* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download SPS-3S - RADProductsOnline, Buy RAD Products Online at Great

Switched-mode power supply wikipedia , lookup

Ground (electricity) wikipedia , lookup

Fault tolerance wikipedia , lookup

Mains electricity wikipedia , lookup

Power over Ethernet wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Distribution management system wikipedia , lookup

Phone connector (audio) wikipedia , lookup

Rectiverter wikipedia , lookup

Installation and Operation Manual

SPS-3S

Multiprotocol FRAD/PAD

Packet Switch

SPS-3S

Multiprotocol FRAD/PAD Packet Switch

Installation and Operation Manual

Notice

This manual contains information that is proprietary to RAD Data Communications Ltd. ("RAD").

No part of this publication may be reproduced in any form whatsoever without prior written approval

by RAD Data Communications.

Right, title and interest, all information, copyrights, patents, know-how, trade secrets and other

intellectual property or other proprietary rights relating to this manual and to the SPS-3S and any

software components contained therein are proprietary products of RAD protected under international

copyright law and shall be and remain solely with RAD.

SPS-3S is a registered trademark of RAD. No right, license, or interest to such trademark is granted

hereunder, and you agree that no such right, license, or interest shall be asserted by you with respect

to such trademark.

You shall not copy, reverse compile or reverse assemble all or any portion of the Manual or the

SPS-3S. You are prohibited from, and shall not, directly or indirectly, develop, market, distribute,

license, or sell any product that supports substantially similar functionality as the

SPS-3S, based on or derived in any way from the SPS-3S. Your undertaking in this paragraph shall

survive the termination of this Agreement.

This Agreement is effective upon your opening of the SPS-3S package and shall continue until

terminated. RAD may terminate this Agreement upon the breach by you of any term hereof. Upon

such termination by RAD, you agree to return to RAD the SPS-3S and all copies and portions thereof.

For further information contact RAD at the address below or contact your local distributor.

International Headquarters

RAD Data Communications Ltd.

North America Headquarters

RAD Data Communications Inc.

24 Raoul Wallenberg St.

Tel Aviv 69719 Israel

Tel: 972-3-6458181

Fax: 972-3-6498250

E-mail: [email protected]

900 Corporate Drive

Mahwah, NJ 07430 USA

Tel: (201) 529-1100, Toll free: 1-800-444-7234

Fax: (201) 529-5777

E-mail: [email protected]

© 1993–2006 RAD Data Communications Ltd.

Publication No. 159-200-10/06

Limited Warranty

RAD warrants to DISTRIBUTOR that the hardware in the SPS-3S to be delivered hereunder shall be

free of defects in material and workmanship under normal use and service for a period of twelve (12)

months following the date of shipment to DISTRIBUTOR.

If, during the warranty period, any component part of the equipment becomes defective by reason of

material or workmanship, and DISTRIBUTOR immediately notifies RAD of such defect, RAD shall have

the option to choose the appropriate corrective action: a) supply a replacement part, or b) request

return of equipment to its plant for repair, or c) perform necessary repair at the equipment's location.

In the event that RAD requests the return of equipment, each party shall pay one-way shipping costs.

RAD shall be released from all obligations under its warranty in the event that the equipment has been

subjected to misuse, neglect, accident or improper installation, or if repairs or modifications were

made by persons other than RAD's own authorized service personnel, unless such repairs by others

were made with the written consent of RAD.

The above warranty is in lieu of all other warranties, expressed or implied. There are no warranties

which extend beyond the face hereof, including, but not limited to, warranties of merchantability and

fitness for a particular purpose, and in no event shall RAD be liable for consequential damages.

RAD shall not be liable to any person for any special or indirect damages, including, but not limited to,

lost profits from any cause whatsoever arising from or in any way connected with the manufacture,

sale, handling, repair, maintenance or use of the SPS-3S, and in no event shall RAD's liability exceed

the purchase price of the SPS-3S.

DISTRIBUTOR shall be responsible to its customers for any and all warranties which it makes relating

to SPS-3S and for ensuring that replacements and other adjustments required in connection with the

said warranties are satisfactory.

Software components in the SPS-3S are provided "as is" and without warranty of any kind. RAD

disclaims all warranties including the implied warranties of merchantability and fitness for a particular

purpose. RAD shall not be liable for any loss of use, interruption of business or indirect, special,

incidental or consequential damages of any kind. In spite of the above RAD shall do its best to provide

error-free software products and shall offer free Software updates during the warranty period under

this Agreement.

