* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download A Large-Size MEMS Scanning Mirror for Speckle Reduction

Raster scan wikipedia , lookup

Mechanical television wikipedia , lookup

Index of electronics articles wikipedia , lookup

Mathematics of radio engineering wikipedia , lookup

Magnetic core wikipedia , lookup

Oscilloscope history wikipedia , lookup

Interferometry wikipedia , lookup

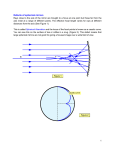

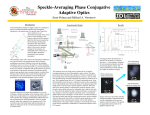

micromachines Article A Large-Size MEMS Scanning Mirror for Speckle Reduction Application † Fanya Li 1,2 , Peng Zhou 2 , Tingting Wang 1,2 , Jiahui He 1,2 , Huijun Yu 2 and Wenjiang Shen 2, * 1 2 * † The School of Materials Science and Engineering, Xi’an Jiaotong University, Xi’an 710049, China; [email protected] (F.L.); [email protected] (T.W.); [email protected] (J.H.) Key Lab of Nanodevices and Applications, Suzhou Institute of Nano-tech and Nano-bionics, Chinese Academy of Sciences, Suzhou 215123, China; [email protected] (P.Z.); [email protected] (H.Y.) Correspondence: [email protected]; Tel.: +86-512-6287-2688 This paper is an extended version of our paper published in the 12th IEEE International Conference on Nano/Micro Engineered and Molecular Systems, 9–12 April 2017, Los Angeles, CA, USA. Academic Editor: Huikai Xie Received: 30 March 2017; Accepted: 24 April 2017; Published: 3 May 2017 Abstract: Based on microelectronic mechanical system (MEMS) processing, a large-size 2-D scanning mirror (6.5 mm in diameter) driven by electromagnetic force was designed and implemented in this paper. We fabricated the micromirror with a silicon wafer and selectively electroplated Ni film on the back of the mirror. The nickel film was magnetized in the magnetic field produced by external current coils, and created the force to drive the mirror’s angular deflection. This electromagnetically actuated micromirror effectively eliminates the ohmic heat and power loss on the mirror plate, which always occurs in the other types of electromagnetic micromirrors with the coil on the mirror plate. The resonant frequency for the scanning mirror is 674 Hz along the slow axis, and 1870 Hz along the fast axis. Furthermore, the scanning angles could achieve ±4.5◦ for the slow axis with 13.2 mW power consumption, and ±7.6◦ for the fast axis with 43.3 mW power consumption. The application of the MEMS mirror to a laser display system effectively reduces the laser speckle. With 2-D scanning of the MEMS mirror, the speckle contrast can be reduced from 18.19% to 4.58%. We demonstrated that the image quality of a laser display system could be greatly improved by the MEMS mirror. Keywords: microelectronic mechanical system (MEMS); speckle reduction; electromagnetic force; optical scanning 1. Introduction Solid-state lasers can provide wider color gamut, longer lifetime, and higher brightness and contrast of images compared to light emitting diodes (LEDs), a popular light source for projection displays [1]. Laser display technology plays a significant role in our life, and can be applied in various fields such as movie theatres, home televisions and conference rooms. However, the existence of speckle degrades the images quality severely, which is an irregularly distributed pattern of light and dark particles caused by the interference of the reflective coherent laser beam from the rough screen comparable to optical wavelength [2–4]. One of the promising speckle reduction technologies in laser projection [5,6] is to employ MEMS scanning mirrors. At present, research on MEMS scanning mirrors are mostly focused on small diameter MEMS mirrors, while rarely on the larger size. Large-size mirrors can not only tolerate high optical power, but also ensure maximum utilization of light energy [7]. Microvision Company in the United States developed an electromagnetic two-dimensional scanning mirror, and successfully applied it to a laser Pico projection system, but the 1-mm diameter of the mirror was unable to meet the requirements of the high lumen imaging display [8]. Oliveira et al. were Micromachines 2017, 8, 140; doi:10.3390/mi8050140 www.mdpi.com/journal/micromachines Micromachines 2017, 8, 140 2 of 10 the pioneers who applied a MEMS scanning mirror to eliminate laser speckle. Limited to a 0.8-mm diameter, the MEMS mirror had issues when used in practical laser display systems [9]. Akram et al. Micromachines 2017, 8, 140 2 of 10 in Vestfold University in Norway further improved the MEMS two-dimensional scanning mirror and improved the quality of the display images,abut its diameter was only 2 mm, and cannot be [8]. Oliveira et al. were the laser pioneers who applied MEMS scanning mirror to eliminate laseralso speckle. usedLimited in hightopower laser displays [10]. The large size and mass of a MEMS two-dimensional a 0.8-mm diameter, the MEMS mirror had issues when used in practical laser displaymirror [9]. Akram et al. in Vestfold University inthe Norway further improved MEMSAttwolimitsystems the possibility of achieving a larger angle unless driving moment is highthe enough. the same scanning mirror andused improved the quality of the laser display but its diameter time,dimensional the oscillating micromirror to reduce the laser speckle shouldimages, also have a high operating was