* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Cooling guidelines PL

Passive solar building design wikipedia , lookup

Fan (machine) wikipedia , lookup

Building insulation materials wikipedia , lookup

Heat exchanger wikipedia , lookup

Thermal comfort wikipedia , lookup

Cogeneration wikipedia , lookup

Thermal conduction wikipedia , lookup

Underfloor heating wikipedia , lookup

Copper in heat exchangers wikipedia , lookup

R-value (insulation) wikipedia , lookup

Ventilation (architecture) wikipedia , lookup

Indoor air quality wikipedia , lookup

Hyperthermia wikipedia , lookup

Dynamic insulation wikipedia , lookup

Atmospheric convection wikipedia , lookup

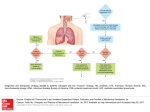

Efficient and innovative cooling and air conditioning in buildings Use of ground heat exchangers Guidebook for building owners and administrators The sole responsibility for the content of this publication lies with the authors. It does not represent the opinion of the Community. The European Commission is not responsible for any use that may be of the information contained therein. 1 Introduction Dear Reader We hope that this Guidebook will reach you and rise your interest up. Whom are we addressing? We are addressing millions of building owners, administrators and developers. To those, who already possess buildings and are going to retrofit them to upgrade the buildings operation standard and also to those who will construct their buildings – residential, service and, public service ones. We can realise that it is not always possible to rationally apply innovative technologies for air conditioning – certainly not everyone will make a decision to undertake such steps. However, there are still more and more applications not only implemented by enthusiastic people but also by those who make economic decisions. Why do we encourage to use energy efficient and innovative cooling technologies in buildings Our common ecological awareness is rising up. We are still more and more convinced that it is our obligation to the future generations, to secure sustainable development of the world, countries, towns and villages. Resources of fossil fuels: hard coal, natural gas, crude oil etc. will be available in the next 40-50 years regarding hydrocarbon fuels, and 200 – 300 years – regarding hard coal. However, we are using still more and more energy. Its consumption for air conditioning purposes in our houses, offices and service places is still increasing. Additional forecasts issued by different independent institutions show that this demand will continue to increase, especially in the developing countries in Central Europe. Even though, any activities oriented at mitigation of energy demand for air conditioning still have a very low priority level and are known to a small group of experts and even smaller group of building administrators and owners. Through this publication and through involving ourselves into implementing process of the COOLREGION project, we would like to change this situation. Which technologies and equipment in buildings This guidebook focuses on these technologies and equipment that from the technical viewpoint could be implemented in buildings and from the economic viewpoint promise to be economically efficient already now or in the future practice. 2 What to consider during the designing process Energy prices are continuously increasing. This situation enforces necessity to save fuels and to reduce energy consumption and stimulates rational use what directly turns into climate protection effects. In order to make any buildng an optimal one it is necessary to find its correct location. Selection of a piece of ground for future construction shall be dictated by a possibility to erect a building oriented to South (acceptable are deviations up to a dozen or so degrees). It is important to have a building site wide enough to functionally design the building inside, especially the residential compartments in a way to assure daylight from the Southern direction, while auxiliary compartments (bathroom, kitchen, wardrobe, technical roms, staircase, corridors) should be located from the Northern side. The building should be of comprehensive shape. Evergy wall corner and angle creates a place in which a thermal bridge may appear. Another question is that a complicated building costs much more in terms of thermal enveloping. The less area for insulation, the better. An important part of passive and energy saving buildings is its South face wall. This wall creates in practice and independent system dedicated to shaddowing in summer and acquiring as much as possible yield from thermal sun radiation during the winter months. In order to meet those two assumptions that seem to be mutually excluning, some design issues need to be resolved. First, it is necessary to correctly install the shaddowing elements in a way that excludes creating of thermal briges. It is also a problematic issue to install any elements to walls having a thick insulation layer. Beside overglazing, shaddowing system and insulation, also solar collectors can be used as well as photovoltaic batteries. Any external walls and faces of the building, elevations, roof, windows or flooplaced on the ground shall have a very low heat transfer coefficients. All of them shall be 2-3 times lower than in cases of standard constructions, respectively (according to the present regulations for new buildings). Requirements under Ordinance Requirements under Ordinanceof the Ministry of Infrastructure of 14 of the Ministry of Infrastructure, on February 2008 r. on detail Technical conditions to be fulfilled Scope and form of by buildings and its locations Energy audit Type of barrier standard for a passive building wsp. przenikania wsp. przenikania wsp. przenikania oprór cieplny oprór cieplny ciepła ciepła ciepła 2. 