* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download 300W STEREO / 600W MONO PurePath HDTM ANALOG

Phone connector (audio) wikipedia , lookup

History of electric power transmission wikipedia , lookup

Stray voltage wikipedia , lookup

Negative feedback wikipedia , lookup

Solar micro-inverter wikipedia , lookup

Power over Ethernet wikipedia , lookup

Audio power wikipedia , lookup

Alternating current wikipedia , lookup

Flip-flop (electronics) wikipedia , lookup

Control system wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Power inverter wikipedia , lookup

Integrating ADC wikipedia , lookup

Oscilloscope history wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Analog-to-digital converter wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Voltage optimisation wikipedia , lookup

Voltage regulator wikipedia , lookup

Mains electricity wikipedia , lookup

Schmitt trigger wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Buck converter wikipedia , lookup

Power supply wikipedia , lookup

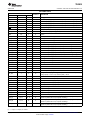

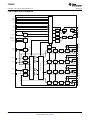

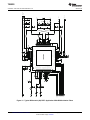

TAS5630 www.ti.com SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 300-W STEREO / 600-W MONO PurePath™ HD ANALOG-INPUT POWER STAGE Check for Samples: TAS5630 FEATURES APPLICATIONS • • • • • 1 23 • • • • • • PurePath™ HD Enabled Integrated Feedback Provides: – Signal Bandwidth up to 80 kHz for High-Frequency Content From HD Sources – Ultralow 0.03% THD at 1 W into 4 Ω – Flat THD at all Frequencies for Natural Sound – 80-dB PSRR (BTL, No Input Signal) – >100-dB (A-weighted) SNR – Click- and Pop-Free Start-Up Multiple Configurations Possible on the Same PCB With Stuffing Options: – Mono Parallel Bridge-Tied Load (PBTL) – Stereo Bridge-Tied Load (BTL) – 2.1 Single-Ended Stereo Pair and Bridge-Tied Load Subwoofer – Quad Single-Ended Outputs Total Output Power at 10% THD+N – 600 W in Mono PBTL Configuration – 300 W per Channel in Stereo BTL Configuration – 145 W per Channel in Quad Single-Ended Configuration High-Efficiency Power Stage (>88%) With 60-mΩ Output MOSFETs Two Thermally Enhanced Package Options: – PHD (64-Pin QFP) – DKD (44-Pin PSOP3) Self-Protection Design (Including Undervoltage, Overtemperature, Clipping, and Short-Circuit Protection) With Error Reporting EMI Compliant When Used With Recommended System Design Mini Combo System AV Receivers DVD Receivers Active Speakers DESCRIPTION The TAS5630 is a high-performance analog-input class-D amplifier with integrated closed-loop feedback technology (known as PurePath HD technology) with the ability to drive up to 300 W (1) stereo into 4-Ω to 8-Ω speakers from a single 50-V supply. PurePath HD technology enables traditional AB-amplifier performance (<0.03% THD) levels while providing the power efficiency of traditional class-D amplifiers. Unlike traditional class-D amplifiers, the distortion curve only increases once the output levels move into clipping. PurePath HD™ PurePath HD technology enables lower idle losses, making the device even more efficient. Coupled with TI’s class-G power-supply reference design for TAS563x, industry-leading levels of efficiency can be achieved. 3 ´ OPA1632 ♫♪ TM ANALOG AUDIO INPUT PurePath HD TAS5630 (2.1 Configuration) ♫♪ ♫♪ ±15 V 12 V 25 V–50 V TM PurePath HD Class-G Power Supply Ref. Design 110 VAC ® 240 VAC (1) Achievable output power levels are dependent on the thermal configuration of the target application. A high-performance thermal interface material between the exposed package heat slug and the heat sink should be used to achieve high output power levels. 1 2 3 Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet. PurePath HD is a trademark of Texas Instruments. All other trademarks are the property of their respective owners. PRODUCTION DATA information is current as of publication date. Products conform to specifications per the terms of the Texas Instruments standard warranty. Production processing does not necessarily include testing of all parameters. Copyright © 2009–2010, Texas Instruments Incorporated TAS5630 SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 www.ti.com These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam during storage or handling to prevent electrostatic damage to the MOS gates. DEVICE INFORMATION Terminal Assignment The TAS5630 is available in two thermally enhanced packages: • 64-Pin QFP (PHD) power package • 44-Pin PSOP3 package (DKD) The package types contain heat slugs that are located on the top side of the device for convenient thermal coupling to the heat sink. DKD PACKAGE (TOP VIEW) 64-pins QFP package 48 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33 GND_A GND_B GND_B OUT_B OUT_B PVDD_B PVDD_B BST_B BST_C PVDD_C PVDD_C OUT_C OUT_C GND_C GND_C GND_D OTW2 CLIP READY M1 M2 M3 GND GND GVDD_C GVDD_D BST_D OUT_D OUT_D PVDD_D PVDD_D GND_D 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 PSU_REF VDD OC_ADJ RESET C_STARTUP INPUT_A INPUT_B VI_CM GND AGND VREG INPUT_C INPUT_D FREQ_ADJ OSC_IO+ OSC_IOSD OTW READY M1 M2 M3 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 44 pins PACKAGE (TOP VIEW) OC_ADJ RESET C_STARTUP INPUT_A INPUT_B VI_CM GND AGND VREG INPUT_C INPUT_D FREQ_ADJ OSC_IO+ OSC_IOSD OTW1 64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49 VDD PSU_REF NC NC NC NC GND GND GVDD_B GVDD_A BST_A OUT_A OUT_A PVDD_A PVDD_A GND_A PHD PACKAGE (TOP VIEW) 44 43 42 41 40 39 38 37 36 35 34 33 32 31 30 29 28 27 26 25 24 23 GVDD_AB BST_A PVDD_A PVDD_A OUT_A OUT_A GND_A GND_B OUT_B PVDD_B BST_B BST_C PVDD_C OUT_C GND_C GND_D OUT_D OUT_D PVDD_D PVDD_D BST_D GVDD_CD PIN ONE LOCATION PHD PACKAGE Electrical Pin 1 Pin 1 Marker White Dot 2 Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated Product Folder Link(s): TAS5630 TAS5630 www.ti.com SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 MODE SELECTION PINS MODE PINS ANALOG INPUT OUTPUT CONFIGURATION 0 Differential 2 × BTL AD mode 1 — — Reserved 0 Differential 2 × BTL BD mode 1 × BTL +2 ×SE 4 × SE M3 M2 M1 0 0 0 0 0 1 0 1 1 Differential single-ended 1 0 0 Single-ended DESCRIPTION BD mode, BTL differential AD mode INPUT_C 1 (1) 0 1 1 1 0 1 1 1 Differential 1 × PBTL (1) INPUT_D (1) 0 0 AD mode 1 0 BD mode Reserved INPUT_C and D are used to select between a subset of AD and BD mode operations in PBTL mode (1=VREG and 0=AGND). PACKAGE HEAT DISSIPATION RATINGS (1) PARAMETER TAS5630PHD RqJC (°C/W) – 2 BTL or 4 SE channels 2.63 1.4 RqJC (°C/W) – 1 BTL or 2 SE channel(s) 4.13 2.04 RqJC (°C/W) – 1 SE channel Pad area (1) (2) (2) TAS5630DKD 6.45 3.45 64 mm2 80 mm2 RqJC is junction-to-case, RqCH is case-to-heat sink RqCH is an important consideration. Assume a 2-mil (0.051-mm) thickness of thermal grease with a thermal conductivity of 2.5 W/mK between the pad area and the heat sink and both channels active. The RqCH with this condition is 1.1°C/W for the PHD package and 0.44°C/W for the DKD package. Table 1. ORDERING INFORMATION (1) (1) TA PACKAGE DESCRIPTION 0°C–70°C TAS5630PHD 64-pin HTQFP 0°C–70°C TAS5630DKD 44-pin PSOP3 For the most current package and ordering information, see the Package Option Addendum at the end of this document, or see the TI website at www.ti.com. Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated Product Folder Link(s): TAS5630 3 TAS5630 SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 www.ti.com ABSOLUTE MAXIMUM RATINGS over operating free-air temperature range unless otherwise noted (1) VALUE UNIT VDD to AGND –0.3 to 13.2 V GVDD to AGND –0.3 to 13.2 V –0.3 to 69 V PVDD_X to GND_X (2) OUT_X to GND_X (2) –0.3 to 69 V –0.3 to 82.2 V BST_X to GVDD_X (2) –0.3 to 69 V VREG to AGND –0.3 to 4.2 V GND_X to GND –0.3 to 0.3 V GND_X to AGND –0.3 to 0.3 V OC_ADJ, M1, M2, M3, OSC_IO+, OSC_IO–, FREQ_ADJ, VI_CM, C_STARTUP, PSU_REF to AGND –0.3 to 4.2 V INPUT_X –0.3 to 5 V RESET, SD, OTW1, OTW2, CLIP, READY to AGND –0.3 to 7 V BST_X to GND_X (2) Continuous sink current (SD, OTW1, OTW2, CLIP, READY) Operating junction temperature range, TJ Storage temperature, Tstg Electrostatic discharge (1) (2) (3) Human-body model (3) (all pins) Charged-device model (3) (all pins) 9 mA 0 to 150 °C –40 to 150 °C ±2 kV ±500 V Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings only, and functional operation of the device at these or any other conditions beyond those indicated under Recommended Operating Conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability. These voltages represents the dc voltage + peak ac waveform measured at the terminal of the device in all conditions. Failure to follow good anti-static ESD handling during manufacture and rework contributes to device malfunction. Ensure operators handling the device are adequately grounded through the use of ground straps or alternative ESD protection. RECOMMENDED OPERATING CONDITIONS over operating free-air temperature range (unless otherwise noted) MAX UNIT PVDD_x Half-bridge supply DC supply voltage MIN NOM 25 50 52.5 V GVDD_x Supply for logic regulators and gate-drive circuitry DC supply voltage 10.8 12 13.2 V VDD Digital regulator supply voltage DC supply voltage 10.8 12 13.2 V 3.5 4 1.8 2 1.6 2 7 10 7 15 7 10 Nominal 385 400 415 AM1 315 333 350 AM2 260 300 335 RL(BTL) RL(SE) Output filter according to schematics in the application information section Load impedance RL(PBTL) LOUTPUT(BTL) LOUTPUT(SE) Output filter inductance Minimum output inductance at IOC LOUTPUT(PBTL) PWM frame rate selectable for AM interference avoidance; 1% resistor tolerance. fPWM Nominal; master mode RFREQ_ADJ PWM frame-rate-programming resistor VFREQ_ADJ Voltage on FREQ_ADJ pin for slave mode operation TJ Junction temperature 4 Ω mH 9.9 10 10.1 AM1; master mode 19.8 20 20.2 AM2; master mode 29.7 30 30.3 Slave mode 3.3 0 Submit Documentation Feedback kHz kΩ V 150 °C Copyright © 2009–2010, Texas Instruments Incorporated Product Folder Link(s): TAS5630 TAS5630 www.ti.com SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 PIN FUNCTIONS PIN Function (1) DESCRIPTION 10 P Analog ground 54 43 P HS bootstrap supply (BST), external 0.033-mF capacitor to OUT_A required. 41 34 P HS bootstrap supply (BST), external 0.033-mF capacitor to OUT_B required. BST_C 40 33 P HS bootstrap supply (BST), external 0.033-mF capacitor to OUT_C required. BST_D 27 24 P HS bootstrap supply (BST), external 0.033-mF capacitor to OUT_D required. CLIP 18 — O Clipping warning; open drain; active-low C_STARTUP 3 5 O Start-up ramp requires a charging capacitor of 4.7 nF to AGND in BTL mode FREQ_ADJ 12 14 I PWM frame-rate-programming pin requires resistor to AGND 7, 23, 24, 57, 58 9 P Ground GND_A 48, 49 38 P Power ground for half-bridge A GND_B 46, 47 37 P Power ground for half-bridge B GND_C 34, 35 30 P Power ground for half-bridge C GND_D 32, 33 29 P Power ground for half-bridge D GVDD_A 55 — P Gate-drive voltage supply requires 0.1-mF capacitor to GND_A GVDD_B 56 — P Gate drive voltage supply requires 0.1-mF capacitor to GND_B GVDD_C 25 — P Gate drive voltage supply requires 0.1-mF capacitor to GND_C GVDD_D 26 — P Gate drive voltage supply requires 0.1-mF capacitor to GND_D GVDD_AB — 44 P Gate drive voltage supply requires 0.22-mF capacitor to GND_A/GND_B GVDD_CD — 23 P Gate drive voltage supply requires 0.22-mF capacitor to GND_C/GND_D INPUT_A 4 6 I Input signal for half-bridge A INPUT_B 5 7 I Input signal for half-bridge B INPUT_C 10 12 I Input signal for half-bridge C INPUT_D 11 13 I Input signal for half-bridge D M1 20 20 I Mode selection M2 21 21 I Mode selection M3 22 22 I Mode selection NC 59–62 – — No connect; pins may be grounded. OC_ADJ 1 3 O Analog overcurrent-programming pin requires resistor to AGND. 64-pin package (PHD) = 22 kΩ. 44-pin PSOP3 (DKD) = 24 kΩ OSC_IO+ 13 15 I/O Oscillator master/slave output/input OSC_IO– 14 16 I/O Oscillator master/slave output/input OTW — 18 O Overtemperature warning signal, open-drain, active-low OTW1 16 — O Overtemperature warning signal, open-drain, active-low OTW2 17 — O Overtemperature warning signal, open-drain, active-low OUT_A 52, 53 39, 40 O Output, half-bridge A OUT_B 44, 45 36 O Output, half-bridge B OUT_C 36, 37 31 O Output, half-bridge C OUT_D 28, 29 27, 28 O Output, half-bridge D 63 1 P PSU reference requires close decoupling of 330 pF to AGND. PVDD_A 50, 51 41, 42 P Power-supply input for half-bridge A requires close decoupling of 0.01-mF capacitor in parallel with 2.2-mF capacitor to GND_A. PVDD_B 42, 43 35 P Power-supply input for half-bridge B requires close decoupling of 0.01-mF capacitor in parallel with 2.2-mF capacitor to GND_B. PVDD_C 38, 39 32 P Power-supply input for half-bridge C requires close decoupling of 0.0- mF capacitor in parallel with 2.2-mF capacitor to GND_C. NAME PHD NO. DKD NO. AGND 8 BST_A BST_B GND PSU_REF (1) I = Input, O = Output, P = Power Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated Product Folder Link(s): TAS5630 5 TAS5630 SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 www.ti.com PIN FUNCTIONS (continued) PIN NAME Function (1) DESCRIPTION PHD NO. DKD NO. 30, 31 25, 26 P Power-supply input for half-bridge D requires close decoupling of 0.01-mF capacitor in parallel with 2.2-mF capacitor to GND_D. READY 19 19 O Normal operation; open-drain; active-high RESET 2 4 I Device reset input; active-low SD 15 17 O Shutdown signal, open-drain, active-low VDD 64 2 P Power supply for digital voltage regulator requires a 10-mF capacitor in parallel with a 0.1-mF capacitor to GND for decoupling. VI_CM 6 8 O Analog comparator reference node requires close decoupling of 1 nF to AGND. VREG 9 11 P Digital regulator supply filter pin requires 0.1-mF capacitor to AGND. PVDD_D 6 Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated Product Folder Link(s): TAS5630 TAS5630 www.ti.com SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 TYPICAL SYSTEM BLOCK DIAGRAM ANALOG_IN_B OSC_IO- BST_A VI_CM /CLIP READY BST_B OUT_A INPUT_A Input DC Blocking Caps ANALOG_IN_A OSC_IO+ C_STARTUP Oscillator Synchronization /OTW1, /OTW2, /OTW /SD /RESET (2) PSU_REF Caps for External Filtering & Startup/Stop System microcontroller or Analog circuitry Input H-Bridge 1 INPUT_B Output H-Bridge 1 2 OUT_B 2 Hardwire PWM Frame Rate Adjust & Master/Slave Mode ANALOG_IN_D nd OUT_C Output H-Bridge 2 Input H-Bridge 2 INPUT_D 2 OUT_D 8 50V PVDD 12V PVDD Power Supply Decoupling SYSTEM Power Supplies GND 8 BST_D OC_ADJ VREG AGND VDD M3 2 Order L-C Output Filter for each H-Bridge BST_C GND M2 GND_A, B, C, D PVDD_A, B, C, D M1 GVDD_A, B, C, D 2 Hardwire Mode Control nd 2 Order L-C Output Filter for each H-Bridge 2-CHANNEL H -BRIDGE BTL MODE INPUT_C Input DC Blocking Caps ANALOG_IN_C FREQ_ADJ Bootstrap Caps Bootstrap Caps 4 GVDD, VDD, & VREG Power Supply Decoupling Hardwire OverCurrent Limit GND GVDD (12V)/VDD (12V) VAC Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated Product Folder Link(s): TAS5630 7 TAS5630 SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 www.ti.com FUNCTIONAL BLOCK DIAGRAM /CLIP READY /OTW1 /OTW2 /SD PROTECTION & I/O LOGIC M1 M2 M3 /RESET C_STARTUP VDD POWER-UP RESET UVP VREG VREG AGND TEMP SENSE STARTUP CONTROL GVDD_A GVDD _C GVDD_B OVER-LOAD PROTECTION GND GVDD_D CURRENT SENSE CB3C OC_ADJ OSC_SYNC_IO+ OSC_SYNC_IO- 4 OSCILLATOR PPSC FREQ_ADJ 4 4 PVDD_X OUT_X GND_X GVDD_A PWM ACTIVITY DETECTOR 4 PSU_REF BST_A PVDD_A PVDD_X PSU_FF VI_CM GND PWM RECEIVER CONTROL TIMING CONTROL GATE-DRIVE OUT_A GND_A GVDD_B INPUT_A BST_B ANALOG LOOP FILTER + PVDD_B + ANALOG LOOP FILTER - + ANALOG COMPARATOR MUX INPUT_C ANALOG LOOP FILTER ANALOG INPUT MUX INPUT_B PWM RECEIVER CONTROL TIMING