* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download CH09-Ops - Oakton Community College

Survey

Document related concepts

International Council of Management Consulting Institutes wikipedia , lookup

Management consulting wikipedia , lookup

Opportunity management wikipedia , lookup

Backflush accounting wikipedia , lookup

Control chart wikipedia , lookup

Demand flow technology wikipedia , lookup

Transcript

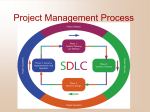

Chapter 09 Production and Operations Management McGraw-Hill/Irwin Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved. Chapter Nine LEARNING GOALS 1. Describe the current state of U.S. manufacturing and what manufacturers have done to become more competitive. 2. Describe the evolution from production to operations management. 3. Identify various production processes and describe techniques that improve productivity, including computer-aided design and manufacturing, flexible manufacturing, lean manufacturing and mass customization. 9-2 Chapter Nine LEARNING GOALS 4. Describe operations management planning issues including facility location, facility layout, materials requirement planning, purchasing, just-in-time inventory control and quality control. 5. Explain the use of PERT and Gantt charts to control manufacturing processes. 9-3 Profile SAMUEL J. PALMISANO IBM • Palmisano, CEO and President of IBM, started in the company in 1973. • The company’s earnings have quadrupled under Palmisano. • Switching the company’s focus from production to service, Palmisano led IBM to enter the emerging global market. 9-4 Chapter Nine NAME that COMPANY This company’s robots manufacture, test, and package motor starters - all untouched by human hands. The machines can fill special orders, even for a single item, without slowing down the process. Name that company! 9-5 Manufacturing and Services in Perspective MANUFACTURING in the U.S. LG1 • The U.S. is still the world’s leading manufacturer. • Manufacturing has continued to grow since 1970. In fact, U.S. manufacturing is 2x bigger than in 1970. • Almost 25% of all goods produced each year come from the U.S. 9-6 Manufacturing and Services in Perspective WHAT is MADE in the USA? LG1 Leading U.S. Manufactured Goods Products Value Number of Employees Chemicals – Pharmaceuticals, cosmetics, soaps, paints, fertilizers $250 Billion 830,000 Americans Transportation Equipment – Cars, planes, trains, ships $195 Billion Over 1.4 Million Americans Processed Foods, Beverages and Tobacco – Cookies, coffee, cigarettes, prepared meals $175 Billion 1.7 Million Americans Computers and Electronics – Computers and communication equipment $146 Billion 1.2 Million Americans Source: Parade Magazine, www.parade.com, accessed June 2011. 9-7 Manufacturing and Services in Perspective Exporters Extraordinaire LG1 Top Ten States that Manufacture Goods for Export Rank State Amount Exported 1 California $142.61 billion 2 Texas $130.66 billion 3 New York $72.58 billion 4 Michigan $67.94 billion 5 Washington $61.99 billion 6 Illinois $57.92 billion 7 Ohio $42.59 billion 8 Florida $41.58 billion 9 New Jersey $36.77 billion 10 Pennsylvania $34.57 billion Source: CNBC, www.cnbc.com, accessed June 2011. 9-8 Manufacturing and Services in Perspective MASSIVE MANUFACTURERS LG1 The Top Ten U.S. Manufacturers Rank Company Industry 1 Exxon Mobil Petroleum and Coal 2 Chevron Petroleum and Coal 3 General Electric Electrical Equipment and Appliances 4 ConocoPhillips Petroleum and Coal 5 Ford Motor Company Automobiles 6 Hewlett-Packard Computers 7 IBM Computers 8 Procter & Gamble Chemicals 9 Archer-Daniels-Midland Food 10 Boeing Aerospace Source: Industry Week, www.industryweek.com, accessed June 2011. 9-9 KEY WORD: SUSTAINABILITY (Thinking Green) • The market for new green products and services is almost endless. • Given the rate of population growth, it’s important to plan ahead for a world with limited resources. • Companies like DuPont, Michelin, Chevron and Nokia are working on sustainability projects. • Procter & Gamble and Kaiser Permanente issue their own mandatory sustainability scorecards to their supply chains. 