* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download L11S08

Oxidation state wikipedia , lookup

Jahn–Teller effect wikipedia , lookup

Metal carbonyl wikipedia , lookup

Stability constants of complexes wikipedia , lookup

Cluster chemistry wikipedia , lookup

Spin crossover wikipedia , lookup

Evolution of metal ions in biological systems wikipedia , lookup

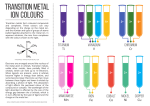

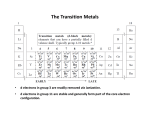

Lecture 11 Metals, Metallurgy, and Coordination Chemistry Text: Chapter 16 Minerals Most metals are found in nature in the form of solid inorganic compounds called minerals. The most important source of metals are oxide, sulfide, and carbonate minerals. Principal Mineral Sources of Some Common Metals Meal Mineral Composition Aluminum Bauxite Al2O3 Chromium Chromite FeCr2O4 Copper Chalcocite Cu2S Chalcopyrite CuFeS2 Malachite Cu2CO3(OH)2 Hematite Fe2O3 Magnetite Fe3O4 Lead Galena PbS Mercury Cinnabar HgS Titanium Rutile TiO2 Ilmenite FeTiO3 Sphalerite ZnS Iron Zinc Metals and Metallurgy 1 Metallurgy Metallurgy is the science and technology of extracting metals from natural sources and preparing them for practical use. Five Steps 1. Mining (getting the ore out of the ground) 2. Concentrating (preparing it for further treatment). Differences in the chemical and physical properties of the mineral of interest and the undesired material, called, gangue, are used to separate the components. Example: Iron maybe separated from gangue in finely ground magnetite by using a magnet to attract the iron. 3. Reduction (to obtain the metal in the 0 oxidation state). 4. Refining (to obtain the pure metal). 5. Mixing with other metals (to form an alloy). Alloys are metallic materials composed of tow or more elements. Pyrometallurgy: Using high temperatures to obtain the free metal. Calcination: the heating of ore to cause decomposition and elimination of a volatile product. PbCO 3 s PbO s CO2 g Roasting : A heat treatment to cause chemical reactions between the ore and the atmosphere of the furnace. 2ZnS s 3O2 g 2ZnO s 2SO2 g 2MnS 2 s 7O2 g 2MnO3 s 4SO2 g Metals and Metallurgy 2 Smelting: a melting process that causes materials to separate into two of more layers. Slag consists of mostly molten silicates in addition to aluminates, phosphates, fluorides, and other inorganic materials. Refining of iron Ore, limestone, and coke are added to the top of the furnace. 2Cs O2 g 2COg Cs H 2Og COg H2 g Around 250°, limestone is calcinated to form lime, which reacts with molten silica to form slag. CaOl SiO2 l CaSiO 3 l Fe 3O4 s 4COg 3Fes 4CO2 g Fe 3O4 s 4H2 g 3Fes 4H2 Og Hydrometallurgy It is the extraction of metals from ores using aqueous reactions. Leaching is the selective dissolution of the desired mineral. Dilute acids, bases, salts, and sometimes water. 4Aus 8CN – aq O2 g 2H 2Ol 4AuCN–2 aq 4OH – aq 2Au CN–2 aq Zn s Zn CN 2– 4 aq 2Aus Al 2O3 H 2Os 2H2Ol 2OH – aq 2AlOH–4 aq Metals and Metallurgy 3 Electrometallurgy molten salts and aqueous solutions Molten NaCl using Downs cell. Cathode : 2Na l 2e – 2Nal Anode : 2Cl – l Cl 2 g 2e – Molten Al2O3 in Hall Process Bauxite Al2O3•nH2O Al2O3 + Na3AlF6 (cryolite) form lower melting mixture than pure Al2O3 Electrolysis gives aluminum metal Cathode : Al l 3e – All Anode : Cs + O2– l CO2 g 4e – Rubies! Al2O3 with small amount of Cr3+ (as Cr2O3) Blue sapphire Fe2+, Ti4+ Electrorefining copper Impure copper anode - dissolves along with impurities Pure copper collected at cathode Cu 2 l 2e – Cus Ered 0.34 V 2H2 Ol + 2e – H 2 g 2OH – aq Ered 0.83 V Metals and Metallurgy 4 Metallic Bonding Properties of Metals luster high heat conductivity electrical conductivity malleable - sheets ductile - wires Electron-Sea Model metal cations in a "sea" of electrons electrons are confined to the metal by electrostatic attractions to the cations electrons are mobile; they are not confined to any particular metal ion (electrons are delocalized) metal atoms form bonds to many neighbors Molecular-Orbital Model Overlap of atomic orbitals on metal atoms to form molecular orbitals. There are a very large number of orbitals in metals. The number of molecular orbitals involved equals the number of atomic orbitals. The number of bonding orbitals is equal to the number of anti-bonding orbitals. As the number of orbitals increases, their energy spacing