2. 2. 2. 2. 2. U [W/m K] R [m K/W] U [W/m K] R [m K/W] U [W/m K] R [m K/W] 3,33 4,00 0,30 0,25 6,67 0,15 ? 1,25 4,00 0,80 0,25 0,25 0,22 0,15 4,00 4,50 6,67 ? oprór cieplny External wall T External wall T Roof / ceiling o > 16 C o i < 16 C i windo 0,59 1,70 0,59 1,70 1,25 External doors 0,38 2,60 bw bw 0,91 ? ? 0,80 1,10 bw – no requirements A typical feture that differs passive buildings from the traditional ones is the way of heating or cooling. This is because passive buildings are not equipped with heating or cooling installations that can usually be found in typical buildings. Cooling and heating is usually carried out along with mechanical ventilating. One should remember that a building should be designed in a way that makes it possible to reduce its basic heating demand to a value of about 15kWh/m2 per year. An important role in reducing energy demand can be dedicated to the use of renewable and alternative energy resources, such as heat pumps or ground heat exchangers. Przeszklenie o współczynniku przenikania ciepła U≤0,8 W/m 2K Szczelne przegrody zewnętrzne o współczynniku przenikania ciepła U<0,15 W/m2K Wywiew Wylot zurzytego powietrza Nawiew Zyski cieplne z promieniowania słonecznego Rekuperator Nagrzewnica Wlot świeżego powietrza Filtr Gruntowy wymiennik ciepła Summarising the above, the following conclusions can be drawn about features to characterise buildings: 1) Demand for energy necessary for heating of one square meter of internal area, during a single heating season shal be below 15 kWh, which is equivalent to combustionof 3 kg of hard coal or 1,5 litter of heating oil. 2) Passive solar yields cover 40% of heat demand. 3) Correctly insulating, low-emission window glazing (3 layers or with a special membrane). 4) Wll insulating window frames. 5) Walls having high insulating properties. 6) Mitigation to an absolute minimum of thermal bridges. 7) Low permeability fr air into and out from the building through the external walls. 8) Compact, not complicated shape of the building. 9) Mechanical ventilation that removes moisture better that the traditional convective one. 10) Heat recovery from ventilation air. 11) No conventional separate hetaing / cooling systems. Heating and cooling are performed by injection of hot or cold air along with mechanical ventilation. 12) Optionally – recovery of heat and chill from the ground. External air blowed into the building should be pre-heated or pre-cooled in a ground heat exchanger. 13) Optionally – recovery and storage of heat from solar heat radiation (solar collectors, transparent insulation, etc.). 14) Optionally – recovery of heat ‘hidden’ in the ventilation air (heat pump air-to-air). 15) Use of shaddings (leave trees, roofs, roller blinds) from the south wall in to order to minimize solar radiation penetration into the building. 3 Use of innovative cooling technologies In case of high thermal insulation properties of the external surfaces, that is usual for passive buildings, the role of ventilation increases significantly, although it often either missunderstood or underestimated. Without an efficient mechanical ventilation, heat recovery by means of a heat recuperator and ‘hidden’ heat recovery by means fo heat pump or ground heat exchanger would not be possible. Fresh air intaken for ventilation of rooms mas pass through a piping system placed under the ground or through a gravel bed in order to become pre-heated. This is a so-called ground heat exchanger which is a common solution used in passive buildings. Ground heat exchanger makes it possible to recover clean energy from the ground. This is a verry efficient kind of equipment (energy consumption derives only from air flow resistance / pressure drop). Furthermore – construction of a ground heat exchanger is relatively simple and cheap – this can be a „home-made” device. Despite numerous advantages of such solution it cannot be used with gravity ventilation, commonly used in buildings. Such heat exchanger can only be used in buildings with mechanical ventilation. Design of ground heat exchanger (GHE) includes a natural bed (layer) of clean, flushed gravel placed in the ground. Air flowing through the gravel (depending on the year season) in the sumer is cooled and dried, in the winter is heated and saturated with moisture and all over a year is filtered by removal of dust and bacteria. Direct contact of the bed with the surrounding ground enables a fast regenaration of the bed temperature. Parameters of the exhaust air downstream the gravel bed are characterised with very slow deviations in time, that can be only detected in a several-month lasting cycles. In practice, during one month these deviations are hard to be noticed. This is a positive effect because the result of this phenomena is that any day-by-day appearing changes in air temperetaure are levelized during a day period and during consecutive days, even if rapid changes in ambient temperature take place. In cases when the ambient temprerature increases