only 2 mm, and also cannot be used in high power laser displays [10]. The large size and mass frequency [11]. of a MEMS two-dimensional mirror limit the possibility of achieving a larger angle unless the driving Based on the above requirements, this paper proposes a 6.5-mm diameter, two-dimensional moment is high enough. At the same time, the oscillating micromirror used to reduce the laser speckle MEMS scanning mirror driven by the electromagnetic method. The efficient electromagnetic drive should also have a high operating frequency [11]. mode not onlyonoffered the requirements, driving moment of theproposes large angle required, but also realized the high Based the above this paper a 6.5-mm diameter, two-dimensional frequency. The mirror is used in a laser projection system to suppress laser speckle. Thisdrive scanning MEMS scanning mirror driven by the electromagnetic method. The efficient electromagnetic mirror with a large diameter could be used in high power laser illumination for high lumen projection. mode not only offered the driving moment of the large angle required, but also realized the high Moreover, the The highmirror frequency of in thea scanning mirrorsystem couldtoeffectively reduce the speckle contrast and frequency. is used laser projection suppress laser speckle. This scanning mirror with a large diameter could be used in high power laser illumination for high lumen projection. bring clearer and more comfortable images. Moreover, the high frequency of the scanning mirror could effectively reduce the speckle contrast and bring clearer and more comfortable images. 2. Design study employed the electromagnetic scanner in Figure 1 to demonstrate the proposed design 2.This Design concept. As indicated in Figure 1a, four external coils (A, B, C, and D) are symmetrically placed in This study employed the electromagnetic scanner in Figure 1 to demonstrate the proposed corresponding positions and kept a certain distance for the mirror’s free deflection. Specifically, the coils design concept. As indicated in Figure 1a, four external coils (A, B, C, and D) are symmetrically placed A and C are located beneath the ferromagnetic film on the outer frame, and coils B and D are placed in corresponding positions and kept a certain distance for the mirror’s free deflection. Specifically, beneath the rectangular on the back offilm theon mirror. Coils A and C coils are responsible for the coils A and C are ferromagnetic located beneathfilm the ferromagnetic the outer frame, and B and D the slow axis, while B and D coils areferromagnetic for the fast axis. A of and coils are driven byCthe are placed beneath the rectangular filmWhen on thethe back theCmirror. Coils A and aresquare ◦ phase difference, the two coils, the bottom magnetic wave signals with theslow sameaxis, frequency responsible for the while B and and 180 D coils are for the fast axis. When the A and C coils are driven theNi square signals the will samecompose frequencyaand 180°magnetic phase difference, two bar and thebysoft filmwave on the outerwith frame closed circuit, the then ancoils, attractive the bottom magnetic bar and the soft Ni film on the outer frame will compose a closed magnetic force will drive the mirror to deflect a certain angle around the slow axis. Similarly, coils B, D, the circuit, then anbar attractive drive thecompose mirror toanother deflect amagnetic certain angle around slow axis.signals bottom magnetic and theforce soft will Ni film will circuit whenthe excitation Similarly, coils B, D, the bottom magnetic bar and the soft Ni film will compose another magnetic are applied to B and D coils, so as to achieve the purpose of the two-dimensional scanning with our circuit when excitation signals are applied to B and D coils, so as to achieve the purpose of the twoproposed model. Figure 1b,c shows the backside of mirror and the external coils, respectively. The two dimensional scanning with our proposed model. Figure 1b,c shows the backside of mirror and the groups of coils the signals aretwo controlled separately, independence, scanning external coils,and respectively. The groups of coils and therefore, the signals good are controlled separately, linearity and accuracy can be achieved for the biaxial scanner.can Detailed dimensions of thescanner. scanner and therefore, good independence, scanning linearity and accuracy be achieved for the biaxial coilsDetailed in our design are summarized in Table 1. dimensions of the scanner and coils in our design are summarized in Table 1. Figure 1. (a) Illustration of the microelectronic mechanical system (MEMS) mirror and the actuation Figure (a) Illustration of the microelectronic system (MEMS) mirror and the actuation coils1.underneath; (b) Back profile of mirror withmechanical nickel; (c) External coils. coils underneath; (b) Back profile of mirror with nickel; (c) External coils. Micromachines 2017, 8, 140 3 of 10 Table 1. The dimensions of designed scanner and coils. Parameter Value Unites Diameter of the mirror Thickness of the mirror 6.5 200 mm µm Width of the axis Slow axis Fast axis 100 160 µm Length of the axis Slow axis Fast axis 1500 1750 µm 200 20 3 2 10 900 30 µm µm mm mm mm Ω Thickness of the axes Thickness of the nickel film Outer diameter of the coil Inner diameter of the coil Height of