decreases until they band together. Metals and Metallurgy 5 3p band vacant 3p E ²E = h ~0 J to excite e- 3s Mg 3s band occupied Mg2 Mg3 Mg10 Mg• antibonding bonding Sc melting point, °C 1541 Cr 1857 Metals and Metallurgy 6 Ni 1455 Conduction Band (Antibonding) Energy Antibonding Band gap Band gap Bonding Valence Band (Bonding) Metal Insulator Element Energy Gap (kJ/mol) Copper 0 Diamond 502 Silicon 100 intrinsic semiconductor p-doped semiconductor p-dopant: Al, Ga Metals and Metallurgy 7 Semiconductor n-doped semiconductor n-dopant: P, As Metals and Metallurgy 8 Alloys Alloys are materials that contain more than one element and have the characteristic properties of metals. Solution alloys are homogenous mixtures. There are two types of solution alloys. Substitutional alloys; in which solute atoms take the positions normally occupies by a solvent atom. Interstitial alloys; in which solute atoms occupy interstitial sites in the metal lattice. In susbtitutional alloys the atoms must have similar atomic radii and the elements must have similar bonding characteristics. In interstitial alloys, one element (usually a nonmetal) must have a significantly smaller radius than the other (in order to fit into the interstitial site). These alloys are much harder, stronger, and less ductile than the pure metal (increased bonding between the nonmetal and metal). Steel is an example of an interstitial alloy (contains up to 3 percent carbon). Mild steel (< 0.2% carbon) used for chains, nails Medium steel (0.2-0.6% carbon) -girders, rails High carbon steel (0.6-1.5% carbon) cutlery, tools, springs Metals and Metallurgy 9 In alloy steels V and Cr are added to steel to increase and improve resistance to stress and corrosion. Stainless steel contains C, Cr (from ferrochrome, FeCr2), and Ni. Heterogeneous alloys : Components not dispersed uniformly Pearlite, two distinct phases: pure iron and Fe3C, cementite Intermetallic Compounds - homogenous alloys that have definite properties and compositions. CuAl2 duraluminum Ni3Al used in aircraft engines Cr3Pt used to coat razor blades Transition Elements d-block ns2(n-1)d transition elements (metals) • high melting solids (excepts mercury, Hg) • metallic sheen • good conductors of electricity and heat electron configuration [noble gas core] nsa (n-1)db Metals and Metallurgy 10 during oxidation s electrons are lost first (first in, first out) Oxidation Numbers 1st series 2+, 3+ common Sc 3+ Ti 4+ (3+) V 4+, 5+ Cr 3+, 6+ Mn 2+, 4+, 7+ Fe ([Ar]3d64s2) Fe2+ ([Ar]3d6) Fe3+ ([Ar]3d5) Higher oxidation states are more common in the 2nd and 3rd series ex: RuO4, OsO4 (+8) Magnetism If a species contains unpaired electrons it is paramagnetic If it has no unpaired electrons it is diamagnetic Ferromagnetism - the magnetic moments become permanently aligned. (Fe, Co, Ni) Chemistry of Selected Transition Metals Chromium In aqueous solution, Cr reacts with acid to form blue Cr2+; Crs 2H aq Cr 2 aq H 2 g In air, Cr2+ readily oxidizes to Cr3+: Metals and Metallurgy 11 4Cr 2 aq O2 g 4H 4Cr 3 aq 2H2 Ol In aqueous solution, chromium is usually present in the +6 oxidation state. In base, chromate (CrO42–) is most stable. In acid, dichromate (Cr2O72–) is the most stable ion. Iron In aqueous solutions iron is present as the +2 (ferrous) or +3 (ferric) oxidation states. Iron reacts with non-oxidizing acids to form Fe2+(aq) In the presence of air, Fe2+ is oxidized to Fe3+. In acid solution, Fe(H2O)63+ forms, but in base Fe(OH)3 precipitates. Copper In aqueous solution, there are to common oxidation states +1(cuprous) and +2(cupric). Cu+ has a 3d10 electronic configuration and it’s salts tend to be white and insoluble in water. Cu(I) disproportionates easily in aqueous solution. 