* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Magnetic Circuits - PEMCLAB

Survey

Document related concepts

Transcript

Power Electronic Systems & Chips Lab., NCTU, Taiwan

Magnetic Circuits

電力電子系統與晶片實驗室

Power Electronic Systems & Chips Lab.

交通大學 • 電機控制工程研究所

Chapter 1 Magnetic Circuits and Magnetic Materials, Fitzgerald & Kingsley's Electric Machinery, 7th Ed, S.D.

Umans, McGraw-Hill Book Company, 2013.

1/91

台灣新竹‧交通大學‧電機控制工程研究所‧電力電子實驗室~鄒應嶼 教授

Modeling the Stator Inductance of an IPMSM

L (t0 )

R

vi

vR

vi

1

s

iL

L

vL

1

L

iL

vR

RL

L1 ( r ) ?

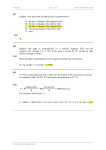

Assume the rotor produces a sinusoidal flux distribution across the air gap,

how to model the stator winding inductance as a function of the rotor

position of an interior permanent magnet synchronous motor (IPMSM)?

REF: Chapter 4 Inductances, Design of Rotating Electrical Machines, Juha Pyrhonen, Tapani Jokinen, Valeria Hrabovcova,

2nd Ed., October 2013, Wiley.

2/91

Modeling of Synchronous Machine in dq-Frame

q

s

is

b axis

id Ld

q

iq Lq d

λs

ib

vb

i1q

PM

s

1q

λPM

e

a'

r

1d

i1d

fd

vF

vs

d

ia

iF

va

a axis

vc

r

PM

id

Electric Equations:

a

ic

Rs

vd Rs sLd e Lq id sPM

v L

i

vd

R

sL

q

e

d

s

q

q ePM

c axis

Ld

e Lqiq

iq

sPM

Torque Equations:

3P

3P

d iq (Ld Lq )id iq

(id Ld PM )iq (Ld Lq )id iq

Te

22

22

Rs

Lq e Ld id

vq

ePM

Te Tf TL J

dm

Bm

dt

Torque Characteristics of Synchronous Machines

q

q

q

q

d

d

d

d

Ld Lq

Ld Lq

Ter 0

Tem Ter

Te

Ld Lq

Ld Lq

m 0

Tem 0

Tem Ter

3P

[(id Ld PM )iq iq id ( Ld Lq )]

22

Tem

Ter

Inductance Plays a Key Role in Motor Characteristics

L1 ( r ) ?

The rotor structure determines the major characteristics of a synchronous machine (SM). For

SM with concentrated winding stator, the inductance of the coil of a segmented teeth can be

calculated as a function its rotor position if the rotor has an anisotropic structure.

Generated electric torque of synchronous machine:

Te

3P

[ I q m I q I d ( Ld Lq )]

22

Design of Rotating Electrical Machines, 2nd Ed., [Chapter 4: Inductances]

Juha Pyrhonen, Tapani Jokinen, Valeria Hrabovcova,

October 2013, Wiley.

[1] I. A. Viorel, A. Banyai, C. S. Martis, B. Tataranu, and I. Vintiloiu, “On the segmented rotor reluctance synchronous motor saliency ratio

calculation,” Advances in Electrical and Electronic Engineering, vol. 5, vo. 1-2, June, 2011.

[2] B.J. Chalmers and A. Williamson, AC Machines Electromagnetics and Design, Research Studies Press Ltd., John Wiley and sons Inc., 1991.

[3] Jong-Bin Im, Wonho Kim, Kwangsoo Kim, Chang-Sung Jin, Jae-Hak Choi, and Ju Lee, “Inductance calculation method of synchronous

reluctance motor including iron loss and cross magnetic saturation,” IEEE Transactions on Magnetics, vol. 45, no. 6, pp. 2803-2806, 2009.

Basic Notations for Electromagnetism

電場強度

Electric field strength

E

[V/m]

磁場強度

Magnetic field strength

H

[A/m]

電力線密度

Electric flux density

D

[C/m2]

磁力線密度

Magnetic flux density

B

[Vs/m2], [T]

電流密度

Current density

J

[A/m2]

電荷密度

Electric charge density, dQ/dV

ρ

[C/m3]

D E

電容率 permittivity of free space (Farads/m)

B H

磁導率 permeability of free space (Henrys/m)

6/91

1865年~電磁理論誕生~馬克士威電磁方程式

1865年英國物理學家詹姆斯·馬克士威以先前的電磁研究成果為基礎,經

由有系統地整理和綜合提出了由20個等式和20個變量組成的電磁理論。

現今電磁理論的數學形式分別由英國的奧利弗·黑維塞(Oliver Heaviside)

、 美 國 的 約 西 亞 · 吉 布 斯 (Josiah Gibbs) 、 與 德 國 的 海 因 里 希 ‧ 赫 茲

(Heinrich Hertz)於1884年前後以向量形式重新表達成目前的四組方程式。

Source of Electric Field E

0

Changing Electric Field

Source of Magnetic Field B 0

Changing Magnetic Field

B

t

E

B 0 J 0

t

E

電磁學天堂祕笈:輕鬆解析最實用的馬克士威方程式

A Student’s Guide to Maxwell’s Equations

作者:夫雷胥 (Daniel Fleisch), 譯者:鄭以禎

出版社:天下文化, 出版日期:2010年10月18日

7/91

Maxwell's Equations (1860s~1970s)

現今使用的馬克士威的方程式包含四個方程式組,它們分別描述了靜電場

、靜磁場、感應電場、與感應磁場的關係,其積分與微分形式表示如下:

電場的高斯定律 (Gauss’s Law for Electric Field)

Q enc

ˆ

nda

E

E

0

S

0

法拉第定律 (Faraday’s Law)

C

E dl

d

dt

S

ˆ

B nda

E

B

t

磁場的高斯定律 (Gauss’s Law for Magnetic Field)

S

ˆ

B nda

0

B 0

安陪-馬克士威定律 (The Ampere-Maxwell Law)

d

B

l

d

I

0 enc

0

C

dt

E

ˆ

E

nda

B

J

S

0

0

t

Symbols and Units of Electromagnetic Quantities

Summary of Quasi-Static Electromagnetic Equations

Electromechanical Dynamics (MIT Course Notes)

s

r

is

ir

s is Ls Lsr ( )ir

r Lsr ( )is ir Lr

dL ( )

Te is ir sr

d

Te

Electromechanical Dynamics, Discrete Systems (Part 1),

Herbert H. Woodson and James R. Melcher,

Wiley, 1st Ed., January 15, 1968.

REF: Electromechanical Dynamics - Part 1 Discrete Systems (Woodson & Melcher, MIT 1968)

Basic Relations of Electrical and Magnetic Field

v(t )

Faraday’s Law

terminal

characteristics

B (t ), (t )

Core

characteristics

H (t ), F (t )

i (t )

Ampere’s Law

Electrical Circuits

Magnetic Circuits

12/91

Magnetic Field

Magnetic fields are produced by electric currents, which can be macroscopic currents in

wires, or microscopic currents associated with electrons in atomic orbits. The magnetic

field B is defined in terms of force on moving charge in the Lorentz force law. The

interaction of magnetic field with charge leads to many practical applications. Magnetic

field sources are essentially dipolar in nature, having a north and south magnetic pole.

The SI unit for magnetic field is the Tesla, which can be seen from the magnetic part of the

Lorentz force law Fmagnetic = qvB to be composed of (Newton x second)/(Coulomb x

meter).

A smaller magnetic field unit is the Gauss (1 Tesla = 10,000 Gauss).

13/91

Right-Handed System and Left-Handed System

z

z

x

y

y

Left-Handed System

x

Right-Handed System

14/91

Magnetic Field of Current: Right-Handed Rule

The magnetic field lines around a long wire which carries an electric current form

concentric circles around the wire. The direction of the magnetic field is

perpendicular to the wire and is in the direction the fingers of your right hand

would curl if you wrapped them around the wire with your thumb in the direction

of the current.

15/91

Ampere’s Law

(a)

H

dl

i

(b)

(a) General formulation of Ampere’s law.

(b) Specific example of Ampere’s law in the case of a winding on a magnetic core

with air gap.