the coil Number of turns for the coil Resistence of the coil We introduced a magnetic circuit model to solve the theoretical value of force shown in Figure 2. Based on the hypothesis [12] that all the magnetic fluxes pass through the core (no leakage except for the air gap), and according to the Maxwell’s magnetic force formula, attractive force could be expressed by: B0 2 A0 F = (1) µ0 In the equation, B0 is defined as the magnetic flux density of the air gap, A0 is the cross-sectional area of the gap, and µ0 is the magnetic permeability of air. According to the Ampere’s Law, we could derive that: I N ·i = Hds = H m lm + H c lc + H 0 ·2x , (2) where N is the number of coil turns, and i is the current flowing through the coil. Hm , Hc , and H0 respectively represent the strength of the magnetic field for the magnetic core, the clapper (ferromagnetic film) and the gap. lm , lc , and x represent the length of the magnetic core, the clapper and the air gap. Because: B Φ H = = (3) µ µA the permeability of air can be negligible compared with the ferromagnetic materials’ permeability, that is to say: µ0 µm , µ0 µc By assuming: Ac = Am = A0 = A (4) Then, substituting (2)–(4) into the Equation (1), the magnetic force can be expressed as follows: F = k 2 i2 x2 (5) where k = µ0 N4 A . Obviously, the value of the driving force is proportional to the square of the current and inversely proportional to the square of the gap length. Micromachines 2017, 8, 140 Micromachines 2017, 8, 140 Micromachines 2017, 8, 140 and inversely proportional to the square of the gap length. and inversely proportional to the square of the gap length. 4 of 10 4 of 10 4 of 10 Figure 2. 2. AA magnetic circuit model consists ofof a magnetic core with copper winding and a clapper Figure magnetic circuit model consists a magnetic core with copper winding and a clapper Figure 2. A magnetic circuit model consists of a magnetic core with copper winding and a clapper made out of ferromagnetic materials. The magnetic field created by the copper coil is concentrated in in made out of ferromagnetic materials. The magnetic field created by the copper coil is concentrated made out ofcore ferromagnetic materials. The magnetic field created by the copper coilpath ispath concentrated in the magnetic and clapper due toto their high permeability. The magnetic circuit is is shown byby the magnetic core and clapper due their high permeability. The magnetic circuit shown the magnetic core and clapper due to their high permeability. The magnetic circuit path is shown by dashed lines. dashed lines. dashed lines. 3. 3. Fabrication Fabrication 3. Fabrication Figure 3 shows the detailed fabrication process. AsAs inin Figure 3a,3a, wewe used a double sided polished Figure 3 shows the detailed fabrication process. Figure used a double sided polished Figure 3 shows the detailed fabrication process. As in Figure 3a, we used a double sided n-type (100) 200-µm thick Si wafer as the starting substrate. A 20-nm Ti adhesion layerlayer and aand 100-nm Au n-type (100) 200-μm thick Si wafer as the starting substrate. A 20-nm Ti adhesion apolished 100-nm n-type (100)sputtered 200-μm thick Sibackside wafer asof the A 20-nm Tiseed adhesion and following a 100-nm coating were on the Sistarting substrate the seed layer for the following Au coating were sputtered on the backside of substrate. Siassubstrate as the layerlayer forelectroplating the Au coating sputtered on thick the backside Si substrate astothe seed patterned layer for the following step. A 20-µmwere thick film of photoresist (AZ4620) was patterned selectively electroplate nickel. electroplating step. A 20-μm film of of photoresist (AZ4620) was to selectively electroplating step. A 20-μm thick film of photoresist (AZ4620) was patterned to selectively After the soft-magnetic Ni electroplating step, the andstep, the Ti/Au thin films and werethe removed electroplate nickel. After the soft-magnetic Ni photoresist electroplating the photoresist Ti/Au by thin electroplate nickel. After the soft-magnetic Ni electroplating step, the photoresist and the Ti/Au thin acetone solution and IBE (ion beam etching) technology, respectively. Then, a second photolithography films were removed by acetone solution and IBE (ion beam etching) technology, respectively. Then, films were removed bythe acetone and IBE (ion etching) technology, respectively. Then, step was used to define window bulk etching, as shown in silicon Figure etching, 3d. Afterasthat, thein a second photolithography step solution wasfor used to silicon define thebeam window for bulk shown a second photolithography step was used to define the window for bulk silicon etching, as shown in structure of the mirror and axes of were by the deep reactive ion etching (DRIE) Figure 3d. After that,plate the structure thereleased mirror plate and axes were released by the deepprocess. reactive Figure 3d. After that, the silicon structure ofcoated the mirror plate axes were released thethe deep reactive Lastly, the front side of the was withof a 120-nm aluminum layer to by form reflective ion etching (DRIE) process. Lastly, the front side the and silicon was coated with a 120-nm aluminum ion etching (DRIE) process. Lastly, the front side of the silicon was coated with a 120-nm aluminum mirror layer surface. to form the reflective mirror surface. layer to form the reflective mirror surface. Figure 3. 