9-10 Manufacturing and Services in Perspective TOP-PAYING SERVICE JOBS LG1 • The U.S. economy is no longer manufacturing based. • 85% of jobs are in the service sector. • The top-paying service jobs in the U.S. are in: - Legal services Medical services Entertainment Accounting Finance Management consulting 9-11 Manufacturers and Service Organizations Become More Competitive LG1 REMAINING COMPETITIVE in GLOBAL MARKETS • U.S. is still the leader in nanotechnology and biotechnology. • How can U.S. businesses maintain a competitive edge? - Focusing on customers - Maintaining close relationships with suppliers - Practicing continuous improvement - Focusing on quality - Saving on costs through site selection - Relying on the Internet to unite companies - Adopting new production techniques 9-12 LEARNING from GERMANY (Reaching Beyond Our Borders) • Ten years ago, Germany’s economy was much like ours today. • Stihl invested in highly trained workers. • Stihl remained competitive in the manufacturing world. • German companies poured money into research and stayed away from high tech products. 9-13 From Production to Operations Management LG2 PRODUCTION and PRODUCTION MANAGEMENT • Production -- The creation of goods using land, labor, capital, entrepreneurship and knowledge (the factors of production). • Production Management -- All the activities managers do to help firms create goods. 9-14 From Production to Operations Management OPERATIONS MANAGEMENT LG2 • Operations Management -- A specialized area in management that converts or transforms resources into goods and services. • Operations management includes: - Inventory management Quality control Production scheduling Follow-up services 9-15 Operations Management in the Service Sector LG2 OPERATIONS MANAGEMENT in the SERVICE SECTOR • All about creating a good experience for those who use the service. • In hotels, like RitzCarlton, operation management includes fine dining, fresh flowers, and training for every employee. 9-16 Operations Management in the Service Sector THERE is an APP for THAT Top Productivity Apps for iPad LG2 App What it Does Price Dropbox Syncs and backs up files Free ServiceMax Helps field employees with data management Free Keynote Use to create and show slide presentations $9.99 Penultimate Note taking made easier $3.99 ZigZag Board An easy-to-carry whiteboard $4.99 Source: Entrepreneur, February 2011. 9-17 Progress Assessment PROGRESS ASSESSMENT • What have U.S. manufacturers done to regain a competitive edge? • What must U.S. companies do to continue to strengthen the country’s manufacturing base? • What led companies to focus on operations management rather than production? 9-18 Production Processes The PRODUCTION PROCESS LG3 9-19 Production Processes FORM UTILITY LG3 • Form Utility -- The value producers add to materials in the creation of finished goods and services. 9-20 Production Processes LG3 GROVE’S BASIC PRODUCTION REQUIREMENTS 1. To build and deliver products in response to the demands of the customer at the scheduled delivery time. 2. To provide an acceptable quality level. 3. To provide everything at the lowest possible cost. 9-21 Production Processes LG3 PROCESS and ASSEMBLY in PRODUCTION • Process Manufacturing -- The part of production that physically or chemically changes materials. • Assembly Process -The part of the production process that puts together components. 9-22 Production Processes KEY PRODUCTION PROCESSES LG3 • Production processes are either continuous or intermittent. • Continuous Process -- Long production runs turn out finished goods over time. • Intermittent Process -- Production runs are short and the producer adjusts machines frequently to make different products. 9-23 Production Processes LG3 MINUTE MADE Production of Some of America’s Favorite Products Product Number of Items Made in a Minute Krispy Kreme Doughnuts 5,208 Chips Ahoy! Cookies 4,000 Twinkies 972 Jello Boxes 764 LifeSavers 100 rolls 9-24 The Need to Improve Production Techniques and Cut Costs LG3 DEVELOPMENTS MAKING U.S. COMPANIES MORE COMPETITIVE 1. Computer-aided design and manufacturing 2. Flexible manufacturing 3. Lean manufacturing 4. Mass customization 9-25 Computer-Aided Design and Manufacturing LG3 COMPUTER-AIDED DESIGN and MANUFACTURING • Computer-Aided Design (CAD) -- The use of computers in the design of products. • Computer-Aided Manufacturing (CAM) -The use of computers in the manufacturing of products. 