CONTROL GATE-DRIVE OUT_B GND_B GVDD_C BST_C PVDD_C PWM RECEIVER CONTROL TIMING CONTROL GATE-DRIVE OUT_C + INPUT_D ANALOG LOOP FILTER GND_C - GVDD_D BST_D PVDD_D PWM RECEIVER CONTROL TIMING CONTROL GATE-DRIVE OUT_D GND_D 8 Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated Product Folder Link(s): TAS5630 TAS5630 www.ti.com SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 AUDIO CHARACTERISTICS (BTL) PCB and system configuration are in accordance with recommended guidelines. Audio frequency = 1 kHz, PVDD_X = 50 V, GVDD_X = 12 V, RL = 4 Ω, fS = 400 kHz, ROC = 22 kΩ, TC = 75°C; output filter: LDEM = 7 mH, CDEM = 680 nF, MODE = 010, unless otherwise noted. PARAMETER PO TEST CONDITIONS Power output per channel MIN TYP MAX RL = 4 Ω, 10% THD+N, clipped output signal 300 RL = 6 Ω, 10% THD+N, clipped output signal 210 RL = 8 Ω, 10% THD+N, clipped output signal 160 RL = 4 Ω, 1% THD+N, unclipped output signal 240 RL = 6 Ω, 1% THD+N, unclipped output signal 160 RL = 8 Ω, 1% THD+N, unclipped output signal UNIT W 125 THD+N Total harmonic distortion + noise 1W Vn Output integrated noise A-weighted, AES17 filter, input capacitor grounded |VOS| Output offset voltage Inputs ac-coupled to AGND SNR Signal-to-noise ratio (1) A-weighted, AES17 filter 100 dB DNR Dynamic range A-weighted, AES17 filter 100 dB Pidle Power dissipation due to idle losses (IPVDD_X) PO = 0, four channels switching (2) 2.7 W (1) (2) 0.03% 270 40 mV 150 mV SNR is calculated relative to 1% THD+N output level. Actual system idle losses also are affected by core losses of output inductors. AUDIO SPECIFICATION (Single-Ended Output) PCB and system configuration are in accordance with recommended guidelines. Audio frequency = 1kHz, PVDD_X = 50 V, GVDD_X = 12 V, RL = 4 Ω, fS = 400 kHz, ROC = 22 kΩ, TC = 75°C; output filter: LDEM = 15 mH, CDEM = 470 mF, MODE = 100, unless otherwise noted. PARAMETER PO TEST CONDITIONS Power output per channel MIN TYP MAX RL = 2 Ω, 10% THD+N, clipped output signal 145 RL = 3 Ω, 10% THD+N, clipped output signal 100 RL = 4 Ω, 10% THD+N, clipped output signal 75 RL = 2 Ω, 1% THD+N, unclipped output signal 110 RL = 3 Ω, 1% THD+N, unclipped output signal 75 RL = 4 Ω, 1% THD+N, unclipped output signal 55 UNIT W THD+N Total harmonic distortion + noise 1W Vn Output integrated noise A-weighted, AES17 filter, input capacitor grounded 340 mV SNR Signal-to-noise ratio (1) A-weighted, AES17 filter 93 dB DNR Dynamic range A-weighted, AES17 filter 93 dB 2 W Pidle (1) (2) Power dissipation due to idle losses (IPVDD_X) PO = 0, four channels switching 0.07% (2) SNR is calculated relative to 1% THD+N output level. Actual system idle losses are affected by core losses of output inductors. Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated Product Folder Link(s): TAS5630 9 TAS5630 SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 www.ti.com AUDIO SPECIFICATION (PBTL) PCB and system configuration are in accordance with recommended guidelines. Audio frequency = 1 kHz, PVDD_X = 50 V, GVDD_X = 12 V, RL = 2 Ω, fS = 400 kHz, ROC = 22 kΩ, TC = 75°C; output filter: LDEM = 7 mH, CDEM = 1.5 mF, MODE = 101-10, unless otherwise noted. PARAMETER PO TEST CONDITIONS Power output per channel MIN TYP MAX RL = 2 Ω, 10% THD+N, clipped output signal 600 RL = 3 Ω, 10% THD+N, clipped output signal 400 RL = 4 Ω, 10% THD+N, clipped output signal 300 RL = 2 Ω, 1% THD+N, unclipped output signal 480 RL = 3 Ω, 1% THD+N, unclipped output signal 310 RL = 4 Ω, 1% THD+N, unclipped output signal UNIT W 230 THD+N Total harmonic distortion + noise 1W Vn Output integrated noise A-weighted 260 mV A-weighted 100 dB A-weighted 100 dB 2.7 W (1) 0.05% SNR Signal to noise ratio DNR Dynamic range Pidle Power dissipation due to idle losses (IPVDD_X) PO = 0, four channels switching (2) (1) (2) SNR is calculated relative to 1% THD-N output level. Actual system idle losses are affected by core losses of output inductors. ELECTRICAL CHARACTERISTICS PVDD_X = 50 V, GVDD_X = 12 V, VDD = 12 V, TC (Case temperature) = 75°C, fS = 400 kHz, unless otherwise specified. PARAMETER TEST CONDITIONS MIN TYP MAX UNIT INTERNAL VOLTAGE REGULATOR AND CURRENT CONSUMPTION VREG Voltage regulator, only used as reference node, VREG VI_CM Analog comparator reference node, VI_CM IVDD VDD supply current IGVDD_X GVDD_x gate-supply current per half-bridge IPVDD_X Half-bridge supply current VDD = 12 V 3 3.3 3.6 V 1.5 1.75 1.9 V Operating, 50% duty cycle 22.5 Idle, reset mode 22.5 50% duty cycle 12.5 Reset mode mA mA 1.5 50% duty cycle with recommended output filter 13.3 mA Reset mode, No switching 870 mA 33 kΩ ANALOG INPUTS RIN Input resistance READY = HIGH VIN Maximum input voltage swing 5 V IIN Maximum input current 342 mA G Voltage gain (VOUT/VIN) 23 dB OSCILLATOR Nominal, master mode fOSC_IO+ AM1, master mode FPWM × 10 AM2, master mode VIH High level input voltage VIL Low level input voltage 3.85 4 3.15 3.33 4.15 3.5 2.6 3 3.35 1.86 MHz V 1.45 V 60 100 mΩ 60 100 mΩ OUTPUT-STAGE MOSFETs RDS(on) 10 Drain-to-source resistance, low side (LS) Drain-to-source resistance, high side (HS) TJ = 25°C, excludes metallization resistance, GVDD = 12 V Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated Product Folder Link(s): TAS5630 TAS5630 www.ti.com SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 ELECTRICAL CHARACTERISTICS (continued) PVDD_X = 50 V, GVDD_X = 12 V, VDD = 12 V, TC (Case temperature) = 75°C, fS = 400 kHz, unless otherwise specified. PARAMETER TEST CONDITIONS MIN TYP MAX UNIT I/O PROTECTION Undervoltage protection limit, GVDD_x and VDD Vuvp,G Vuvp,hyst (1) 9.5 V 0.6 V (1) Overtemperature warning 1 95 100 105 °C OTW2 (1) Overtemperature warning 2 115 125 135 °C OTWhyst Temperature drop needed below OTW temperature for OTW to be inactive after OTW event OTW1 (1) 25 Overtemperature error OTE (1) 145 155 °C 165 °C OTE-OTW differential 30 °C A reset must occur for SD to be released following an OTE event. 25 °C fPWM = 400 kHz 2.6 ms Resistor – programmable, nominal peak current in 1-Ω load, 64-pin QFP package (PHD) ROCP = 22 kΩ 19 A Resistor – programmable, nominal peak current in 1-Ω load, 44-Pin PSOP3 package (DKD), ROCP = 24 kΩ 19 A Overcurrent limit protection, latched Resistor – programmable, nominal peak current in 1-Ω load, ROCP = 47 kΩ 19 A IOCT Overcurrent response time Time from switching transition to flip-state induced by overcurrent 150 ns IPD Internal pulldown resistor at output of each half-bridge Connected when RESET is active to provide bootstrap charge. Not used in SE mode 3 mA OTEhyst (1) OLPC Overload protection counter Overcurrent limit protection IOC STATIC DIGITAL SPECIFICATIONS VIH High-level input voltage VIL Low-level input voltage Ilkg Input leakage current INPUT_X, M1, M2, M3, RESET 2 V 0.8 V 100 mA kΩ OTW/SHUTDOWN (SD) RINT_PU Internal pullup resistance, OTW1 to VREG, OTW2 to VREG, SD to VREG VOH High-level output voltage VOL Low-level output voltage IO = 4 mA FANOUT Device fanout OTW1, OTW2, SD, CLIP, READY No external pullup (1) Internal pullup resistor External pullup of 4.7 kΩ to 5 V 20 26 32 3 3.3 3.6 4.5 V 5 200 30 500 mV devices Specified by design. Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated Product Folder Link(s): TAS5630 11 TAS5630 SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 www.ti.com TYPICAL CHARACTERISTICS, BTL CONFIGURATION TOTAL HARMONIC+NOISE vs OUTPUT POWER OUTPUT POWER vs SUPPLY VOLTAGE THD+N - Total Harmonic Distortion + Noise - % 10 TC = 75°C 5 PO - Output Power - W 2 1 0.5 0.2 4W 0.1 6W 0.05 0.02 8W 0.01 0.005 20m 100m200m 1 2 5 10 20 50 100 PO - Output Power - W 400 8W 120 100 80 60 40 20 0 25 30 35 40 45 PVDD - Supply Voltage - V SYSTEM EFFICIENCY vs OUTPUT POWER TC = 75°C 4W 220 200 6W 180 Efficiency - % PO - Output Power - W 6W UNCLIPPED OUTPUT POWER vs SUPPLY VOLTAGE 240 160 8W 140 120 100 80 60 40 30 35 40 45 PVDD - Supply Voltage - V 50 100 95 90 85 80 75 70 65 60 55 50 45 40 35 30 25 20 15 10 5 0 8W 6W 50 4W TC = 25°C THD+N at 10% 0 Figure 3. 