* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download ILP-Based Synthesis for Sample Preparation Applications on Digital

Survey

Document related concepts

Transcript

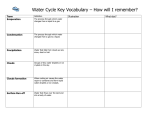

ILP-Based Synthesis for Sample Preparation Applications on Digital Microfluidic Biochips ABHIMANYU YADAV, TRUNG ANH DINH, DAIKI KITAGAWA AND SHIGERU YAMASHITA Digital Microfluidic Biochips A typical digital microfluidic biochip consists of a two dimensional control electrode array, peripheral devices such as dispensing ports, optical detectors, integrated logic and surrounding control pins as illustrated in the figure. Due to electro wetting phenomenon, assigning time-varying voltage values to activate/deactivate the electrodes in an appropriate strategy can move droplets. To precisely control the movements of the droplets, electrodes are connected to control pins to realize input signals as shown in the figure. Solved Example. Sort of … A very simple bio-assay carried out on a bio-chip. Involves few different chemicals in blue to start with. These will be placed in the Dispensing Ports . Notice that the given graph is simple DAG. What will stored in the integrated logic is the topological ordering of this graph, so that the chip knows what to do next. The nodes in orange are mixing operations that need to performed on the input droplets. It is interesting how droplets are mixed. The following video will demonstrate the dispensing ports in action and the droplets being mixed. Biochip in Action Some observations Observation1 : A mixing operation requires a certain number of cells to execute. Observation2 : It is not economically feasible to have a chip with infinite number of cells. Conclusion : As a result, there will be an upper bound on the number of mixing operations that can execute simultaneously. Also, we would want to finish the entire application in the least amount of time possible. The graph Scheduling Problem with constraints This is what the entire problem narrows down to. Various researchers have devised methods to compute the optimal scheduling. Some have used SAT solvers while others have used ILP ( Integer Linear Programming ) to solve this problem. The entire research is focussed on devising a method to find the scheduling in the quickest possible time. This Paper It proposes one such technique. This technique is based on ILP. The entire ILP formulation is indeed quite simple and easy to understand. One Example here to show how to proceed. Label each mixing operation with a label i N. Let Xit be a binary variable which takes the value 1 if mixing operation i is running at time t. This constraint be formulated using ILP as follows: t 𝑛𝑖=0 Xit <= 3