* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download IT318lab7

Buck converter wikipedia , lookup

Power engineering wikipedia , lookup

Three-phase electric power wikipedia , lookup

Mains electricity wikipedia , lookup

Electric machine wikipedia , lookup

Electrification wikipedia , lookup

Alternating current wikipedia , lookup

Voltage optimisation wikipedia , lookup

Rectiverter wikipedia , lookup

Commutator (electric) wikipedia , lookup

Electric motor wikipedia , lookup

Brushless DC electric motor wikipedia , lookup

Induction motor wikipedia , lookup

Brushed DC electric motor wikipedia , lookup

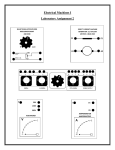

IT 318 - Lab #7 Motors Objective Observe the operational characteristics of the three major types of motors relative to speed, torque, current, and motion. Equipment Required DC power supply, variac, DMM, integrated brushless DC motor, DC motor on stand, AC shaded-pole induction wall-plugged motor. Procedures These 3 groups of procedures may be done in any order; it does not matter which motor you begin with. DC Motor 1. With the motor disconnected, turn the shaft at various speeds with your fingers and feel the way it rotates. Record your observations. 2. Connect the motor to +6 Volts with no load and measure the armature current. 3. Briefly stall the motor with your fingers and measure the armature current. Do not leave the motor stalled for more than a few seconds. Record this value. 4. Vary the load on the armature; observe the resulting armature current. Do this by applying a 10g weight to a cotton string draped over the flywheel. Then increase to 20g, 30g, 40g and so on up to 100g. Plot the resulting relationship. 5. Continue incrementing the load on the motor by increasing the weights in 10g increments (or more if necessary); observe the weight required to stall your motor. Remember to not leave the motor stalled for more than a few seconds. 6. Create a speed/voltage plot by measuring the RPM of the motor at +2 Volts, then again at +3 Volts, +4 Volts, +5 Volts, and +6 Volts. The RPM may be measured by measuring the frequency of the tachometer output wires, then dividing by 3 (the number of armature windings). 7. Reverse the power supply leads to the motor, so that you are essentially applying -6 Volts to the motor. Record your observation of what happens. Brushless DC Motor It is important to remember that all brushless DC motors require external commutation. This particular model has the commutation electronics built into the motor. Be sure to observe the proper connections for the motor, or it will not function as you would expect. Use the 24 Volt output of the power supply for wire #1 (red) and wire #2. Make sure you do not reverse these two wires. Use another variable output of the power supply for wire #4 (speed command), but make sure you do not exceed the 5V maximum for this input. Note: for this motor, it is essential that you never reverse the polarity of the applied voltage, or you will burn out the commutation electronics. 1. With the motor disconnected, turn the shaft at various speeds with your fingers and feel the way it rotates. Record your observations. 2. With the motor wires properly connected, measure the no-load current with a speed voltage of 1.0 Volts. Repeat for speed voltages of 3.0 Volts, 4.0 Volts, and 5.0 Volts. 3. Apply a variable load to the motor by placing a metal rod on and perpendicular to the shaft. Observe the current response as you change the frictional load using the metal rod. 4. How would you reverse the direction of this type of motor? (study the spec sheet). Once you’ve figured it out, try it and record your observations. Shaded-Pole AC Induction Motor AC induction motors use the commutation effect of the AC voltage; no brushes, commutator, nor external commutation is required. These are some of the simplest motors made, but the shaded-pole variety of AC induction motor suffers from extremely low starting torque. 1. With the motor disconnected, turn the shaft at various speeds with your fingers and feel the way it rotates. Record your observations. How freely does the shaft rotate? 2. Connect the motor to the output of the variac. Start with the variac set to 0. Record the armature current and observe the rpm as you change the output of the variac to 20, 40, 60, 80, then 100. 3. Turn the variac back down to 20. Invert the plug from the motor into the variac; record your observations when you plug it back in with the leads thus reversed. What do you think it would take to reverse the direction of rotation of a shaded-pole AC induction motor? 4. Turn the variac to 50. Hold the motor and rotor firmly and then plug it in; feel the starting torque. Would you expect it to be more? Conclusion Summarize the results of this lab in relation to the objective. Build a table of comparison for these three motor types. What did you learn? What more would you like to know? Were any problems encountered? If so how were they resolved. Write this as though you are teaching the concepts from this lab to a student just getting into electronics and computers.