC max, mA

Power dissipation Pmax, mW

Beta gain β

Frequency fmax, MHz

KT312Б

(BF240)

npn

35

4

30

225

25…100

120

B

Pinouts

E

KT345Б

(BC513)

pnp

20

4

200

300

50…150

350

C

B E

KT3107A

(BC557)

pnp

45

5

100

300

20…140

200

C

KT347A

pnp

15

4

50

150

30...400

500

B E

C

C

B

KT816Б

(BD234)

pnp

45

5

3000

1000

25...275

3

E

ECB

3. Thyristor datasheet

Quantity

Forward current IF max, mA

Forward voltage UF max, V

Reverse voltage UR max, V

Gate voltage UG max, V

Gate current IG max, mA

KУ201E

2000

100

100

6

100

BRX45-T

800

60

60

0,9

0,2

A

Pinouts

A

G C

2N5060

800

30

30

1,2

0,2

C

G A

NTE5402

800

100

100

0,8

0,05

C

G A

G

C

4. Opamp datasheet

Quantity

Supply voltage, V

Open-loop voltage gain, dB

Slew rate, V/µs

Gain-bandwidth product, MHz

Input impedance, Ω

OPA 2681

±6

56…100

1200…2100

45…90

5

10

15

OPA 2703

4…12

120

0,6

1

9

10

OPA 300

2,7…5,5

95…106

80

150

13

10

OPA 337

2,7…5,5

100…120

4,6

12,5

13

10

Annexes

5. Color coding

Examples

16

Annexes

6. Breadboard layout

17