9-26 Computer-Aided Design and Manufacturing LG3 COMPUTER-INTEGRATED MANUFACTURING • Computer-Integrated Manufacturing (CIM) -The uniting of computeraided design with computeraided manufacturing. • CIM is expensive but it cuts as much as 80% of the time needed to program machines to make parts. 9-27 Flexible Manufacturing FLEXIBLE MANUFACTURING LG3 • Flexible Manufacturing -- Designing machines to do multiple tasks so they can produce a variety of products. • Allen-Bradley uses flexible manufacturing to build motor starters. • 26 machines and robots build, test and package parts. 9-28 Lean Manufacturing LEAN MANUFACTURING LG3 • Lean Manufacturing -- Using less of everything than in mass production. • Compared to others, lean companies: - Take half the human effort. Have half the defects in finished products. Require one-third the engineering effort. Use half the floor space. Carry 90% less inventory. 9-29 Mass Customization MASS CUSTOMIZATION LG3 • Mass Customization -- Tailoring products to meet the needs of a large number of individual customers. • More manufacturers are learning to customize. • Mass customization exists in the service sector too. 9-30 MASS CUSTOMIZATION of CANDY (Spotlight on Small Business) • Chocomize lets customers customize their chocolate bars. • Co-founder, Eric Heinbockel, sought funding help from his family. • Chocomize now has three full-time chocolate makers and is expected to be a success. 9-31 Progress Assessment PROGRESS ASSESSMENT • What is form utility? • Define and differentiate the following: process manufacturing, assembly process, continuous process and intermittent process. • What is the integration of CAD and CAM called? • What is mass customization? 9-32 Operations Management Planning OPERATIONS MANAGEMENT LG4 • Operations management planning helps solve problems like: - Facility location - Facility layout - Materials requirement planning - Purchasing - Inventory control - Quality control 9-33 Facility Location FACILITY LOCATION LG4 • Facility Location -The process of selecting a geographic location for a company’s operations. • Rising numbers of Internet businesses means brick-and-mortar retailers must find great locations. 9-34 STAY or LEAVE (Making Ethical Decisions) • Potential of low-cost labor is very attractive to companies hoping to remain competitive. • However, shuttering operations and moving can often cause severe economic problems in dependent areas. • What would you do if you were the CEO of ChildrenWear Industries faced with this problem? 9-35 Taking Operations Management to the Internet LG4 OPERATIONS MANAGEMENT on the INTERNET • Sometimes businesses outsource engineering, design and manufacturing to other companies. • Often these relationships are managed through the Internet. • Many companies are developing Internet-focused strategies. 9-36 Facility Location in the Future FUTURE FACILITY LOCATION LG4 • Information technology gives firms increased flexibility in terms of location. • Telecommuting -- Working from home via computer. 9-37 Facility Layout SETTING UP the FACILITY LG4 • Facility Layout -- The physical arrangement of resources, including people, to most efficiently produce goods and provide services. • Facility layout depends on the processes performed: - Service: Help customers find products - Manufacturing: Improve efficiency 9-38 Facility Layout FACILITY LAYOUT OPTIONS LG4 1. Assembly Line Layout – Workers do only a few tasks at a time. 2. Modular Layout – Teams of workers produce more complex units of the final product. 3. Fixed-Position Layout – Allows workers to congregate around the product. 4. Process Layout – Similar equipment and functions are grouped together. 