* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download environmental behaviour of tensile membrane structures

Survey

Document related concepts

Underfloor heating wikipedia , lookup

Hyperthermia wikipedia , lookup

Solar water heating wikipedia , lookup

Copper in heat exchangers wikipedia , lookup

Building insulation materials wikipedia , lookup

Thermal conductivity wikipedia , lookup

Insulated glazing wikipedia , lookup

Thermal comfort wikipedia , lookup

R-value (insulation) wikipedia , lookup

Thermal conduction wikipedia , lookup

Transcript

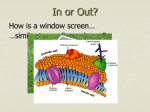

ENVIRONMENTAL BEHAVIOUR OF TENSILE MEMBRANE STRUCTURES Amira ElNokaly*, John Chilton and Robin Wilson School of the Built Environment, University of Nottingham, University Park, Nottingham, NG7 2RD, United Kingdom ABSTRACT This paper considers the environmental properties of spaces enclosed by tensile membrane structures (TMS). Limitations in the understanding of the environmental and thermal performance of TMS have to some extent hindered their acceptance by building clients and the building industry. A review of the early attempts to model the thermal environment of spaces enclosed by TMS is given and their environmental and thermal properties are discussed. The lack of appropriate tools for the investigation of their internal environment is identified and a need for further research in this area is suggested as a route to fully realising the potential benefits offered by TMS. Keywords: Environmental behaviour; Tensile membrane enclosures; Thermal performance; Fabric structures 1. INTRODUCTION: Fabric structures were originally used to provide shelter where materials were scarce, or mobility was required. Nowadays the issue of resource scarcity applies not only to materials but also to energy, and here again TMS have a potential role to play. Developments in material technology and the understanding of the structural behaviour TMS mean that it is now technically feasible to enclose very large spaces with a minimum of material. However, whilst the structural design of TMS can be approached with almost total confidence, the environmental performance of the spaces they enclose is still relatively poorly understood. Today, with the vast rate of technological progress and the deep concern over how this may be affecting our environment, there is a growing need to make the best appropriate use of solar energy in order to reduce conventional energy consumption. This has lead to a growth in the relevance of environmentally friendly architecture within which TMS have a useful role to play. *Corresponding author. Tel.: +44-0115-9513165; Fax: +44-0115-9513159. E-mail address:[email protected]; [email protected] 1 Engineered TMS are a structurally efficient means of enclosing large volumes using architectural forms that enjoy interesting spatial geometry. Although, the design and construction of such lightweight structures has become an established discipline, their potential is not yet fully realised. They can be used as climate modifiers in both hot and cold regions, offering in some circumstances conditions suitable for human occupation and in others a protected microclimate within which conventional buildings may be sited and operated in a highly efficient manner. As these are light and flexible structures there is also potential for folding the fabric membranes to change their function at different time of the day or season of the year 9. Despite the extensive research on the form finding and analysis of the complex threedimensional shapes of TMS and improvements in the material strength and durability of membranes that make possible these new applications difficulty in accurately quantifying the nature of the environment within these spaces means that these applications remain relatively unexplored. This paper reviews the range of approaches that have been adopted to predict the environmental performance of TMS, highlighting some of their limitations. It describes how TMS may be applied as climatic modifiers and outlines some of the features that the next generation of predictive tools should offer in order that those responsible for applying these environmental concepts may do so with the same degree of confidence as those responsible for the design of the structure. 