* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download tach model research paper

Electric motor wikipedia , lookup

Resilient control systems wikipedia , lookup

Three-phase electric power wikipedia , lookup

Utility frequency wikipedia , lookup

Electrification wikipedia , lookup

Power engineering wikipedia , lookup

Power inverter wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Electronic engineering wikipedia , lookup

Hendrik Wade Bode wikipedia , lookup

Amtrak's 25 Hz traction power system wikipedia , lookup

Regenerative circuit wikipedia , lookup

Control theory wikipedia , lookup

Voltage optimisation wikipedia , lookup

Induction motor wikipedia , lookup

Alternating current wikipedia , lookup

Mains electricity wikipedia , lookup

Buck converter wikipedia , lookup

Negative feedback wikipedia , lookup

Distribution management system wikipedia , lookup

Brushed DC electric motor wikipedia , lookup

Stepper motor wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Power electronics wikipedia , lookup

Control system wikipedia , lookup

Opto-isolator wikipedia , lookup

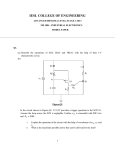

1 A Motor Feedback Demonstration Model for a Control Systems Class Andrew L. Wallner, Student Member, AES, Student Member, IEEE performance from an operating device. Abstract—In the educational context of control systems study, it is useful to provide tangible models of discussed concepts. One of the most typical applications of feedback control system theory is that of tachometer-feedback motor speed control. A small scale model can be implemented within a moderate budget using readily available analog components. The design, construction, operation, and performance of one such system are discussed here. I. INTRODUCTION T HE intent of this project is to investigate an application of control system theory and to describe its implementation in a small scale motor speed control system. The implemented system is to be used as a model for individual experimentation or classroom demonstration. The design of the system is openended to allow further study of control system theory and development of the presented model design. Investigation into the operation of the model design can provide a practical example of electronic control circuitry and gives exposure to factors involved in the realization of the abstracted system concepts. A. Open vs. Closed Loop Systems If, in an open-loop system, a device is expected to produce a particular output given a certain input, the system can perform in an unsatisfactory way if an internal or external force interrupts the device’s operation unbeknownst to the controller. A closed loop system does a better job of achieving the expected operation. It does so by informing the controller of the device’s actual operation, and therefore allows it to perform appropriate controlling actions to maintain the expected performance. INSTRUCTION CONTROLLER OPERATION (a) ADJUSTABLE CONTROLLER OPERATION INSTRUCTION VERIFICATION OF PERFORMANCE (b) Fig. 1. Block diagrams of control systems: (a) open-loop, (b) closed-loop. In closed-loop systems, the process of performance measurement and subsequent controller adjustment is itself an adjustable process. This sub-process determines how the controller responds to deviation reported by the fed-back measurement, the performance verification signal. Usually, the characteristics of this response are built or programmed into the system before operation. Fig. 1. a small motor/ flywheel assembly with an optical tachometer. II. CONTROL THEORY Even at the risk of being simplistic, it is important to mention the overall goal of a control system. Figure 1 contains diagrams of open and closed-loop control systems. The purpose of a closed loop system, such as a tachometerfeedback motor control, is to maintain an expected A. L. Wallner is an engineering student at Calvin College in Grand Rapids, MI 49546 USA (e-mail: [email protected]). B. Feedback Modes Feedback can be positive or negative. Positive feedback is, generally, unstable. It increases the effects of measured deviation in a compounding way; as an operation deviates, positive feedback will cause it to deviate more. This is what happens when a microphone is turned up too far. The sound of a lecturer’s voice is amplified so much that the sound emanating from the public address system is picked up by the microphone again and again, until the system reaches its loudest possible volume. This happens at the first deviating frequency, and then usually at harmonics of that tone, resulting in the ringing sound that is for many people the definition of feedback. Negative feedback promotes stability. As an 2 operating process deviates, the feedback is used to decrease the extent of the deviation. A good control system employing negative feedback should be able to maintain an instructed operation even when the operating process is affected by some form of disturbance. Feedback characteristics comprise the majority of control system design [1]. The most basic form of feedback is linear. Linear feedback applies a percentage of the system output, inverted, to attenuate a portion of the system input and compensate for the detected deviation. This arrangement works well, but reduces the magnitude of the process output since it is always held in check by the compensating signal. Greater amounts of feedback