* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Polarization controllable Fresnel lens using dye

Low-energy electron diffraction wikipedia , lookup

Nanochemistry wikipedia , lookup

Sessile drop technique wikipedia , lookup

Diamond anvil cell wikipedia , lookup

History of metamaterials wikipedia , lookup

Transformation optics wikipedia , lookup

X-ray crystallography wikipedia , lookup

State of matter wikipedia , lookup

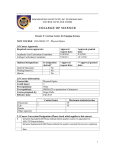

Polarization controllable Fresnel lens using dye-doped liquid crystals: An Inquiry Joshua T. Wiersma ([email protected]) College of Optical Sciences, University of Arizona, Tucson, Arizona 85721 Abstract: A Fresnel zone plate lens can be demonstrated using dye-doped liquid crystal film using photo-induced alignment. The aligned liquid crystal produces orthogonal polarization states for odd and even zones. The lens possesses the properties of being scattering free, having a very low operating voltage (~5Vrms), producing zero and first focus orders that can be separated, having adjustable diffraction efficiency, and having controllable polarization control. The ease with which the Fresnel plate can be fabricated along with the aforementioned properties of the plate give it many advantages over many other liquid crystal Fresnel plates for many applications [2]. Introduction: Fresnel lenses are widely used in areas such as photonics, optical imaging, long distance optical communication, as well as space navigation. Fresnel zone plates can be manufactured using methods such as lithography, etching, ion milling, or thin film deposition. A polarization controllable Fresnel lens is useful in applications where the amount of light needs to be controlled such as maskless lithography, projection displays, or variable optical attenuators. Liquid crystals are often used for fabricating a Fresnel lens due to its high birefringence and low operating voltage [2]. Liquid crystals have long been used for light attenuation due to their properties. Liquid crystals can be described as anisotropic, birefringent, elongated, dipole particles of a substance which has an inherently large dipole moment. All of these properties make liquid crystals a suitable choice for a polarization controllable Fresnel lens [5]. Scientific Description: The Fresnel plate’s fabrication process consisted of injecting a mixture of liquid crystal and azo dye between two glass slides. The liquid crystal utilized during fabrication was E7 (Merck) while the azo dye was Methyl Red (Aldrich). The ratio between the liquid crystal and the azo dye was 99:1 respectively. After being thoroughly mixed, the mixture was injected into a 10 m gap between two indiumtin-oxide (ITO) coated glass slides. The bottom slide had been previously coated with a thin polyvinyl alcohol film (PVA) and was subsequently gently buffed. The strong anchoring energy of the rubbed surface of the bottom slide induced a homogeneous liquid crystal layer to be formed [2] The process of fabricating a polarization controllable dye-doped liquid crystal Fresnel lens is much simpler than the microstructuring techniques used to fabricate one from quartz glass and liquid crystal. The fabrication of a polarization controllable Fresnel lens using quartz glass and liquid crystal involves computer-aided design and multiple processing by photolithography and reactive ion etching. Thus, the fabrication process is much more involved than that required when using dye-doped liquid crystals [3]. In order to orient the liquid crystal molecules to the desired direction, the dye-doped liquid crystal must be illuminated with linearly polarized light of a wavelength close to the dye’s absorption peak. The linearly polarized light induces a trans-cis isomerization of the dye, followed by molecular reorientation, diffusion, and absorption onto the surface of the untreated slide. This causes the long axes of the dye molecules to orient themselves along the untreated slide which in turn causes the liquid crystal to orient themselves along the direction of the dye’s long axis. However, due to the competition between the orienting force of the absorbed dyes and the anchoring force from the rubbed bottom slide, the sample must be illuminated for roughly 15 minutes at a relatively high intensity (=532nm @ I=50 mW/cm2). Under these conditions, the dye can generate an anchoring force strong enough to over come that from the rubbed bottom slide. In order to generate the Fresnel zone patterns, the illuminating light passes through a photomask with the desired Fresnel pattern. After the aligning process, light passing through the odd zones of the sample cell the polarization of the light is rotated 90 while light passing through the even zones of the sample cell is unchanged [2]. The