2. EARLY ATTEMPTS TO INVESTIGATE THE THERMAL PERFORMANCE OF SPACES ENCLOSED BY FABRIC MEMBRANES. Early quantitative investigations assumed that the internal conditions of TMS could be predicted from a simple estimation of the total heat transfer between the external and internal surfaces of the membrane itself. To quantify this boundary heat transfer they adopted the simple steady state technique designed for the analysis of conventional structures, which was based on thermal transmittance or U- values 8. Further work appearing in an internal report by Du Pont 12 reported in Harvies thesis8, suggested that the thermal behaviour of these structures could be defined more accurately by the combination of two concepts, the Uvalue and the solar heat gain coefficient or “shading coefficient” (a property applied to solar heat gain through fabric membranes, relative to the solar heat gain through glass). Most of the membrane manufacturers today to express the thermal performance of their product in terms of these two quantities 2 and will often quote two U- values, one for standard winter conditions and one for standard summer conditions. However, adopting a steady state analysis technique, which was developed to predict the internal climate of conventional building types is not strictly appropriate for describing the thermal performance of TMS. U-value is a function of the thermal resistivity of the materials from which the building envelope is made and surface resistance effects. In a conventional structure, the material resistance term is dominant and heat conduction across the building envelope is therefore proportional to the difference in temperature of the air on either side of it. The fact that surface resistances are dependent on a great number of environmental parameters other than air temperature, and that these are largely neglected has minimal impact on the estimate of the U-values of conventional construction materials. The same assumption does not hold for membranes. Their negligible thickness results in heat flow being determined by the surface effects. To be described properly therefore, surface heat transfer should be expressed in terms of the difference between the temperature of the membrane surfaces and the environmental conditions that exist on either side of them. While use by the industry of different U-values for summer and winter may help to account for some variation in the surface effects, the approach is far from satisfactory for accurate prediction of thermal behaviour. Problems exist also with the use of shading coefficients, which assume that the amount of heat entering an enclosed space as a result of solar radiation falling on its external surface is linearly related to the intensity of that solar radiation. Whilst this is a reasonable assumption for glazed enclosures, experimental work has shown8,11,13, that in the case of membranes, the proportion of absorbed solar radiation subsequently radiated into the enclosed space is dependant not only on the solar intensity but also on the difference between the temperature of its surfaces and the environmental conditions on either side of them. Thus, it can be seen that in case of fabric membranes both the thermal transmission and solar heat gain are dependant upon the nature of the internal and external environments as well as the thermal state of the membrane. Techniques developed for the analysis of conventional construction types do not adequately account for these effects and so can not be expected to give reliable predictions of TMS thermal 3 performance. That should take into account the complex non-linear nature of internal conditions, for example. Hart et al.7, carried out three sets of simulations using a modified version of a computer model DOE-2.1 to predict the energy consumption of a standard design shopping arcade under varied climatic conditions found within 19 cities around the USA. The simulation was firstly performed for a single membrane roof, then a double and finally a conventional roof. The model assumed the membrane to be a large window with thermal calculations based on the use of shading coefficients and U-values and internal conditions that were assumed to be entirely uniform. Sinofsky 11 used a similar simple boundary model to investigate the thermal performance of retail space using a modified version of DOE-2. He recognised the limitations implicit in the use of U-values and shading coefficients in the investigation of the thermal behaviour of spaces enclosed by fabric membrane and proposed that thermal models should be modified in order to allow more of the significant membrane properties to be taken into consideration. While subsequent investigators have taken steps to account for the unique thermal behaviour of membranes, their analysis has by and large made other assumptions that limit the applicability of their results. Perhaps the most significant of these is the assumption that the environment within the enclosure is homogeneous. Field measurements undertaken by Wu et al. 14, in an attempt to understand the thermal behaviour of these structures identified stratification and suggested it might have potential as an energy saving strategy for fabric roof structures in certain seasons and locations. If left undisturbed as shown in figure 1, it was suggested that stratification could be used in the hot season to prevent extreme heat from penetrating into the low-level zone occupied by people. The investigators also recommended that for internal stratification to be predicted properly, the thermal behaviour of the space enclosed by the fabric structure, and not only the boundary heat transfer, should be properly understood. 