yield more control, but at the cost of reduced output. C. P.I.D. Control More sophisticated topologies apply a feedback signal that is not just merely a proportion of the output. Such feedback signals are generated based on the absolute magnitude, (integrated) output, and also from the rate of change (the derivative) of the output. By using combinations of these signals, a system can be designed that recovers from disturbances in almost any desired way. Using a combination of proportional, integral, and derivative (PID) signals, it is possible to control the three possible response errors: 1.) overshoot, the over-correction in response to the detected error, 2.) settling time, how quickly the output returns to the expected value, 3.) steady state error, the difference between the desired value and the actual, stabilized output. This also allows the use of feedback without a reduction in output magnitude. It is important to note two things: 1.) corrections to the three error modes are not directly related to the three PID parameters, and 2.) PID control can also be used to regulate open loop systems, though without the benefit of disturbance correction. D. Advanced Control Methods It is the interdependence of the amount of each PID parameter on system response that has given the task of tuning PID controls the reputation of being more of an art than science. For these reasons, automated means of adjusting PID loops have become very popular. An extension of this convenience has been the development of fuzzy logic controls and neural-net controls. Both of these approaches seek to optimize controller operation through examination of longterm trends. Fuzzy logic implements a guess-and-check system for specific parameter controls with is defining characteristic being the consideration of a parameter’s degree of accuracy [2]. It keeps track of trends, and makes new guesses if the trends are approaching an undesirable condition. Neural nets are an extension of this idea. They differ in their “learning” capability. Rather than merely iterating parameters, neural nets can create new combinations of parameters to evaluate [3]. For both of these technologies, system commissioning is greatly simplified when compared to PID loops, as it requires only “teaching” rather than precise measurement and manual adjustment. Both of these can respond to the situation and take action based on expected results. In the demonstration project presented here, only proportional negative feedback is implemented. The practical design has inherent elements of integral and derivative gain to provide system stability, but does not have any user-adjustable ID parameters. However, the system is designed to accommodate the future addition of ID circuitry. Both fuzzy and neural controls require computer processors, so implementation of such devices would distractingly increase the model’s complexity. III. SYSTEM CONCEPT The basic design for the system was shown on a schematic presented for analytical evaluation as an in-class example of a linear-feedback control system. It consists of four major functional blocks, the variable power supply, the motor and load, the velocity measurement, and the regulation circuitry. A. Operation of Example System The system presented was a design that used a linear power amplifier for power adjustment and a generator connected to the motor output to produce a feedback signal. power disturbance output reference + T3 - T1/T2 MOTOR LOAD (power adjustment) POTENTIOMETER GENERATOR Fig. 1. Block diagram of a generator feedback motor speed control system. The schematic also included a power rectification circuit to allow the low voltage dc system to operate from a standard 240v ac mains. The power amplifier was a cascaded power transistor pair controlled by a regulating signal transistor. The signal transistor was in a common-emitter configuration and, in response to the current produced by the generator, would sink the power transistors’ reference current to ground, thus implementing negative feedback. B. Conceptual Motivation It was desirable to assemble a similar circuit. Apparently, such a demonstration system is available for purchase, but at a prohibitive expense. The simplicity of the design suggested that it should be easily reproduced in a moderately-equipped electronics lab. When components were searched for, it proved to be less convenient to identically reproduce the presented system. There were three factors that motivated the decision to seek a different design: 1.) a suitably matched motor / generator pair was not found, 2.) appropriate bi-polar power transistors were not available in-house, and 3.) it was desirable to demonstrate a system topology that better depicts current trends in circuit design. It was decided to design a system that uses pulse-width modulation (PWM) to adjust the power delivered to the motor 3 and a non-contact tachometer to measure the rotational speed of the motor output. These decisions directly addressed the motivating design factors in the following ways: 1.) a noncontact tachometer eliminates the need for a generator, 2.) available power MOSFET transistors can be used, and 3.) PWM is one of the most common methods of power adjustment used in recent designs. This design approach also reflects current trends in system development; specifically, the growth in system complexity. The availability