Direction of magnetic field due to currents

Ampere’s Law: Magnetic field along a path

16/91

Ampere’s Law

H dl I

B dl I

B

dl

B H

H = magnetic field intensity (Ampere-turns/m)

= magnetic permeability of material

(Wb/A.m, or Henery/m)

B = magnetic flux density (Tesla, Weber/m2)

= permeability of free space

0 4 10 7 H / m

r

I, if contour encloses I

H dl 0, if contour does not enclose I

0

r = relative permeability (between 2000-80,000 for ferromagnetic materials)

17/91

Permeability: Relationship Between B and H

Ampere,s Law

H dl I

permeability = =

H = magnetic field intensity (Ampere-turns/m)

= magnetic permeability of material (Wb/A.m, or Henry/m)

B = magnetic flux density (Tesla, Weber/m2)

B

H

r

0

= permeability of free space

0 4 10 7 H / m

r = relative permeability (between 2000-6000 for general ferromagnetic materials used in

electrical machines)

In magnetics, permeability is the ability of a material to conduct flux. The magnitude of the

permeability at a given induction is a measure of the ease with which a core material can be

magnetized to that induction. It is defined as the ratio of the flux density B to the magnetizing

force H. Manufacturers specify permeability in units of Gauss per Oersted (G/Oe).

cgs:

gauss

tesla

0 = 1

10 4

oersted oersted

mks:

henrry

meter

0 = 4 10 7

18/91

磁通量單位:韋伯 (Wb), 磁通量密度單位:特斯拉(Tesla)

磁通量的國際制(SI)單位,紀念德國物理學家韋伯而命名。簡稱韋﹐用Wb表示。

韋伯定義如下﹕令通過單匝線圈的磁通量在 1秒鐘內均勻地減小到零。如果在該線

圈中激發產生的感應電動勢為 1 伏特,則原來通過該線圈的磁通量為 1 韋伯。即

1Wb=1V.s。

韋伯是國際單位制的導出單位﹐用基本單位表示的關係式為:

米2‧千克‧秒-2 ‧安培-1 (m 2 ‧kg‧s-2‧A-1) = 伏秒 (Volt‧sec)

1882 年西門子在英國科學進展協會上第一次提出以『韋伯』作為磁通量單位,

1895年得到英國科學進展協會承認,1948年得到國際計量大會的承認。

韋伯和 CGS電磁系中的磁通量單位馬克斯威之間的換算關係為﹕

1韋伯相當於108馬克斯威。[1 Wb = 108 Maxwell]

磁通量密度的單位是特斯拉(Tesla)。 [1 Tesla = 1 Wb/m2]

1 oersted = 1000/4 ampere/turn = 79.57747154594 ampere/meter 80 A/m

19/91

Properties of Ferromagnetic Materials

B, Wb/m2

B

A is the cross-sectional area

A

B r0H

1.4

1.2

i

1.0

0.8

N

0.6

0.4

0.2

DC Excitation

0

0

200

400

600

800

H, A-turn/m

1000

A toroidal coil and the

magnetic field inside it.

Ferromagnetic materials, composed of iron and alloys of iron with cobalt,

tungsten, nickel, aluminum, and other metals, are by far the most common

magnetic materials.

Transformers and electric machines are generally designed so that some

saturation occurs during normal, rated operating conditions.

20/91

B-H Curve, Permeability, and Incremental Permeability

B H r 0 H

Relation between B- and H-fields.

Incremental Permeability

B

H

Bs

B

B

H

B

H

B

B

H H

H

Linear region

Hs

Magnetic intensity H, [A-turns/m]

The B-H characteristics of a

core material is high nonlinear.

Depends on its average

current,

current

ripple,

switching

frequency,

and

operation temperature.

When

measuring

the

inductance of a magnetic

circuit, it should first to

identify its operating point.

21/91

B-H Curve of Major Materials

The set of magnetization curves as shown in

left figure represents an example of the

relationship between B and H for soft-iron and

steel cores but every type of core material will

have its own set of magnetic hysteresis curves.

You may notice that the flux density increases

in proportion to the field strength until it

reaches a certain value were it can not

increase any more becoming almost level and

constant as the field strength continues to

increase.

This is because there is a limit to the amount of flux density that can be generated by the core as all the

domains in the iron are perfectly aligned. Any further increase will have no effect on the value of M, and

the point on the graph where the flux density reaches its limit is called Magnetic Saturation also known as

Saturation of the Core and in our simple example above the saturation point of the steel curve begins at

about 3000 ampere-turns per meter.

22/91

B-H Characteristics of a Magnetic Material

Hs

Performance Tradeoffs: saturation Bs, permeability , resistivity (core

loss), remanence Br, and coercivity Hc.

Flux Density or B-Field

B H r 0 H

Cross-sectional area A

H-field

H

i

BA

N

i

N

(a)

(b)

Determination of the magnetic field direction via the right-hand in (a) the general case

and (b) a specific example of a current-carrying coil wound on a toroidal core.

The total flux pass through the coil with N turns is called

flux linkage and named as . N

24/91

Continuity of Flux

B dA

A(closed surface)

A

B dA 0

A2

A1

1

2

3

A3

1 2 3 0

B1 A1 B2 A2 B3 A3 0 or

k

0

k

25/91

Magnetic Cores

Ideal Inductor

i

Negligible winding resistance

Perfect coupling between windings

v

N

An ideal core

v N

d

dt

d

1

vdt

N

( t1 ) ( t 0 )

1

N

t1

t0

vdt

The above equation shows that the change in flux during a time interval t0-t1 is

proportional to the integral of the voltage over the interval, or the volt-seconds applied

to the winding.

26/91

Ideal Inductor [Define its Initial Conduction]

i

v

i

N

(a) Circuit model.

(b) -i characteristic (or B-H curve).

v

v

0

t

0

(c) v is a step input; (t0) = 0.

(d) v = Vm sin t ; (t0) = 0.

v

v

0

t

(e) v is a square wave; (t0) = -m.

0

(f) v = Vm sin t ; (t0) = -m.

27/91

Magnetic Field Strength H of Some Configurations

long, straight wire

Toroidal Coil

Long solenoid

28/91

Inductance of Wound Magnetic Core

magnetic flux per turnwebers (Wb) [1 Wb = 108 Maxwell]

i

v

B magnetic flux density webers/meter2 (teslas)

flux linkage webers

N

A core cross-sectional area square meters

H magnetic field strength ampere-turns/meter

N number of turns

d

di

d

N

dt

dt

dt

d

d

L N

di

di

v L

i coil current ampere

l m mean length of magnetic flux path meters

permeability henrys/meter (4×10-7 in perfect vacuum)

N

BA

and

L inductancehenrys

Ni

H

lm

The inductance of a wound magnetic core is directly proportional

to the incremental permeability of the core material, which is the

slope of the B-H curve.

N 2 A dB

N 2 A

L

l m dH

lm

29/91

Inductance of a Core

i

A

N

v

N2 A

L

r o

le

le

r o C1 N 2

L N2

r C N 2

L le1

(a)

Flux saturation

slope L

(b)

i

L A

C1

A

l

C o C1 o

A

l

The inductance L represents the capability of

magnetic flux density produced by unit current of

a circuit loop.

30/91

Magnetic Reluctance and Permeance

Cross-sectional

area A

Mean path length l

i

H dl

H

N

H

Permeability

Magnetic-motive force (mmf)

Ni

l

A

Reluctance

Permeance

1

Hl Ni

Ni

l

Ni

B

l

A

ANi

Ni

l

l

A

Ni

31/91

Inductance of a Toroidal Core (Self Inductance)

Cross-sectional

area A

Mean path length l

Weber-turns (=N)

i

N

L

i

Amp (I)

Permeability

For a magnetic circuit that has a linear relationship between and i because of material of

constant permeability or a dominating air gap, we can define the -i relationship by the selfinductance (or inductance) L as

L

i

N

i

ANi

l

L

i

N ANi

A

N 2

i l

l

where =N, the flux linkage, is in weber-turns. Inductance is measured in henrys or weberturns per amp.

32/91

Flux Density Distribution of a Toroidal Core

Representing the magnetic vector potential (A), magnetic flux (B), and current

density (j) fields around a toroidal inductor of circular cross section. Thicker lines

indicate field lines of higher average intensity. Circles in cross section of the core

represent B flux coming out of the picture. Plus signs on the other cross section of

the core represent B flux going into the picture. Div A = 0 has been assumed. 33/91

A toroidal coil and the

magnetic field inside it.

Energy Stored in a Core

N: number of turns

Mean path length l

Cross-sectional

area Ac

The energy stored in the core:

t

E L Pdt

0

t

0

Li ' di '

1 2

LI

2

The energy density (energy/volume) is:

I

LI 2

1 1 N 2 Ac

B

Ac l

Ac l 2

l

1 B2

B2

2

2r 0

1

2

Permeability

A N2

LN

l

2

B 2l 2

2 2

N

The energy stored in the core:

EL

1 2

LI BVcore

2

Vcore: volume of the core

Chapter 11 Inductance and Magnetic Energy of Introduction to Electricity and Magnetism, MIT 8.02 Course Notes, Sen-Ben Liao, Peter

Dourmashkin, and John Belche, Prentice Hall, 2011.