12 4W Figure 2. 260 20 0 25 TC = 75°C THD+N at 10% Figure 1. 300 280 340 320 300 280 260 240 220 200 180 160 140 100 500 200 300 400 600 2 Channel Output Power - W 700 Figure 4. Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated Product Folder Link(s): TAS5630 TAS5630 www.ti.com SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 TYPICAL CHARACTERISTICS, BTL CONFIGURATION (continued) SYSTEM POWER LOSS vs OUTPUT POWER 80 75 70 OUTPUT POWER vs CASE TEMPERATURE 340 320 300 TC = 25°C THD+N at 10% 65 Power Loss - W PO - Output Power - W 4W 60 55 50 45 40 6W 35 30 25 20 15 10 5 0 8W 0 100 200 300 400 500 2 Channel Output Power - W 600 280 260 240 220 200 180 160 140 120 100 80 60 40 20 0 10 4W 6W 8W THD+N at 10% 20 Figure 5. 30 40 50 60 70 80 90 100 110 120 TC - Case Temperature - °C Figure 6. NOISE AMPLITUDE vs FREQUENCY +0 -10 -20 Noise Amplitude - dB -30 -40 -50 TC = 75°C, VREF = 31.9 V, Sample Rate = 48 kHz, FFT Size = 16384 -60 -70 -80 -90 -100 -110 -120 4W -130 -140 -150 -160 0k 2k 4k 6k 8k 10k 12k 14k 16k 18k 20k 22k f - Frequency - Hz Figure 7. Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated Product Folder Link(s): TAS5630 13 TAS5630 SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 www.ti.com TYPICAL CHARACTERISTICS, SE CONFIGURATION TOTAL HARMONIC DISTORTION + NOISE vs OUTPUT POWER OUTPUT POWER vs SUPPLY VOLTAGE 5 TC = 75°C 4W 2 3W PO - Output Power - W THD+N - Total Harmonic Distortion + Noise - % 10 1 2W 0.5 0.2 0.1 0.05 0.02 0.01 0.005 20m 200m 1 2 5 10 20 PO - Output Power - W 50 100 170 160 TC = 75°C 150 THD+N at 10% 2W 140 130 3W 120 110 100 4W 90 80 70 60 50 40 30 20 10 0 25 30 35 40 45 PVDD - Supply Voltage - V Figure 8. 50 Figure 9. PO - Output Power - W OUTPUT POWER vs CASE TEMPERATURE 14 180 170 160 150 140 130 120 110 100 90 80 70 60 50 40 30 20 10 0 10 2W 3W 4W THD+N at 10% 20 30 40 50 60 70 80 90 100 110 120 TC - Case Temperature - °C Figure 10. Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated Product Folder Link(s): TAS5630 TAS5630 www.ti.com SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 TYPICAL CHARACTERISTICS, PBTL CONFIGURATION TOTAL HARMONIC DISTORTION + NOISE vs OUTPUT POWER OUTPUT POWER vs SUPPLY VOLTAGE 5 650 TC = 75°C 2W TC = 75°C THD+N at 10% 2W 550 3W 2 3W 500 4W 1 0.5 0.2 600 PO - Output Power - W THD+N - Total Harmonic Distortion + Noise - % 10 6W 8W 0.1 0.05 450 4W 400 6W 350 8W 300 250 200 150 0.02 100 0.01 0.005 20m 50 0 25 100m 200m 1 2 5 10 20 50 100 200 700 PO - Output Power - W 30 35 40 45 PVDD - Supply Voltage - V Figure 11. 50 Figure 12. OUTPUT POWER vs CASE TEMPERATURE 700 2W 650 THD+N at 10% 600 PO - Output Power - W 550 500 3W 450 400 4W 350 300 6W 250 8W 200 150 100 50 0 10 20 30 40 50 60 70 80 90 100 110 120 TC - Case Temperature - °C Figure 13. Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated Product Folder Link(s): TAS5630 15 TAS5630 SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 www.ti.com APPLICATION INFORMATION PCB MATERIAL RECOMMENDATION FR-4 2-oz. (70-mm) glass epoxy material is recommended for use with the TAS5630. The use of this material can provide for higher power output, improved thermal performance, and better EMI margin (due to lower PCB trace inductance). PVDD CAPACITOR RECOMMENDATION The large capacitors used in conjunction with each full bridge are referred to as the PVDD capacitors. These capacitors should be selected for proper voltage margin and adequate capacitance to support the power requirements. In practice, with a well-designed system power supply, 1000 mF, 63-V supports more applications. The PVDD capacitors should be the low-ESR type, because they are used in a circuit associated with high-speed switching. DECOUPLING CAPACITOR RECOMMENDATIONS To design an amplifier that has robust performance, passes regulatory requirements, and exhibits good audio performance, quality decoupling capacitors should be used. In practice, X7R should be used in this application. The voltage of the decoupling capacitors should be selected in accordance with good design practices. Temperature, ripple current, and voltage overshoot must be considered. This fact is particularly true in the selection of the 2.2-mF capacitor that is placed on the power supply to each half-bridge. It must withstand the voltage overshoot of the PWM switching, the heat generated by the amplifier during high power output, and the ripple current created by high power output. A minimum voltage rating of 63 V is required for use with a 50-V power supply. SYSTEM DESIGN RECOMMENDATIONS The following schematics and PCB layouts illustrate best practices used for the TAS5630. 16 Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated Product Folder Link(s): TAS5630 R_RIGHT_N IN_RIGHT_P IN_LEFT_N IN_LEFT_P /RESET 10uF C16 10uF C14 10uF C12 10uF C10 C17 100pF C15 100pF C13 100pF C11 100pF C18 100pF READY /CLIP GND GND R19 47k GND GND GND GND GND 10k R21 100nF C22 VREG 1nF C21 4.7nF 22.0k C20 R20 330pF GND 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 /OTW1 /SD OSC_IO- OSC_IO+ FREQ_ADJ INPUT_D INPUT_C VREG AGND GND VI_CM INPUT_B INPUT_A C_STARTUP /RESET OC_ADJ GND C30 100nF GND 3.3R GND VREG 57 U10 TAS5630PHD C31 100nF 58 C33 100nF GND C40 33nF GND GND C32 100nF 3.3R 3.3R R33 R32 C43 33nF C63 2.2uF GND_D GND_C GND_C OUT_C OUT_C PVDD_C PVDD_C BST_C BST_B PVDD_B PVDD_B OUT_B OUT_B GND_B GND_B GND_A GND C60 2.2uF 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 GND C62 2.2uF C61 2.2uF GND L13 7uH 7uH L12 C42 33nF C41 33nF L11 7uH L10 7uH 1000uF C65 C53 680nF C52 680nF GND C51 680nF C50 680nF C72 1nF GND C73 1nF GND 1000uF C66 C71 1nF GND C70 1nF R73 3.3R C77 10nF C76 10nF R72 3.3R GND GND C68 47uF 63V R71 3.3R C75 10nF C74 10nF R70 3.3R GND C67 1000uF GND GND C69 2.2uF GND C64 1000uF GND PVDD GND PVDD GVDD/VDD (+12V) OUT_RIGHT_P + - GND OUT_RIGHT_M C78 10nF R74 3.3R OUT_LEFT_P + - OUT_LEFT_M PVDD GVDD/VDD (+12V) www.ti.com /OTW2 /OTW1 /SD OSC_IO- OSC_IO+ 100R R13 100R R12 100R R11 100R R10 100R R18 VREG GND C26 100nF 61 C23 C25 10uF 64 VDD /OTW2 17 63 PSU_REF /CLIP 18 62 19 NC READY 60 NC M1 20 GVDD_C R31 26 3.3R GVDD_D 54 BST_A BST_D 27 53 OUT_A OUT_D 28 56 GVDD_B 55 GVDD_A OUT_A OUT_D 29 52 30 51 PVDD_A PVDD_D 50 PVDD_A PVDD_D 49 GND_A GND_D 31 59 NC M2 21 NC M3 22 GND GND 23 GND GND 24 Product Folder Link(s): TAS5630 25 Copyright © 2009–2010, Texas Instruments Incorporated 32 R30 TAS5630 SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 Figure 14. Typical Differential-Input BTL Application With BD Modulation Filters Submit Documentation Feedback 17 READY /CLIP /OTW2 /OTW1 /SD OSC_IO- OSC_IO+ IN_N IN_P /RESET 10uF 10uF 100R 100R 100R GND GND GND 100pF 100pF 100pF GND VREG 47k VREG GND GND GND GND GND 10k 100nF 1nF 4.7nF 22.0k VREG GND GND 1 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 GND GND 100nF /OTW1 /SD OSC_IO- OSC_IO+ FREQ_ADJ INPUT_D INPUT_C VREG AGND GND VI_CM INPUT_B INPUT_A C_STARTUP /RESET OC_ADJ 330pF 10uF 64 VDD /OTW2 17 63 PSU_REF /CLIP 18 62 19 61 100nF NC READY 60 NC 20 NC GND 100nF GND GND GND 59 100nF VREG GND 3.3R 33nF GND GND 100nF TAS5630PHD NC M3 22 M1 58 GND GND 23 M2 56 GVDD_B GVDD_C 3.3R 3.3R 33nF 3.3R GVDD_D 26 54 BST_A BST_D 27 57 GND GND 24 Product Folder Link(s): TAS5630 25 Submit Documentation Feedback 21 55 GVDD_A OUT_A OUT_D 28 53 OUT_A OUT_D 29 52 30 51 PVDD_A PVDD_D 49 GND_A GND_D 50 PVDD_A PVDD_D 31 18 32 VDD (+12V) 2.2uF 100V GND_D GND_C GND_C OUT_C OUT_C PVDD_C PVDD_C BST_C BST_B PVDD_B PVDD_B OUT_B OUT_B GND_B GND_B GND_A GND 2.2uF 100V 48 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 GND 2.2uF 100V 2.2uF 100V GND 33nF 33nF 7uH 7uH 7uH 7uH 1000uF 