of inexpensive modules permits systems of greater complexity, and offers greater design flexibility and control. IV. SYSTEM DESIGN After consideration of the important characteristics of the original example system, it was determined that any proposed design must contain the following: 1.) a motor driven by a variable power supply, 2.) a motor speed sensor, and 3.) a (reference) – (feedback) controller input. The design must also be able to be used in a classroom or laboratory setting with commonly available test equipment. Based on these requirements and the other motivating factors, the system presented here was developed. A. Overview Figure 2 depicts the functional blocks of the system. These correlate directly to the functions of the original example system, with the exception of the reference adjustment, which is an additional feature of the new design. As will be discussed later, this new system is voltage controlled—a subtle difference from the original current-controlled circuit. power reference voltage output (speed) + PWM adjustment disturbance MOTOR LOAD feedback OPTICAL TACHOMETER adjustment Fig. 2. Block diagram of an optical tachometer-feedback motor speed control system with pulse-width modulator (PWM) power adjustment. The functionality of each of these blocks is realized largely through the use of integrated circuits. This increase in system complexity is the most noticeable compromise in comparison to the original design. It is possible that the increased complexity can detract from the transparency of the design, that is, it may be less obvious how the system operates, but if the system is examined as an assembly, it is obviously similar to the original. B. Power Supply While the schematic of the original design had provision for connection to ac line power, this design calls for connection to a regulated dc supply. The control circuit is presently configured for connection to +/- 15 volts and the motor supply can be from the same source, or a separate dc supply with a shared ground. With minimal modification, the motor drive circuit could be isolated from the control circuitry, if it was to be used with a different motor-supply combination. No overcurrent, over-voltage, or polarity protection devices are incorporated in the design. It is expected that this system will be operated in a laboratory setting connected to a protected and regulated power source. The motor drive circuit is robust and can withstand continuous operation. C. Power Adjustment Circuit The current amplifier stage of the original circuit is replaced by a voltage-controlled PWM driver connected to a MOSFET switch. The pulse width modulation varies the duty cycle of a carrier signal to the MOSFET switch. The switch delivers full-voltage power to the motor for a period of time determined by the modulated carrier signal. 1) Pulse-Width Modulation In a PWM system, if a carrier signal modulated to have a 100% duty cycle will trigger a MOSFET to connect the motor to the supply voltage constantly. If the carrier is modulated to 50%, the switch will be closed for only half of the carrier signal period and, as power is time dependant (power in Watts = Joules / second), the motor will receive half as much power. It follows, that the carrier frequency has no apparent effect on the long-term power delivered to the motor, but is important in speed regulation. Consider a small dc motor with a low-inertia load that takes 1 second to reach full speed; it is connected to a PWM supply. The carrier frequency is .01 Hz and the duty cycle is 50%. The motor will run for 50 seconds, and be stationary for another 50 seconds. It is true that the power delivered to the motor is half of what it could have received in the 100 second cycle, but the speed of the motor in operation was not affected. Consider the same arrangement, but with a carrier frequency of 100 Hz. In 0.05 sec. (half the carrier period), the motor is nowhere near full operating speed. In the next 0.05 sec. (the “off” portion of the duty cycle), the motor slows somewhat, but has enough inertia to keep turning. In the next cycle, another pulse of power is delivered, but not enough for the motor to reach full speed. Within a few cycles, the speed will center about a certain value. If the frequency of the carrier is high enough, its inverse, the period of consecutive pulses will be short enough that the irregular power delivered to the motor will not result in irregular motion. Because the increments of power from one pulse to the next are small, they do not overcome the inertia maintaining the motor’s speed. For successful PWM speed regulation, the carrier frequency should be as high a possible. Limitations on the upper limit of carrier frequency include signal generation and conveyance, but the most common limitation is inability of a motor coil to pass a high frequency signal. When applied to a motor, high frequency components that cannot make a complete circuit constructively interfere within the coils and produce high voltage transients that can damage insulation. This is called reflected-wave phenomenon and is of concern to designers of variable-frequency motor drives, a technology that employs a 4 similar modulated switching technique. The design presented here uses a carrier frequency of 1000Hz. 2) PWM implementation For this system, a PWM controller is realized with three main devices: 1.) the