* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Electrical Hazards and Arc Flash Awareness

Ground loop (electricity) wikipedia , lookup

Voltage optimisation wikipedia , lookup

Electrification wikipedia , lookup

Mechanical-electrical analogies wikipedia , lookup

Electronic engineering wikipedia , lookup

Alternating current wikipedia , lookup

Telecommunications engineering wikipedia , lookup

Electrical substation wikipedia , lookup

Electromagnetic compatibility wikipedia , lookup

History of electric power transmission wikipedia , lookup

Electrical engineering wikipedia , lookup

Mains electricity wikipedia , lookup

Mercury-arc valve wikipedia , lookup

Circuit breaker wikipedia , lookup

Portable appliance testing wikipedia , lookup

Stray voltage wikipedia , lookup

Ground (electricity) wikipedia , lookup

Earthing system wikipedia , lookup

Electrical wiring wikipedia , lookup

Electrician wikipedia , lookup

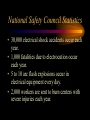

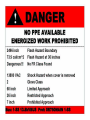

Electrical Hazards and Arc Flash Awareness Instructor: Brian Terry Class Outline • • • • Welcome/Overview Accident Statistics Electrical Terminology Introduction to Electrical Hazards – – – – Electrical Shock / Electrocution Electrical Burns Arc Flash Arc Blast Class Outline • Arc Hazard Boundary • Four Approach Boundaries – – – – Limited Approach Boundary Restricted Approach Boundary Prohibited Approach Boundary Flash Protection Approach Boundary • Qualified and Unqualified Persons • Energized Electrical Work Permit • Arc Flash Hazard Marking Requirements Class Outline • PPE / FR Clothing • Safe Work Practices • Identifying Other Electrical Hazards – – – – – – – – Inadequate Wiring Hazards Overload Hazards Grounding Hazards Identifying Disconnects Clear Spaces Ground Paths Guarding Live Parts Clues that Electrical Hazards Exist Accident Statistics National Safety Council Statistics • 30,000 electrical shock accidents occur each year. • 1,000 fatalities due to electrocution occur each year. • 5 to 10 arc flash explosions occur in electrical equipment every day. • 2,000 workers are sent to burn centers with severe injuries each year. Introduction to Electrical Hazards Hazards of electricity • There are five main types of electrical injuries: – – – – – Electrical shock Electrocution (death due to electrical shock) Electrical Burns Arc Flash Arc Blast Electrical Shock • Received when current passes through the body • Severity of the shock depends on: – Path of current through the body – Amount of current flowing through the body – Length of time the body is in the circuit • LOW VOLTAGE DOES NOT MEAN LOW HAZARD Dangers of Electrical Shock • Currents greater than 75 mA* can cause ventricular fibrillation (rapid, ineffective heartbeat) • Will cause death in a few minutes unless a defibrillator is used • 75 mA is not much current – a small power drill uses 30 times as much * mA = milliampere = 1/1,000 of an ampere How is an electrical shock received? • When two wires have different potential differences (voltages), current will flow if they are connected together • If you come into contact with an energized (live) wire, and you are also in contact with a Neutral, grounded wire, a conductor with a different phase voltage, current will pass through your body and YOU WILL RECEIVE A SHOCK How is an electrical shock received? • If you are in contact with an energized wire or any energized electrical component, and also with any grounded object, YOU WILL RECEIVE A SHOCK! • You can even receive a shock when you are not in contact with a ground – If you contact both wires of a 240-volt cable, YOU WILL RECEIVE A SHOCK and possibly be electrocuted Electrocution • Accidental death by electric shock. • An average of one worker is electrocuted on the job every day. • NSCS states that 1,000 fatalities due to electrocution occur each year. Electrical Burns • Most common shock-related, nonfatal injury • Occurs when you touch electrical wiring or equipment that is improperly used or maintained • Typically occurs on the hands • Very serious injury that needs immediate attention Arc Flash • Arc flash occurs when an