RAD's cumulative liability to you or any other party for any loss or damages resulting from any claims,

demands, or actions arising out of or relating to this Agreement and the SPS-3S shall not exceed the sum

paid to RAD for the purchase of the SPS-3S. In no event shall RAD be liable for any indirect, incidental,

consequential, special, or exemplary damages or lost profits, even if RAD has been advised of the

possibility of such damages.

This Agreement shall be construed and governed in accordance with the laws of the State of Israel.

Product Disposal

To facilitate the reuse, recycling and other forms of recovery of waste

equipment in protecting the environment, the owner of this RAD product

is required to refrain from disposing of this product as unsorted municipal

waste at the end of its life cycle. Upon termination of the unit’s use,

customers should provide for its collection for reuse, recycling or other

form of environmentally conscientious disposal.

General Safety Instructions

The following instructions serve as a general guide for the safe installation and operation of

telecommunications products. Additional instructions, if applicable, are included inside the manual.

Safety Symbols

Warning

This symbol may appear on the equipment or in the text. It indicates

potential safety hazards regarding product operation or maintenance to

operator or service personnel.

Danger of electric shock! Avoid any contact with the marked surface while

the product is energized or connected to outdoor telecommunication lines.

.

Protective earth: the marked lug or terminal should be connected to the building

protective earth bus.

Warning

Some products may be equipped with a laser diode. In such cases, a label

with the laser class and other warnings as applicable will be attached near

the optical transmitter. The laser warning symbol may be also attached.

Please observe the following precautions:

• Before turning on the equipment, make sure that the fiber optic cable is

intact and is connected to the transmitter.

• Do not attempt to adjust the laser drive current.

• Do not use broken or unterminated fiber-optic cables/connectors or look

straight at the laser beam.

• The use of optical devices with the equipment will increase eye hazard.

• Use of controls, adjustments or performing procedures other than those

specified herein, may result in hazardous radiation exposure.

ATTENTION: The laser beam may be invisible!

In some cases, the users may insert their own SFP laser transceivers into the product. Users are alerted

that RAD cannot be held responsible for any damage that may result if non-compliant transceivers are

used. In particular, users are warned to use only agency approved products that comply with the local

laser safety regulations for Class 1 laser products.

Always observe standard safety precautions during installation, operation and maintenance of this

product. Only qualified and authorized service personnel should carry out adjustment, maintenance or

repairs to this product. No installation, adjustment, maintenance or repairs should be performed by

either the operator or the user.

Handling Energized Products

General Safety Practices

Do not touch or tamper with the power supply when the power cord is connected. Line voltages may be

present inside certain products even when the power switch (if installed) is in the OFF position or a fuse is

blown. For DC-powered products, although the voltages levels are usually not hazardous, energy hazards

may still exist.

Before working on equipment connected to power lines or telecommunication lines, remove jewelry or any

other metallic object that may come into contact with energized parts.

Unless otherwise specified, all products are intended to be grounded during normal use. Grounding is

provided by connecting the mains plug to a wall socket with a protective earth terminal. If an earth lug is

provided on the product, it should be connected to the protective earth at all times, by a wire with a

diameter of 18 AWG or wider. Rack-mounted equipment should be mounted only in earthed racks and

cabinets.

Always make the ground connection first and disconnect it last. Do not connect telecommunication cables

to ungrounded equipment. Make sure that all other cables are disconnected before disconnecting the

ground.

Connection of AC Mains

Make sure that the electrical installation complies with local codes.

Always connect the AC plug to a wall socket with a protective ground.

The maximum permissible current capability of the branch distribution circuit that supplies power to the

product is 16A. The circuit breaker in the building installation should have high breaking capacity and must

operate at short-circuit current exceeding 35A.

Always connect the power cord first to the equipment and then to the wall socket. If a power switch is

provided in the equipment, set it to the OFF position. If the power cord cannot be readily disconnected in

case of emergency, make sure that a readily accessible circuit breaker or emergency switch is installed in the

building installation.

In cases when the power distribution system is IT type, the switch must disconnect both poles

simultaneously.

Connection of DC Mains

Unless otherwise specified in the manual, the DC input to the equipment is floating in reference to the ground.

Any single pole can be externally grounded.