carrier frequency generator, 2.) the voltage-to-duty-cycle modulator, and 3.) the power switching unit. The carrier generator is simply a multivibrator created with a 555 timer IC. It produces a steady 1000Hz square wave. The device used was a Texas Instruments NE555. A schematic from the corresponding data sheet [5] is shown, modified, in the left half of Fig. 3. The frequency and duty cycle are a function of resistor and capacitor values; they are calculated below in (1) and (2), respectively. fc 1.44 1005Hz ( RA 2 RB ) CC DC 1 RB 50.4% R A 2 RB (1) (2) Where: RA 1.1k, RB 68k, C 10nF Fig. 3. Schematic of carrier signal generator (U1), a 555 timer configured for astable (clock) operation, and the VC-PWM (U2), a 555 timer configured for duty cycle modulation. The voltage-to-duty-cycle modulator function is accomplished with a second 555 timer. It varies the duty cycle of its square wave output proportionately to the amplitude of the voltage present at the modulation input. The frequency of the cycles is that of the signal applied to the clock input from the carrier generator. This circuit, also modified from the TI data sheet, is shown in the right half of Fig. 3. 3) Power Switching The final stage of the PWM is simply a high-speed switch used to toggle the motor’s connection to the power source. Its major component is a MOSFET transistor. For this application, an International Rectifier IRF130 was used. Many other power MOSFETs would be equally suitable devices, and possibly less over-qualified. The `130 is rated at 14A and up to 100V, so no heat-sink was required for this design. Since all MOSFETS are susceptible to damage caused by reversebias voltages, a diode is connected between the drain and source of the transistor to divert transient over-voltages to the power source and parallel buffer capacitor. The circuit is shown in Fig. 4. Fig. 4. Schematic of MOSFET power switch circuit with motor. D. Motor Assembly The motor selected is a permanent magnet dc motor. It is a high-quality rotary actuator that has published performance characteristics. This sophistication is not mandatory for the design’s operation, but can be useful for comparison of a theoretical analysis with empirical testing. The model chosen is from the Canon Precision FN30S series [6]. The load connected to the motor is a simple flywheel. The wheel is a solid aluminum cylinder measured to have a 25.4cm diameter, a 12.7mm length, and a 4mm, axially concentric hole. It also has a threaded hole that accommodates a #4-40 x ¼” sockethead set-screw in perpendicular orientation to the concentric hole. The end of the wheel that is not directed toward the motor has two finishes. One half of its surface area is a semicircle of the smooth, bare aluminum. The other half is covered with a non-reflective finish. This gives the optical tachometer a target for counting revolutions. E. Optical Tachometer The optical tachometer provides a way of detecting rotation of the flywheel without damping its mechanical energy. It counts rotations by sensing light reflected off of the wheel’s end. It is comprised of four major components: 1.) the photodetector, 2.) the pulse shaper, 3.) the frequency-to-voltage converter, and 4.) the output buffer. 1) Photo-detector The photo-detector is a diffuse light-reflection sensor. For its operation, a red LED is used to illuminate the target to be sensed. Light reflecting off the target is detected by a photodiode oriented symmetrically to the incident angle of the LED. The photodiode, which appeared to be a somewhat standard (though unmarked), component worked suitably to detect the red wavelengths. For maximum sensitivity, the diode is used in an unbiased “photovoltaic mode” [7]. This arrangement works by sensing the voltage produced by photons “pushing” electrons across the diode’s p-n junction. This highly sensitive configuration has inherent signal bandwidth limitations, but the charge-carrier propagation time does not limit performance in the present application. The voltage produce by the incident red light is on the order of 0.01-0.1mV. This voltage is amplified by an LF366 JFET input operational amplifier. The JFET input preamp presents a high impedance load and a minimally interfering bias current 5 to the delicate signal produced by the photodiode. As diagrammed in Fig. 5., it was determined that using a 10 mega ohm feedback resistor produces output voltages near 0V when the diode was subjected to ambient light and about 2V when exposed to moderate amounts of red light. Fig. 5. Schematic of photo-detector and preamp. 2) Pulse shaper The output of the photo-detector preamp provides a somewhat inconsistent analog waveform. A pulse shaper is used to create square digital pulses. This function is accomplished with an LM193 voltage comparator. The comparator is set to produce full-voltage pulses when the preamp’s output increases above a threshold slightly higher that the noise floor. A limited amount of hysteresis is incorporated to reduce false triggering. 