* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Controller Schematic Design

Microcontroller wikipedia , lookup

Integrating ADC wikipedia , lookup

Josephson voltage standard wikipedia , lookup

Analog-to-digital converter wikipedia , lookup

Gender of connectors and fasteners wikipedia , lookup

Operational amplifier wikipedia , lookup

Electrical connector wikipedia , lookup

Power electronics wikipedia , lookup

Valve audio amplifier technical specification wikipedia , lookup

Two-port network wikipedia , lookup

Current source wikipedia , lookup

D-subminiature wikipedia , lookup

XLR connector wikipedia , lookup

Schmitt trigger wikipedia , lookup

Current mirror wikipedia , lookup

Valve RF amplifier wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Power MOSFET wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Voltage regulator wikipedia , lookup

Rectiverter wikipedia , lookup

Surge protector wikipedia , lookup

Opto-isolator wikipedia , lookup

Printed circuit board wikipedia , lookup

Surface-mount technology wikipedia , lookup

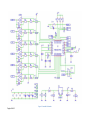

Controller for a Robotic Hand Prof. Mihai AGAPE Palatul Copiilor Drobeta Turnu Severin - Filiala Orşova This work is part of the project “Remote Controlled Arm Project”, no. LLP-LdV/PAR/2010/RO/023. The project was financed by the European Commission in the Long Life Learning Program, action Leonardo da Vinci Partnership. This publication reflects the views only of the author, and the Commission cannot be held responsible for any use which may be made of the information contained therein. Resume: The purpose of this paper is to present a controller designed to control the fingers of a robotic hand via some servomechanisms. Figure 1 – Robotic hand with 6 servomechanisms which act 4 fingers and 1 thumb (3D design and prototype) This paper is a revised version of the article „Controler pentru comanda degetelor unui braţ robotic”, published in the magazine Conexiuni 6 (I.S.S.N. 1584 – 8645), pg. 51 – 62. The magazine can be downloaded from http://www.didactic.ro/magazines/download/id/2428. Controller Specifications The controller has to control the 6 servomechanisms (2 servos for the thumb and one servo for each finger) which actuate the fingers (Figure 1). The controller receives commands from a computer and information about the pressure exerted by fingers. The description above can be converted in the next requirements for the controller: - 6 PWM outputs which have to transmit the signals for the servomechanisms (i.e. signals with period T = 20 ms and variable pulse width between 1 and 2 ms); - 6 analog inputs which have to receive the information about the pressure exerted by the fingers; - 2 I/O for serial communication interface (RXD and TXD); Pagina 1 din 11 - 2 I/O for communication via I2C / TWI interface (SCL and SDA). Solutions for Implementing the Specifications Communication Interfaces In order to establish the communication via serial interface and I2C we use the dedicated pins of the microcontroller. PWM Outputs For the 6 PWM outputs we can use the dedicated PWM outputs of the microcontroller or we can use ordinary digital outputs and generate the PWM signals by software. For the first case the resolution of generated PWM signals is poor (the duty factor of the PWM signal varies between 5% and 10 %). A better precision of the PWM signal can be obtained by software generation. I chose the second solution. Analog Inputs We could use pressure sensors for measuring the pressure exerted by finger, but this would increase the complexity of the robotic hand. A better solution is to consider that the force exerted by fingers is proportional with the torque of the servo, which in turn is proportional with the current passing through the motor of the servo. We can use a resistor connected serially with the motor. The voltage across the resistor is proportional with the electrical current of the motor; therefore the voltage is proportional with the force exerted by the finger. Because the range of the voltage across resistor is very little, we will use a circuit for amplifying the signal to the right level. We will use 6 analog inputs, one for each servomechanism. Choosing the Microcontroller I chose an ATmega8 microcontroller which corresponds to the application as pins number and probably as needed memory. Controller Schematic Design In original article I presented the design of the controller schematic step by step. In this version I gave up this approach; I just present the final result. The link http://www.didactic.ro/magazines/download/id/2428 is for those interested in a step by step approach. I used the software „Target 3001!” for the schematic and PCB design. I modified the first version of the schematic when I designed