4 Solar Radiation Membrane Boundary External Temperature Sky Condition Stratification within the enclosed space Air Velocity Internal Temperature COMFORT LEVEL WITHIN THE ENCLOSED SPACE Figure 1: Stratification in tensile membrane enclosures ( after Harvie 8). Early dynamic models failed to account for behaviour such as thermal stratification and buoyancy within the enclosure and the high contrast in the membrane surface temperature from one point to the other around the membrane skin. As such phenomena are likely to impact significantly both on occupant comfort and the performance of any structures enclosed by the membrane, the results from such studies while throwing more light on the behaviour of TMS, fail to tell the whole story. Moseley and Croome 3investigated the thermal behaviour of spaces enclosed by fabric membranes, using finite difference, response factor and the admittance methods for predicting the internal temperature within an air supported structure, which had been built for their research. Although this approach represented an improvement on work that had gone before, the techniques were originally developed for the analysis of more conventional, thermally massive buildings and also assumed that internal conditions were entirely uniform. Perhaps the most comprehensive investigation of TMS environmental behaviour to date has been undertaken by Harvie 8. His initial work concentrated on understanding the thermal behaviour of the fabric membrane. The results provided input to a general purpose computational fluid dynamics (CFD) model that used an iterative approach based on a nodal network of finite volumes or cells for the investigation of spaces enclosed by fabric membranes. Harvie’s work on understanding membrane performance confirmed many of the observations of previous researchers, e.g. that membranes are highly sensitive to changes in environment and have a very changeable thermal behaviour, and also identified that heat transfer was a direct result of convection surface heat transfers and thermal optical properties of the material. 5 External reflected solar radiatio Solar Radiation Convection Long wave Infra red radiation Absorption To Conduction 2. Memb rane Ti Convection Absorption Internal reflected solar radiation Long Wave Infra red radiation Figure 2: The Heat Transfer Model Representation of the Thermal Behaviour of Fabric Membranes (after Harvie.8) This improved understanding of membrane behaviour coupled with the ability of CFD to model dynamic internal environmental phenomena, such as air movement, led to new understanding of the internal processes that occur. An interesting observation resulting from this work was that contrasting internal surface temperature between the changeable membrane surface temperature and the more massive internal surfaces such as the floor generates the thermal gradients that occur in the enclosed space. That is the closer to the membrane surfaces the greater the response to the external environmental changes. The effect of these different response rates was suggested as the cause of internal stratification. Lack of computing power and probably time constraints of the researcher restricted the further development of this work and scope still exists to refine the modelling techniques and use these as tools to learn more about TMS thermal behaviour. 3. ENVIRONMENTAL PROPERTIES OF TENSILE MEMBRANES Fabric structures can cover large areas using little material for the building skin, doing more with less, embodying the concept of minimum surface area and maximum resource efficiency. The thickness of the fabric membrane, typically around 1mm in the case of coated woven fabric membranes and 50 to 200m for ETFE foil 4, also permits the skin to function as a passive filter, capable of modifying both thermal and light levels within the enclosed space to minimise reliance on conventional energy sources to control the 6 internal environment. Selection of materials with appropriate optical properties offers a means of creating spaces where daylight levels are accentuated or creating more protected shaded spaces. Given that widespan enclosures often make high demands on electric lighting it is important that appropriate use is made of lightweight transparent structures to allow natural daylight throughout the enclosed space in order to save energy. 