3) Frequency-to-voltage converter The frequency of the digital pulses produced by the photodetector and pulse shaper is translated into a voltage by an LM 331. The voltage/frequency relationship is a function of resistor and capacitor values. This relationship is shown in (3) and a schematic, modified from the `331 datasheet, is in Fig. 6. Fig. 6. Schematic of frequency to voltage converter. Vout f in 2.09V RL ( Rt Ct ) RS (3) 4) Output buffer The output buffer is simply a voltage follower that isolates the output of the frequency to voltage converter from the input impedance of the device to which it is connected. This is necessary to allow the feedback signal to be attenuated with a potentiometer. The feedback voltage can be adjusted without altering the relationship presented in (3), above. The voltage follower is realized with an LM301 op-amp. It is also useful to note that the buffered voltage level can be used as a stimulus to almost any circuit. It leaves provision for the insertion of advanced control circuitry into the feedback loop. F. Controller The controller delivers the duty cycle instruction signal to the PWM motor drive. It synthesizes this signal from a reference signal and the feedback loop. All three signals are dc voltages and it is required that the feedback signal be subtracted from the reference signal, so this function is realized with a direct-coupled unity-gain difference amplifier. Another LM 301 op-amp is used for this purpose. The reference signal is the voltage that corresponds to the desired motor speed. This voltage is obtained from the positive voltage supply with a potentiometer voltage divider. The feedback signal is also adjustable with a similar mechanism. The reference voltage selected with the potentiometer is applied to the non-inverting input of the difference amp and the selected feedback signal is applied to the inverting input. The output to the PWM drive is then the (reference) – (feedback) signal. V. ANALYSIS A. Calculations As documented, many calculations were performed in the development of the circuit design for this system. In addition to the critical calculations shown, other component values were determined with quick calculations and estimations. As will be discussed, it is advisable that this entire system be reanalyzed and some component values be reselected for optimal performance. B. Simulations There are three major ways that this design can be simulated. Each examines a different level of abstracted operation. They are the: 1.) detailed electrical, 2.) detailed functional, and 3.) abstract functional. 1) Detailed electrical First, the electrical characteristics can be examined. Depending on whether the motor load is represented dynamically, this simulation approach would have the most parameters and be the most complex. It would likely yield detail about many parameters that are not of interest. This virtual model would require a powerful simulation tool, such as OrCAD PSpice®. The student evaluation version of the software does not support all the devices used in the design, nor does it allow simulation of the quantity of components involved. However, the program is mentioned here because its companion program Capture® was used as a CAD tool for the schematic layout. 2) Detailed functional An approach that would yield similar detail regarding the operation of the system, would entail creating a detailed model of the functional blocks that the circuit components instantiate. This approach was taken using Simulink® for MATLAB® from The MathWorks, Inc. and is introduced as follows: First, a basic open-loop PWM / motor model is created. 6 This model is tested against known parameters, if available. Second, a model of the tachometer is created. Third, a feedback loop is connected and examined. In development of this project a PWM / motor model was created and two Simulink models of the Canon FN30S were implemented. The basic PWM / motor model is shown in Fig. 7. One of the motor models used the format of a known working model from Carnegie Mellon University [9], shown in Fig. 8. The other was developed based on a topology from White [10] and is shown in Fig. 9. The two models were used to investigate the role of the motor model parameters in simulation. White’s model uses a motor velocity constant, which, is what is provided with the Canon motor data. The CMU model uses a mechanical damping ratio. This ratio was tentatively calculated for the FN30S using (4). Neither of these models effectively reproduced the data found in the published specifications. It appears, however, that the discrepancy lies in the numbers, not the structure of the model. Further investigation should reveal coherent results. mech starting _ torque mech _ const Fig. 7. Basic PWM motor simulation. (4) 3) Abstract functional It is recommended that, for purposes of investigation into feedback control mechanism, the most basic simulation be developed. This transparent approach ignores the individual mechanisms of the functional blocks, such as the PWM instantiation of the speed controller. If interest lies only in system behavior, there is no need to observe the inner workings of the system. C. Financial Economic considerations are becoming a vital part of almost all aspects of engineering design. While financial matters ought not interfere with the technical quality of engineering matters, they are often motivating factors when determining a design’s feasibility or success. Often, after the questions, “could it work?” and “is it physically possible?” are asked, comes the question “what is the cost?” Since one of the motivations of this project was to minimize expense, the cost of development is considered here. Since the design procedure is intended for education, time and