34/91

Typical Energy Density of a Ferrite Core

Ec

B2

B

2r 0

Ve

For a typical ferrite, assuming the relative permeability is about r = 2000, and the

saturation flux density Bsat = 0.3 T (3000 G), we get (for most ungapped ferrite

cores) a typical power density of

0 .3 2

Ec

B2

B

17 . 9 J/m 3

7

2 r 0 2 2000 4 10

Ve

0 4 10 7 H/m

4 10 Newton/A

7

2

Ec

18 J/m 3 18 μJ/cm

Ve

( r 2000, B sat 3000G)

3

一般典型的鐵氧體鐵心 (Ferrite core)的儲能密度約為每立方公分18微

焦爾。假設開關頻率為100 kHz,最大開關責任比為50%,工作於臨界

導通模式(CRM),則其可處理之平均功率約為3.6瓦。以36瓦的反馳式

電源供應器為例,其鐵心體積約為10立方公分。

35/91

Inductance of Air-Core Solenoid

H dl N i

Dc

lc

lc

0

Hdl

Long air-core solenoid

lc d

lc

( 0 )dl

Hl c Ni

2 lc d

lc d

( 0 )dl

2 lc 2 d

2 lc d

( 0 )dl Ni

H N

i

lc

d

d ( BA)

dH 4 107 N 2 A N 2 Dc2 2

N

0 NA

107

LN

di

di

di

lc

lc

0 4 10 7 H/m

4 10 7 Newton/A 2

where

L inductance in henrys

N Total number of turns

A cross-sectional area inside of solenoid coil in square meters ( D c2 / 4 )

Dc diameter of solenoid in meters

l c length of solenoid in meters

36/91

Inductance of a Solenoid

This is a single purpose calculation which gives you the inductance value when you make any change in the parameters.

Small inductors for electronics use may be made with air cores. For larger values of inductance and for transformers, iron is

used as a core material. The relative permeability of magnetic iron is around 200.

This calculation makes use of the long solenoid approximation. It will not give good values for small air-core coils, since they

are not good approximations to a long solenoid.

http://hyperphysics.phy-astr.gsu.edu/hbase/electric/indsol.html

37/91

Inductance of a Solenoid

D=10 mm

I

b

c

l=50 mm

N=30

WD=1.0 mm

a

d

Wire diameter

I , if contour encloses I

does not enclose I

H d l 0, if contour

http://hyperphysics.phy-astr.gsu.edu/hbase/electric/indsol.html

38/91

HW: Inductance of an Air-Core Solenoid

D=10 mm

I

b

c

l=50 mm

N=30

a

WD=1.0 mm

d

Wire diameter

An air-core solenoid with construction parameters as shown above, solve the following

problems:

1. Calculate the ideal equivalent inductance of the air-coil solenoid?

2. Compute the equivalent inductance of the air-coil solenoid.

3. Make a Maxwell simulation of the flux distribution of the air-core solenoid and compare

the simulated inductance with the the analytical result.

39/91

Simple Magnetic Circuits

c

F

F

c

g c

Analogy between electric and magnetic circuits.

Electrical-Magnetic Analogy

Magnetic Circuit

mmf Ni

Flux

reluctance

permeability

Electric Circuit

v

i

R

1/, where =resistivity

i

N

41/91

Equivalent Electrical Circuit of a Magnetic Circuit

Reluctance

i

N

Inductance

Magnetic

Ni

1

A

N N 2

L

i

i

Electrical

Ohm' s law :

l

v

R

A/

i

k N mim

Kirchhoff' s voltage law : i Rk v m

Kirchhoff's current law : ik 0

k

k

k

m

k

0

l

(unit : H -1 )

A

m

k

42/91

Magnetic Circuits of a Gapped Core

l1 = mean path length

i1

in

i1

Airgap: Hg

N1

g

H

Core: H1

(a)

(b)

mean flux path in the ferromagnetic material

43/91

Modeling of a Simple Magnetic Circuit

i

v

mean flux path in the air gap

lg

b

a

N

magnetic motive force (mmf)

(unit: Ampere-turns)

li

mean flux path in the

ferromagnetic material

H dl

b

a

I

a

H i dl H g dl N i

b

Hi : Magnetic field intensity in the ferromagnetic material

Hg : Magnetic field intensity in the air gap

H i l i H g l g Ni

44/91

Modeling of a Simple Magnetic Circuit

Bi

B H

i

li

Bg

g

l g Ni

Flux

B

A

dS

The surface integral of flux density is equal to the flux.

If the flux density is uniformly distributed over the cross-sectional area, then

g B g Ag

i Bi Ai

The streamlines of the flux density are closed, therefore i g

lg

li

Ni

i Ai

g Ag

li

i Ai

i

g

i g ( i g ) Ni

lg

g Ag

45/91

Modeling of the Air-Gap

mean flux path in the air gap

lg

i

v

Rg

N

li

b

a

mean flux path in the

ferromagnetic material

Ni

Rc

In general,

Rg Rc

46/91

Inductance of a Slotted Ferrite Core

AC: Cross Section Area

i

v

N

lg

b

a

NBc Ac N 2 0 Ac

L

i

lg

The shearing of an idealized B-H loop due to an air gap.

台灣新竹‧交通大學‧電機控制工程研究所‧電力電子實驗室~鄒應嶼 教授

47/91

Air-gap Fringing Fields

Reluctance of the air gap:

g

lg

g Ag

The effect of the fringing fields is to increase the

effective cross-section area Ag of the air gap.

Fringing flux decreases the total reluctance of the

magnetic path and, therefore, increases the

inductance by a factor, F, to a value greater than

the one calculated.

[1] Colonel Wm. T. McLyman, Fringing Flux and Its Side Effects, AN-115 Kg Magnetics Inc.

[2] Colonel Wm. T. McLyman, Chapter 3 Magnetic Cores of Transformer and Inductor Design Handbook, Fourth Edition, CRC

Press, April 26, 2011.

[3] W.A. Roshen, “Fringing field formulas and winding loss due to an air gap,” IEEE Transactions on Magnetics, vol. 43, no. 8, pp.

3387-3394, 2007.

48/91

Fringing Flux at the Gap

The effect of the fringing fields is to increase the effective cross-section area Ag of the air gap. The fringing

flux effect is a function of gap dimension, the shape of the pole faces, and the shape, size and location of the

winding. Its net effect is to shorten the air gap. Fringing flux decreases the total reluctance of the magnetic

path and, therefore, increases the inductance by a factor, F, to a value greater than the one calculated. In most

practical applications, this fringing effect can be neglected.

49/91

A Simple Wound-Rotor Synchronous Machine

Calculate the air-gap flux density Bg

The magnetic structure of a synchronous machine is

shown schematically in the right figure. Assuming that

rotor and stator iron have infinite permeability ( ),

find the air-gap flux and flux density Bg. For this

example I = 10 A, N = 1000 turns, g = 1 cm, and Ag =

2000 cm2.

2 lg

2 10 2

g

g Ag 4 10 7 0.2

F

1000 10

0.13 Wb

g

g

Bg

Ag

0.13

0.65 T

0.2

50/91

Flux linkage, Inductance, and Energy

Faraday’s Law

When magnetic field varies in time an electric field is produced in space as

determined by Faraday’s Law:

E ds

C

d

B da

dt S

v(t )

d

dt

Line integral of the electric field intensity E around a closed contour C is equal to

the time rate of the magnetic flux linking that contour.

Since the winding (and hence the contour C) links the core flux N times then

above equation reduces

The induced voltage is usually referred as electromotive force to represent the

voltage due to a time-varying flux linkage.

v(t )

d

d

N

dt

dt

51/91

Direction of EMF

The direction of emf: If the winding terminals were short-circuited a current

would flow in such a direction as to oppose the change of flux linkage.

(t ) max sin t Ac Bmax sin t

e(t ) Nmax cos t Emax cos t

e(t)

N

Emax Nmax 2 f NAc Bmax

Erms 2 f NAc Bmax

52/91

Example: Estimate the Inductance of a Gapped Core

The magnetic circuit of Fig. (a) consists of an N-turn winding on a magnetic

core of infinite permeability with two parallel air gaps of lengths g1 and g2 and

areas A1 and A2, respectively.

Find (a) the inductance of the winding and (b) the flux density Bl in gap 1 when

the winding is carrying a current i. Neglect fringing effects at the air gap.

53/91

Example: Plot the Inductance as a Function of Relative

Permeability

The magnetic circuit as shown below has dimensions Ac = Ag = 9 cm2, g = 0.050 cm, lc = 30

cm, and N = 500 tums. With the given magnetic circuit, using MATLAB to plot the inductance

as a function of core relative permeability over the range 100 ≤ r ≤ 100,000.

(a)

(b)

54/91

Example: Plot the Inductance as a Function of the Air

Gap Length

The magnetic circuit as shown below has dimensions Ac = Ag = 9 cm2, lc = 30 cm, and N = 500

tums. With the given magnetic circuit, r = 70,000. , using MATLAB to plot the inductance as

a function of the air gap length over the range 0.01 cm ≤ g ≤ 0.1 cm.

