* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download BIO1004 Microbial biotech 2015 for online taster course cut down

Survey

Document related concepts

Transcript

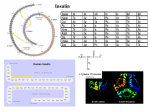

BIO1004: Microbial biotechnology Dr Alison Graham 19 November 2015 Ridley Building 2 Room 5.68 [email protected] What is biotechnology? •Use of organisms to make useful products. •Application of organisms or their cellular components to specific processes. •Can include organisms manipulated by genetic engineering. •Also called industrial microbiology. Microbial biotechnology: some examples Medical • insulin • antibiotics • anti-venom • Botox • vaccines Food and beverages • bread • cheese • citric acid • alcohol • QuornTM • probiotics • marmite • yoghurt Enzyme production • washing powder enzymes • amylases – hydrolyse starch to other sugars • DNA polymerases Environmental applications • bioremediation • biosensors • agriculture e.g. Rhizobium • sewage treatment Microbial biotechnology: some examples Medical • insulin • antibiotics • anti-venom • Botox • vaccines Food and beverages • bread • cheese • citric acid • alcohol • QuornTM • probiotics • marmite • yoghurt Enzyme production • washing powder enzymes • amylases – hydrolyse starch to other sugars • DNA polymerases Environmental applications • bioremediation • biosensors • agriculture e.g. Rhizobium • sewage treatment Not new Wine, cheese, bread produced with aid of microbes. How have things changed? Ability to manipulate cells to control what they produce and how they produce it. Now, many many more substances are produced by microbes (e.g. food, medicines, chemicals). In 2012… Europe USA Private Revenue companies 1799 $20 billion 1859 $64 billion Source: Biotechnology in Europe, 2014, EY and EuropaBio By the end of the lecture, you will be able to… • Describe the characteristics that are required of a microbial process for it to be industrially useful. • Explain the difference between primary and secondary metabolites. • Describe the key steps in the industrial production of: • Penicillin • Insulin Characteristics required for industrial use It is economically advantageous to do so (e.g. more economical than chemical processes). • Must produce large quantities of the required product (high yield) • Must grow rapidly in liquid culture • Must be suitable for growth in large batch or continuous fermentation systems • Must use nutrients which can be obtained readily and cheaply • Product must be easily separated from other compounds produced by the organism • Must be able to be scaled up • Must not be pathogenic • Beneficial if easily genetically engineered Primary metabolites and secondary metabolites Primary metabolites • Products produced up to end of exponential phase of growth. • Often associated with essential energy metabolism, e.g. lactic acid, ethanol. Production of product mimics cell growth Primary metabolites and secondary metabolites Secondary metabolites • Produced at end of exponential and during stationary phase of growth. • Characteristic of specific organisms. • Not essential for growth. • Production varies depending on environmental conditions. Production of product starts at or near beginning of stationary phase Antibiotic production Penicillin – famously discovered by Alexander Fleming. The Nobel Prize in Physiology or Medicine 1945 “for the discovery of penicillin and its curative effect in various infectious diseases” with Ernst Chain and Howard Florey. b-lactam antibiotics – prevent peptidoglycan cross-links forming. Antibiotic production Penicillin – famously discovered by Alexander Fleming. The Nobel Prize in Physiology or Medicine 1945 “for the discovery of penicillin and its curative effect in various infectious diseases” with Ernst Chain and Howard Florey. b-lactam antibiotics – prevent peptidoglycan cross-links forming. Penicillin production • Produced by Penicillium chrysogenum. • Originally (1 mg/L), now (~50 g/L). • Grown in a fed-batch culture. Photos from: http://www.abdn.ac.uk/ims/research/microbiology/profiles/l.a.glover http://www.flickr.com/photos/ajc1/2902232380/ Penicillin production First stage – focused on growth. Second stage – when the target biomass is achieved, “starve” the culture to induce stress. This triggers the production of the antibiotic. About 40 h before penicillin produced but production can last for a further 100+ hours. • • Aerobic, ~26 °C, Nutrients: • corn steep liquor (by-product of the production of corn starch - rich in nitrogen and growth factors), • whey (by-product of cheese production – lactose) • glucose and lactose are common sugars used Harvesting penicillin excreted into medium by cells. Figure by MIT OpenCourseWare Production of insulin • Insulin regulates uptake of glucose from the blood into cells. • Type I diabetes is caused by lack of insulin high blood sugar. • Originally purified from pancreas of slaughtered pigs and cows. • Not identical to human insulin so not as effective and could potentially cause allergic reaction. • Genetic engineering enabled human insulin to be produced by microorganisms. • Insulin made of an A and B chain linked by disulphide bonds • Proinsulin produced then C-peptide removed to produce insulin • Two options industrially (bacteria or yeast as host): • Both chains produced separately then joined • Proinsulin produced then cleaved Photo from: http://www.bbc.co.uk/news/health-16657425 Leonard Thompson – first human to receive an injection of insulin in 1922 Johnson (2003) Penicillin is a secondary metabolite produced by 1. Penicillium expansum 2. Penicillium chrysogenum 3. Penicillium notatum 86% 9% 1. 5% 2. 3. Which production method is used to make penicillin? 1. Batch culture 2. Continuous culture 3. Fed-batch culture 85% 11% 1. 5% 2. 3. Suggested further reading on industrial microbiology: • Staley et al. Microbial Life, 2nd ed. Relevant parts of Chapter 31. • Slonczewski and Foster, Microbiology: An evolving science. Relevant parts of Chapter 16. • Demain AL (2000) Microbial biotechnology. Trends in biotechnology 18:26-31. Suggested further reading on insulin production: • Johnson IS (2003) The trials and tribulations of producing the first genetically engineered drug. Nature reviews: Drug discovery 2:747-751. • https://www.youtube.com/watch?v=iMosKBs-v0E