* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Brass - Germicidal and Anti-Microbial Applications

Survey

Document related concepts

Transcript

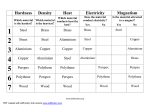

Brass - Germicidal and antimicrobial applications[edit] copied from Wikipedia, June 12, 2013 Main article: Antimicrobial copper-alloy touch surfaces See also: Antimicrobial properties of copper, Copper alloys in aquaculture The copper in brass makes brass germicidal. Depending upon the type and concentration of pathogens and the medium they are in, brass kills these microorganisms within a few minutes to hours of contact.[15][16][17] The bactericidal properties of brass have been observed for centuries and were confirmed in the laboratory in 1983.[18] Subsequent experiments by research groups around the world reconfirmed the antimicrobial efficacy of brass, as well as copper and other copper alloys (see Antimicrobial copper-alloy touch surfaces).[15][16][17] Extensive structural membrane damage to bacteria was noted after being exposed to copper. In 2007, U.S. Department of Defense’s Telemedicine and Advanced Technology Research Center (TATRC) began to study the antimicrobial properties of copper alloys, including four brasses (C87610, C69300, C26000, C46400) in a multi-site clinical hospital trial conducted at the Memorial Sloan-Kettering Cancer Center (New York City), the Medical University of South Carolina, and the Ralph H. Johnson VA Medical Center (South Carolina).[19][20] Commonly touched items, such as bed rails, over-the-bed tray tables, chair arms, nurse's call buttons, IV poles, etc. were retrofitted with antimicrobial copper alloys in certain patient rooms (i.e., the “coppered” rooms) in the Intensive Care Unit (ICU). Early results disclosed in 2011 indicate that the coppered rooms demonstrated a 97% reduction in surface pathogens versus the non-coppered rooms. This reduction is the same level achieved by “terminal” cleaning regimens conducted after patients vacate their rooms. Furthermore, of critical importance to health care professionals, the preliminary results indicated that patients in the coppered ICU rooms had a 40.4% lower risk of contracting a hospital acquired infection versus patients in non-coppered ICU rooms.[19][21][22] The U.S. Department of Defense investigation contract, which is ongoing, will also evaluate the effectiveness of copper alloy touch surfaces to prevent the transfer of microbes to patients and the transfer of microbes from patients to touch surfaces, as well as the potential efficacy of copperalloy based components to improve indoor air quality. In the U.S., the Environmental Protection Agency regulates the registration of antimicrobial products. After extensive antimicrobial testing according to the Agency’s stringent test protocols, 355 copper alloys, including many brasses, were found to kill more than 99.9% of methicillin-resistant Staphylococcus aureus (MRSA), E. coli O157:H7, Pseudomonas aeruginosa, Staphylococcus aureus, Enterobacter aerogenes, and vancomycin-resistant Enterococci (VRE) within two hours of contact.[15][23] Normal tarnishing was found to not impair antimicrobial effectiveness. Antimicrobial tests have also revealed significant reductions of MRSA as well as two strains of epidemic MRSA (EMRSA-1 and EMRSA-16) on brass (C24000 with 80% Cu) at room temperature (22 °C) within three hours. Complete kills of the pathogens were observed within 4 1⁄2 hours. These tests were performed under wet exposure conditions. The kill timeframes, while impressive, are nevertheless longer than for pure copper, where kill timeframes ranged between 45 to 90 minutes.[17] A novel assay that mimics dry bacterial exposure to touch surfaces was developed because this test method is thought to more closely replicate real world touch surface exposure conditions. In these conditions, copper alloy surfaces were found to kill several million Colony Forming Units of Escherichia coli within minutes.[24] This observation, and the fact that kill timeframes shorten as the percentage of copper in an alloy increases, is proof that copper is the ingredient in brass and other copper alloys that kills the microbes.[25] The mechanisms of antimicrobial action by copper and its alloys, including brass, is a subject of intense and ongoing investigation.[16][24][26] It is believed that the mechanisms are multifaceted and include the following: 1) Potassium or glutamate leakage through the outer membrane of bacteria; 2) Osmotic balance disturbances; 3) Binding to proteins that do not require or utilize copper; 4) Oxidative stress by hydrogen peroxide generation. Research is being conducted at this time to determine whether brass, copper, and other copper alloys can help to reduce cross contamination in public facilities and reduce the incidence of nosocomial infections (hospital acquired infections) in healthcare facilities. Also, owing to its antimicrobial/algaecidal properties that prevent biofouling, in conjunction with its strong structural and corrosion-resistant benefits for marine environments, brass alloy netting cages are currently being deployed in commercial-scale aquaculture operations in Asia, South America, and the USA.