63V 1000uF 63V 1uF 250V GND 1uF 250V 1000uF 63V 1000uF 63V GND GND 1nF 100V 1nF 100V GND GND 47uF 63V GND 3.3R 10nF 100V 10nF 100V 3.3R GND 10nF 100V + GVDD (+12V) PVDD OUT_LEFT_P GND OUT_LEFT_M GND 2.2uF 100V 3.3R PVDD GVDD (+12V) TAS5630 SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 www.ti.com Figure 15. Typical Differential (2N) PBTL Application With BD Modulation Filters Copyright © 2009–2010, Texas Instruments Incorporated READY /CLIP /OTW2 /OTW1 /SD OSC_IO- OSC_IO+ IN_D IN_C IN_B IN_A /RESET Copyright © 2009–2010, Texas Instruments Incorporated Product Folder Link(s): TAS5630 147kW 165kW 187kW 191kW 50V 49V 48V <48V GND GND GND GND R_COMP 100R 100R 100R GND 100pF 100pF 100pF 100pF 100pF PVDD PVDD C A Submit Documentation Feedback 470uF 50V 470uF 50V 470uF 50V 470uF 50V GND GND GND GND GND GND GND R_COMP R_COMP 10k 1% 10k 1% 10k 1% 10k 1% 10k 100nF 1nF 10nF 22.0k VREG GND 10k 10k GND 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 470nF 250V 470nF 250V /OTW1 /SD OSC_IO- OSC_IO+ 100nF 100V 100nF 100V 100nF 100V 100nF 100V FREQ_ADJ INPUT_D INPUT_C VREG AGND GND VI_CM INPUT_B INPUT_A C_STARTUP /RESET OC_ADJ 330pF 61 62 GND GND 10nF 100V 100V 10nF 3.3R 3.3R 10nF 100V 100V 10nF 3.3R 3.3R GND GND GND GND 100nF 54 GND GND OUT_C_P + - OUT_C_M GND GND OUT_A_P + - OUT_A_M 100nF VREG GND PVDD PVDD D B GND GND 100nF TAS5630PHD 52 3.3R 33nF 53 470uF 50V 470uF 50V 470uF 50V 470uF 50V 3.3R 3.3R 33nF 51 GND GND 1% 10k 1% 10k R_COMP 1% 10k 1% 10k R_COMP 2.2uF GND_D GND_C GND_C 10k 10k OUT_C OUT_C PVDD_C PVDD_C BST_C BST_B PVDD_B PVDD_B OUT_B OUT_B GND_B GND_B GND_A GND 2.2uF 48 47 33 34 35 36 37 38 39 40 41 42 43 44 45 46 470nF 250V 470nF 250V 100nF 100V 100nF 100V 100nF 100V 100nF 100V GND 2.2uF 2.2uF GND 33nF 33nF GND GND 10nF 100V 47uF 63V 100V 10nF 3.3R 3.3R 10nF 100V 100V 10nF 3.3R 3.3R 15uH 15uH 15uH 15uH GND GND OUT_D_P + - OUT_D_M GND GND OUT_B_P + - OUT_B_M GND GND 2.2uF GND 10nF 3.3R GVDD (+12V) D PVDD C PVDD B PVDD A GVDD (+12V) www.ti.com PVDD 10uF 10uF 10uF 10uF 100R 100R 47k GND GND 100nF 60 NC VREG 100nF 49 GND_A 3.3R 50 PVDD_A 10uF 64 VDD /OTW2 17 63 PSU_REF /CLIP 18 NC 19 59 NC M3 22 READY 58 GND GND 23 NC 20 57 GND GND 24 M1 56 GVDD_B GVDD_C 25 M2 21 55 GVDD_A GVDD_D 26 BST_A BST_D 27 OUT_A OUT_D 28 OUT_A OUT_D 29 PVDD_A PVDD_D 30 PVDD_D 31 GND_D 32 VDD (+12V) TAS5630 SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 Figure 16. Typical SE Application 19 READY /CLIP /OTW2 /OTW1 /SD OSC_IO- OSC_IO+ IN_RIGHT IN_LEFT IN_CENTER_N IN_CENTER_P /RESET 10uF 10uF 10uF 10uF 100R 100R 100R 100R 100R GND GND GND GND GND 100pF 100pF 100pF 100pF 100pF 47k VREG GND GND GND GND GND 10k 100nF VREG 1nF 10nF 22.0k GND GND 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 /OTW1 /SD OSC_IO- OSC_IO+ FREQ_ADJ INPUT_D INPUT_C VREG AGND GND VI_CM INPUT_B INPUT_A C_STARTUP /RESET OC_ADJ 330pF GND GND 100nF 64 VDD 10uF 100nF 61 VREG GND GND GND 100nF 57 59 GND 100nF GND 3.3R 33nF GND GND 100nF TAS5630PHD GND GND 63 18 /OTW2 17 PSU_REF /CLIP 56 GVDD_B GVDD_C 3.3R 3.3R 3.3R 33nF GVDD_D 26 VDD (+12V) 27 54 BST_A BST_D 53 OUT_A OUT_D 28 60 62 NC READY 19 NC M1 20 NC 21 NC M3 22 M2 55 GVDD_A OUT_A OUT_D 29 52 30 51 PVDD_A PVDD_D 50 PVDD_A PVDD_D 58 GND GND 23 Product Folder Link(s): TAS5630 24 Submit Documentation Feedback 25 49 GND_A GND_D 31 20 32 2.2uF 100V GND_D GND_C GND_C OUT_C OUT_C PVDD_C PVDD_C BST_C BST_B PVDD_B PVDD_B OUT_B OUT_B GND_B GND_B GND_A GND 2.2uF 100V 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 GND 2.2uF 100V 2.2uF 100V GND 15uH PVDD 15uH PVDD 33nF 33nF GND 10k 1% 10k 1% 10k 1% 470uF 50V 470uF 50V GND R_COMP 10k 1% 470uF 50V GND R_COMP GND 47uF 63V 470uF 50V 1000uF 63V GND 10k 10k 10nF 100V 3.3R GND 2.2uF 100V 7uH 680nF 250V GND 680nF 250V 7uH GND 470nF 250V GND GND 470nF 250V GND 100V 10nF 100nF 100V 100nF 100V 10nF 100V 100V 10nF 100nF 100V 100nF 100V 10nF 100V 1nF 100V 1nF 100V 1000uF 63V 3.3R GND 3.3R 3.3R GND 3.3R 3.3R 10nF 100V 10nF 100V 3.3R GND GVDD (+12V) PVDD OUT_RIGHT_P + - OUT_RIGHT_M OUT_LEFT_P + - OUT_LEFT_M PVDD OUT_CENTER_P GND + - OUT_CENTER_M PVDD GVDD (+12V) TAS5630 SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 www.ti.com Figure 17. Typical 2.1 System Differential-Input BTL and Unbalanced-Input SE Application Copyright © 2009–2010, Texas Instruments Incorporated Copyright © 2009–2010, Texas Instruments Incorporated Product Folder Link(s): TAS5630 READY /OTW 10uF 10uF 10uF 10uF 100R R60 100R R53 100R R54 100R R45 100R R13 C81 100pF C80 100pF C79 100pF C82 100pF GND C78 100pF VREG R44 47k GND GND GND GND GND GND R20 10k C86 100nF GND GND VREG 22 21 20 19 18 17 16 15 14 13 12 11 9 8 7 6 5 4 3 2 1 10 VREG GND 1nF GND C35 100nF C42 C85 4.7nF 24k C45 R14 330pF C44 10uF M3 M2 M1 READY /OTW /SD OSC_IO- OSC_IO+ GVDD_CD BST_D PVDD_D PVDD_D OUT_D OUT_D GND_D GND_C OUT_C PVDD_C BST_C BST_B PVDD_B OUT_B GND_B GND_A OUT_A OUT_A PVDD_A PVDD_A BST_A GVDD_AB TAS5630DKD FREQ_ADJ INPUT_D INPUT_C VREG AGND GND VI_CM INPUT_B INPUT_A C_STARTUP /RESET OC_ADJ VDD PSU_REF U12 100nF C89 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 R31 GND 100nF C84 33nF C88 1.5R 33nF 33nF GND C37 C41 GND 33nF C33 GND C87 100nF C34 2.2uF C91 2.2uF C90 2.2uF C83 2.2uF GND 7uH 680nF 250V GND GND 63V 1000uF 680nF 250V 7uH GND 63V 1000uF 7uH 680nF 250V GND 680nF 250V 7uH 1nF 100V 1nF 100V GND 1000uF 63V 47uF 63V 1nF 100V 1nF 100V 1000uF 63V GND 3.3R 10nF 100V 10nF 100V 3.3R GND GND + OUT_RIGHT_P GND OUT_RIGHT_M 10nF 100V 3.3R OUT_LEFT_P + - OUT_LEFT_M GND 2.2uF 100V 3.3R 10nF 100V 10nF 100V 3.3R GND GVDD (+12V) PVDD PVDD PVDD GVDD (+12V) www.ti.com /SD OSC_IO- OSC_IO+ IN_RIGHT_N IN_RIGHT_P IN_LEFT_N IN_LEFT_P /RESET VDD (+12V) C38 100nF R34 1.5R TAS5630 SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 Figure 18. Typical Differential-Input BTL Application With BD Modulation Filters, DKD Package Submit Documentation Feedback 21 TAS5630 SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 www.ti.com THEORY OF OPERATION POWER SUPPLIES To facilitate system design, the TAS5630 needs only a 12-V supply in addition to the (typical) 50-V power-stage supply. An internal voltage regulator provides suitable voltage levels for the digital and low-voltage analog circuitry. Additionally, all circuitry requiring a floating voltage supply, e.g., the high-side gate drive, is accommodated by built-in bootstrap circuitry requiring only an external capacitor for each half-bridge. To provide outstanding electrical and acoustical characteristics, the PWM signal path, including gate drive and output stage, is designed as identical, independent half-bridges. For this reason, each half-bridge has separate gate drive supply pins (GVDD_X), bootstrap pins (BST_X), and power-stage supply pins (PVDD_X). Furthermore, an additional pin (VDD) is provided as supply for all common circuits. Although supplied from the same 12-V source, it is highly recommended to separate GVDD_A, GVDD_B, GVDD_C, GVDD_D, and VDD on the printed-circuit board (PCB) by RC filters (see application diagram for details). These RC filters provide the recommended high-frequency isolation. Special attention should be paid to placing all decoupling capacitors as close to their associated pins as possible. In general, inductance between the power supply pins and decoupling capacitors must be avoided. (See reference board documentation for additional information.) For a properly functioning bootstrap circuit, a small ceramic capacitor must be connected from each bootstrap pin (BST_X) to the power-stage output pin (OUT_X). When the power-stage output is low, the bootstrap capacitor is charged through an internal diode connected between the gate-drive power-supply pin (GVDD_X) and the bootstrap pin. When the power-stage output is high, the bootstrap capacitor potential is shifted above the output potential