(a)

55/91

Example: Magnetic circuit with two windings

The following figure shows a magnetic circuit with an air gap and two windings. In this case

note that the mmf acting on the magnetic circuit is given by the total ampere-turns acting on the

magnetic circuit (i.e., the net ampere turns of both windings) and that the reference directions

for the currents have been chosen to produce flux in the same direction.

0 Ac

g

1 N1 N12

0 Ac

i

N

N

1

1 2

g

i2

56/91

Example: Analysis of a Switching Inductor

A switching inductor can be used as a fundamental energy storage cell with a switching power

converting system. Assume components in the following circuit are all ideal, make an analysis

of the given problems. Assume the duty ratio for the MOSFET switch is 20%.

iL

L

R

Vdc

iS

S

D

iD

VDC 48 V

f s 20 kHz

L 5 mH

R 10

Calculate the current ripple (peak-to-peak) of the inductor current.

57/91

Recommended Books

電磁學天堂祕笈:輕鬆解析最實用的馬克士威方程式

A Student’s Guide to Maxwell’s Equations

作者:夫雷胥 (Daniel Fleisch), 譯者:鄭以禎

出版社:天下文化, 出版日期:2010年10月18日

A Student's Guide to Vectors and Tensors,

Daniel A. Fleisch,

Cambridge University Press, 1st Ed., November 14, 2011.

Introduction to Electricity and Magnetism,

MIT 8.02 Course Notes,

Sen-Ben Liao, Peter Dourmashkin, and John Belche,

Prentice Hall, 2011.

Electricity and Magnetism,

W. N. Cottingham and D. A. Greenwood,

Cambridge University Press, 1st Ed., November 29, 1991.

58/91

References: Magnetic Circuits

[1]

[2]

[3]

[4]

G. K. Dubey, Fundamentals of Electrical Drives, Alpha Science International, Ltd, March 30th 2001.

Chapter 1: Magnetic Circuits and Magnetic Materials, Fitzgerald & Kingsley's Electric Machinery, S.D. Umans, 7th Ed, McGraw-Hill

Book Company, 2013.

Chapter 11 Inductance and Magnetic Energy, Introduction to Electricity and Magnetism, MIT 8.02 Course Notes, Sen-Ben Liao, Peter

Dourmashkin, and John Belche, Prentice Hall, 2011.

Chapter 4 Inductances, Design of Rotating Electrical Machines, Juha Pyrhonen, Tapani Jokinen, Valeria Hrabovcova, 2nd Ed., October

2013, Wiley.

Introduction to Electrodynamics,

David Griffiths,

4th Ed., Addison-Wesley, October 6, 2012.

59/91

Power Electronic Systems & Chips Lab., NCTU, Taiwan

Modeling of Practical Inductors

電力電子系統與晶片實驗室

Power Electronic Systems & Chips Lab.

交通大學 • 電機控制工程研究所

台灣新竹‧交通大學‧電機控制工程研究所‧電力電子實驗室~鄒應嶼 教授

60/91

Modeling of Practical Inductors

Ideal impedance model is for a simple linear relationship between

frequency and impedance.

Z ( j )

RAC

L

RDC

RC

1

C

C

R

L

0

(a) Examples of inductor

1

LC

(c) Frequency response

(b) Equivalent circuit

Not true across the whole frequency range for real components!

For practical capacitors and inductors with nonlinear characteristics, its frequency responses

are only valid for small signal perturbation around its operating point this operating point are

generally highly dependent on its dc value, frequency, and temperature.

61/91

Building a Model of a Real Inductor

Ideal inductor

Perfectly conducting wire

Core of ‘ideal’ magnetic

material

Practical inductor

Real wires have small DC resistance

Real wire resistance is frequency dependent

Real inductor may saturate

Real magnetic materials for inductors are both

frequency and temperature dependent!

Parasitic capacitance exists between turns of

the coil, between layers if wound in layers

Parasitic lead capacitance

iL

iL

vL

vL

diL

dt

L( f )

R( f )

C

62/91

Simple Model for Real Inductors

RESR

L

The inductor is modeled as a constant inductance with a series

connected resistance (RESR).

As frequency increases, the inductive impedance increases

This model does not resonate (no capacitance)

There is a corner frequency where the inductive impedance begins

to dominate

63/91

Simple Model for Real Inductors

Example Parameter: L=100 nH, R=2

L

R

Z ( j ) j L R

f 3dB

L

R

Time Constant [sec]

1/

R

Corner frequency [Hz]

2 2 L

f3dB

R

2

3.18 MHz

2 L 2 100109

64/91

Improved Model for Practical Inductors

L

R

Parallel resonant circuit

Resonant frequency is r 0 1 2

C

L

1

Q C 0

2Q

R

R = series resistance

C = parallel capacitance

1

Z ( j ) ( R j L ) ||

jC

Z ( j )

R j L

1 j RC 2 LC

1

LC

r

1

R2

LC 4 L2

In general, R and C are quite small, and the

resonant frequency can be approximated to the

undamped natural frequency 0:

L CR 2

r 0

1

LC

[1] R. L. Boylestad, Introductory Circuit Analysis, 12th Edition, Prentice Hall, 2010.

[2] Electromagnetic Compatibility Handbook, Kenneth L. Kaiser, CRC Press, 2005.

[3] Cartwright, K., E. Joseph, and E. Kaminsky, “Finding the Exact Maximum Impedance Resonant Frequency of a Practical Parallel

Resonant Circuit without Calculus,” Technology Interface Internat. J., vol.11, no. 1, Fall/Winter 2010, pp. 26-36.

Improved Model for Practical Inductors

Example Parameter: L=100 nH, R=2 C=10 pF

L

C

R

Z ( j ) ( R j L) ||

1

jC

66/91

More Complex Models for HF Inductor

Fairly accurate model for SMT

chip inductor

67/91

Simple Electro-Magnetic Circuits

Equivalent Circuit

Toroidal Inductance

Block Diagram

68/91

Transient Response of Inductance

Vdc

u (t )

If the above PWM voltage is applied to an ideal

inductor, what will be the current waveform?

What about a practical inductor?

69/91

Inductor with Resistance

Block Diagram

Equivalent circuit of a linear

inductor with coil resistance

70/91

Magnetic Saturation

Weber-turns (=N)

L

i

Amp (I)

71/91

AC Excitation of Ferromagnetic Materials

B (or )

i

b

c

N

a

H (or F)

i(t)

e

d

t

Hysteresis Loop

72/91

Magnetic Domains

magnetic moment (dipole)

magnetic domain

Magnetic domains oriented randomly.

Magnetic domains lined up in the presence

of an external magnetic field.

73/91

Hysteresis Curves of a Ferromagnetic Core in AC

Excitation

B

B

Magnetization or B-H Curve

Residual Flux Density

Br

Coercive Force

saturation

-Hc

H

H

area hysteresis loss

Hysteresis Loop

台灣新竹‧交通大學‧電機控制工程研究所‧電力電子實驗室~鄒應嶼 教授

74/91

AC Excitation of a Magnetic Circuit

Ac: cross-section surface area

i

N

v(t)

mean flux path in the

lc ferromagnetic material

Assume a sinusoidal variation of the core flux (t); thus

(t)= maxsint=Ac Bmax sint

amplitude of the flux density

From Faradays law, the voltage induced in the N-turn winding is

v(t)

where

d

Nw max 2 fNA c B max

dt

v rms

1

v max 2fNAc Bmax

2

and

v max N max 2 fNA c B max

75/91

AC Excitation of a Magnetic Circuit

Excitation phenomena. (a) Voltage, flux, and exciting current; (b) corresponding

hysteresis loop.

76/91

AC Excitation Phenomena of a Magnetic Circuit

i

vs

vs

i

N

i

t i

t

i

t

i

(a)

i

HC

(b)

(a) Voltage, flux, and excitation current; (b) corresponding hysteresis loop.

To produce the magnetic field in the core requires current in the excitation winding know as the

excitation current i

For the given , we can obtain the corresponding i from the B-H hysteresis loop. Because =

BcAc , and i = HcBLc /N

The saturated hystersis loop will result peakly excitation current with sinusoidal flux variation

77/91

Core Saturation Due to Over-Excitation

i

N

vs

( t1 )

1

N

t1

t0

v s ( t ) dt ( t0 )

( t0 ) 0

78/91

Core Saturation Due to Over-Excitation

i

N

vs

79/91

Core Saturation Due to Residual Flux

i

vs

N

( t1 )

1

N

t1

t0

v s ( t ) dt ( t0 )

( t0 ) 0

Power transformer inrush current caused by residual flux at switching instant; flux (green), iron

core's magnetic characteristics (red) and magnetizing current (blue).

80/91

Inrush Electric Current in a Transformer

What really happen

i

vs

N

What you assume

81/91

Typical Waveform of Magnetizing Inrush Current

In practical applications, the winding resistance and losses of the core will

decay residual flux and the dc offset due to initial volts-sec integration.