rapidly, that occure sometimes in winter and intermedium periods, as well as during rapid drops of temperature in summer, owing to the fact that the exchangers respond with a certain delay, it may happen that during certain periods of time, from the ventilation viewpoint, the parapeters of air downstream the bed are worse that the ambient air parameters. Correctly operated automatic control system shoule assure intake of the air from the better source. In autumn and by the end of summer, the air temperature downstream the bed is higher than during the winter and spring months. In the turn of August and September this temperature may reach as much as 22°C at ambient temperature of +32°C. In turn of February and March ma be -2°C at. ambient -20°C, especially with strong frost „attack” in January and February. A big inertia of the exchanger results in the fact that climat Quarters of the bed temperature are shift in relation to the climate seasons. This shift reaches about two months. Possible configurations of GHE: In the places where surface ground water appears, a GHE may be located in different configurations in relation to the ground surface. a) The GHE may be entirely hidden under the ground surface (only the air intake head stays over the ground). b) The GHE is partly submerged. A part of the exchanger is located under the ground and the remaining part is elevated above the ground surface. c) The GHE beside a ground slope. One or two walls of the exchanger belong to this slope. d) (not illustrated) Bottom of the GHE lies on the ground. The insulation inserted several dozen centimeters into the ground and on the slope surface makes it possible to elevate ground isothermal lines above its surface, into the exchanger. In order to obtain comparable thermal effect the GHE capacity shall be increased. Calculations of energy effects to come from using a Ground Heat Exchanger for building ventilation and air conditioning. In order to determine heating and cooling capacity of a ground heat exchanger, a simplified method can be applied for designing. This is the IGSPA (The International Grodnu Source Heat Pump Association) method. Following this method, the exchanger capacity is calculated from the below formula: Qw = Vn ⋅ ρ ⋅ c p ⋅ (t1 − t e ) 3,6 [W ], where: Qw – exchanger capacity Vn – amount of introduced ventilation air ρ – air density downstream the GHE cp – specific heat of the air downstream the GHE t1 – air temperature downstream the GHE te – ambient air temperature. Average ambient air temperatures are pre-assumed according to the Polish Standard PN-82/B-02403 while temperatures downstream the ground heat exchanger can be assumed following the example specification of a ventilation system coupled with a GHE, as in the Figure below. Symbols: tp - indoor temperature in the building tm - temperature of the air mix or downstream the recuperator (efficiency up to 70%) tz - tw - outdoor and indoor temperatures tgw - temperature at the GHE outlet tnoz tnoc - temperature of in-blown air. Necessary amount of the air can be determined on the basis of air replacement multiplicity or from the necessary amount of air per capita. Number of ventilation air replacements per hour is called ‘air replacement multiplicity’. This value depends not only on cubature of rooms but also on the place and intensity of air pollution. Experimental values gained for different types of rooms / compartments vary in a wide range. It can be assumed that e.g. for office rooms the hourly air replacement intensity shall reach a value of about 1, in classrooms – 2 and residential rooms – 0,5. By multiplying the replacement multiplicity for a chosen type of room by its cubature the amount of ventilation air can be determined. Another way to determine the ventilation air amount is to base it upon the number of persons who use the rooms. The Polish National Standard PN-83/B-03430 on ventilation in residential and public service buildings defines amounts of ventilation air injected from the outdoor, per capita. Typical values are as follows: 20 m3/h for every person present in a room 30 m3/h per every person in a room in case of rooms in which smoking is allowed. Basic properties of GHE 1. Simple design of GHE, use of available and cheap materials makes it possible to manufacture a GHE, generally in any place and any conditions. This entails a possibility of common use of this equipment for ventilation, air conditioning and thermal ventilation. 2. Utilisation in a simple way of the natural energy resources of the ground at small depth for cooling and heating of the ventilation air stream 3. Use of e ground heat exchanger is purely a way to use renewable energy resource. An investor who makes a decision to construct such equipment may apply for a grant or a preference investment loan from The Bank for Environment Protection or from the National or Voivodeship Fund for Environment Protection and Water Management. 4. Use of a GHE may generate additional savings related to automation of air conditioning equipment because due to the inertia of a GHE the parameters of air at the GHE outlet do not depend (to a large extent) on the changes in outdoor air properties at the GHE intake. Outlet air parameters are relatively stable in a long time horizon and do not require ongoing control. 