* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download PowerIT Liquid-filled Groundmount Transformer

Stepper motor wikipedia , lookup

Buck converter wikipedia , lookup

Opto-isolator wikipedia , lookup

Three-phase electric power wikipedia , lookup

Ground (electricity) wikipedia , lookup

History of electric power transmission wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Electrical substation wikipedia , lookup

Resonant inductive coupling wikipedia , lookup

Stray voltage wikipedia , lookup

Voltage optimisation wikipedia , lookup

Distribution management system wikipedia , lookup

Rectiverter wikipedia , lookup

Alternating current wikipedia , lookup

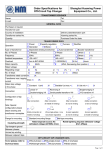

PowerIT Vacuum Cast Coil Dry Type Distribution Transformers Tap changer operation Industrial IT Enabled products from ABB are the building blocks for greater productivity, featuring all the tools necessary for lifecycle product support in consistent electronic form. Previous warnings. Before you make the tap position change, you must take into account next warnings and local regulation for working in HV electrical systems: This operation must be carried out without voltage in transformer, and its terminals must be connected to earth. The suitable tool for operating the tap changer is a 10 mm or 19 mm wrench depending on what is the screw size. The screw size is M6 or M12 according to the transformer characteristics. Picture 1 A 10 mm or 19mm wrench will be used, depending the needs. Steps The dry type transformers, are supplied with the tap changer in the position corresponding to the transformer voltage nominal values. If the tap change is necessary you must act as the next table shows. Prepared By: Vanessa John Date: 15/04/2004 Approved By: Carlos García Date: 16/04/2004 Applicability: Lang: English Document No. 1LES100007-ZB ABB Rev. No: 0 Page No: Page 2 of 3 Title: 1.0 Tap changer operation 1. Look up in rating plate the required position according to the electrical system characteristics. This table shows the suitable tap position to obtain the nominal BT voltage value, from each HV voltage value. 2. Slack the screws carefully, by means of the wrench. Separate the entire group made up with 2 hexagonal-head screw, 1 connection plate, 2 washers, and 2 lock washers. 3. Be extremely careful and don´t mislay any tap group item. If necessary, the replacement of one item must be by another item with the same constructive characteristics. Washer Connection plate Lock Washer 4. Fit the group between the suitable terminals that you want to link. Screw it after you make sure that between the bolt and connection plate surfaces there are not any foreign body, and mentioned surfaces are clean of dust or dirt. 5. Screws must be adjusted with a tightening torque of 8 N·m in M6 screws and 60 N·m in M12 screws. You must be sure that both surfaces are perfectly coupled in flat form. Note. The tapping in different coils of a transformer must be always in the same position. Tightening torque: 8 N·m in M6 screws 60 N·m in M12 screws Prepared By: Vanessa John Date: 15/04/2004 Approved By: Carlos García Date: 16/04/2004 Applicability: Lang: English Document No. 1LES100007-ZB ABB Rev. No: 0 Page No: Page 3 of 3 Title: 1.0 Tap changer operation