3.1. Optical properties The optical properties of fabric membranes differ significantly from those of glass. Glass tends to have much higher solar transmittance, and lower reflectance than fabric membranes. Membrane properties also change more significantly at higher angles of solar incidence 8. It was these differences in properties that led Harvie 8 to conclude that the use of shading coefficient was inappropriate for describing optical properties of fabric membranes. The thermal optical properties of a material distinguish its radiant behaviour within the thermal spectrum. The amount and direction of the conduction of heat through the fabric structure depends greatly on the internal and external air temperatures, the wind speed, and on the thickness of the fabric and whether it is single or double membrane 10. In spite of the fact that structural foils such as ETFE can be more translucent than glass, the optical properties of fabric membranes are very much different from those of glass as stated earlier in this paper. Glass tends to have much higher solar transmittance, and lower reflectance than that of fabric membranes. This means that the effect of the solar reflectance is higher in fabric membranes than for glass. This results in the tendency of fabric membrane properties to change more significantly at higher angles of solar incidence8. One of the main advantages of TMS is their high percentage of translucency. The percentage of transmittance in coated woven fabric ranges between 0 to 20 %; this percentage is 93 % in ETFE cushions4. Harvie 8stated that the solar optical properties of both PVC coated polyester samples and PTFE coated glass fibre samples displayed very similar trends. Whereas, these trends were apparently different from the 7 displayed behaviour of glass. Thus, it was considered that the use of shading coefficient was insufficient to describe the thermal optical properties of fabric membranes. Harvie 8measured the optical properties of membranes in an attempt to have more significant data than that acquired by previous researchers. He used Edwards Type integrating sphere and spectrophotometers for his measurements. 100% 7 90% 15 32 80% Precentage % 70% 69.92 60% 80.2 74.29 78.22 Diffused Reflectance 50% 40% 78 60 30% 20% Diffused Absorptance Diffused Transmittance 24.75 18.29 17.97 10% 15.45 3.81 5.33 7.43 0% 4.35 Type 2 0.7 mm Type 3 0.85 mm PTFE New 0.75 PTFE Weathered 0.75 mm 8 Clear float glass 6mm Reflecting glass (Silver) 6mm Type of Material Figure 3:Comparison of Solar Optical Properties of membrane samples measured by Harvie 8 and Typical Glass Products2. Type 2 is a typical PVC coated polyester, gauge 0.7mm, 3 is PVC coated polyester, gauge 0.85 mm, Verseidag Indutex PTFE coated glass (new), gauge 0.75 mm, Verseidag Indutex PTFE coated glass (weathered), gauge 0.75 mm are compared with a typical float glass surface 6mm gauge 2, and a reflective glass surface 6 mm gauge. As can clearly be seen from figure 1, the transmittance (NN) and (D) % for PVC polyester membrane Type (2 &3) is inversely related to the thickness of the membrane while in case of the (D) % of absorptance and reflectance it is directly related to the thickness of the membrane. This means that the thinner the membrane the more translucent and the more glare-free light is admitted through the membrane to the enclosed space. In the case of PTFE glass (new), and PTFE glass (weathered), it is clear that the weathered membrane transmittance % (D), is higher than in case of PTFE glass (new), with both having the same thickness of 0.75 mm. It also seems that reflectance increases whilst absorptance decreases with 8 weathering, as a consequence of the change in colour from “oatmeal” to almost white. Comparing the behaviour of fabrics to that of glass made it completely obvious, that there is a great difference between their behaviour. 3.2. Lighting performance Providing natural light is a very important use of solar energy. Not only does natural lighting improve the visual quality of space, but it also reduces the need for electric lights. This saves energy used for lighting spaces and may also save energy used for cooling, as electric lights often contribute to internal heat gains and lead to a requirement for cooling plant. A bright delightful interior is one of the characteristics of buildings with membrane enclosures. The translucency of the membrane material controls the penetration of light while the interior is kept bright. The fact that sunlight striking the membrane surface is diffusely transmitted to the internal space also helps to minimise problems of glare. It is this range of light transmission characteristics that make TMS useful for applications such as sports facilities, for outdoor shelters, for music, dance and theatrical activities. The luminosity of fabric membrane roofs is basically influenced by three main factors 1. The availability of the outside daylight. The light transmission of the fabric roof material. The reflection/absorption of the membrane surface inside the space. Given the directional characteristics of membrane materials, the internal luminance of the fabric roof depends on the orientation of the curved surface to the sun and sky 1. Thus the internal luminance depends on the altitude of the sun and the sky condition, which change continually during the day and from season to season. Similarly the shape of the roof itself and its orientation plays an important role in the internal luminance, if properly adjusted it can either make use of sunlight to light the interior or provide solar protection by working as an effective shading device 9. This results in significant variation in the luminance of the internal roof. As a whole, these dynamic changes cause a considerable variation in lighting performance within the enclosed space and represent a valuable tool that may be used by the designer to manipulate the internal environment. 