A a soft start procedure can be used to reduce this effect and a balance control

loop can be used to eliminate this dc offset in application to inverters.

82/91

Saturation of an Inductor (Incremental Inductance)

Weber-turns (=N)

Cross-sectional

area Ac

Mean path length l

L(I x )

N

i

i

iIx

Amp (I)

Permeability

I

x

A practical inductor will saturate as the current is increased.

The incremental inductance is defined as the inductance at a specified current

with small signal perturbation, this is equivalent to a linear inductance for current

around this operating point.

Note: In the given example, the current source as a perturbation source.

83/91

Measuring the Incremental Inductance at Specific

Operating Points (1/3)

Weber-turns (=N)

S1

Vdc

B

N

S2

C

S3

L(I x )

S4

i

iIx

Amp (I)

A

Practical inductors are nonlinear and its incremental inductance (smallsignal inductance) is highly dependent on its operating point, such as

its average current, the magnitude of current ripples, the switching

frequency, and the core temperature, etc.

The winding inductance of a synchronous machine is nonlinear, especially

for an interior PMSM. This characteristics is useful for the detection of its

rotor pole position under sensorless control. Devise a scheme to measure

the incremental inductance for different operation points (A, B, and C)?

84/91

Measuring the Incremental Inductance at Specific

Operating Points (2/3)

0.1mH, IL(pp)=2A, 20 kHz

inductor

S1

S3

8 Ohm, 50W,

Cement Resistors

e

A

v AB

Vdc

S2

S4

Ro

B

v AB

L

L

L

R R ESR Ro 2 R DS ( ON )

Ts e

RESR

Design an inductor with 0.1 mH, average current from 1 A to 6A, and operating with

switching frequency of 20 kHz. An illustrated design example can be found in [1].

Devise an incremental inductance measurement scheme for operation points of A (0A), B

(4A), and C (8A) with a current ripple of 20 kHz, 2 A (peak-to-peak).

Make a simulation study in consideration of the RDS(ON) and the diode forward voltage drop.

Make experimental verifications for the proposed scheme.

REF: [1] Inductor Design in Switching Regulators (Technical Bulletin SR-1A, Magnetics).pdf

85/91

Compute the Inductance of a Toroidal Ferrite Core

60-turn toroidal inductor with

the TN23/14/7 ferrite core

TN23/14/7 Ring Core

[1] Rosa Ana Salas and Jorge Pleite, “Simple procedure to compute the inductance of a toroidal ferrite core from the linear to the saturation

regions,” Materials, no. 6, pp. 2452-2463, 2013.

86/91

TN23147-3R1 - Ferroxcube

Effective Core Parameters

Permeability as a Function of Frequency of Different Materials

B and H Magnetic Fields Inside the Toroidal Core

Moduli of the B and H magnetic fields as a function of the distance from the center of the

inductor core (x = 30 mm) obtained by 2D (red dashed line) and 3D (black solid line) simulations,

for (a,b) I = 0.0057 A (linear region); (c,d) I = 0.16 A (intermediate region); (e,f) I = 3 A

(saturation region).

89/91

Winding Inductances of an IPMSM

a

La-bc

1.5Lq

1.5Ld

La-bc

b

IPMSM stator coil

N

N

S

La-bc

3/2

2

Rotor pole position ()

S

N

S

/2

0

c

3 Ld Lq Ld Lq

cos 2

2

2

2

S

S

N

N

90/91

Mid-Term Report (April 15, 2016)

Modeling of the Stator Winding Inductance

L1 ?

L1 ( r ) ?

1. Define the stator structure, mechanical dimensions, winding

mechanism, and material parameters of the segmented motor.

2. Construct an equivalent circuit for a single segment of the stator

teeth and calculate its inductance. Make a Maxwell simulation to

verify the calculation.

3. Put the segmented teeth into the stator but without the rotor, make

a Maxwell simulation to calculate the inductance of a single stator

segment.

4. Define the rotor structure and material parameters and make a

Maxwell simulation to calculate the inductance of a single stator

segment as a function of the rotor pole position.

91/91

UNITS

FOR MAGNETIC

PROPERTIES

Quantity

Symbol

Gaussian & cgs emu a

Conversion

factor, C b

SI & rationalized mks C

Magnetic flux density,

magnetic induction

B

gauss (0) d

10- 4

tesla (T), Wb/m 2

maxwell (Mx), G·cm 2

Magnetic flux

weber (Wb), volt second (V·s)

Magnetic potential difference,

ma~netomotive force

U,F

gilbert (Gb)

Magnetic field strength,

,magnetizing force

H

oersted (Oe),e Gb/cm

A/m!

(Volume) magnetization g

M

emu/cm 3 h

A/m

(Volume) magnetization

477M

G

A/m

Magnetic polarization,

intensity of magnetization

1,1

emu/cm 3

477 X 10- 4

T, Wb/m 2i

(Mass) magnetization

(F,

emu/g

1

477 X 10- 7

A.m 2/kg

Wb·m/kg

Magnetic moment

m

emu, erg/G

10- 3

A.m 2, joule per tesla (l/T)

Magnetic dipole moment

j

emu, erg/G

477 X 10- 10

Wb·m'

M

10/477

dimensionless

henry per meter (H/m), Wb/(A.m)

dimensionless, emu/cm 3

(V 01 ume) susceptibility

ampere (A)

(Mass) susceptibility

Xp, K p

cm 3/g, emu/g

477 X 10- 3

(477)2 X 10- 10

m3/kg

H.m 2/kg

(Molar) susceptibility

Xmo}, K mo]

cm 3/mol, emu/mol

477 X 10- 6

(477)2 X 10- l3

m3/mol

H·m 2/mol

Permeability

1J-

dimensionless

477 X 10- 7

H/m, Wb/(A·m)

Relative permeability j

1J-r

not defined

(Volume) energy density,

energy product k

W

erg/cm 3

10- l

J/m 3

Demagnetization factor

D,N

dimensionless

1/477

dimensionless

dimensionless

a. Gaussian units and cgs emu are the same for magnetic properties. The defining relation is B =H + 477M.

b. Multiply a number in Gaussian units by C to convert it to SI (e.g., 1 G X 10- 4 T /G = 10- 4 T).

c. SI (Systeme International d'Unites) has been adopted by the National Bureau of Standards. Where two conversion factors are

given, the upper one is recognized under, or consistent with, SI and is based on the definition B = 1J-o(H + M), where

1J-o = 477 X 10- 7 H/m. The lower one is not recognized under SI and is based on the definition B =1J-oll +J, where the symbol

I is often used in place of J.

d. 1 gauss = 105 gamma (1').

e. Both oersted and gauss are expressed as em -1I2. g 1l2.S -1 in terms of base units.

/. A/m was often expressed as "ampere-turn per meter" when used for magnetic field strength.

g. Magnetic moment per unit volume.

h. The designation "emu" is not a unit.

i. Recognized under SI, even though based on the definition B = 1J-oll +J. See footnote c.

j. 1J-r = 1J-/1J-o = 1 + X, all in SI. 1J-r is equal to Gaussian 1J-.

k. B·H and 1J-oM·H have SI units J/m 3; M·H and B·H /477 have Gaussian units erg/cm 3.

R. B. Goldfarb and F. R. Fickett, U.S. De~artment of Commerce, National Bureau of Standards, Boulder, Colorado 80303, March 1985

NBS Special Publication 696 For sale by the Superintendent of Documents, U.S. Government Printing Office, Washington, DC 20402

CHAPTER

Fitzgerald & Kingsley's Electric Machinery,

1

Stephen Umans,

McGraw-Hill Education, 7th Ed., Jan. 28, 2013.

agnetic Circuits and

agnetic Materials

he objective of this book is to study the devices used in the interconversion

of electric and mechanical energy. Emphasis is placed on electromagnetic rotating machinery, by means of which the bulk of this energy conversion takes

place. However, the techniques developed are generally applicable to a wide range of

additional devices including linear machines, actuators, and sensors.

Although not an electromechanical-energy-conversion device, the transformer is

an important component of the overall energy-conversion process and is discussed

in Chapter 2. As with the majority of electromechanical-energy-conversion devices

discussed in this book, magnetically coupled windings are at the heart of transformer

performance. Hence, the techniques developed for transformer analysis form the basis

for the ensuing discussion of electric machinery.

Practically all transformers and electric machinery use ferro-magnetic material

for shaping and directing the magnetic fields which act as the medium for transferring and converting energy. Permanent-magnet materials are also widely used in

electric machinery. Without these materials, practical implementations of most familiar electromechanical-energy-conversion devices would not be possible. The ability

to analyze and describe systems containing these materials is essential for designing

and understanding these devices.

This chapter will develop some basic tools for the analysis of magnetic field

systems and will provide a brief introduction to the properties of practical magnetic

materials. In Chapter 2, these techniques will be applied to the analysis of transformers. In later chapters they will be used in the analysis of rotating machinery.