and thus provides a suitable voltage supply for the high-side gate driver. In an application with PWM switching frequencies in the range from 300 kHz to 400 kHz, it is recommended to use 33-nF ceramic capacitors, size 0603 or 0805, for the bootstrap supply. These 33-nF capacitors ensure sufficient energy storage, even during minimal PWM duty cycles, to keep the high-side power stage FET (LDMOS) fully turned on during the remaining part of the PWM cycle. Special attention should be paid to the power-stage power supply; this includes component selection, PCB placement, and routing. As indicated, each half-bridge has independent power-stage supply pins (PVDD_X). For optimal electrical performance, EMI compliance, and system reliability, it is important that each PVDD_X pin is decoupled with a 2.2-mF ceramic capacitor placed as close as possible to each supply pin. It is recommended to follow the PCB layout of the TAS5630 reference design. For additional information on recommended power supply and required components, see the application diagrams in this data sheet. The 12-V supply should be from a low-noise, low-output-impedance voltage regulator. Likewise, the 50-V power-stage supply is assumed to have low output impedance and low noise. The power-supply sequence is not critical as facilitated by the internal power-on-reset circuit. Moreover, the TAS5630 is fully protected against erroneous power-stage turnon due to parasitic gate charging. Thus, voltage-supply ramp rates (dV/dt) are non-critical within the specified range (see the Recommended Operating Conditions table of this data sheet). SYSTEM POWER-UP/POWER-DOWN SEQUENCE Powering Up The TAS5630 does not require a power-up sequence. The outputs of the H-bridges remain in a high-impedance state until the gate-drive supply voltage (GVDD_X) and VDD voltage are above the undervoltage protection (UVP) voltage threshold (see the Electrical Characteristics table of this data sheet). Although not specifically required, it is recommended to hold RESET in a low state while powering up the device. This allows an internal circuit to charge the external bootstrap capacitors by enabling a weak pulldown of the half-bridge output. Powering Down The TAS5630 does not require a power-down sequence. The device remains fully operational as long as the gate-drive supply (GVDD_X) voltage and VDD voltage are above the undervoltage protection (UVP) voltage threshold (see the Electrical Characteristics table of this data sheet). Although not specifically required, it is a good practice to hold RESET low during power down, thus preventing audible artifacts including pops or clicks. 22 Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated Product Folder Link(s): TAS5630 TAS5630 www.ti.com SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 ERROR REPORTING The SD, OTW, OTW1 and OTW2 pins are active-low, open-drain outputs. Their function is for protection-mode signaling to a PWM controller or other system-control device. Any fault resulting in device shutdown is signaled by the SD pin going low. Likewise, OTW and OTW2 go low when the device junction temperature exceeds 125°C and OTW1 goes low when the junction temperature exceeds 100°C (see the following table). SD OTW1 OTW2, OTW 0 0 0 Overtemperature (OTE) or overload (OLP) or undervoltage (UVP) 0 0 1 Overload (OLP) or undervoltage (UVP). Junction temperature higher than 100°C (overtemperature warning) 0 1 1 Overload (OLP) or undervoltage (UVP) 1 0 0 Junction temperature higher than 125°C (overtemperature warning) 1 0 1 Junction temperature higher than 100°C (overtemperature warning) 1 1 1 Junction temperature lower than 100°C and no OLP or UVP faults (normal operation) DESCRIPTION Note that asserting either RESET low forces the SD signal high, independent of faults being present. TI recommends monitoring the OTW signal using the system microcontroller and responding to an overtemperature warning signal by, e.g., turning down the volume to prevent further heating of the device resulting in device shutdown (OTE). To reduce external component count, an internal pullup resistor to 3.3 V is provided on both SD and OTW outputs. Level compliance for 5-V logic can be obtained by adding external pullup resistors to 5 V (see the Electrical Characteristics table of this data sheet for further specifications). DEVICE PROTECTION SYSTEM The TAS5630 contains advanced protection circuitry carefully designed to facilitate system integration and ease of use, as well as to safeguard the device from permanent failure due to a wide range of fault conditions such as short circuits, overload, overtemperature, and undervoltage. The TAS5630 responds to a fault by immediately setting the power stage in a high-impedance (Hi-Z) state and asserting the SD pin low. In situations other than overload and overtemperature error (OTE), the device automatically recovers when the fault condition has been removed, i.e., the supply voltage has increased. The device functions on errors, as shown in the following table. BTL Mode Local error in A B C D PBTL Mode Turns Off or in A+B C+D Local error in Turns Off or in A B C SE Mode Local error in Turns Off or in A A+B+C+D D B C D A+B C+D Bootstrap UVP does not shut down according to the table; it shuts down the respective half-bridge. PIN-TO-PIN SHORT-CIRCUIT PROTECTION (PPSC) The PPSC detection system protects the device from permanent damage if a power output pin (OUT_X) is shorted to GND_X or PVDD_X. For comparison, the OC protection system detects an overcurrent after the demodulation filter, whereas PPSC detects shorts directly at the pin before the filter. PPSC detection is performed at startup, i.e., when VDD is supplied; consequently, a short to either GND_X or PVDD_X after system startup does not activate the PPSC detection system. When PPSC detection is activated by a short on the output, all half-bridges are kept in a Hi-Z state until the short is removed; the device then continues the startup sequence and starts switching. The detection is controlled globally by a two-step sequence. The first step ensures that there are no shorts from OUT_X to GND_X; the second step tests that there are no shorts from OUT_X to PVDD_X. The total duration of this process is roughly proportional to the capacitance of the output LC Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated Product Folder Link(s): TAS5630 23 TAS5630 SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 www.ti.com filter. The typical duration is <15 ms/mF. While the PPSC detection is in progress, SD is kept low, and the device does not react to changes applied to the RESET pins. If no shorts are present the PPSC detection passes, and SD is released, a device reset does not start a new PPSC detection. PPSC detection is enabled in BTL and PBTL output configurations; the detection is not performed in SE mode. To make sure the PPSC detection system is not tripped, it is recommended not to insert resistive load to GND_X or PVDD_X. OVERTEMPERATURE PROTECTION The two different package options have individual overtemperature protection schemes. PHD Package: The TAS5630 PHD package option has a three-level temperature-protection system that asserts an active-low warning signal (OTW1) when the device junction temperature exceeds 100°C (typical), (OTW2) when the device junction temperature exceeds 125°C (typical) and, if the device junction temperature exceeds 155°C (typical), the device is put into thermal shutdown, resulting in all half-bridge outputs being set in the high-impedance (Hi-Z) state and SD being asserted low. OTE is latched in this case. To clear the OTE latch, RESET must be asserted. Thereafter, the device resumes normal operation. DKD Package: The TAS5630 DKD package option has a two-level