* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Speed of Sound Experiment

Alternating current wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Sound level meter wikipedia , lookup

Transmission line loudspeaker wikipedia , lookup

Public address system wikipedia , lookup

Mains electricity wikipedia , lookup

Integrated circuit wikipedia , lookup

Regenerative circuit wikipedia , lookup

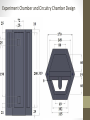

Speed of Sound Experiment Pre-CDR Team BalloonWorks Table of Contents • Introduction • Mission Goal • Expected Outcomes • Mission Requirements • Payload Design • Electrical, Software, and Mechanical Design • Risk Management Introduction Mission Goal To measure the speed of sound in Earth’s atmosphere in order to establish a relationship between speed of sound and altitude up to 30,480 meters and to consider the effects of atmospheric properties on the speed of sound. Expected Outcomes • Speed of sound is primarily dependent on temperature. • Speed of sound will decrease until the balloon reaches the tropopause. • Speed of sound remain constant in the tropopause. • Speed of sound will increase in the stratosphere. • Humidity is expected to play a minor role in determining the speed of sound when compared to temperature changes. Mission Requirements • Team BalloonWorks and the payload shall comply with all LaACES requirements. • The payload shall measure the speed of sound in ambient atmospheric conditions in order to construct a profile of the speed of sound versus altitude. • The payload shall obtain temperature, pressure and humidity to verify the data gathered on the speed of sound. • Team BalloonWorks shall retrieve and analyze data post flight. Payload Design Principle of Operation • Ultrasonic transmitter will emit an ultrasonic pulse. • Receiver will detect the pulse after it travels through ambient air. • Test circuit will determine the time it takes for the pulse to travel the fixed distance between transmitter and receiver. • Payload will have both an experiment and circuitry chamber. • Experiment chamber will allow temperature inside to be equal to ambient temperature and will contain the transmitter and receiver. • Circuitry chamber will be closed to the environment and will hold the power supply, test circuit, and BalloonSat. System Design Electrical Design • Main Components • • • • • • BASIC Stamp RTC EEPROM Transmitter Receiver Test Circuit • • • • • • • Driver Op-amp Comparator Flip-Flop Oscillator 2 Stage Counters I/O Expander • Power Supply Test Circuit • • • • • • Driver Op-amp Comparator Flip-Flop Oscillator 2 Stage Counters • I/O Expander Power Budget • 5 V input to all components after regulation • Maximum supply currents • 4 hours time Component BalloonSat Comparator Flipflop Clock Counter 1 Counter 2 I/O Expander Total Needed Current (mA) 100 6 100 25 70 70 125 496 Charge (mA-hours) 400 24 400 100 280 280 500 1984 Power Supply • 8 Energizer Ultimate Lithium AA Batteries in series to output 12 V to the BalloonSat and test circuit. • Both BalloonSat and test circuit require 5 V. BalloonSat has a voltage regulator (U3). Test circuit will have a voltage regulator. • U3 and test circuit’s voltage regulator will need to be in parallel with the batteries. • Every component in the test circuit will need to be in parallel with the test circuit’s voltage regulator but not with the batteries. Power Supply • Per Battery: 500 mA, 2000 mA-hrs Software Design • Pre-Flight Program • Sets all hardware pins and variables • Sets EEPROM address • Sets RTC Initialize all hardware pins and declare all variables Initiate EEPROM address to 0 Set RTC to desired HH:MM:SS Display Flight Program Read the address from the EEPROM on the BASIC Stamp Is EEPOM ADDR>=max EEPROM Address Yes End Program No Write_To_EEPROM SubRoutine Get_Time Sub-Routine Switch the set pin on the FlipFlop from high to low and then back to high Send a 40kHz pulse Counter Sub-Routine Comparator_Status Sub-Routine Write_To_EEPROM SubRoutine Reset the counters Pause in order to maintain consistent data acquisition of every fifteen seconds Write address to the EEPROM on the BASIC Stamp Flight Program-Subroutines Get_Time: Turn RTC and SCLK pins low Comparator_Status: Enter DO loop Bring RTC pin high Transmit to Stamp Turn RTC pin back to low Comp=1 No Loop Return Return Counter: Write_To_EEPROM: I2COUT command I2COUT command I2CIN command Pause Pause Return Yes Return Run the term232 program to save data into a file Post-Flight Program Is EEPOM ADDR>=max EEPROM Address No Use the I2CIN command to retrieve the data for the EEPROM Display the data showing the address as well as the values Pause Yes End Program Mechanical Design • Purpose of Mechanical Design • Hexagonal Design • Extruded polystyrene rigid foam insulation material Experiment Chamber and Circuitry Chamber Design Circuitry Embracement and Battery Holder Design Top Cover Weight Budget Components Weight Approximation Payload Structure 130g BalloonSat Circuit Board 70g Testing Circuit Board 70g Batteries 115g Supports 30g Total 415g Risk Management