In this book it is assumed that the reader has basic knowledge of magnetic

and electric field theory such as is found in a basic physics course for engineering

students. Some readers may have had a course on electromagnetic field theory based

on Maxwell's equations, but an in-depth understanding of Maxwell's equations is not

a prerequisite for mastery of the material of this book. The techniques of magneticcircuit analysis which provide algebraic approximations to exact field-theory solutions

T

1

2

CHAPTER 1

Magnetic Circuits and Magnetic Materials

are widely used in the study of electromechanical-energy-conversion devices and form

the basis for most of the analyses presented here.

1.1

The complete, detailed solution for magnetic fields in most situations of practical

engineering interest involves the solution of Maxwell's equations and requires a set

of constitutive relationships to describe material properties. Although in practice

exact solutions are often unattainable, various simplifying assumptions permit the

attainment of useful engineering solutions. 1

We begin with the assumption that, for the systems treated in this book, the frequencies and sizes involved are such that the displacement-current term in Maxwell's

equations can be neglected. This term accounts for magnetic fields being produced

in space by time-varying electric fields and is associated with electromagnetic radiation. Neglecting this term results in the magneto-quasi-static form of the relevant

Maxwell's equations which relate magnetic fields to the currents which produce

them.

(1.1)

i

B-da=O

(1.2)

Equation 1.1, frequently referred to as Ampere's Law, states that the line integral

of the tangential component of the magnetic field intensity H around a closed contour C

is equal to the total current passing through any surface S linking that contour. From

Eq. 1.1 we see that the source of His the current density J. Eq. 1.2, frequently referred

to as Gauss' Law for magnetic fields, states that magnetic flux density B is conserved,

i.e., that no net flux enters or leaves a closed surface (this is equivalent to saying that

there exist no monopolar sources of magnetic fields). From these equations we see

that the magnetic field quantities can be determined solely from the instantaneous

values of the source currents and hence that time variations of the magnetic fields

follow directly from time variations of the sources.

A second simplifying assumption involves the concept of a magnetic circuit. It is

extremely difficult to obtain the general solution for the magnetic field intensity Hand

the magnetic flux density B in a structure of complex geometry. However, in many

practical applications, including the analysis of many types of electric machines, a

thtee-dimensional field problem can often be approximated by what is essentially

1 Computer-based numerical solutions based upon the finite-element method form the basis for a number

of commercial programs and have become indispensable tools for analysis and design. Such tools are

typically best used to refine initial analyses based upon analytical techniques such as are found in this

book. Because such techniques contribute little to a fundamental understanding of the principles and

basic performance of electric machines, they are not discussed in this book.

1.1

Introduction to Magnetic Circuits

Mean core

length lc

Cross-sectional

areaAc

Magnetic core

permeability f1,

Figure 1.1 Simple magnetic circuit. )._ is the winding flux

linkage as defined in Section 1.2.

a one-dimensional circuit equivalent, yielding solutions of acceptable engineering

accuracy.

A magnetic circuit consists of a structure composed for the most part of highpermeability magnetic material. 2 The presence of high-permeability material tends

to cause magnetic flux to be confined to the paths defined by the structure, much as

currents are confined to the conductors of an electric circuit. Use of this concept of

the magnetic circuit is illustrated in this section and will be seen to apply quite well

to many situations in this book. 3

A simple example of a magnetic circuit is shown in Fig. 1.1. The core is assumed

to be composed of magnetic material whose magnetic permeability fJ., is much greater

than that of the surrounding air (JJ., >> tJvo) where /Jvo = 4n x 1o- 7 Him is the magnetic

permeability of free space. The core is of uniform cross section and is excited by a

winding of N turns carrying a current of i amperes. This winding produces a magnetic

field in the core, as shown in the figure.

Because of the high permeability of the magnetic core, an exact solution would

show that the magnetiC flux is confined almost entirely to the core, with the field lines

following the path defined by the core, and that the flux density is essentially uniform

over a cross section because the cross-sectional area is uniform. The magnetic field

can be visualized in terms of flux lines which form closed loops interlinked with the

winding.

As applied to the magnetic circuit of Fig. 1.1, the source of the magnetic field

in the core is the ampere-turn product N i. In magnetic circuit terminology N i is the

magnetonwtive force (mmf) F acting on the magnetic circuit. Although Fig. 1.1 shows

only a single winding, transformers and most rotating machines typically have at least

two windings, and N i must be replaced by the algebraic sum of the ampere-turns of

all the windings.

2

In its simplest definition, magnetic permeability can be thought of as the ratio of the magnitude of the

magnetic flux density B to the magnetic field intensity H.

3 For a more extensive treatment of magnetic circuits see A.E. Fitzgerald, D.E. Higgenbotham, and A.

Grabel, Basic Electrical Engineering, 5th ed., McGraw-Hill, 1981, chap. 13; also E.E. Staff, M.I.T.,

Magnetic Circuits and Transformers, M.I.T. Press, 1965, chaps. 1 to 3.

3

4

CHAPTER 1

Magnetic Circuits and Magnetic Materials

The net magnetic flux ¢ crossing a surface S is the surface integral of the normal

component of B; thus

¢=

1

B·da

(1.3)

In SI units, the unit of¢ is the weber (Wb).

Equation 1.2 states that the net magnetic flux entering or leaving a closed surface

(equal to the surface integral of B over that closed surface) is zero. This is equivalent

to saying that all the flux which enters the surface enclosing a volume must leave

that volume over some other portion of that surface because magnetic flux lines form

closed loops. Because little flux "leaks" out the sides of the magnetic circuit of Fig. 1.1,

this result shows that the net flux is the same through each cross section of the core.

For a magnetic circuit of this type, it is common to assume that the magnetic

flux density (and correspondingly the magnetic field intensity) is uniform across the

cross section and throughout the core. In this case Eq. 1.3 reduces to the simple scalar

equation

(1.4)

where

c/Je =core flux

Be = core flux density

Ae = core cross-sectional area

From Eq. 1.1, the relationship between the mmf acting on a magnetic circuit and

the magnetic field intensity in that circuit is. 4

(1.5)

The core dimensions are such that the path length of any flux line is close to

the mean core length le. As a result, the line integral of Eq. 1.5 becomes simply the

scalar product Hele of the magnitude of H and the mean flux path length le. Thus,

the relationship between the mmf and the magnetic field intensity can be written in

magnetic circuit terminology as

(1.6)

where He is average magnitude of H in the core.

The direction of He in the core can be found from the right-hand rule, which can

be stated in two equivalent ways. (1) Imagine a current-carrying conductor held in the

right hand with the thumb pointing in the direction of current flow; the fingers then

point in the direction of the magnetic field created by that current. (2) Equivalently, if

the coil in Fig. 1.1 is grasped in the right hand (figuratively speaking) with the fingers

4

In general, the mmf drop across any segment of a magnetic circuit can be calculated as

portion of the magnetic circuit.

JHdl over that

1.1

Introduction to Magnetic Circuits

pointing in the direction of the current, the thumb will point in the direction of the

magnetic fields.

The relationship between the magnetic field intensity H and the magnetic flux

density B is a property of the material in which the field exists. It is common to assume

a linear relationship; thus

(1.7)

where f.1, is the material's magnetic permeability. In SI units, His measured in units of

amperes per meter, B is in webers per square meter, also known as teslas (T), and JL

is in webers per ampere-turn-meter, or equivalently henrys per 1neter. In SI units the

permeability of free space is /Lo = 4Jr X 1o- 7 henrys per meter. The permeability of

linear magnetic material can be expressed in terms of its relative permeability JLr, its

value relative to that of free space; JL = /Lr/LO· Typical values of /Lr range from 2,000 to

80,000 for materials used in transformers and rotating machines. The characteristics

of ferromagnetic materials are described in Sections 1.3 and 1.4. For the present we

assume that J.l,r is a known constant, although it actually varies appreciably with the

magnitude of the magnetic flux density.

Transformers are wound on closed cores like that of Fig. 1.1. However, energy

conversion devices which incorporate a moving element must have air gaps in their

magnetic circuits. A magnetic circuit with an air gap is shown in Fig. 1.2. When

the air-gap length g is much smaller than the dimensions of the adjacent core faces,

the core flux c/Jc will follow the path defined by the core and the air gap and the

techniques of magnetic-circuit analysis can be used. If the air-gap length becomes

excessively large, the flux will be observed to "leak out" of the sides of the air gap

and the techniques of magnetic-circuit analysis will no longer be strictly applicable.

Thus, provided the air-gap length g is sufficiently small, the configuration of

Fig. 1.2 can be analyzed as a magnetic circuit with two series components both

carrying the same flux¢: a magnetic core of permeability f.l,, cross-sectional area Ac

and mean length lc, and an air gap of permeability fLo, cross-sectional area Ag and

length g. In the core

(1.8)

+

Mean core

length lc

i

---+-

+--Air gap,

permeability fl-o,

AreaAg

Magnetic core

permeability fl-,

AreaAc

Figure 1.2 Magnetic circuit with air gap.

