* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Instituto Nacional de Astrofísica, Optica y Electrónica.

Survey

Document related concepts

Diffraction wikipedia , lookup

Newton's laws of motion wikipedia , lookup

State of matter wikipedia , lookup

Newton's theorem of revolving orbits wikipedia , lookup

Old quantum theory wikipedia , lookup

History of fluid mechanics wikipedia , lookup

Thomas Young (scientist) wikipedia , lookup

Equations of motion wikipedia , lookup

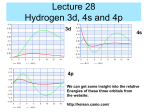

Hydrogen atom wikipedia , lookup

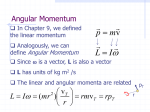

Angular momentum wikipedia , lookup

Matter wave wikipedia , lookup

Photon polarization wikipedia , lookup

Accretion disk wikipedia , lookup

Angular momentum operator wikipedia , lookup

Theoretical and experimental justification for the Schrödinger equation wikipedia , lookup

Transcript