effort is not explicitly quantified. It should be noted that this design is developed with the intent that it can be reproduced by undergraduate engineering students within the context of a control systems class. With such consideration, it is believed that subsequent similar projects will pose challenges intellectually, and not necessarily temporally. The design of this system is based on components available in a college electronics lab. All the parts are readily available, so the cost of materials (already depreciated) is zero. Admittedly, there is a positive list price associated with the developed prototype, but a quick estimate would suggest that, to replicate the design from recently purchased components, would cost less than $20. The itemization of development, component purchase, assembly, and maintenance costs is a task recommended to be done before and during progression of the prototype through its stages of revision. VI. TESTING Fig. 8. DC motor model using back-emf. Fig. 9. DC motor model using velocity constant. A prototype of the system was assembled and tested. It performed very well. The test assembly is shown in Fig. 10. The most significant test performed was the verification of the PWM duty cycle increase in response to decreased tachometer frequency. After setting a less-than-full power speed reference and increasing feedback the amount just until the speed decreased, the duty cycle of the signal delivered to the motor would increase as the tachometer frequency decreased. Thus, if the flywheel was slowed by applied friction, the power to the motor was increased to compensate and maintain the expected speed. 7 ACKNOWLEDGMENT The author gratefully acknowledges the contributions of the following persons to this project: B. Bouma, C. Holwerda, M. E. Husson, J. Lester, K. Palmer, P. F. Ribeiro, and D. Ryskamp. REFERENCES [1] Fig. 10. Prototype assembly showing system on breadboard, regulated power supply, and oscilloscopes. VII. CONCLUDING REMARKS The design, construction, and testing of a small scale motor speed control system provides an excellent method of investigating control system theory and its practical application. The development of a pulse-width modulated switching motor drive presents many power-systems issues for the designer to consider. The development of a highsensitivity optical detector is a good exercise in analog design and touches on concepts relative to control systems such as frequency response, bandwidth, gain and phase margins, and compensation to promote stability. The testing of the assembled system provides undeniable validity to the abstract concepts considered. Furthermore, this project is a selfevident study of feasibility, demonstrating the opportunity to wisely use available resources. It is also, hopefully, an impetus for future, similar applications and projects. The design presented here, is not complete by any measure, but is a starting point for ongoing development. APPENDIX A. Comments for further development. There are a few known issues regarding circuit performance. These are being investigated and will be documented later. A schematic of the prototype circuit is available. B. Availability of prototype The prototype will be left available for inspection and testing at Calvin College. R. C. Dorf, R. H. Bishop, Modern Control Systems, ed. 9. Upper Saddle River, New Jersey: Prentice Hall, 2001, p. 553. [2] Steven D. Kaehler, “Fuzzy Logic – An Introduction” (2004, Dec). [online]. Available: http://www.seattlerobotics.org/encoder/mar98/fuz/fl_part1.html [3] H. T. Nguyen, N. R. Prasad, C. L. Walker, E. A. Walker, A First Course in Fuzzy and Neural Controls, Boca Raton: Chapman & Hall/ CRC, 2003, p.168, 86 [4] P. Avoke, presentation on neural networks, Calvin College ENGR 315. (2004, Dec 8). (unpublished presentation) [5] (Data sheet) NE555 Precision Timers, Publication SLFS022E, Texas Instruments, (2004, March) [online] Available: http://www.ti.com [6] (data sheet) DC motor catalog 2003(English), Canon Precision, Inc., [online] Available: http://www.canon-prec.co.jp/english/e.pdf [7] Designing Photodiode Amplifier Circuits with OPA128, Burr - Brown, Tucson, AZ, Application Bulletin AB-077, Jan. 1994. [online] Available: http://www.ti.com [8] (Datasheet) LM231A/LM231/LM331A/LM331 Precision Voltage-toFrequency Converters, Publication DS005680, National Semiconductor, (1999, June) [online] Available: http://www.national.com [9] Control Tutorials for MATLAB® and Simulink®, Addison-Wesley Publishing Company, Inc., 1998 [online] Available: http://www.library.cmu.edu/ctms/ctms/index.htm [10] Dr. J. R. White, “Dynamic Model of a Permanent Magnet DC Motor” (Spring 1997), UMass-Lowell, [online] Available: http://www.profjrwhite.com/ system_dynamics/sdyn/s6/s6fanal/s6fanal.html Andrew L. Wallner was born in Milwaukee, WI in 1981 and has ties to Chattanooga, TN and Sheboygan, WI. He studied at the University of Wisconsin, Sheboygan and Lakeshore Technical College, in Manitowoc, WI. He is currently a student at Calvin College pursuing a Bachelor of Science in Engineering degree with a concentration in electrical engineering in May 2005. His employment experience included work at a tool and equipment company, Quasius Equipment, Calvin College Technical Services, and an engineering internship at Red Arrow Products. His fields of interest include audio processing, and analog electronics. 8