5. Air parameters at the gravel bed outlet are subject to very slow variations in the function of time and are noticable only over a few-months lasting cycle. During a period of one month such changes are practically neglicible. This phenomenon gives a convenient result because any daily rapid changes of outdor air are levelised as well on a daily basis as for longer periods of time, when rapid increase or drop of ambient temperature can be observed. 6. High capacity and low operation costs of a GHE make it possible to use only the outdoor air for ventilation – without necessity of blending it with used air through recirculation. Up to date, the largest GHE in Poland has total capacity of 137 thousand m3/hour. 7. Only the costs of air transportation across the gravel bed are caried (pressure drom of ca 100 Pa) without costs of its heating or cooling. 8. A GHE assures to entirely cover chill demand during the summer period. The relation between energy input (fan) and energy yield reaches an average value of 1:15. 9. Air stream from the GHE that enters the recuperators (even at winter extreme conditions with –20oC outdoor) does not cause freezing of the cross heat exchnger because the recuperator inlet temperature is close to 0oC or is positive. 10. Use of GHE in the winter period makes it possible to gain up to 50% of ventilation heat from the ground. 11. Recirculation or use of a recuperator allows to gain further amounts of heat, up to 20-30%. 12. Average maximum temperature difference of the air upstream and downstream a GHE in summer 10÷12°C, and in winter 18÷20°C refers to extreme outdoor air temperatures reaching +32°C i -20°C respectively. The average thermal effect of the gravel bed equals 1kW/m3 and during the summer and winter peak conditions it reaches even up to 2kW per 1m3 of the bed. 13. Best energy effects are obtained during the extreme weather conditions, i.e. for low outdoor temperatures in winter and high outdoor temperatures in summer. Any harmful peaks are „cut” out. 14. Dowstream the GHE the air humidity is reduced in the summer period, e.g. from 15,2 down to 12,7 g/kg, while during winter air humidity increases. 4 Good existing examples Energy efficient buildings complex of the EXBUD Company, with cubature of 96.000 m3, incorporates many energy efficient solutions of heating system based on ground heat exchangers and heat pumps. Energy gained from the ground through pipels either tubular heat exchangers and from waste heat. Further heat savings result from automatic control of ventilation parameters and air replacement and temperature in some rooms and selected periods of time. Energy efficient installation systems include recovery of additional energy from outdoor renewable sources, by means of using: tubeless ground heat and substance exchangers, tubular ground heat exchnger; An unique in Poland renewable energy resource are the ground heat exchangers use in this building complex for pre-heating of fresh ventilation air in winter and its cooling in summer. These exchanger are displaced around the complex at a small depth, under the grassbeds. The accumulative – transferring bed a layer of fine granite has been used. The relation between input capacity (fan motor power) and the energy effects (yield) reaches 1:30. Most of the buildings in this Centre has been equipped with such tubeless exchangers. In the hotel building a ground tubular exchanger has been installed in which ventilation air is pre-heated in winter and cooled in summer as the result of its flow through the piping system positioned under the ground at the depth of 1,5 to 2,0 meters. A sinle-family building using alternative energy sources for cooling and air conditioning. The building is located on concrete cross-shaped foundations, between which two Ground Heat Exchangers filled with flushed river gravel. The building is well enveloped in terms of thermal insulation. Walls: k < 0,30 [W/m2K], Roof: k < 0,25 [W/m2K], Windows: k = 1,1 [W/m2K], In addition to that, a heat pump (air-to-water) operates in the building. Cooling of the outdoor air intaken into the buildings goes in the result of air flow through a bed of gravel located in the ground. Owing to use of flushed river gravel and owing to positioning the fireplace inthe central part of the building, the objects presents perfect accumulative properties. The building has been occupied since 2003 and according to the reports by its owner the object assures high comfort of use with very low expences for energy carriers. 5 Further information We hope that this Guidebook will reach you and rise your interest up with energy efficiency and innovative technologies of cooling. For detail information and data please visit: www.eplan.info.pl/coolregion and www.taniaklima.pl TANIA KLIMAtyzacja gruntowa i ogrzewanie ul. Graniczna 49 j Poland 41-408 Mysłowice tel:[+48] (32) 201 61 68 6 Literature / sources 1) Joanna Rucińska - “Zastosowanie uproszczonej metody projektowania gruntowego wymiennika ciepła do oceny jego efektywności energetycznej”, Politechnika Warszawska, “Building Physics in Theory and Practise” 2) Sławomir Kurpaska, Hubert Latała, Kazimierz Rutkowski - „Analiza wydajności cieplnej gruntowego wymiennika ciepła w instalacji wykorzystującej pompę ciepła”, Inżynieria Rolnicza 11/2006 3) Sławomir Pasierb, Mariusz Bogacki, Arkadiusz Osicki, Jerzy Wojtulewicz – „Odnawialne Źródła Energii. Efektywne wykorzystanie w budynkach. Finansowanie przedsięwzięć”, poradnik FEWE 4) Witold Piecha „Opłacalna wymiana”, Magazyn Instalatora 02/2006