Due to the high current capability of DC mains systems, care should be taken when connecting the DC supply

to avoid short-circuits and fire hazards.

DC units should be installed in a restricted access area, i.e. an area where access is authorized only to

qualified service and maintenance personnel.

Make sure that the DC supply is electrically isolated from any AC source and that the installation complies

with the local codes.

The maximum permissible current capability of the branch distribution circuit that supplies power to the

product is 16A. The circuit breaker in the building installation should have high breaking capacity and must

operate at short-circuit current exceeding 35A.

Before connecting the DC supply wires, ensure that power is removed from the DC circuit. Locate the

circuit breaker of the panel board that services the equipment and switch it to the OFF position. When

connecting the DC supply wires, first connect the ground wire to the corresponding terminal, then the

positive pole and last the negative pole. Switch the circuit breaker back to the ON position.

A readily accessible disconnect device that is suitably rated and approved should be incorporated in the

building installation.

If the DC mains are floating, the switch must disconnect both poles simultaneously.

Connection of Data and Telecommunications Cables

Data and telecommunication interfaces are classified according to their safety status.

The following table lists the status of several standard interfaces. If the status of a given port differs from

the standard one, a notice will be given in the manual.

Ports

Safety Status

V.11, V.28, V.35, V.36, RS-530,

X.21, 10 BaseT, 100 BaseT,

Unbalanced E1, E2, E3, STM, DS-2,

DS-3, S-Interface ISDN, Analog voice

E&M

SELV

xDSL (without feeding voltage),

Balanced E1, T1, Sub E1/T1

TNV-1 Telecommunication Network Voltage-1:

FXS (Foreign Exchange Subscriber)

TNV-2 Telecommunication Network Voltage-2:

Safety Extra Low Voltage:

Ports which do not present a safety hazard. Usually

up to 30 VAC or 60 VDC.

Ports whose normal operating voltage is within the

limits of SELV, on which overvoltages from

telecommunications networks are possible.

Ports whose normal operating voltage exceeds the

limits of SELV (usually up to 120 VDC or telephone

ringing voltages), on which overvoltages from

telecommunication networks are not possible. These

ports are not permitted to be directly connected to

external telephone and data lines.

FXO (Foreign Exchange Office), xDSL

(with feeding voltage), U-Interface

ISDN

TNV-3 Telecommunication Network Voltage-3:

Ports whose normal operating voltage exceeds the

limits of SELV (usually up to 120 VDC or telephone

ringing voltages), on which overvoltages from

telecommunication networks are possible.

Always connect a given port to a port of the same safety status. If in doubt, seek the assistance of a

qualified safety engineer.

Always make sure that the equipment is grounded before connecting telecommunication cables. Do

not disconnect the ground connection before disconnecting all telecommunications cables.

Some SELV and non-SELV circuits use the same connectors. Use caution when connecting cables.

Extra caution should be exercised during thunderstorms.

When using shielded or coaxial cables, verify that there is a good ground connection at both ends. The

earthing and bonding of the ground connections should comply with the local codes.

The telecommunication wiring in the building may be damaged or present a fire hazard in case of

contact between exposed external wires and the AC power lines. In order to reduce the risk, there are

restrictions on the diameter of wires in the telecom cables, between the equipment and the mating

connectors.

Caution

Attention

To reduce the risk of fire, use only No. 26 AWG or larger telecommunication line cords.

Pour réduire les risques s’incendie, utiliser seulement des conducteurs de

télécommunications 26 AWG ou de section supérieure.

Some ports are suitable for connection to intra-building or non-exposed wiring or cabling only. In such

cases, a notice will be given in the installation instructions.

Do not attempt to tamper with any carrier-provided equipment or connection hardware.

Electromagnetic Compatibility (EMC)

The equipment is designed and approved to comply with the electromagnetic regulations of major

regulatory bodies. The following instructions may enhance the performance of the equipment and will

provide better protection against excessive emission and better immunity against disturbances.

A good earth connection is essential. When installing the equipment in a rack, make sure to remove all

traces of paint from the mounting points. Use suitable lock-washers and torque. If an external

grounding lug is provided, connect it to the earth bus using braided wire as short as possible.

The equipment is designed to comply with EMC requirements when connecting it with unshielded

twisted pair (UTP) cables. However, the use of shielded wires is always recommended, especially for

high-rate data. In some cases, when unshielded wires are used, ferrite cores should be installed on

certain cables. In such cases, special instructions are provided in the manual.