9 4. USE OF TOPOLOGY TO MANIPULATE THE INTERNAL ENVIRONMENT As mentioned earlier the unclear understanding of the environmental behaviour of spaces enclosed by TMS might be an obstacle for different applications of the structure. Designers must think of other ways of using the fabric membranes in order to offer significant benefits to the occupiers and the clients. Sometimes the mis-application of the technology after selling it to the client leads to dissatisfaction with the internal conditions. This usually happens when using the structure in a function different than what it has been designed for at the first instance. Tensile structures can be used as microclimate modifiers in a number of different ways. For example the use of retractable fabrics or canopies, the arrangement of the internal thermal mass, as shading device, for inducing airflow inside the enclosure, some of these ideas are discussed below. a) b) Radiant Heat Reflective Surface Air Flow Re-radiation of Heat in the Enclosure Thermal Mass c) d) Reradiation to the Night-sky Fresh Air Shading Device Air Flow Thermal Mass f) e) Warm Air Warm Air Stack Effect Cool Air 1. Cool Air Flow Arrangement of the Internal Thermal Mass Figure 4: Using topology in manipulating internal comfort within or underneath the structure. 10 In winter fabric structures should be tight to prevent prevailing wind as shown in figure 4 (a & b). Making good use of the thermal mass, as in walls and floors to store heat during the day and re-emit it into the enclosed space at night. At the same time it should prevent re-radiation of heat absorbed in the daytime to the night sky. Having internal highly reflective membrane surface and the form of the structure itself can help in this. It can be used as shading device in hot climates where the sun heat is extremely high. Early wind tunnel experiments that I had run at Nottingham University, and through the accurate visualisation of airflow had shown that air tends to deflect downward just as it enters the structure, this can be effectively used in inducing airflow in fabric membrane structures in hot climates, figure 4(c) and can be used for natural ventilation also. The use of retractable canopies or fabrics in hot climates can be very useful as opening the structure at night will permit cross ventilation and also re-radiate the heat absorbed during the day to the night sky. Fountains and pools can be used along with this structure for cooling, as passive cooling techniques figure 4(d). Figure 4(e) shows how the stack effect can be effectively used in these types of structures. Painting the annex with a darker colour can simulate the absorption of more solar radiation so as to heat up faster than the rest of the fabric, this will rapid the escape of the warmer air out, and cooler air will replace it faster. Tensile fabric membrane structures can be effectively used as a buffer zone between the external environment and the internal one as shown in figure 4(f). The accurate studied arrangement of the thermal mass inside the structure can work as micro-environment controller in both hot and temperate climates. 5. USING FABRIC STRUCTURES AS A RENEWABLE ENERGY SOURCE Many developing countries are located in intense solar regions where shade is an important criterion in building design and electricity is also an expensive commodity. The idea of having a low cost structure that works as both a shading device and an electricity generator has always been a dream in these countries. Laminating thin film amorphous silicon cells onto coated fabrics offers a means of attaining such a goal. The result is a shading fabric that also acts as a power station generating renewable, non-polluting energy. Although the technology is of relatively low efficiency, with a solar to electrical conversion of around 58%, the cells are lightweight, flexible and relatively inexpensive 5. TMS too offer significant surface areas on which to deploy the technology. This technology has tremendous potential in tropical, hot regions with high solar gain. The first example of this application was the Tensile Pavilion in the Under the Sun exhibition at the Cooper-Hewitt, National Design Museum in 1998. The fabric, a PVC mesh Ferrari fabric 11 that had amorphous silicon PV film laminated onto it 6 were used on a solar canopy. Although a small tensile structure, it demonstrated the principle, providing shade from solar heat and also generating enough electricity to support communication and limited power without any grid connection. 