9-39 Facility Layout ASSEMBLY LINE LAYOUT LG4 9-40 Facility Layout MODULAR LAYOUT LG4 9-41 Facility Layout PROCESS LAYOUT LG4 9-42 Facility Layout FIXED-POSITION LAYOUT LG4 9-43 Materials Requirement Planning MRP and ERP LG4 • Materials Requirement Planning (MRP) -- A computer-based operations management system that uses sales forecasts to make sure parts and materials are available when needed. • Enterprise Resource Planning (ERP) -- A newer version of MRP, combines computerized functions into a single integrated software program using a single database. 9-44 Purchasing PURCHASING LG4 • Purchasing -- The function that searches for high-quality material resources, finds the best suppliers and negotiates the best price for goods and services. • The Internet has transformed purchasing. 9-45 Just-in-Time Inventory Control INVENTORY CONTROL LG4 • Just-in-Time (JIT) Inventory Control -- The production process in which a minimum of inventory is kept and parts, supplies and other needs are delivered just in time to go on the assembly line. • To work effectively, the process requires excellent coordination with suppliers. 9-46 Quality Control QUALITY CONTROL LG4 • Quality -- Consistently producing what the customer wants while reducing errors before and after delivery. • Six Sigma Quality -- A quality measure that allows only 3.4 defects per million opportunities. Photo Courtesy of: Argonne National Laboratory 9-47 Quality Control LG4 STATISTICAL QUALITY CONTROL & STATISTICAL PROCESS CONTROL • Statistical Quality Control -- A process used to continually monitor all phases of the production process. • Statistical Process Control -- A process of testing statistical samples of product components at each stage of production. • Measuring quality along the production process reduces the need for quality control at the end. 9-48 The Baldrige Awards The BALDRIGE AWARDS LG4 • Companies can apply for awards in these areas: - Manufacturing - Services - Small Businesses - Non-Profit/Government - Education - Healthcare 9-49 The Baldrige Awards THE WINNERS ARE… 2010 Baldrige Award Recipients LG4 Company Category Where from? MEDRAD Manufacturing Warrendale, PA Nestlé Purina PetCare Manufacturing St. Louis, MO Freese and Nichols Small Business Ft. Worth, TX K & N Management Small Business Austin, TX Studer Group Small Business Gulf Breeze, FL Advocate Good Samaritan Hospital Healthcare Downers Grove, IL Montgomery County Public Schools Education Rockville, MD Source: National Institute of Standards and Technology, www.quality.nist.gov, accessed June 2011. 9-50 ISO 9000 and ISO 14000 Standards WHAT is ISO? LG4 • The International Organization for Standardization (ISO) is a worldwide federation of national standards bodies. • ISO 9000 -- The common name given to quality management and assurance standards. • ISO 14000 -- A collection of the best practices for managing an organization’s impact on the environment. 9-51 Progress Assessment PROGRESS ASSESSMENT • What are the major criteria for facility location? • What is the difference between MRP and ERP? • What is just-in-time inventory control? • What are Six Sigma quality, the Baldrige Award, ISO 9000 and ISO 14000? 9-52 Control Procedures: PERT and Gantt Charts PERT LG5 • Program Evaluation and Review Technique (PERT) -- A method for analyzing the tasks involved in completing a given project and estimating the time needed. 9-53 Control Procedures: PERT and Gantt Charts STEPS INVOLVED in PERT LG5 1. Analyzing and sequencing tasks 2. Estimating the time needed to complete each task 3. Drawing a PERT network illustrating the first two steps 4. Identifying the critical path • Critical Path -- The sequence of tasks that takes the longest time to complete. 9-54 Control Procedures: PERT and Gantt Charts PERT CHART for a MUSIC VIDEO LG5 9-55 Control Procedures: PERT and Gantt Charts GANTT CHARTS LG5 • Gantt Chart – A bar graph that shows what projects are being worked on and how much has been completed. 9-56 Control Procedures: PERT and Gantt Charts LG5 GANTT CHART for a DOLL FACTORY 9-57 Progress Assessment PROGRESS ASSESSMENT • Draw a PERT chart for making breakfast of threeminute eggs, buttered toast and coffee. Define the critical path. • How could you use a Gantt chart to keep track of production? 9-58