Disconnect all wires which are not in permanent use, such as cables used for one-time configuration.

The compliance of the equipment with the regulations for conducted emission on the data lines is

dependent on the cable quality. The emission is tested for UTP with 80 dB longitudinal conversion loss

(LCL).

Unless otherwise specified or described in the manual, TNV-1 and TNV-3 ports provide secondary

protection against surges on the data lines. Primary protectors should be provided in the building

installation.

The equipment is designed to provide adequate protection against electro-static discharge (ESD).

However, it is good working practice to use caution when connecting cables terminated with plastic

connectors (without a grounded metal hood, such as flat cables) to sensitive data lines. Before

connecting such cables, discharge yourself by touching earth ground or wear an ESD preventive wrist

strap.

FCC-15 User Information

This equipment has been tested and found to comply with the limits of the Class A digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the Installation and Operation manual, may cause harmful interference to the radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

Canadian Emission Requirements

This Class A digital apparatus meets all the requirements of the Canadian Interference-Causing

Equipment Regulation.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel

brouilleur du Canada.

Warning per EN 55022 (CISPR-22)

Warning

This is a class A product. In a domestic environment, this product may cause

radio interference, in which case the user will be required to take adequate

measures.

Avertissement

Cet appareil est un appareil de Classe A. Dans un environnement résidentiel, cet

appareil peut provoquer des brouillages radioélectriques. Dans ces cas, il peut

être demandé à l’utilisateur de prendre les mesures appropriées.

Achtung

Dieses ist ein Gerät der Funkstörgrenzwertklasse A. In Wohnbereichen können

bei Betrieb dieses Gerätes Rundfunkströrungen auftreten, in welchen Fällen der

Benutzer für entsprechende Gegenmaßnahmen verantwortlich ist.

Declaration of Conformity

Manufacturer's Name:

RAD Data Communications Ltd.

Manufacturer's Address:

24 Raoul Wallenberg St.

Tel Aviv 69719

Israel

Declares that the product:

Product Name:

SPS-3S

Conforms to the following standard(s) or other normative document(s):

EMC:

Safety:

EN 55022 (1994)

Limits and methods of measurement of radio disturbance

characteristics of information technology equipment.

EN 50082-1 (1992)

Electromagnetic compatibility – Generic immunity standards

for residential, commercial and light industry.

EN 60950 (1992/93)

Safety of information technology equipment, including

electrical business equipment.

Supplementary Information:

The product herewith complies with the requirements of the EMC Directive 89/336/EEC and the Low

Voltage Directive 73/23/EEC. The product was tested in a typical configuration.

Tel Aviv, 7 November 1996

Haim Karshen

VP Quality

European Contact: RAD Data Communications GmbH, Otto-Hahn-Str. 28-30,

85521 Ottobrunn-Riemerling, Germany

Contents

Chapter 1. Introduction

1.1 Overview..................................................................................................................... 1-1

1.2 Technical Specifications............................................................................................... 1-2

Chapter 2. Installation

2.1 Introduction................................................................................................................. 2-1

2.2 Unpacking ................................................................................................................... 2-1

2.3 Site Requirements........................................................................................................ 2-2

Power................................................................................................................................... 2-2

Data Channel Connections ................................................................................................... 2-2

Main Links Connections........................................................................................................2-2

Front and Rear Panel Clearance ............................................................................................ 2-2

Ambient Requirements ......................................................................................................... 2-2

2.4 Hardware Configuration .............................................................................................. 2-3

General Information ............................................................................................................. 2-3

Internal Jumpers ................................................................................................................... 2-4

Interface Board ..................................................................................................................... 2-5

Jumper Setting Procedure .....................................................................................................2-6

2.5 Installation in 19" Racks ............................................................................................... 2-7

Installation of the Unit .......................................................................................................... 2-7

2.6 Cable Connections ...................................................................................................... 2-8

General ................................................................................................................................ 2-8

Asynchronous Data Channel Connections ............................................................................. 2-8

Synchronous Links Connection ............................................................................................. 2-8

Power Connection ................................................................................................................ 2-8

Chapter 3. Operation

3.1 General ....................................................................................................................... 3-1

3.2 Controls, Indicators and Connectors ............................................................................ 3-1

Front Panel ........................................................................................................................... 3-1

Rear Panel ............................................................................................................................ 3-3