5

6

CHAPTER 1

Magnetic Circuits and Magnetic Materials

and in the air gap

¢

(1.9)

Ba=Ac

1:>

Application of Eq. 1.5 to this magnetic circuit yields

+ Hgg

:F = Hclc

(1.10)

and using the linear B-H relationship of Eq. 1.7 gives

B

+ ___!

g

(1.11)

JLo

Here the :F = Ni is the mmf applied to the magnetic circuit. From Eq. 1.10 we

see that a portion of the mmf, Fe = Hclc, is required to produce magnetic field in the

core while the remainder, :Fg = Hgg produces magnetic field in the air gap.

For practical magnetic materials (as is discussed in Sections 1.3 and 1.4), Be

and He are not simply related by a known constant permeability JL as described by

Eq. 1.7. In fact, Be is often a nonlinear, multi-valued function of He. Thus, although

Eq. 1.10 continues to hold, it does not lead directly to a simple expression relating

the mmf and the flux densities, such as that of Eq. 1.11. Instead the specifics of the

nonlinear Be-He relation must be used, either graphically or analytically. However, in

many cases, the concept of constant material permeability gives results of acceptable

engineering accuracy and is frequently used.

From Eqs. 1.8 and 1.9, Eq. 1.11 can be rewritten in terms of the flux ¢cas

:F = ¢ (__!_:__

J-LAc

+

_g_)

JLoAg

(1.12)

The terms that multiply the flux in this equation are known as the reluctance (R)

of the core and air gap, respectively,

(1.13)

g

Ra=-1:>

JLoAg

(1.14)

and thus

(1.15)

"Finally, Eq. 1.15 can be inverted to solve for the flux

:F

¢=---

Rc+Rg

(1.16)

or

:F

¢ = ---;---

+-g!LoAg

(1.17)

1.1

I

Introduction to Magnetic Circuits

~

---+-

nc

Rl

+

+

v

:F

ng

R2

I---v-

¢=

- (R 1 +R2)

:F

('Rc + 'Rg)

(b)

(a)

Figure 1.3 Analogy between electric and magnetic circuits.

(a) Electric circuit. (b) Magnetic circuit.

In general, for any magnetic circuit of total reluctance Rtob the flux can be found as

¢

= _!__

(1.18)

Rtot

The term which multiplies the mmf is known as the permeance P and is the inverse

of the reluctance; thus, for example, the total permeance of a magnetic circuit is

Ptot

=

1

(1.19)

rn

/'\-tot

Note that Eqs. 1.15 and 1.16 are analogous to the relationships between the current and voltage in an electric circuit. This analogy is illustrated in Fig. 1.3. Figure 1.3a

shows an electric circuit in which a voltage V drives a current I through resistors R1

and R2 • Figure 1.3b shows the schematic equivalent representation of the magnet~c

circuit of Fig. 1.2 . Here we see that the mmf :F (analogous to voltage in the electric

circuit) drives a flux ¢ (analogous to the current in the electric circuit) through the

combination of the reluctances of the core Rc and the air gap Rg. This analogy between the solution of electric and magnetic circuits can often be exploited to produce

simple solutions for the fluxes in magnetic circuits of considerable complexity.

The fraction of the mmf required to drive flux through each portion of the magnetic

circuit, commonly referred to as the mnif drop across that portion of the magnetic

circuit, varies in proportion to its reluctance (directly analogous to the voltage drop

across a resistive element in an electric circuit). Consider the magnetic circuit of

Fig. 1.2. From Eq. 1.13 we see that high material permeability can result in low core

reluctance, which can often be made much smaller than that of the air gap; i.e., for

(fl,Ac/lc) >> (f.loAg/ g), Rc << Rg and thus Rtot ~ Rg. In this case, the reluctance

of the core can be neglected and the flux can be found from Eq. 1.16 in terms of :F

and the air-gap properties alone:

¢ ~ :F

Rg

= :FfJ,oAg = Ni

g

f.loAg

g

(1. 20)

7

8

CHAPTER 1

Magnetic Circuits and Magnetic Materials

Fringing

fields

++--+---+- Air gap

H-+++-t-1-HI-H--+-H-+H

Figure 1.4 Air-gap fringing fields.

As will be seen in Section 1.3, practical magnetic materials have permeabilities which

are not constant but vary with the flux level. From Eqs. 1.13 to 1.16 we see that as

long as this permeability remains sufficiently large, its variation will not significantly

affect the performance of a magnetic circuit in which the dominant reluctance is that

of an air gap.

In practical systems, the magnetic field lines "fringe" outward somewhat as they

cross the air gap, as illustrated in Fig. 1.4. Provided this fringing effect is not excessive,

the magnetic-circuit concept remains applicable. The effect of these fringing fields is to

increase the effective cross-sectional area Ag of the air gap. Various empirical methods

have been developed to account for this effect. A correction for such fringing fields

in short air gaps can be made by adding the gap length to each of the two dimensions

making up its cross-sectional area. In this book the effect of fringing fields is usually

ignored. If fringing is neglected, Ag = A c.

In general, magnetic circuits can consist of multiple elements in series and

parallel. To. complete the analogy between electric and magnetic circuits, we can

generalize Eq. 1.5 as

(1.21)

where F is the mmf (total ampere-turns) acting to drive flux through a closed loop of a

magnetic circuit, and Fk = Hklk is the mmf drop across the k'th element of that loop.

This is directly analogous to Kirchoff's voltage law for electric circuits consisting of

voltage sources and resistors

(1.22)

where V is the source voltage driving current around a loop and Rkik is the voltage

drop across the k'th resistive element of that loop.

1.1

Introduction to Magnetic Circuits

Similarly, the analogy to Kirchoff's current law

(1.23)

n

which says that the net current, i.e. the sum of the currents, into a node in an electric

circuit equals zero is

(1.24)

1l

which states that the net flux into a node in a magnetic circuit is zero.

We have now described the basic principles for reducing a magneto-quasi-static

field problem with simple geometry to a magnetic circuit model. Our limited purpose

in this section is to introduce some of the concepts and terminology used by engineers

in solving practical design problems. We must emphasize that this type of thinking

depends quite heavily on engineering judgment and intuition. For example, we have

tacitly assumed that the permeability of the "iron" parts of the magnetic circuit is a

constant known quantity, although this is not true in general (see Section 1.3), and

that the magnetic field is confined solely to the core and its air gaps. Although this is a

good assumption in many situations, it is also true that the winding currents produce

magnetic fields outside the core. As we shall see, when two or more windings are

placed on a magnetic circuit, as happens in the case of both transformers and rotating

machines, these fields outside the core, referred to as leakage fields, cannot be ignored

and may significantly affect the performance of the device.

The magnetic circuit shown in Fig. 1.2 has dimensions Ac = Ag = 9 cm2, g = 0.050 em,

lc = 30 em, and N =500 turns. Assume the value Mr =70,000 for core material. (a) Find the

reluctances Rc and Rg. For the condition that the magnetic circuit is operating with Be= 1.0 T,

find (b) the flux ¢ and (c) the current i.

II Solution

a. The reluctances can be found from Eqs. 1.13 and 1.14:

lc

0.3

10-7)(9

Rc

=- = 70,000 (4n

fJ.-rfJ.-oAc

Rg

8

=- = -----'---= 4.42 X 105

fJ.,oAg

(4n X 10-7)(9 X

X

5 x 10-4

b. From Eq. 1.4,

c. From Eqs. 1.6 and 1.15,

.

l=

F

N

X

10-4)

= 3.79 X

103

A· turns

Wb

A · turns

Wb

9

10

CHAPTER 1

Magnetic Circuits and Magnetic Materials

Find the flux cjJ and ctment for Example 1.1 if (a) the number of turns is doubled to N = 1000

turns while the circuit dimensions remain the same and (b) if the number of turns is equal to

N =500 and the gap is reduced to 0.040 em.

Solution

a. cjJ

b. dJ

= 9 x IQ-4 Wb and i = 0.40 A

= 9 X IQ-4 Wb and i = 0.64 A

The magnetic structure of a synchronous machine is shown schematically in Fig. 1.5. Assuming

that rotor and stator iron have infinite permeability (J.L -7 oo ), find the air-gap flux cjJ and flux

density Bg. For this example I= 10 A, N = 1,000 turns, g = 1 em, and Ag = 200 cm2 •

II Solution

Notice that there are two air gaps in series, of total length 2g, and that by symmetry the\ flux

density in each is equal. Since the iron permeability is assumed to be infinite, its reluctance is

negligible and Eq. 1.20 (with g replaced by the total gap length 2g) can be used to find the flux

7

- N I J.LoAg - 1000(10)(4n X 10- )(0.02) - 12 6 Wb

¢. m

2g

0.02

and

cjJ

0.0126

Ba = - =

= 0.630 T

" Ag

0.02

Figure 1.5 Simple synchronous machine.