3. Fabrication flow forfor thethe MEMS mirror. (a)(a) Ti/Au seed layer sputtering; (b)(b) thick photoresist Figure Fabrication flow MEMS mirror. Ti/Au seed layer sputtering; thick photoresist Figure 3.spinning Fabrication flow for the MEMS mirror. (a) Ti/Au seed layer sputtering; (b) thick (AZ4620) exposure; (c)(c)nickel electroplating and photoresist removal; (d)photoresist (AZ4620) spinningand and exposure; nickel electroplating and photoresist removal; (d)second second (AZ4620) spinning and exposure; (c) nickel and photoresist removal; (d) second photolithography and Ti/Au films removal; (e)(e) Sielectroplating etching (DRIE); (f)(f) Al layer coating. photolithography and Ti/Au films removal; Si etching (DRIE); Al layer coating. photolithography and Ti/Au films removal; (e) Si etching (DRIE); (f) Al layer coating. Micromachines 2017, 8, 140 Micromachines 2017, 8, 140 Micromachines 2017, 8, 140 5 of 10 5 of 10 5 of 10 4. 4. Characterization Characterization and and Results Results 4. Characterization and Results Figure Figure 44 shows shows the the package package method method and and fully fully assembled assembled prototype. prototype. The The whole whole package package is is Figure shows the packageThe method and fully assembled The package similar the4sandwich sandwich structure: The uppermost cover isprototype. to protect the whole mirror from theis similar to the structure: uppermost glassglass cover is to protect the mirror from the external similar to the sandwich Thetop uppermost glassthe cover isthe to is protect the mirror from theincident external external environment; 1.2-mm thick plastic topabove spacer above mirror isto chosen a large environment; a 1.2-mma structure: thick plastic spacer mirror chosen ensureto aensure large environment; athe 1.2-mm thick plastic top Ni spacer above the mirror is chosen to ensure ais large incident incident angle; distance between theand film and thecoils bottom coils0.45 is about 0.45 mm, which is the angle; the distance between the Ni film the bottom is about mm, which the thickness angle; theofdistance between theThe Ni film andbottom the bottom coilsspacer is about 0.45 mm, which is theallowable thickness thickness thespacer. bottomThe spacer. thickness of thespacer bottomdefines defines the maximum of the bottom thickness of the the maximum allowable rotation of the coils bottom spacer. The thickness ofplaced the coil bottom spacer defines the maximum allowable rotation angle; arecoils symmetrically placed in the the driving are applied rotation angle; are symmetrically in holder, the coiland holder, and the currents driving currents are through applied angle; coils are symmetrically placed in theboard coil holder, and the driving currents are applied through electrical connections to the printed (PCB) pads. The whole device is only through electrical connections to the circuit printed circuit board (PCB) pads. The wholesize device size16ismm only× electrical connections to the printed circuit board (PCB) pads. The whole device size is only 16 mm × 16mm mm× × 12 16 16 mm. mm × 12 mm. 16 mm × 12 mm. Figure 4. 4. (a) (a) Package Package method; method; (b) (b) Fully Fully assembled assembled prototype. prototype. Figure Figure 4. (a) Package method; (b) Fully assembled prototype. After packaging, the device was tested with the setup shown in Figure 5. In the measurement, After the was tested with the in 5. In Afterpackaging, packaging, thedevice device tested thesetup setupshown shown inFigure Figure Inthe themeasurement, measurement, two Ampere meters were used towas record the with relation between the current and5.the mirror’s scanning two Ampere meters were used to record the relation between the current and the mirror’s scanning two Ampere meters were used was to record the relation the current the mirror’s scanning property. A function generator employed to sendbetween square waves with aand certain frequency to the property. AAfunction generator was employed to send square waves with aacertain frequency to property. function generator was employed to send square waves with certain frequency tothe the coils as the excited signal, and to the oscilloscope for monitoring phase difference between input coils as the excited signal, and to the oscilloscope for monitoring phase difference between input coils as the excited signal, and to the oscilloscope for monitoring phase difference between input channels. The 2-D scanning mirror’s vertical and horizontal axes were driven independently by channels. The 2-D scanning mirror’s vertical and and horizontal axes were independently by signals channels. The scanning mirror’s vertical horizontal axes driven were driven independently by signals from the2-D function generator. from thefrom function generator. signals the function generator. Function generator Function generator CH2 CH1 CH2 CH1 Oscilloscope Oscilloscope CH1CH2 CH1CH2 Ampere meter Ampere meter Ampere meter Ampere meter Figure 5.5. Schematic measurement setup: the 2-D scanning mirror was was driven driven independently independently by by Figure Figure 5. Schematic measurement setup: the 2-D scanning mirror was driven independently by function generators. generators. function