3.3 Operating Instructions ................................................................................................. 3-3

General ................................................................................................................................ 3-3

Power-On ............................................................................................................................ 3-3

Normal Operation ................................................................................................................ 3-4

Power-Off ............................................................................................................................ 3-4

3.4 What to do in Case of Malfunction .............................................................................. 3-4

Preliminary Checks ............................................................................................................... 3-4

Troubleshooting.................................................................................................................... 3-4

Appendix A. Connector Pinouts

SPS-3S

i

Table of Contents

ii

Installation and Operation Manual

SPS-3S

Chapter 1

Introduction

1.1

Overview

SPS-3S is a FRAD/PAD packet switch that enables multiprotocol connection

between the enterprise headquarters and remote branches, and it also provides

packet switching capability for both X.25 and Frame Relay.

SPS-3S has three ports which support aggregate data rates up to 2 Mbps. Each port

can be configured to any of the following protocols: X.25, Frame Relay, HDLC,

STM, ASYNC (soft-selectable for each port), SNA/SDLC (for X version only) or

IP/SLIP (for X version only). Switching between ports is provided for X.25, Frame

Relay, SDLC and encapsulated protocols.

The ports can be V.24, V.35, X.21, V.36, DDS or RS-530. Link 1 can be ISDN-S or

IR-ETH. Interfaces for the ports can be DCE or DTE layer 1 (user configurable). An

optional DDS interface can be provided only on port 1 and is always DTE layer 1.

The SPS-3S supports a wide range of applications. For information on the SPS-3S

features and applications, refer to the RAD Packet Switching Applications Guide.

Figure 1-1. SPS-3S Unit

SPS-3S

Overview

1-1

Chapter 1 Introduction

1.2

Interfaces

Protocols

Control Port

1-2

Installation and Operation Manual

Technical Specifications

Number of ports

3 multiprotocol and 1 async port

Data Rate

Each link aggregates up to 2 Mbps

Interface

V.24, V.35, X.21, RS-530 (selected during

ordering) DDS for port 1 only

Connectors: Link 1 (DTE)

V.24

X.21

V.35

V.36

RS-530

IR-ETH

ISDN

DDS

25-pin D-type, female

25-pin D-type, female

25-pin D-type, female

25-pin D-type, female

25-pin D-type, female

10BaseT, UTP cable, RJ-45

S-interface, UTP cable, RJ-45

RJ-45, female (X version only)

Connectors: Link 2 and 3

(DTE or DCE)

V.24

X.21

V.35

V.36

RS-530

25-pin D-type, female

25-pin D-type, female

25-pin D-type, female

25-pin D-type, female

25-pin D-type, female

Compatibility

X.25, Frame Relay, HDLC, STM, ASYNC (softselectable for each port), SNA/SDLC (for X

version only), IP/SLIP (for X version only).

X.25

Complies with 1988 UTI X.25, LAP-B.

STM

Compatible with STM-4, STM-8, STM-16 and

STM-24 statistical multiplexers.

Frame Relay

Supports CLLM, LMI and ANSI PVC

management protocols; complies with ANSI

T1.606, T1.617 Annex D, T1.618, and UTI

Rec. Q.922 Annex A.

IP (X version only)

Supports IP encapsulation over X.25 network

(complies with RFC 1356) or Frame Relay

network (complies with RFC 1490). Supports

dial-up link for X.25 with X.32 protocols

Packet Size

Up to 4096 bytes for X.25

Up to 8192 bytes for other protocols

Data Rate

75 bps to 38.4 kbps

Flow Control

XON/XOFF

CTS/RTF

Command Mode

X.28, extended

Terminal Handling

Enhanced asynchronous terminal, handling

beyond X.3 requirements.

Technical Specifications

SPS-3S

Installation and Operation Manual

Chapter 1 Introduction

Interface

Compatible with AT&T PUB 62310: Standard

Digital Data Services, Channel Interface

Specifications

Connector

RJ-45 (8 pins)

Data Rates

4.8, 9.6, 19.2 and 56 kbps

Timing

Recovered from line signal

Locked to receive signal, internal oscillator

Attenuation

Up to 43 dB

Range

(AWG 24, 0.6 mm)

9.6 kbps: 6.5 miles (10.5 km)

19.2 kbps: 5 miles (8 km)

56 kbps: 4 miles (6.5 km)

Transmit BPV sequence

Zero suppression

Received BPV sequence

Out of service (OOS)