temperature-protection system that asserts an active-low warning signal (OTW) when the device junction temperature exceeds 125°C (typical) and, if the device junction temperature exceeds 155°C (typical), the device is put into thermal shutdown, resulting in all half-bridge outputs being set in the high-impedance (Hi-Z) state and SD being asserted low. OTE is latched in this case. To clear the OTE latch, RESET must be asserted. Thereafter, the device resumes normal operation. UNDERVOLTAGE PROTECTION (UVP) AND POWER-ON RESET (POR) The UVP and POR circuits of the TAS5630 fully protect the device in any power-up/down and brownout situation. While powering up, the POR circuit resets the overload circuit (OLP) and ensures that all circuits are fully operational when the GVDD_X and VDD supply voltages reach the levels stated in the Electrical Characteristics table. Although GVDD_X and VDD are independently monitored, a supply voltage drop below the UVP threshold on any VDD or GVDD_X pin results in all half-bridge outputs immediately being set in the high-impedance (Hi-Z) state and SD being asserted low. The device automatically resumes operation when all supply voltages have increased above the UVP threshold. DEVICE RESET When RESET is asserted low, all power-stage FETs in the four half-bridges are forced into a high-impedance (Hi-Z) state. In BTL modes, to accommodate bootstrap charging prior to switching start, asserting the reset input low enables weak pulldown of the half-bridge outputs. In the SE mode, the output is forced into a high-impedance state when asserting the reset input low. Asserting reset input low removes any fault information to be signaled on the SD output; i.e., SD is forced high. A rising-edge transition on reset input allows the device to resume operation after an overload fault. To ensure thermal reliability, the rising edge of reset must occur no sooner than 4 ms after the falling edge of SD. SYSTEM DESIGN CONSIDERATIONS A rising-edge transition on the reset input allows the device to execute the startup sequence and starts switching. Apply audio only when the state of READY is high; that starts and stops the amplifier without having audible artifacts that are heard in the output transducers. If an overcurrent protection event is introduced, the READY signal goes low; hence, filtering is needed if the signal is intended for audio muting in non-microcontroller systems. The CLIP signal indicates that the output is approaching clipping. The signal can be used to either an audio volume decrease or intelligent power supply controlling a low and a high rail. The device inverts the audio signal from input to output. The VREG pin is not recommended to be used as a voltage source for external circuitry. 24 Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated Product Folder Link(s): TAS5630 TAS5630 www.ti.com SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 OSCILLATOR The oscillator frequency can be trimmed by external control of the FREQ_ADJ pin. To reduce interference problems while using a radio receiver tuned within the AM band, the switching frequency can be changed from nominal to lower values. These values should be chosen such that the nominal and the lower-value switching frequencies together result in the fewest cases of interference throughout the AM band, and can be selected by the value of the FREQ_ADJ resistor connected to AGND in master mode. For slave-mode operation, turn off the oscillator by pulling the FREQ_ADJ pin to VREG. This configures the OSC_I/O pins as inputs, which must be slaved from an external clock. PRINTED CIRCUIT BOARD RECOMMENDATION Use an unbroken ground plane to have a good low-impedance and -inductance return path to the power supply for power and audio signals. PCB layout, audio performance and EMI are linked closely together. The circuit contains high, fast-switching currents; therefore, care must be taken to prevent damaging voltage spikes. Routing of the audio input should be kept short and together with the accompanying audio-source ground. A local ground area underneath the device is important to keep solid to minimize ground bounce. Netlist for this printed circuit board is generated from the schematic in Figure 14. Note T1: PVDD bulk decoupling capacitors C60–C64 should be as close as possible to the PVDD_X and GND_X pins; the heat sink sets the distance. Wide traces should be routed on the top layer with direct connection to the pins and without going through vias. No vias or traces should be blocking the current path. Note T2: Close decoupling of PVDD with low impedance X7R ceramic capacitors is placed under the heat sink and close to the pins. Note T3: Heat sink must have a good connection to PCB ground. Note T4: Output filter capacitors must be linear in the applied voltage range, preferably metal film types. Figure 19. Printed Circuit Board – Top Layer Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated Product Folder Link(s): TAS5630 25 TAS5630 SLES220B – JUNE 2009 – REVISED FEBRUARY 2010 www.ti.com Note B1: It is important to have a direct-low impedance return path for high current back to the power supply. Keep impedance low from top to bottom side of PCB through a lot of ground vias. Note B2: Bootstrap low-impedance X7R ceramic capacitors placed on bottom side provide a short, low-inductance current loop. Note B3: Return currents from bulk capacitors and output filter capacitors Figure 20. Printed Circuit Board – Bottom Layer REVISION HISTORY Changes from Original (July 2009) to Revision A • Page Deleted Product Preview from the PHD package ................................................................................................................. 3 Changes from Revision A (September 2009) to Revision B Page • Changed several frame-rate specifications in Recommended Operating Conditions .......................................................... 4 • Changed oscillator frequency specifications in Electrical Characteristics .......................................................................... 10 • Changed specification for overload protection counter in Electrical Characteristics .......................................................... 11 26 Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated Product Folder Link(s): TAS5630 PACKAGE OPTION ADDENDUM www.ti.com 11-Apr-2013 PACKAGING INFORMATION Orderable Device Status (1) Package Type Package Pins Package Drawing Qty Eco Plan Lead/Ball Finish (2) MSL Peak Temp Op Temp (°C) Top-Side Markings (3) (4) TAS5630DKD NRND HSSOP DKD 44 29 Green (RoHS & no Sb/Br) CU NIPDAU Level-4-260C-72 HR 0 to 70 TAS5630 TAS5630DKDR NRND HSSOP DKD 44 500 Green (RoHS & no Sb/Br) CU NIPDAU Level-4-260C-72 HR 0 to 70 TAS5630 TAS5630PHD NRND HTQFP PHD 64 90 Green (RoHS & no Sb/Br) CU NIPDAU Level-5A-260C-24 HR 0 to 70 TAS5630 TAS5630PHDR NRND HTQFP PHD 64 1000 Green (RoHS & no Sb/Br) CU NIPDAU Level-5A-260C-24 HR 0 to 70 TAS5630 (1) The marketing status values are defined as follows: ACTIVE: Product device recommended for new designs. LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect. NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design. PREVIEW: Device has been announced but is not in production. Samples may or may not be available. OBSOLETE: TI has discontinued the production of the device. (2) Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check http://www.ti.com/productcontent for the latest availability information and additional product content details. TBD: The Pb-Free/Green conversion plan has not been defined. Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes. Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and package, or 2) lead-based die adhesive used between the die and leadframe. The component is otherwise considered Pb-Free (RoHS compatible) as defined above. Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material) (3) MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature. (4) Multiple Top-Side Markings will be inside parentheses. Only one Top-Side Marking contained in parentheses and separated by a "~" will appear on a device. If a line is indented then it is a continuation of the previous line and the two combined represent the entire Top-Side Marking for that device. Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release. In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis. Addendum-Page 1 Samples PACKAGE OPTION ADDENDUM www.ti.com 11-Apr-2013 Addendum-Page 2 PACKAGE MATERIALS INFORMATION www.ti.com 7-May-2016 TAPE AND REEL INFORMATION *All dimensions are nominal Device Package Package Pins Type Drawing SPQ Reel Reel A0 Diameter Width (mm) (mm) W1 (mm) TAS5630DKDR HSSOP DKD 44 500 330.0 24.4 TAS5630PHDR HTQFP PHD 64 1000 330.0 24.4 Pack Materials-Page 1 B0 (mm) K0 (mm) P1 (mm) W Pin1 (mm) Quadrant 14.7 16.4 4.0 20.0 24.0 Q1 17.0 17.0 1.5 20.0 24.0 Q2 PACKAGE MATERIALS INFORMATION www.ti.com 7-May-2016 *All dimensions are nominal Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm) TAS5630DKDR HSSOP DKD TAS5630PHDR HTQFP PHD 44 500 367.0 367.0 45.0 64 1000 367.0 367.0 45.0 Pack Materials-Page 2 PACKAGE OUTLINE DKD0044A PowerPAD TM SSOP - 3.6 mm max height SCALE 1.000 PLASTIC SMALL OUTLINE C SEATING PLANE 14.5 TYP 13.9 A 0.1 C PIN 1 ID AREA 42X 0.65 44 1 EXPOSED THERMAL PAD 12.7 12.6 16.0 15.8 NOTE 3 2X 13.65 22 23 44X (2.95) 0.38 0.25 0.12 C A B 5.9 5.8 B 11.1 10.9 NOTE 4 (0.15) EXPOSED THERMAL PAD 3.6 3.1 (0.28) TYP SEE DETAIL A 0.35 GAGE PLANE 0 -8 0.3 0.1 1.1 0.8 DETAIL A TYPICAL 4218846/A 07/2016 PowerPAD is a trademark of Texas Instruments. NOTES: 1. All linear dimensions are in millimeters. Any dimensions in parenthesis are for reference only. Dimensioning and tolerancing per ASME Y14.5M. 2. This drawing is subject to change without notice. 3. This dimension does not include mold flash, protrusions, or gate burrs. Mold flash, protrusions, or gate burrs shall not exceed 0.15 mm per side. 4. The exposed thermal pad is designed to be attached to an external heatsink. www.ti.com EXAMPLE BOARD LAYOUT DKD0044A PowerPAD TM SSOP - 3.6 mm max height PLASTIC SMALL OUTLINE 44X (2) SEE DETAILS SYMM 1 44 44X (0.45) 42X (0.65) SYMM (R0.05) TYP 22 23 (13.2) LAND PATTERN EXAMPLE SCALE:6X SOLDER MASK OPENING METAL METAL UNDER SOLDER MASK SOLDER MASK OPENING 0.05 MAX AROUND 0.05 MIN AROUND NON SOLDER MASK DEFINED SOLDER MASK DEFINED SOLDER MASK DETAILS NOT TO SCALE 4218846/A 07/2016 NOTES: (continued) 5. Publication IPC-7351 may have alternate designs. 6. Solder mask tolerances between and around signal pads can vary based on board fabrication site. www.ti.com EXAMPLE STENCIL DESIGN DKD0044A PowerPAD TM SSOP - 3.6 mm max height PLASTIC SMALL OUTLINE 44X (2) 1 SYMM 44 44X (0.45) 42X (0.65) SYMM (R0.05) TYP 23 22 (13.2) SOLDER PASTE EXAMPLE BASED ON 0.125 MM THICK STENCIL SCALE:6X 4218846/A 07/2016 NOTES: (continued) 7. Laser cutting apertures with trapezoidal walls and rounded corners may offer better paste release. IPC-7525 may have alternate design recommendations. 8. Board assembly site may have different recommendations for stencil design. www.ti.com IMPORTANT NOTICE FOR TI DESIGN INFORMATION AND RESOURCES Texas Instruments Incorporated (‘TI”) technical, application or other design advice, services or information, including, but not limited to, reference designs and materials relating to evaluation modules, (collectively, “TI Resources”) are intended to assist designers who are developing applications that incorporate TI products; by downloading, accessing or using any particular TI Resource in any way, you (individually or, if you are acting on behalf of a company, your company) agree to use it solely for this purpose and subject to the terms of this Notice. TI’s provision of TI Resources does not expand or otherwise alter TI’s applicable published warranties or warranty disclaimers for TI products, and no additional obligations or liabilities arise from TI providing such TI Resources. TI reserves the right to make corrections, enhancements, improvements and other changes to its TI Resources. You understand and agree that you remain responsible for using your independent analysis, evaluation and judgment in designing your applications and that you have full and exclusive responsibility to assure the safety of your applications and compliance of your applications (and of all TI products used in or for your applications) with all applicable regulations, laws and other applicable requirements. You represent that, with respect to your applications, you have all the necessary expertise to create and implement safeguards that (1) anticipate dangerous consequences of failures, (2) monitor failures and their consequences, and (3) lessen the likelihood of failures that might cause harm and take appropriate actions. You agree that prior to using or distributing any applications that include TI products, you will thoroughly test such applications and the functionality of such TI products as used in such applications. TI has not conducted any testing other than that specifically described in the published documentation for a particular TI Resource. You are authorized to use, copy and modify any individual TI Resource only in connection with the development of applications that include the TI product(s) identified in such TI Resource. NO OTHER LICENSE, EXPRESS OR IMPLIED, BY ESTOPPEL OR OTHERWISE TO ANY OTHER TI INTELLECTUAL PROPERTY RIGHT, AND NO LICENSE TO ANY TECHNOLOGY OR INTELLECTUAL PROPERTY RIGHT OF TI OR ANY THIRD PARTY IS GRANTED HEREIN, including but not limited to any patent right, copyright, mask work right, or other intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information regarding or referencing third-party products or services does not constitute a license to use such products or services, or a warranty or endorsement thereof. Use of TI Resources may require a license from a third party under the patents or other intellectual property of the third party, or a license from TI under the patents or other intellectual property of TI. TI RESOURCES ARE PROVIDED “AS IS” AND WITH ALL FAULTS. TI DISCLAIMS ALL OTHER WARRANTIES OR REPRESENTATIONS, EXPRESS OR IMPLIED, REGARDING TI RESOURCES OR USE THEREOF, INCLUDING BUT NOT LIMITED TO ACCURACY OR COMPLETENESS, TITLE, ANY EPIDEMIC FAILURE WARRANTY AND ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT OF ANY THIRD PARTY INTELLECTUAL PROPERTY RIGHTS. TI SHALL NOT BE LIABLE FOR AND SHALL NOT DEFEND OR INDEMNIFY YOU AGAINST ANY CLAIM, INCLUDING BUT NOT LIMITED TO ANY INFRINGEMENT CLAIM THAT RELATES TO OR IS BASED ON ANY COMBINATION OF PRODUCTS EVEN IF DESCRIBED IN TI RESOURCES OR OTHERWISE. IN NO EVENT SHALL TI BE LIABLE FOR ANY ACTUAL, DIRECT, SPECIAL, COLLATERAL, INDIRECT, PUNITIVE, INCIDENTAL, CONSEQUENTIAL OR EXEMPLARY DAMAGES IN CONNECTION WITH OR ARISING OUT OF TI RESOURCES OR USE THEREOF, AND REGARDLESS OF WHETHER TI HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. You agree to fully indemnify TI and its representatives against any damages, costs, losses, and/or liabilities arising out of your noncompliance with the terms and provisions of this Notice. This Notice applies to TI Resources. Additional terms apply to the use and purchase of certain types of materials, TI products and services. These include; without limitation, TI’s standard terms for semiconductor products http://www.ti.com/sc/docs/stdterms.htm), evaluation modules, and samples (http://www.ti.com/sc/docs/sampterms.htm). Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265 Copyright © 2017, Texas Instruments Incorporated