function generators. The results are plotted in Figure 6. The deflection angle can be calculated from the length of the The results in Figure 6. The deflection can be calculated fromthe themicro-mirror length of the scanning line andare theplotted distance between the screen and angle the scanning mirror. When scanning line and the distance between the screen and the scanning mirror. When the micro-mirror Micromachines 2017, 8, 140 Micromachines Micromachines2017, 2017,8,8,140 140 6 of 10 66of of10 10 worked the vibration state, torsion angles increased with the AC (alternating Theat results are plotted in Figure 6. mechanical The deflection angle can be calculated from of the worked at the resonant resonant vibration state, mechanical torsion angles increased with thethe AClength (alternating current) driving currents (refer to root-mean-square values of the current flowing in the coils) scanning line and the distance between the screen and the scanning mirror. When the micro-mirror current) driving currents (refer to root-mean-square values of the current flowing in the coils) for for both axis fast scanning angle ±4.5° at the applied current worked the resonant state, mechanical torsion angles increased with (alternating both the theatslow slow axis and and vibration fast axis. axis. The The slow slow scanning angle could could achieve achieve ±4.5° atthe theAC applied current of and consumption of the scanning could reach ±7.6° the current) driving currents (refer to root-mean-square values of the currentangle flowing in the coils) forat both of 21 21 mA mA and power power consumption of 13.2 13.2 mw, mw, and and the fast fast scanning angle could reach ±7.6° at the ◦We applied current 38 mA and maximum power consumption of 43.3 mw. used a 0.45-mm thick the slow axis and fast axis. The slow scanning angle could achieve ± 4.5 at the applied current of applied current 38 mA and maximum power consumption of 43.3 mw. We used a 0.45-mm thick ◦ bottom spacer here, so the maximum allowable rotation angle for the slow axis and fast axis were 21 mA and power consumption of 13.2allowable mW, androtation the fastangle scanning angle could ±7.6 the bottom spacer here, so the maximum for the slow axisreach and fast axisatwere ±4.5° and ±8° theoretically, matching well with the experimental data. By tuning the driving applied current 38 mA and maximum power consumption of 43.3 mW. We used a 0.45-mm thick ±4.5° and ±8° theoretically, matching well with the experimental data. By tuning the driving ◦ frequency, the frequency response of recorded. shows the bottom spacer so the maximum rotationangle angle could for thebe slow axis andFigure fast axis77were ±4.5 frequency, thehere, frequency response allowable of the the scanning scanning angle could be recorded. Figure shows the ◦ frequency responses of the slow and fast axes when 20 mA was applied to a coil. According to the results, and ±8 theoretically, matching the experimental data. By tuning the According driving frequency, the frequency responses of the slowwell and with fast axes when 20 mA was applied to a coil. to the results, the resonant frequencies were 674 Hz and 1870 Hz for the slow and fast axes, respectively. The quality frequency response of the scanning angle could be recorded. Figure 7 shows the frequency responses the resonant frequencies were 674 Hz and 1870 Hz for the slow and fast axes, respectively. The quality factor Q calculated the equation [13]: of the slow and fast axesby when 20 mA was applied to a coil. According to the results, the resonant factor Q was was calculated by the following following equation [13]: frequencies were 674 Hz and 1870 Hz for the slow andf fast axes, respectively. The quality factor Q was f0 (6) Q calculated by the following equation [13]: (6) Q == 0 Δf Δf f0 where is bandwidth. = half-power (6) where is isthe theresonant resonantfrequency, frequency,and and ∆∆ Q isthe the half-power bandwidth.From Fromthe themeasured measuredcurve, curve, ∆ f we can derive the Q value; 122 for the slow axis and 623 for the fast axis. The large difference of we can derive the Q value; 122 for the slow axis and 623 for the fast axis. The large difference of Q Q where f is the resonant frequency, and ∆ f is the half-power bandwidth. From the measured curve, we 0 values values between between the the slow slow and and fast fast axes axes was was due due to to the the dependence dependence of of damping damping on on the the resonant resonant can derive the Q value; 122 for the slow axis and 623 for the fast axis. The large difference of Q values 0.5 frequency. frequency. The The Q Q value value increases increases with with the the resonant resonant mode modeand andis is proportional proportional to toff0.5 according accordingto to Chu Chu between the slow and fast axes was due to the dependence of damping on the resonant frequency. et [14]. As shown Figure 1, scanning of the by C coils, and the et al. al. Asincreases shown in in Figure 1, the the slow slow scanning the mirror mirror is istodriven driven by A A and and coils, the The Q[14]. value with the resonant mode and isofproportional f0.5 according toCChu et and al. [14]. outer frame is scanning together with the mirror plate. So, the air damping is severer and the Q value As shown in is Figure 