the PCB for facilitate the traces routing. The important modifications were the interchange of the operational amplifiers and changes of the connections between amplifiers outputs and analog inputs of the microcontroller. Final version of the schematic is presented in Figure 2. The way I designed the electronic diagram is explained further. Pagina 2 din 11 Figure 2 – Controller’s Schematic Pagina 3 din 11 Microcontroller’s pins allocation Pins for General Use (15) A part of the microcontroller’s pins are used in a similar manner regardless the application specificity. In this category I include the next 15 pins: 3, 5, 21 GND 15 PB3 (MOSI) Programming connector - pin 4 4, 6 VCC 16 PB4 (MISO) Programming connector - pin 1 18 AVCC 17 PB5 (SCK) Programming connector - pin 3 20 AREF 29 PC6 (RESET/) Programming connector - pin 5 7, 8 PB6, PB7 XTAL 27, 28 PC4, PC5 TWI Interface VCC and GND (Digital Supply Voltage and Ground) Digital Supply Voltage has to be connected between VCC and GND pins. I connected pins 3, 5 and 21 to ground (GND). I connected pins 4 and 6 to VCC. The capacitor C1, which filters the digital supply voltage, is connected between VCC and GND. AVCC (Analog Supply Voltage) and AREF (Analog Reference) The analog supply voltage AVCC is connected to VCC through a low pass LC filter L1, C2. The capacitor C3, which filters the reference voltage for A/D converter (CA/D), is connected to the analog reference pin AREF. XTAL (XTAL=PB6 and XTAL2=PB7) and RESET/ (=RC6) For generating clock we are using a 16 MHz quartz crystal (Q1) connected between PB6 and PB7 pins. These 2 pins are decoupled by 2 capacitors (C4 and C5). Reset pin (RC6) is connected to VCC by resistor R1 and to GND by a pushbutton (S1) which resets the microcontroller when is pushed. By connecting a capacitor to the ground (C6) we obtain the reset when the power supply is connected. The reset pin is connected also to the programming port. SPI and TWI interface TWI has 2 signal lines SCL (PC5) and SDA (PC4). A pull-up resistor is connected at each line. The SPI (Serial Peripheral Interface) is used for microcontroller’s programming. AVRISP programmer (ISP – In circuit Serial Programmer) is connected to a 6 pin connector. The programming connector has next pin configuration: 1 - MISO (PB4) 2 - VCC 3 - SCK (PB5) 4 - MOSI (PB3) Pagina 4 din 11 5 - RESET/ (RC6) 6 – GND Pins for Specific Use (17) 17 pins are available for specific application requirements. Servos Control (6) We used digital output pins PD2…PD7 to control the servos. The servos are connected at K2…K7 connectors. Each connector has 3 pins with next signals: GND (by resistors R4…R9); V+; PWM Signal. The servos are not connected directly to the ground, but through the R4…R9 resistor which have a very little resistance (0.2 Ω). The current through the resistors is the same as the one passing through the corresponding servo. If we measure the voltage across the resistors we have information about the electrical current and therefore about the torque of the servo. Servos supply voltage is V+ and is different from VCC, digital supply voltage. Measuring Current trough Servos (6) The voltages across resistors R4…R9 are small (maximum 0.2V) therefore I used amplifiers to increase them. We use 3 LM358, dual operational amplifiers ICs, to realize 6 non-inverting amplifiers. The voltage across the resistor for current sensing is amplified in such a way the voltage range at the amplifier’s output is 02.5V. The outputs of the six amplifiers are connected to the inputs ADC0…ADC3, ADC6 and ADC7 of microcontroller. We didn’t use ADC4 and ADC5 because are used for TWI interface. USART Connector (2) The pins TXD (PD1) and RXD (PD0) of the serial port are available at K9 connector. Unused Pins (3) A total of 3 pins (PB0, PB1 and PB2) are unused and they are available at K10 connector. Voltage Regulator The board has a 5V voltage regulator (IC5). The diode D1 protects the circuit if the battery is connected with wrong polarity. We could use a p channel MOSFET transistor, which assure a smaller voltage drop, but this is not necessary as long as battery voltage (across K11 connector) is big enough (7,2V). The D2 LED, connected to the voltage regulator output shows the presence of the supply voltage on board. We use the C7, C14 and C15 capacitors, connected between VCC and GND, to filter out the supply voltage near operational amplifiers. Pagina 5 din 11 Bill of Materials The list of components to build the controller is found in Table 1. Pos 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 Quantity 3 2 4 6 1 1 1 1 1 3 1 1 7 7 1 1 1 1 7 2 6 6 1 1 Name C1,C2,C3 C4,C5 C6,C7,C14,C15 C8,C9,C10,C11,C12,C13 C16 C17 D1 D2 IC1 IC2,IC3,IC4 IC5 K1 K2,K3,K4,K5,K6,K7,K10 K8,K9,K13,K14,K15,K16,K17 K11 K12 L1 Q1 