* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

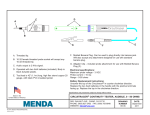

Download Model 428B Clip-On Milliammeter

Galvanometer wikipedia , lookup

Tektronix analog oscilloscopes wikipedia , lookup

Analog-to-digital converter wikipedia , lookup

Power MOSFET wikipedia , lookup

Superheterodyne receiver wikipedia , lookup

Integrating ADC wikipedia , lookup

Schmitt trigger wikipedia , lookup

Transistor–transistor logic wikipedia , lookup

Power electronics wikipedia , lookup

Phase-locked loop wikipedia , lookup

Index of electronics articles wikipedia , lookup

Oscilloscope wikipedia , lookup

Oscilloscope history wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Regenerative circuit wikipedia , lookup

Operational amplifier wikipedia , lookup

Two-port network wikipedia , lookup

Valve audio amplifier technical specification wikipedia , lookup

Negative-feedback amplifier wikipedia , lookup

Wien bridge oscillator wikipedia , lookup

Radio transmitter design wikipedia , lookup

Current mirror wikipedia , lookup

Valve RF amplifier wikipedia , lookup

Opto-isolator wikipedia , lookup