electrical current passes through air. • It creates temperatures up to 30,000 o F • It burns skin and ignites clothing causing additional burns. • It can create an explosion • It can create dangerous vapors Arc Blast • Arc blast occur when the extreme temperatures of the electrical arc cause explosive expansion of both the surrounding air and the metal in the arc’s path. • It creates extremely high air pressure • A very loud sound • The force sends flying shrapnel and molten metal in a 270o outward radius. What happens during an Arc Flash /Blast? • An Arc Flash is the result of a rapid release of energy due to an arcing fault between a phase bus bar and another phase bus bar, Neutral or a Ground. • During an arc fault, The ionized air is the conductor. • After the short burns away, the arc fault is then sustained by the establishment of highly conductive plasma. • This massive energy discharge burns the bus bars, vaporizing the copper, expanding rapidly into an explosive volume of approximately 40,000 to 1. • This explosion devastates everything in its path, creating deadly shrapnel as it dissipates. Laboratory Controlled Arc Blast Short Circuit A B Arc Fault A B Electrical Arc Flash 35,000 °F Molten Metal Pressure Waves Sound Waves Shrapnell Copper Vapor: Solid to Vapor Expands by 67,000 times Hot Air-Rapid Expansion Intense Light Results Sound P1 141.5 db @ 2 ft. >2160 lbs/sq.ft T2 T1 >225°C / 437°F T3 > 225°C / 437°F 50°C / 122°F > Indicates Meter Pegged Arc Flash PPE What about Circuit Protection? • The arc fault current is usually much less than the available bolted fault current and below the rating of circuit breakers. • Unless these devices have been selected to handle the arc fault condition, they will NOT trip and the full force of an arc flash will occur. Are there any circuit protection devices that can suppress fault currents during arc flash conditions? • The answer is Yes!, some companies incorporate transformers and other arc fault suppression devices in there circuit breakers that limit the amount of fault current available during an Arc flash condition. • These are being developed and may be available for certain applications. • But by NO means, this takes the complete arc flash hazard away. Industry Standards for arc flash prevention • OSHA 29 Code of Federal Regulations (CFR) part 1910 Subpart S • NFPA 70 National Electrical Code • NFPA 70E Standard for Electrical Safety Requirements for Employee Workplaces. • IEEE Standard 1584 Guide for Performing Arc Flash Hazard Calculations. Compliance with OSHA involves adherence to a six-point plan: • 1. A facility must provide, and be able to demonstrate, a safety program with defined responsibilities. • 2. Calculations for the degree of Arc Flash Hazard. • 3. Correct personal protective equipment (PPE) for workers. • 4.Training for workers on the hazards of Arc Flash. • 5. Appropriate tools for safe working. • 6. Warning labels on equipment. (provided by the owner of the equipment, Not manufacturers) Qualified vs Unqualified • Qualified Person. A qualified person shall be trained and knowledgeable of the construction and operation of equipment or a specific work method and be trained to recognize and avoid the electrical hazards that might be present with respect to that equipment or work method. • One who has skills and knowledge related to the construction and operation of the electrical equipment and installations and has received safety training to recognize and avoid the hazards involved. • A person can be considered qualified with respect to certain equipment and methods but still be unqualified for others. Qualified vs Unqualified • Unqualified Persons. Unqualified persons shall be trained in, and be familiar with, any electrical safety related practices necessary for their safety. • A person who is not a qualified person. Why a Safety Program • • • • • • • • Safer work environment Personnel Safety Fewer work related injuries Fewer days missed due to work injuries Lower insurance rates Fewer medical cost to employee and employer A more confident workforce The saving of lives of qualifies and unqualified personnel Hazard Video • http://www.youtube.com/watch?v=4bBvmP Rqfmo 130.4 Approach Boundaries to Energized Electrical Conductors or Circuit Parts 130.4 Approach Boundaries to Energized Electrical Conductors or Circuit Parts 130.4 Approach Boundaries to Energized Electrical Conductors or Circuit Parts Approach Boundaries – NFPA 70E Limited Approach Boundary • Unqualified persons must stay a safe distance call the Limited Approach Boundary. – 3.5 ft. for fixed circuit parts ( 50 to 750 volts) – 10 ft. for exposed movable conductors ( 50 to 750 volts) – Boundaries increase as voltage gets higher to more than 23 ft in some cases. Minimum Required Labeling ! WARNING Arc Flash and Shock Hazard Appropriate PPE Required 24 inch Flash Hazard Boundary 3 cal/cm2 Flash Hazard at 18 inches 480 42 12 1 VAC inch inch inch Shock Hazard when Cover is removed Limited Approach Restricted Approach - 500 V Class 00 Gloves Prohibited Approach - 500 V Class 00 Gloves Date: 6/28/2001 Bldg. ECR #1 Equipment Name: Slurry Pump Starter ! WARNING Arc Flash and Shock Hazard Appropriate PPE Required 24 inch Flash Hazard Boundary 3 cal/cm•2 Flash Hazard at 18 inches 1DF PPE Level, 1 Layer 6 oz Nomex ®, Leather Gloves Faceshield 480 VAC Shock Hazard when Cover is removed 36 inch Limited Approach 12 inch Restricted Approach - 500 V Class 00 Gloves 1 inch Prohibited Approach - 500 V Class 00 Gloves Equipment Name:Slurry Pump Starter Courtesy E.I. du Pont de Nemours & Co. Hazard Category One • Clothing with a minimum Arc Rating: 4 Cal/cm2 • 100% cotton Jeans min weight (12 oz/yd2) or FR rated pants. • FR rated Shirt or FR rated coveralls. • Electrically rated Hard Hat. • Non-conductive safety eyewear. • Example: Removing bolted cover to expose live parts on panel boards rated 240V and below. Hazard Category Two • Clothing with a minimum Arc Rating: 8 Cal/cm2 • Under layer of 100% non-melting natural fiber (cotton/wool). • FR rated shirt / pants or coveralls. • FR rated Face shield or flash suit hood. • Electrically rated Hard Hat, Eye protection, Boots and gloves. • Example: Performing diagnostic testing or voltage measurements on 600V switchgear. Hazard Category Three • Clothing with a minimum Arc Rating: 25 Cal/cm2 • Two Under layers of 100% non-melting natural fiber (cotton/wool) rated at 15 Cal/cm2 which will give a combine protection of 30 Cal/cm2 or a multi-layer flash suit rated at 40 Cal/cm2. • FR rated flash suit hood. • Electrically rated Hard Hat. • Eye protection. • Boots with dielectric overshoes. • Electrically insulated FR rated gloves. • And hearing protection for exposure to 200 dB or better. Hazard Category Four • • • • • • • • Clothing with a minimum Arc Rating: 40 Cal/cm2 40 Cal/cm2 Flash suit. FR rated flash suit hood. Electrically rated Hard Hat. Eye protection. Boots with dielectric overshoes. Electrically insulated FR rated gloves. And hearing protection for exposure to 200 dB or better. So, What Do I Do If I’m (Way) Above 40 cal/cm2 Solutions • Above 40 cal/cm2 – Label equipment warning that no PPE is available – Refer to safety procedures – Must use engineered solution • • • • • • • • • • Current limiting fuses Arc Resistant switchgear Remote racking Remote operation through Smart Equipment Zone Interlocking IP20 shrouding Re-coordinating protective devices Increasing distance Enabling instantaneous function De-energizing before operation PPE / FR Clothing Personal Protective Equipment (PPE) • Anytime your body crosses the Restrictive Approach Boundary or the Flash Protection Boundary, You Must wear PPE to protect you from Arc Flash and Electrical Shock. Depending on the task, you may need: • Rubber insulated gloves and insulated tools to protect against electrical shock. • Leather hand and arm covers ro protect against arc flash burns and flying debris. • Head, face, neck, chin, eye and body protection. • Hearing protection • Dielectric overshoes • A full multi-layer flash suit, including hood, face shield and suplied air may be needed for higher risk. Prohibited Clothing • • • • • • Polyester Nylon Rayon Any blend of the above fabrics Any metallic or conductive clothing. Metal/ Plastic Jewelry Category One Clothing 5 Cal/cm2 Category