focusing properties of the sample cell were studied using an expanded He-Ne laser beam which passed through a linear polarizer which was aligned with the rubbed axis of the sample cell. The light then passed through the sample, an analyzer, and finally onto a CCD camera (SBIG Model ST-2000XM) connected to a computer. When light passes through the even zones of the sample cell, the polarization of the light is not changed since the even zones consist of homogeneous liquid crystals. When light passes through the odd zones of the sample cell, the polarization of the light is rotated by 90. Thus, the light leaving the sample cell is orthogonally polarized. Therefore, the final polarization of the diffracted light is rotated by 45. The polarization states of the 0th and 1st diffraction orders are orthogonal to each other due to the diffraction character of the polarization grating. The 0th and 1st diffraction orders respectively correspond to the zero and first focus orders. If the analyzer is at a 45 angle with respect to the laser beam’s polarization, the first focus order will pass while if the analyzer is at a -45 angle, the zero focus order will pass. A smaller image is created by the first order focus when compared with the zero order focus [2]. The diffraction efficiency of the sample cell can be varied as a function of an applied voltage. The relative phase difference () between the adjacent odd and even zones determines the first order diffraction efficiency of a Fresnel lens. The relative phase difference is given by Eq. (1), 2 d (neven nodd ) (1) where “d” is the cell gap and “neven” and “nodd” are the respective effective indices of refraction of the liquid crystal in the even and odd zones. When the applied voltage exceeds roughly 1Vrms the liquid crystal begins to be reoriented by the electric field. When the relative phase difference reaches about 1.5, the diffraction efficiency reaches a maximum of roughly 31%. This occurs at about 2Vrms, after this point the diffraction efficiency gradually declines since the index of refraction of both the even and the odd zones is reduced [2]. The dye-doped liquid crystal technique has many advantages over techniques using polymer-stabilized liquid crystals. The polymer-stabilized liquid crystal Fresnel lens plate has a lower peak diffraction efficiency (23%) at a higher operating voltage (roughly 9Vrms). Also, a slight light scattering occurs when using polymer-stabilized liquid crystals in comparison with dye-doped liquid crystals [4]. Conclusion: A relatively simple fabrication process lead to the creation of a polarization controllable Fresnel lens using dye-doped liquid crystals. Illumination of the sample cell through a Fresnel patternd photomask creates even and odd zones in the sample. The different focus orders of the lens can be separated using an analyzer. The sample cell remains scatter free and operates at a relatively low voltage. The diffraction efficiency peak of the lens is roughly 31% and is achieved at an operating voltage of roughly 2Vrms [2]. Biographical Sketch: Dr. Shin-Tson Wu earned his Bachelor of Science degree in physics from National Taiwan University and his Doctor of Philosophy degree in quantum electronics from the University of Southern California. The photonics and displays research group at the University of Central Florida (UCF) is currently head by Dr. Wu who joined UCF in 2001. Dr. Wu came to UCF after an 18 year stint working at Hughes Research Laboratories. In addition, Dr. Wu is a fellow of the Society for Information Display (SID), Institute of Electrical and Electronics Engineers (IEEE), and the Optical Society of America (OSA). Dr. Wu has won numerous awards including the UCF Distinguished Researcher Award, IEEE Outstanding Engineer Award, SID Special Recognition Award, SID Distinguished Student Paper Award, ERSO (Taiwan) Special Achievement Award, Hughes Team Achievement Award, and Hughes Annual Outstanding Paper Award. Additionally, Dr. Wu is the founding Editor-in-Chief of the IEEE/OSA Journal of Display Technology. Furthermore, Dr. Wu has co-authored 4 books, 5 book chapters, over 350 papers, and can claim more than 55 issued and pending patents – some of which are currently being implemented [1]. Citations: 1. http://lcd.creol.ucf.edu/ 2. T. -H. Lin, Y. Huang, A. Y. G. Fuh, and S. -T. Wu, "Polarization controllable Fresnel lens using dye-doped liquid crystals," Opt. Express 14, 2359-2364 (2006). 3. M. Ferstl and A. Frisch, "Static and dynamic Fresnel zone lenses for optical interconnections," J. Mod. Opt. 43, 1451-1462 (1996). 4. Y. H. Fan, H. Ren and S. T. Wu, "Switchable Fresnel lens using polymer-stabilized liquid crystals," Opt. Express 11, 3080-3086 (2003). 5. K. Thomas, “Liquid Crystals and their Applications,” Optosonic Press (1970).