1, thetogether slow scanning the mirror driven bydamping A and C coils, and the outer frame scanning with theofmirror plate.isSo, the air is severer andouter the Qframe value is smaller the axis is together with thescanning. mirror plate. So, the air damping is severer and the Q value is smaller for isscanning smaller for for the slow slow axis scanning. the slow axis scanning. slow slowaxis axis Mechanicalangle(deg) angle(deg) Mechanical Mechanicalangle(deg) angle(deg) Mechanical 5 5 4 4 3 3 2 2 1 1 0 0 4 4 6 6 8 8 10 12 14 16 18 20 22 10 12 14 16 18 20 22 Current(mA) Current(mA) 8 8 7 7 6 6 5 5 4 4 3 3 2 2 1 1 0 0 0 0 fast fastaxis axis 5 5 10 10 (a) (a) 15 15 20 20 25 25 30 30 Current(mA) Current(mA) 35 35 40 40 (b) (b) Resonant frequency = 674Hz 4 Resonant frequency = 674Hz 4 Q = 122 Q = 122 slow slowaxis axis 3 3 2 2 1 1 0 0 400 400 500 500 600 600 700 700 Frequency(Hz) Frequency(Hz) (a) (a) 800 800 900 900 Mechanicalangle(deg) angle(deg) Mechanical Mechanicalangle(deg) angle(deg) Mechanical Figure 6. Current-angle relationship: (a) slow axis; (b) fast axis. Figure6. 6.Current-angle Current-anglerelationship: relationship:(a) (a)slow slowaxis; axis;(b) (b)fast fastaxis. axis. Figure 3.5 3.5 Resonant frequency = 1870Hz Resonant frequency = 1870Hz Q = 623 3.0 Q = 623 3.0 fast fastaxis axis 2.5 2.5 2.0 2.0 1.5 1.5 1.0 1.0 0.5 0.5 0.0 0.0 1700 1700 1750 1750 1800 1800 1850 1850 1900 1900 Frequency(Hz) Frequency(Hz) (b) (b) Figure 7. Frequency response: (a) slow axis; (b) fast axis. Figure Figure7. 7.Frequency Frequencyresponse: response:(a) (a)slow slowaxis; axis;(b) (b)fast fastaxis. axis. 1950 1950 2000 2000 Micromachines 2017, 8, 140 7 of 10 Reliability is crucial to the successful application of MEMS devices when they reach commercialization [15,16]. To study the shock resistance of our fabricated devices, a shock test was performed in air at room temperature as follows [17]. A scanner prototype was fixed to a shock table by 3 M Epoxy Adhesive. Acceleration corresponded to the height of the table from which it was dropped. A piezoelectric transducer (PZT) sensor was mounted to the shock table to record actual acceleration. In the test, we changed the fixed direction so that the shock was applied in three (X, Y, Z) orientations, where the X and Y directions were along the fast axis and the slow axis respectively, and the Z direction was perpendicular to the mirror plane. The table was dropped to the floor three times in a row with three orthorhombic orientations, and half sine shock pulses with certain widths were produced. No significant fracture or electrical failures were observed until the prototype was tested at 900 g for X direction and 1500 g for Y, Z directions, where g is the gravity acceleration (g ≈ 9.8 m/s2 ), demonstrating that the micro-mirror and applied package structure have good shock resistance. In addition, a vibration test was carried out on Electro Dynamic Shakers with varying frequencies (from 20 Hz to 2000 Hz) at a constant acceleration of 20 g [17]. After three periods of shaking, the device could still operate as before. These results show that the device is reliable and durable for practical applications. 5. Application to Speckle Reduction In the application to laser projectors, the speckle phenomenon emerges by reflecting highly coherent laser beams with single wavelengths on random rough surfaces, resulting in a random spatial intensity distribution [18]. One of the criterion to describe speckle is speckle contrast ratio, which is defined as [19]: q C = h I 2 i−h I i2 hIi × 100% (7) q where h I 2 i and h I i represent the square mean value and the mean light intensity, h I 2 i − h I i2 denotes the standard deviation. The lower the C value, the clearer images could be derived, which is now of great concern. As presented in Figure 8, the simplified speckle reduction system consists of a laser diode, a fabricated scanning mirror, a light pipe, optics elements such as a focusing lens and a diffuser with high transmittance, and a charge-coupled device (CCD) camera for acquiring pattern information. With the two-dimensional scanning of the mirror, the laser beam was reflected onto the diffuser placed at the entrance of the light pipe with angle diversity at different times. After multiple reflections inside the light pipe, the uniform illumination will be formed at the exit surface, which, with the existence of subsequent imaging optics, form the picture on the screen. The scanning area can be changed with different driving currents, however, we need to control the total reflected light entering into the light pipe. According to speckle suppression theory [20,21], once the speckle images at different times and different positions are uncorrelated, then these irrelevant speckle figures are finally superimposed on each other during a frame image formed on the screen. If N independent speckle patterns are overlapped on an intensity basis, and we assume that each pattern has an equal mean intensity, the speckle contrast C in the integrated image is reduced to [4]: 1 C= √ N (8) where N is the number of independent speckle patterns. We could derive that the higher the value of N, the lower the value of speckle contrast results. In our measurement, the focus length and aperture f-number of the CCD imaging lens are 