Two Clothing 11 Cal/cm2 kit Category Three Clothing 25 Cal/cm2 Category Four Clothing 40 Cal/cm2 100 Cal/cm2 FR rated Clothing Safe Work Practices Safe Work Practices OSHA 1910.333 (a) (1) & NFPA 70E 130 (A) (1) not to work “hot” or “live” except : 1. Deenergizing introduces additional or increased hazards 2. Infeasible due to equipment design or operational limitations Wearing Proper PPE? Safe work Practices • Remove conductive articles. • Wear natural fibers (100% cotton/100% wool). • Clothing should be loose-fitting and FR rated. • Wear eye protection – safety glasses or goggles under Face shields or hoods. • Get an Energized Electrical Work Permit. Safe work Practices • Double check tools and equipment voltage ratings. • Keep tools and equipment from accidentally coming in contact with live parts. • All parts are considered Live until you test to make sure. • Work in adequate lighting. Safe work Practices • Never reach blindly into equipment. • Never be put into a position where you could fall into live parts. • Keep vehicles and mechanical equipment 10 feet from energized overhead lines. • Do not touch Vehicles that could accidentally become energized without proper PPE. Safe work Practices • Keep unqualified persons out of the area beyond the Limited Approach Boundary. • Use attendants to keep unqualified people out of the area. • Attendants may be needed to observe the qualified worker for safety reasons. Identifying Other Electrical Hazards Inadequate Wiring Hazards • A hazard exists when a conductor is too small to safely carry the current Example: using a portable tool with an extension cord that has a wire too small for the tool – The tool will draw more current than the cord can handle, causing overheating and a possible fire without tripping the circuit breaker – The circuit breaker could be the right size for the circuit but not for the smaller-wire extension cord Overload Hazards • If too many devices are plugged into a circuit, the current will heat the wires to a very high temperature, which may cause a fire • If the wire insulation melts, arcing may occur and cause a fire in the area where the overload exists, even inside a wall Grounding Hazards • Frequently violated OSHA standards • Metal parts of an electrical wiring system that we touch (switch plates, ceiling light fixtures, conduit, etc.) should be at zero volts relative to ground • Housings of motors, appliances or tools that are plugged into improperly grounded circuits may become energized • If you come into contact with an improperly grounded electrical device, YOU WILL BE SHOCKED ! Grounding Path • The path to ground from circuits, equipment, and enclosures must be permanent and continuous Identifying Disconnects • Each disconnect must be labeled indicating its purpose, unless located and arranged so the purpose is evident Clear Spaces • Must have access to working space around electrical equipment. • Must have at least 3’ in front of switch boards or motor control centers Guarding of Live Parts • Must guard live parts of electric equipment operating at 50 volts or more against accidental contact by: – Approved cabinets/enclosures, or – Location or permanent partitions making them accessible only to qualified persons, or – Elevation of 8 ft. or more above the floor or working surface • Mark entrances to guarded locations with conspicuous warning signs Guarding of Live Parts • Must enclose or guard electric equipment in locations where it would be exposed to physical damage • Violation shown here is physical damage to conduit Clues that Electrical Hazards Exist • Tripped circuit breakers or blown fuses • Warm tools, wires, cords, connections, or junction boxes • GFCI that shuts off a circuit • Worn or frayed insulation around wire or connection Conclusion • Arc Flash Awareness is an important part of any electrical workers training. • The standards used are to protect qualified electrical workers and the Unqualified. • Proper PPE should always be used for the Hazard Category established for the equipment. • Safe work practices should always be followed on and off the Job… Your life may depend upon it. End of Lecture