2Cu aq Cu 2 aq Cus Cu(II) is the more common oxidation state. Many Cu(II) salts are soluble: CuSO4, Cu(NO3)2, and CuCl2. Metals and Metallurgy 12 Coordination Chemistry Coordination Compounds coordination sphere (all atoms within the brackets) central metal ligands acts as Lewis acid have at least one lone pair of electrons (Lewis base) Coordination number number of ligands attached to metal [Ag(NH3)2]+ central metal: Ag ligands: NH3 coordination number: 2 Ligands monodentate "one toothed" donates one pair of electrons ex: H2O NH3 H H Br- CN– H O N H Cl- H Cl Br Metals and Metallurgy 13 C N Polydentate or chelating ligands bidentate "two toothed" donates two pairs of electrons H2N en (ethylene diamine) O NH2 O C O H2N NH2 M O 2– O C C C O O O M oxalato H3C C O H C – C CH3 H3C O C H C O O M acac Metals and Metallurgy 14 C CH3 N N N N M phen N H2N NH2 NH2 tren edta (ethylene diamine tetraacetic acid) up to 6 O O O O C N N C O Cu NH2 CH2 O C O 2 amino acid chelate Metals and Metallurgy 15 O C O O metal chelate - results from a polydentate ligand attaching to a metal 0 C HS HS C H2 CH C H2 OH British Anti-Lewisite Used to treat heavy metal (Tl, As, Hg, Cr) poisoning by forming water soluble chelate of the metal, that is eliminated through the kidneys Metals and Metallurgy 16 Naming Coordination Compounds 1. In naming a coordination compound that is a salt, name the cation first and then the anion. 2. When giving the name of the complex ion or molecule, name first, in alphabetical order, followed by the name the ligands of the metal. • if the ligand is an anion whose name ends in -ite or -ate, the final e is changed to o (sulfate sulfato) • if the ligand is an anion whose name ands in ide, the ending is changed to o (chloro, bromo, iodo) • if the ligand is a neutral molecule, its common name is usually used. The exceptions are water which become aqua, ammonia becomes ammine, and CO, called carbonyl • When there is more than one of a particular monodentate ligand with q simple name, the number of ligands is designated by the appropriate prefix: di, tri, tetra, penta, hexa. If the ligand is complicated the prefix changes to bis, tris, tetrakis, pentakis, hexakis, followed by the ligand name in parentheses. 3. If the complex ion is an anion, the suffix ate is added to the metal name. 4. Following the name of the metal, the oxidation number of the metal is given in Roman numerals. Metals and Metallurgy 17 Geometries Common coordination numbers are 2, 4, and 6 CN = 2 Linear CN = 4 Tetrahedral, Square Planar (Common for d8) CN = 6 Octahedral M M M M M M Metals and Metallurgy 18 Isomers Structural Isomers - different bonds Linkage isomers O X X X X N M X X O N O M X O X X nitrito red X nitro yellow Coordination sphere isomers 3+ H2O H2O Cr OH2 H2O 3Cl OH2 H2O Cl Cr OH2 H2O OH2 OH2 green violet Stereoisomers - same bonds, different spatial arrangements. Geometric Isomers Cis and Trans isomers Cl Cl Pt H3N Cis NH3 + Cl Cl NH3 Pt H3N Trans Metals and Metallurgy 19 Cl Cl •2H2O H2 N Cl Cl H2 N NH2 NH2 Co N H2 Co N H2 Cl H2N N H2 Cl Cis Trans Fac and Mer Isomers Cl Cl N Cr Cr Cl N N Cl Cl NH3 NH3 Cl NH3 Cr Cl Cr NH3 H3N Fac Cl Cl H3 N Mer Metals and Metallurgy 20 Optical Isomers Mirror images but not superimposable H3 N Br Br M M Cl I I H3 N enantiomers NH3 Cl I Br Br M M Cl - Cl NH3 I Must have four different groups attached to central atom O O O O M HN M N NH O O NH N HN Metals and Metallurgy 21 Bonding in Coordination Compounds z x y dz2 x dxy y x z y dx2-y2 dxz z dyz Oh Td Metals and Metallurgy 22 square planar x2-y2 xy z2 xz, yz Magnetic Properties High-spin Low-spin low splitting orbitals are similar in energy large splitting orbitals are dissimilar in energy Low spin only d4 through d7 ² ² Metals and Metallurgy 23 Oh Color Visible spectrum 400 to 700 nm ROY G BIV RED GREEN 700 BLUE 400 nm INCREASING ENERGY Combination of Three Primary Colors RED, GREEN, and BLUE White light is a product of all colors Absorption of one color produces a combination of the other two If we see yellow, a combination of red and green, then blue is absorbed. In transition metal complexes, absorption of light is a measure of the energy levels of the metal atom or ion. Absorption of energy (²) ² Metals and Metallurgy 24 Oh The energy of light absorbed by the complex is related to the crystal field splitting, ∆, caused by the ligands. Spectrochemical Series Halides < C2O42- < H2O < NH3 = en < phen < CNsmall field splitting large orbital splitting small ∆ large ∆ weak field ligands strong field ligands Fe(CN)64- absorbs violet Fe(H2O)62+ absorbs red see lemon yellow see blue-green Metals and Metallurgy 25 Complex Wavelength Color absorbed Color of Complex 700 red green [Co(C2O4)3]3- 600, 420 yellow, violet dark green [Co(H2O)6]3+ 600, 400 yellow, violet blue green [Co(NH3)6]3+ 475, 340 Blue, ultraviolet yellow-orange [Co(en)3]3+ 470, 340 Blue, ultraviolet yellow-orange [Co(CN)6]3- 310 Ultraviolet pale yellow absorbed [CoF6]3- Metals and Metallurgy 26