R1,R10,R12,R14,R16,R18,R20 R2,R3 R4,R5,R6,R7,R8,R9 R11,R13,R15,R17,R19,R21 R22 S1 Value C-SMD_0805_50V_5%_0,1µF 18pF 0,1µF 0,047µF 10µF 22µF 1N4001 LED-SMD1206_green ATMEGA8(TQFP32) LM358D LM2940CS K2X03 K1X03 K1X02 C1x2 C1x2 BLM21AF121SN1D QUARZ_16,0000MHZ 10K 2K2 R5,08_DIN 100k 1K Taster_Kurzhub Package 0805 0805 0805 0805 1411_ELKO 2412_ELKO D_GRID10,16 1206 TQFP32(7X7) SO8_SOT96-1 TO263/3 2X03 1X03 1X02 1X02 ANSCHLUSSKLEMME_2 0805 HC49/U 0805 0805 1206 0805 0805 PUSHBUTTON_QUICKLIFT Table 1 – Bill of Materials PCB Design The step by step approach for documenting the design of PCB was very difficult and that’s why I chose to present just the results. I designed the single sided PCB in 3 steps: - I placed the components on the board; - I routed the traces; - I exported the files for PCB making. I chose to manually components placing and trace routing, because the results are much better than automatically placing and routing. Next I will show you the drawings for PBC making. Pagina 6 din 11 PCB Layouts PCB composite top view The printed circuit and placement of components are shown in Figure 3. Principal elements in the drawing are: - bottom layer tracks, colored in red; - top THD components footprints, colored in black; - bottom SMD components footprints, colored in white blue. PCB dimensions are 65 mm x 55 mm. In order to have a better clearance of the drawing, the ground plane is not presented in Figure 3. Because I didn’t succeed to route all traces on a single layer I used some bridges placed on top face (drowned with thick black line). Figure 3 – PCB Composite Top View (Components Placement and Copper Traces) Pagina 7 din 11 Bottom Layer Tracks Bottom PCB Layout, used to make the board, is shown in Figure 1. Figure 1 – Bottom Layer Tracks Silk-screens Silk-screens, for top (THD components) and bottom (SMD components) sides, are shown in Figure 2. Figure 2 – Silk-screens for top and bottom sides Pagina 8 din 11 3D views 3D views generate by CAD software “Target 3001!” are shown in Figure 3. Figure 3 – 3D Views (Bottom and Top) PCB Manufacturing The printed circuit board was made using TTS (Toner Transfer System) method. We used blue PnP (Press and Peel) foil for transfer because the resolution is better than for white PnP foil. In Figure 4 you can see that the toner transfer is better for the left board than for the right board. The drawings printed on the board were corrected by redrawing unprinted connections with a marker and removing the short-circuits by scratching. Figure 4 – Single Side PCB Laminate and PnP Foil after toner transfer (2 instances) Pagina 9 din 11 In Figure 5 you can see the printed circuit board after etching. There are few over etched areas but the functionality of the board is not affected. Figure 5 – PCB after Etching Components Placing and Soldering The components were placed according to the design with some exceptions (Figure 6). For R4…R9 resistors we used THD components because we didn’t find 0.1 Ω SMD resistors. Board design allowed modifications (making drills) to mount the THD resistors. One of lesson learned from this project, is to use both footprints for critical components – THD and SMD – in the PCB design process, as the availability of components is a factor in this case. Figure 6 – Board Assembly Populated with Components (Bottom and Top View) We used a soldering iron to solder the SMD and THD components. Pagina 10 din 11 Conclusions The controller has functioned well at the preliminary tests. For actuation of the entire robotic arm we can choose to design another controller to command the remaining servos of the arm. Other solution is to use a single controller for all robotic arm servos. In the second case, probably we have to drop out the facility of measuring the fingers pressure force. This paper could be useful for people who want to understand how to use Atmel microcontrollers in applications. Bibliography 1. *** ATmega8(L) Rev. 2486Z–AVR–02/11. Atmel. http://www.atmel.com/Images/doc2486.pdf. 2. Agape, Mihai (august 2011). „Controler pentru comanda degetelor unui braţ robotic”. Conexiuni 6 (I.S.S.N. 1584 – 8645): 51 - 62. Conexiuni 6 magazine can be downloaded by following the link http://www.didactic.ro/magazines/download/id/2428. 3. Agape, Mihai (decembrie 2007). „Utilizarea foliilor PnP la realizarea circuitelor imprimate”. Conexiuni 2-3 (I.S.S.N. 1584 – 8645): 36 – 42. Conexiuni 2-3 magazine can be downloaded by following the link http://www.didactic.ro/magazines/download/id/723. This project has been funded with support from the European Commission. This publication reflects the views only of the author, and the Commission cannot be held responsible for any use which may be made of the information contained therein. Translated by Scientix (www.scientix.eu) Pagina 11 din 11