6. THE NEED FOR FUTURE RESEARCH It is important to note that work has been undertaken by leading firms involved in TMS design such as Buro Happold, Ove Arup and others for UK millennium projects. This work has addressed condensation issues within the fabric, airflow studies, CFD modelling, etc. Most of the work relates to specific individual design projects, and is not in the public domainThere is a need, recognised by the design community, both for general guideline inform the outline design stage of projects and for predictive tools for detailed design. For this to happen, further detailed investigations should be carried out in this field at a number of different levels. Detailed investigation into the thermal and optical properties of fabric membranes and studies of Internal and external surface convection heat transfer to inform modelling of enclosures is required. The development of models (possibly as part of a CFD code) tailored to suit the particular characteristics of fabric structures and capable of accounting for the complicated topology, time variant climatic inputs and complicated internal temperature and air flow behaviour is necessary Use of these models to develop general design guidance and quantitative descriptions of how these systems behave should be undertaken. In addition to ensuring the appropriate and effective application of TMS by the industry, and hence avoiding unrealistic expectations on the part of the occupier of both comfort conditions and operating costs, such tools would permit the continued development of environmental control strategies and TMS materials with enhanced thermal properties. 7. CONCLUSION Fabric membranes are thin translucent materials that have insufficient mass to significantly affect their thermal behaviour. At any instant, it is reasonable to assume that their thermal behaviour results from their surface heat transfer and their characteristic thermal optical properties at that instant. Early 12 approaches adopted for predicting the thermal behaviour of TMS, based on U-values, and shading coefficients proved inappropriate. Alternative approaches to the problem have been explored and work is now required to develop these to the point where they may be used to inform the design process. If fabric structures are to compete with more conventional building types, which have well established levels of environmental performance and face fairly strict energy consumption legislation, designers and manufacturers must be able to accurately predict their environmental and thermal behaviour and ensure an appropriate comfort level for the occupiers of the spaces. REFERENCES 1 Boonyatikarn S, Wu HF, and Engen WB. Lighting performance and prediction of fabric roof structures. Proceedings of the International Symposium on Architectural Fabric Structures: The design process. 1984; AFAI. pp.197200. 2 Button D, et al. GLASS IN BUILDING " A Guide to Modern Architectural Glass Performance". Oxford, London: Pilkington Glass Ltd, 1993. 3 Croome D, Moseley P. Temperature prediction methods for lightweight structures. The design of air supported structures. The Institute of Structural Engineers. 1984; London: pp. 247-260. 4 Gayle SR, Tanno S, & Cripps A. ETFE foil cushions as an alternative to glass for roofs and atria. Department of the Environment, Transport and the Regions. (DETR): Buro Happold Ltd. Document No.1,2,3 &4. DETR Sponsored research project. 5 Goldsmith N. Materials for the new millennium. Proceedings of the International Symposium of Widespan Enclosures. University of Bath. Bath, England. 2000 pp. 137-141. 6 Goulding JR, et al. Energy in architecture: The European passive solar handbook. Batsford, London: 1992. 7 Hart GH. Analysis using DOE 2.1B to predict the annual energy use of a retail store covered with an insulated fabric roof. The Architectural Fabric Structures Institute. Proceedings of the International Symposium on Architectural Fabric Structures/ The design process. Nov., 1984, Orlando, Florida. USA: pp: 181-186. 8 Harvie GN. An investigation into the thermal behaviour of spaces enclosed by fabric membranes. [Phd Thesis]. Cardiff: University of Cardiff, 1995. 9 Medlin RL. Fabric structures and the environment. Fabric Architecture 2000 Mar/April, 2000. pp. 52-55. 13 10 Navvab M. Fabric structures as daylighting systems [Web Page]. Available at URL:http://www.lightforum.com/design/ALM048.html.. (Accessed 21 Nov. 2000) 11 Sinofsky M. Thermal performance of fabric in permanent construction. Proceedings of ASHRAE Annual conference . June 1985. 12 Solenberger FR. Thermal gain of architectural fabrics. E. I. m Du Pont Du Nemours// & Company, 1979 Nov. Report No.: Internal Report To P. Biesert. 13 Winklemann F. "Modifications to DOE2.1B for Fabric Roof Loads Analysis". Energy and Environment Division: Lawrence Berkeley Lab., 1984. 14 Wu HF. The stratification in fabric roof structures: A strategy of energy conservation and system design. The proceedings of the international symposium on Architectural Fabric Structures: The design process. 1984; AFSF. pp. 192-6. 14