* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Commutator

Power inverter wikipedia , lookup

Current source wikipedia , lookup

Opto-isolator wikipedia , lookup

Mains electricity wikipedia , lookup

Loading coil wikipedia , lookup

Voltage optimisation wikipedia , lookup

Brushless DC electric motor wikipedia , lookup

Induction motor wikipedia , lookup

Protective relay wikipedia , lookup

Skin effect wikipedia , lookup

History of electric power transmission wikipedia , lookup

Galvanometer wikipedia , lookup

Stray voltage wikipedia , lookup

Utility pole wikipedia , lookup

Ignition system wikipedia , lookup

Transformer types wikipedia , lookup

Electric motor wikipedia , lookup

Alternating current wikipedia , lookup

Electric machine wikipedia , lookup

Magnetic core wikipedia , lookup

Buck converter wikipedia , lookup

Transformer wikipedia , lookup

Coil winding technology wikipedia , lookup

Resonant inductive coupling wikipedia , lookup

Stepper motor wikipedia , lookup

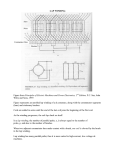

Design of Commutator and Brushes Commutator and brush arrangement are used to convert the bidirectional current to unidirectional current Brushes are located at the magnetic neutral axis ( mid way between two adjacent poles) The phenomenon of commutation is affected by resistance of the brush, reactance emf induced by leakage flux, emf induced by armature flux. Classification of commutation process Resistance commutation Retarded commutation Accelerated commutation Sinusoidal commutation Commutator is of cylindrical in shape and placed at one end of the armature Consists of number of copper bars or segments separated from one another by a suitable insulating material of thickness of 0.5 to 1mm Number of commutator segments = no. of coils in the armature Materials used : Commutator segments: Hard Drawn Copper or Aluminum Copper Insulation :Mica, Resin Bonded Asbestos Brushes :Natural Graphite, Hard Carbon , Electro Graphite, Metal Graphite Design formulae 1. No. of commutator segments, C = ½ u.S a where, u – coils sides/slot Sa – no. of armature slots 2. Minimum no. of segments = Ep/15 3. Commutator segment pitch = βc = πDc/C where, Commutator Diameter Dc – 60% to 80% of diameter of armature βc ≥ 4mm 4. Current carried by each brush Ib= 2Ia/P for lap winding Ib= Ia for wave winding 5. Total brush contact area/spindle Ab= Ib/δb 6. Number of brush locations are decided by the type of winding Lap winding: No of brush location = no. of poles Wave winding : No of brush location =2 7. Area of each individual brush should be chosen such that , it does not carry more than 70A Let , ab – Contact area of each brush nb – Number of brushes / spindle Contact area of brushes in a spindle, Ab = nb. ab also ab = wb.tb Ab = nb. wb.tb Usually, tb = (1 to 3) βc wb = Ab/ nb. Tb = ab/tb 8. Lc – depends on space required for mounting the brushes and to dissipate the heat generated by commutator losses Lc = nb(wb + Cb) + C1 + C2 where, Cb - Clearnace between brushes (5mm) C1 - Clearance allowed for staggering of brushes (10mm, 30mm) C2 – Clearance for allowing end play (10 to 25 mm) 9. Losses : Brush contact losses: depends on material, condition, quality of commutation Brush friction losses Brush friction loss Pbf = μ pb AB.Vc μ – Coefficient of friction pb-Brush contact pressure on commutator (N/m 2) AB - Total contact area of all brushes (m2) AB =P Ab (for lap winding) = 2 Ab (for wave winding) Vc – Peripheral speed of commutator (m/s) Design of Interpoles Interpoles: Small poles placed between main poles Materials Used: Cast steel (or) Punched from sheet steel without pole shoes Purposes: To neutralize cross magnetizing armature MMF To produce flux density required to generate rotational voltage in the coil undergoing commutation to cancel the reactance voltage. Since both effects related to armature current, interpole winding should be connected in series with armature winding Average reactance voltage of coil by Pitchelmayer’s Equation is, Erav = 2Tc ac Va.L .λ Inductance of a coil in armature =2Tc2 .L .λ Normally, Length of interpole = length of main pole Flux density under interpole, Bgi = ac. λ .(L/Lip) where, Lip- length of interpole In general, Bgi = 2 Iz. Zs. (L/Lip). (1/Va.Tc).λ mmf required to mmf required to over come ATi establish Bgi armature reaction MMF required to establish Bgi = 800000Bgi.Kgi.lgi MMF required to Iz .Z overcome 2P armature reaction ( without compensating winding) I .Z (1 - ) z AT 2P No.of turns i Ia ( with compensating winding) Current density in 2 , δi 2.5 to 4 A/mm interpole winding Area of X - section of Ia A ip interpole conductor, δi Losses and efficiency : 1. Iron Loss - i)Eddy current loss ii) Hysteresis loss 2. Rotational losses - Windage and friction losses 3. Variable or copper loss Condition for maximum efficiency : Constant Loss= Variable Loss