1.2 Flux Linkage, Inductance, and Energy

For the magnetic structure of Fig. 1.5 with the dimensions as given in Example 1.2, the air-gap

flux density is observed to be Bg = 0.9 T. Find the air-gap flux¢ and, for a coil of N = 500

turns, the current required to produce this level of air-gap flux.

Solution

¢ = 0.018 Wb and i = 28.6 A.

1.2 FLUX LINKAGE, INDUCTANCE,

AND ENERGY

When a magnetic field varies with time, an electric field is produced in space as

determined by another of Maxwell's equations refened to as Faraday's law:

i

d { B · da

dt Js

E·ds=

(1.25)

Equation 1.25 states that the line integral of the electric field intensity E around a

closed contour C is equal to the time rate of change of the magnetic flux linking

(i.e., passing through) that contour. In magnetic structures with windings of high

electrical conductivity, such as in Fig. 1.2, it can be shown that the E field in the wire

is extremely small and can be neglected, so that the left-hand side ofEq. 1.25 reduces

to the negative of the induced voltage5 e at the winding terminals. In addition, the flux

on the right-hand side ofEq. 1.25 is dominated by the core flux¢. Since the winding

(and hence the contour C) links the core flux N times, Eq. 1.25 reduces to

e=Nd<p=dA

dt

dt

(1.26)

where Ais the flux linkage of the winding and is defined as

A= N<p

(1.27)

Flux linkage is measured in units of webers (or equivalently weber-turns). Note that

we have chosen the symbol <p to indicate the instantaneous value of a time-varying

flux.

In general the flux linkage of a coil is equal to the surface integral of the normal

component of the magnetic flux density integrated over any surface spanned by that

coil. Note that the direction of the induced voltage e is defined by Eq. 1.25 so that if

the winding terminals were short-circuited, a cunent would flow in such a direction

as to oppose the change of flux linkage.

For a magnetic circuit composed of magnetic material of constant magnetic

permeability or which includes a dominating air gap, the relationship between A

5

The term electromotive force (emf) is often used instead of induced voltage to represent that component

of voltage due to a time-varying flux linkage.

11

12

CHAPTER 1

Magnetic Circuits and Magnetic Materials

and i will be linear and we can define the inductance L as

A.

L=i

(1.28)

Substitution ofEqs. 1.5, 1.18 and 1.27 into Eq. 1.28 gives

L=

N2

(1.29)

Rtot

from which we see that the inductance of a winding in a magnetic circuit is proportional

to the square of the turns and inversely proportional to the reluctance of the magnetic

circuit associated with that winding.

For example, from Eq. 1.20, under the assumption that the reluctance of the core

is negligible as compared to that of the air gap, the inductance of the winding in

Fig. 1.2 is equal to

(1.30)

Inductance is measured in henrys (H) or weber-turns per ampere. Equation 1.30

shows the dimensional form of expressions for inductance; inductance is proportional

to the square of the number of turns, to a magnetic permeability and to a crosssectional area and is inversely proportional to a length. It must be emphasized that

strictly speaking, the concept of inductance requires a linear relationship between

flux and mmf. Thus, it cannot be rigorously applied in situations where the nonlinear characteristics of magnetic materials, as is discussed in Sections 1.3 and 1.4,

dominate the performance of the magnetic system. However, in many situations of

practical interest, the reluctance of the system is dominated by that of an air gap

(which is of course linear) and the non-linear effects of the magnetic material can be

ignored. In other cases it may be perfectly acceptable to assume an average value of

magnetic permeability for the core material and to calculate a corresponding average

inductance which can be used for calculations of reasonable engineering accuracy.

Example 1~3 illustrates the former situation and Example 1.4 the latter.

The magnetic circuit of Fig. 1.6a consists of an N -turn winding on a magnetic core of infinite

permeability with two parallel air gaps of lengths g 1 and g2 and areas A1 and A2 , respectively.

Find (a) the inductance of the winding and (b) the flux density B1 in gap I when the

winding is carrying a current i. Neglect fringing effects at the air gap.

Solution

a. The equivalent circuit of Fig. 1.6b shows that the total reluctance is equal to the parallel

~ combination of the two gap reluctances. Thus

<P=

Ni

1.2 Flux Linkage, Inductance, and Energy

+

Ni

(a)

(b)

Figure 1.6 (a) Magnetic circuit and (b) equivalent circuit for Example 1.3.

where

From Eq. 1.28,

).

L=

N¢

b. From the equivalent circuit, one can see that

Ni

JJ, 0 A 1Ni

¢1=-=-nl

gl

and thus

In Example 1.1, the relative permeability of the core material for the magnetic circuit of Fig. 1.2

is assumed to be Jl,r = 70, 000 at a flux density of 1.0 T.

a. In a practical device, the core would be constructed from electrical steel such as M-5

electrical steel which is discussed in Section 1.3. This material is highly nonlinear and its

relative permeability (defined for the purposes of this example as the ratio BI H) varies

from a value of approximately Jl,r = 72,300 at a flux density of B = 1.0 T to a value of on

the order of Jl,r = 2,900 as the flux density is raised to 1.8 T. Calculate the inductance

under the assumption that the relative permeability of the core steel is 72,300.

b. Calculate the inductance under the assumption that the relative permeability is equal to

2,900.

13

14

CHAPTER 1

Magnetic Circuits and Magnetic Materials

Solution

a. From Eqs. 1.13 and 1.14 and based upon the dimensions given in Example 1.1,

Rc = _lc_·_ =

f.Lrf.LoAc

72,300 (4n

X

0.3

10-7)(9

= 3.67

X

X

103 A ·turns

Wb

while Rg remains unchanged from the value calculated in Example 1.1 as

Rg = 4.42 x 105 Aturns/Wb.

Thus the total reluctance of the core and gap is

Rtot

= Rc + Ra = 4.46 X

o

A· turns

105 -Wb

--

and hence from Eq. 1.29

N2

L = =

Rtot

5002

= 0.561 H

4.46 X 105

b. For f.Lr = 2,900, the reluctance of the core increases from a value of 3.79 x 103 A· turns I

Wb to a value of

Rc = __

Zc_ = _____0_.3_____ = 9.1 5 X 104 _A_·_tu_rn_s

f.Lrf.LoAc

2,900 (4n X 10-7)(9 X

Wb

and hence the total reluctance increases from 4.46 x 105 A· turns I Wb to 5.34 x 105 A ·

turns I Wb. Thus from Eq. 1.29 the inductance decreases from 0.561 H to

N2

L = =

Rtot

5002

= 0.468 H

5.34 X 105

This example illustrates the linearizing effect of a dominating air gap in a magnetic

circuit. In spite of a reduction in the permeablity of the iron by a factor of 72,300/2,900 =

25, the inductance decreases only by a factor of 0.46810.561 = 0.83 simply because the

reluctance of the air gap is significantly larger than that of the core. In many situations, it

is common to assume the inductance to be constant at a value corresponding to a finite,

constant value of core permeability (or in many cases it is assumed simply that f.Lr ~ oo ).

Analyses based upon such a representation for the inductor will often lead to results which

are well within the range of acceptable engineering accuracy and which avoid the

immense complication associated with modeling the non-linearity of the core material.

Repeat the inductance calculation of Example 1.4 for a relative permeability f.Lr = 30,000.

Solution

L

= 0.554H

Using MATLAB,6 plot the inductance of the magnetic circuit of Example 1.1 and Fig. 1.2 as

; function of core permeability over the range 100 :S f.Lr :S 100,000.

6

"MATLAB" ia a registered trademarks of The Math Works, Inc., 3 Apple Hill Drive, Natick, MA

01760, http://www.mathworks.com. A student edition ofMatlab is available.

1.2 Flux Linkage, Inductance, and Energy

II Solution

Here is the MATLAB script:

clc

clear

% Permeability of free space

muO = pi*4.e-7;

%All dimensions expressed in meters

Ac = 9e-4; Ag = 9e-4; g

Se-4; lc = 0.3;

N

500;

%Reluctance of air gap

Rg = g/(muO*Ag);

mur = 1:100:100000;

Rc = lc./(mur*muO*Ac);

Rtot = Rg+Rc;

L = W'2. /Rtot;

plot(mur,L)

xlabel('Core relative permeability')

ylabel('Inductance [H] ')

The resultant plot is shown in Fig. 1.7. Note that the figure clearly confirms that, for the

magnetic circuit of this example, the inductance is quite insensitive to relative permeability

0.6

0.5

53'

'";; 0.4

§

u

.§ 0.3

,s

0.2

0.1

2

3

7

4

5

6

Core relative permeability

8

9

X

10

104