25 mm and 8, respectively. The CCD has a pixel size of 3.75 µm × 3.75 µm and is located at 2 m away from the screen. We explored the mirror’s stationary and vibrating conditions and their influence on the speckle contrast ratio. The calculated data by Matlab based on Equation (7) is presented in Table 2. When the Micromachines 2017, 8, 140 Micromachines 2017, Micromachines 2017, 8, 8, 140 140 8 of 10 of 10 10 88 of 2. When the mirror was working, the contrast was 4.58% during 50 ms integration time of the CCD 2. When the mirror was working, the contrast was 4.58% during 50 ms integration time of the CCD camera, whenthe thecontrast mirror was off, the 50 contrast was 18.19% atof the same time. mirror was and working, wasturned 4.58% during ms integration time the CCDintegration camera, and camera, and when the mirror was turned off, the contrast was 18.19% at the same integration time. Figure 9 shows speckle images and without workingtime. mirror. With the 2-D when the mirror wasthe turned off, contrast the contrast was with 18.19% at the same the integration Figure 9 shows Figure 9 shows theMEMS speckle contrast images contrast with andforwithout the working display mirror.could With be thereduced 2-D of the mirror, the laser projection thescanning speckle contrast images withthe andspeckle without the working mirror. With the 2-D scanning of the scanning of the MEMS mirror, the speckle contrast for the laser projection display could be reduced frommirror, 18.19%the to 4.58%. This resultfor demonstrated that the scanning of thebe mirror can from disturb the spatial MEMS speckle contrast the laser projection display could reduced 18.19% to from 18.19% to 4.58%. This result demonstrated that the scanning of the mirror can disturb the spatial and This temporal of the source and suppress forand lasertemporal projection 4.58%. resultcoherences demonstrated thatlaser the scanning of the mirror the canspeckle disturb pattern the spatial and temporal coherences of the laser source and suppress the speckle pattern for laser projection images. of the laser source and suppress the speckle pattern for laser projection images. coherences images. MEMS mirror MEMS mirror t1 Diffuser Light pipe Diffuser Light pipe Lens Lens t1 t2 t2 t3 t3 Laser beam Laser beam Computer Computer CCD CCD Screen Screen LD LD Figure 8. Speckle reduction system. Figure 8. Speckle reduction system. Figure 8. Speckle reduction system. Table 2. The speckle contrast by different measurement systems. Table 2. The speckle contrast by different measurement systems. Table 2. The speckle contrast by different measurement systems. Measurement Integration IntegrationMaxmium MaxmiumMinimum Minimum MeanMean Contrast Contrast Measurement Measurement Integration Maxmium Minimum Mean Contrast System Time/ms Intensity Intensity Intensity Value/% System Time/ms Intensity Intensity Intensity Value/% System Time/ms Intensity Intensity Intensity Value/% With mirror 50 157 108 126 4.58 With mirror 50 157 108 126 4.58 With mirror 50 157 108 126 4.58 Without mirror 50 255 94 179 18.19 Without mirror 50 255 94 179 18.19 Without mirror 50 255 94 179 18.19 Figure 9. Speckle contrast images when CCD integration time to ms: 50 ms: (a) Speckle pattern Figure 9. Speckle contrast images when CCD integration time waswas set set to 50 (a) Speckle pattern Figure 9. Speckle contrast images when CCD integration time was set to 50 ms: (a) Speckle pattern with inactive scanning mirror, C = 18.19%; (b) Speckle reduction pattern with active mirror, C = 4.58%. with inactive scanning mirror, C = 18.19%; (b) Speckle reduction pattern with active mirror, C = 4.58%. with inactive scanning mirror, C = 18.19%; (b) Speckle reduction pattern with active mirror, C = 4.58%. 6. Conclusions 6. Conclusions 6. Conclusions WeWe have proposed and fabricated a alarge-size mirror can canmeet meetthe have proposed and fabricated large-sizeMEMS MEMSscanning scanningmirror. mirror. Our mirror We have proposed and fabricated a large-size MEMS scanningangle mirror. Our mirror canreduction meet the therequirements requirements of high resonant frequency and large deflection used for speckle of high frequency and large deflection angle used for speckle reduction requirements of successfully high resonant frequency and large contrast deflection angle used for speckle reduction application, and reduces thethe laser speckle from 18.19% to 4.58%. In addition, thethe application, and successfully reduces laser speckle contrast from 18.19% to 4.58%. In addition, application, and successfully reduces the laser speckle contrast from 18.19% to 4.58%. In addition, the fabricated devices have a shock resistance of more than 900900 g and good vibration resistance, which is is fabricated devices have a shock resistance of more than g and good vibration resistance, which fabricated devices havein a shock resistance of more than 900 g and good vibration resistance, which is alsoalso crucial when used commercial applications. crucial when used in commercial applications. also crucial when used in commercial applications. Micromachines 2017, 8, 140 9 of 10 Acknowledgments: This research was supported by the National Key Research and Development Program of China (Grant No. 2016YFB0402003). The authors are grateful to SINANO’s Nano Fabrication Facility (NFF) for their support in the fabrication process of micromirrors and related reliability tests. Author Contributions: W.S. offered conceptual advices for finishing this article; J.H. and H.Y. gave technical support and offered assistance in the whole experiment process; F.L. mainly collected data about the performance for the mirror and wrote the manuscript; P.Z. and T.W. were responsible for the data of speckle reduction. All authors discussed the results and commented on the manuscript at all stages. Conflicts of Interest: The authors declare no conflict of interest. References 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. Tong, Z.; Shen, W.; Song, S.; Cheng, W.; Cai, Z.; Ma, Y.; Wei, L.; Ma, W.; Xiao, L.; Jia, S.; et al. Combination of micro-scanning mirrors and multi-mode fibers for speckle reduction in high lumen laser projector applications. Opt. Express 2017, 25, 3795–3804. [CrossRef] [PubMed] Subramaniam, S.; Le, C.P.; Kaur, S.; Kalicinski, S.; Ekwinska, M.; Halvorsen, E.; Akram, M.N. Design, modeling, and characterization of a microelectromechanical diffuser device for laser speckle reduction. J. Microelectromech. Syst. 2014, 23, 117–127. Young, E.J.; Kasdin, N.J.; Carlotti, A. Image Analysis with Speckles Altered by a Deformable Mirror. Available online: http://proceedings.spiedigitallibrary.org/proceeding.aspx?articleid=1744172 (accessed on 25 April 2017). Tong, Z.; Chen, X.; Akram, M.N.; Aksnes, A. Compound speckle characterization method and reduction by optical design. J. Disp. Technol. 2012, 8, 132–137. [CrossRef] Heger, A.; Schreiber, P.; Höfer, B. Development and Characterisation of a Miniaturized Laser Projection Display Based on MEMS-Scanning-Mirrors. Available online: http://proceedings.spiedigitallibrary.org/ proceeding.aspx?articleid=1345482 (accessed on 25 April 2017). Kim, S.; Han, Y.G. Suppression of speckle patterns based on temporal angular decorrelation induced by multiple beamlets with diverse optical paths. J. Korean Phys. Soc. 2014, 64, 527–531. [CrossRef] Chen, X.; Svensen, Ø.; Akram, M.N. Speckle reduction in laser projection using a dynamic deformable mirror. Opt. Express 2014, 22, 11152–11166. Sprague, R.B.; Montague, T.; Brown, D. Bi-Axial Magnetic Drive for Scanned Beam Display Mirrors. Available online: http://proceedings.spiedigitallibrary.org/proceeding.aspx?articleid=859733 (accessed on 25 April 2017). Oliveira, L.C.M.; Barbaroto, P.R.; Ferreira, L.O.S.; Doi, I. A novel Si micromachined moving-coil induction actuated mm-sized resonant scanner. J. Micromech. Microeng. 2005, 16, 165. [CrossRef] Akram, M.N.; Tong, Z.; Ouyang, G.; Chen, X.; Kartashov, V. Laser speckle reduction due to spatial and angular diversity introduced by fast scanning micromirror. Appl. Opt. 2010, 49, 3297–3304. [CrossRef] [PubMed] Bayat, D. Large Hybrid High Precision MEMS Mirrors. Ph.D. Dissertation, École Polytechnique Fédérale de Lausanne, Lausanne, Switzerland, 2011. Bleuler, H.; Cole, M.; Keogh, P.; Larsonneur, R.; Larsonneur, R.; Maslen, E.; Okada, Y.; Traxler, A. Magnetic Bearings: Theory, Design, and Application to Rotating Machinery; Springer Science & Business Media: Berlin, Germany, 2009. Chen, M.; Yu, H.; Guo, S.; Xu, R.; Shen, W. An electromagnetically-driven MEMS micromirror for laser projection. In Proceedings of the 10th IEEE International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Xi’an, China, 7–11 April 2015; pp. 605–607. Chu, H.M.; Hane, K. Design, fabrication and vacuum operation characteristics of two-dimensional comb-drive micro-scanner. Sens. Actuators A Phys. 2011, 165, 422–430. [CrossRef] Tanner, D.M.; Walraven, J.A.; Helgesen, K.; Helgesen, K.; Irwin, L.W.; Brown, F.; Smith, N.F.; Masters, N. MEMS reliability in shock environments. In Proceedings of the 38th Annual 2000 IEEE International Reliability Physics Symposium, San Jose, CA, USA, 10–13 April 2000; pp. 129–138. Naumann, M.; Dietze, O.; McNeil, A.; Mehner, J.; Daniel, S. Reliability of anchors at surface micromachined devices in shock environments. In Proceedings of the 2013 Transducers & Eurosensors XXVII: The 17th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS & EUROSENSORS XXVII), Barcelona, Spain, 16–20 June 2013; pp. 570–573. Micromachines 2017, 8, 140 17. 18. 19. 20. 21. 10 of 10 GB4590-84, Mechanical and Climatic Test Methods for Semiconductor Integrated Circuits. Available online: http://down.bzwxw.com/12/GB%204590-1984.pdf (accessed on 25 April 2017). (In Chinese) Lee, J.Y.; Kim, T.H.; Yim, B.B.; Bu, J.U.; Kim, Y.J. Speckle reduction in laser picoprojector by combining optical phase matrix with twin green lasers and oscillating MEMS mirror for coherence suppression. Jpn. J. Appl. Phys. 2016, 55, 08RF03. [CrossRef] Pan, J.W.; Shih, C.H. Speckle reduction and maintaining contrast in a LASER pico-projector using a vibrating symmetric diffuser. Opt. Express 2014, 22, 6464–6477. [CrossRef] [PubMed] Pei, T.H.; Yeh, F.C.; Tsai, K.Y.; Li, J.H.; Liu, Z.R.; Hung, C.L. Simulation and experiment of speckle reduction by the beam splitting method on a pico-projection system. Adv. Mater. Res. 2014, 933, 572–577. [CrossRef] Goodman, J.W. Speckle Phenomena in Optics: Theory and Applications; Roberts and Company Publishers: Greenwood Village, CO, USA, 2007. © 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).