Out of frame (OOF)

DSU Loopback

General

Indicators

Power

Sync Channel 1

Sync Channel 2

Sync Channel 3

ACTIV Channel 1

ACTIV Channel 2

ACTIV Channel 3

Error

Overflow

Test

ACT

Power

Power

100 to 230 VAC (±10%)

47 to 63 Hz

Power Consumption

20W max

Height

42 mm (1.7 in)

Width

215 mm (8.5 in)

Depth

240 mm (9.4 in)

Weight

1.2 kg (2.6 lb)

Temperature

0°–45°C (32°–113°F)

Humidity

Up to 90%, non-condensing

DDS Links

(X version only)

Physical

Environment

SPS-3S

Technical Specifications

1-3

Chapter 1 Introduction

1-4

Technical Specifications

Installation and Operation Manual

SPS-3S

Chapter 2

Installation

2.1

Introduction

This chapter provides mechanical and electrical installation procedures and basic

operating procedures for SPS-3S.

SPS-3S is delivered completely assembled. It is designed for installation as a

desktop unit or mounted in a 19" rack.

After installing the unit, refer to the RAD Packet Switching Guide for system

configuration information and procedures.

In case a problem is encountered, refer to the RAD Packet Switching Guide for test

and diagnostics instructions.

2.2

Unpacking

A preliminary inspection of the equipment container should be made before

unpacking. Evidence of damage should be noted and reported immediately.

To unpack the equipment:

1. Place the container on a clean flat surface.

2. Cut all straps.

3. Open or remove top.

4. Take out the unit carefully and place it securely on a clean surface.

5. Inspect the product for damage. Report immediately any damage found.

SPS-3S

Unpacking

2-1

Chapter 2 Installation

Installation and Operation Manual

2.3

Site Requirements

Power

The SPS-3S unit should be installed within 1.5m (5 feet) of an easily accessible

grounded AC outlet capable of furnishing 115 or 230VAC, in accordance with the

nominal supply voltage of the unit.

Data Channel Connections

SPS-3S has an RJ-45 connector for the asynchronous data channel. Refer to the

RAD Packet Switching Guide for pin allocations.

Main Links Connections

SPS-3S has three main link connectors. The main links connector depends on the

ordered interface:

•

V24:

25-pin D-type, female connector

•

X.21:

25-pin D-type, female connector (via adapter cable)

•

V.35:

25-pin D-type, female connector (via adapter cable)

•

RS-530:

25-pin D-type, female connector

•

V.36:

25-pin D-type female connector (via adapter cable)

•

IR-ETH:

10BaseT, UTP cable, RJ-45

•

ISDN:

S-interface, UTP cable, RJ-45

•

DDS:

8-pin RJ-45, female connector.

Appendix A provides the pin allocations.

Front and Rear Panel Clearance

When the unit is installed in a 19" rack, allow at least 90 cm (36 inches) of frontal

clearance for operator access. Allow at least 10 cm (4 inches) clearance at the rear

of the unit for interface cable connections.

Ambient Requirements

The ambient operating temperature of the SPS-3S should be 0° to 45°C

(32° to 122°F), at a relative humidity of up to 90%, non-condensing.

2-2

Site Requirements

SPS-3S

Installation and Operation Manual

2.4

Chapter 2 Installation

Hardware Configuration

General Information

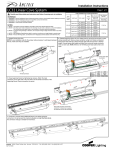

SPS-3S contains two different types of printed circuit boards. Figure 2-1 shows an

internal view of the unit with the different boards.

•

The main board contains most of the SPS-3S circuits, and has two jumpers.

•

Three main link interface boards for SPS-3S which determine the interface

type. The appropriate board is installed in the factory in accordance with your

order, and cannot be replaced by the customer. See the RAD Packet Switching

Guide for further details.

This paragraph provides information on the functions of the internal jumpers, and

provides step-by-step instructions for setting these jumpers. The default settings for

each jumper are also listed.

Note

The default settings of the SPS-3S jumpers are usually suitable for most applications.

Check the default positions explained below. If your requirements are different, set

the internal jumpers in accordance with your requirements before the installation.

All other configuration actions are performed using the SPS-3S command facility

after installation is completed. Detailed instructions for these operations appear in

the RAD Packet Switching Guide.

Figure 2-1. SPS-3S Internal Board

SPS-3S

Hardware Configuration

2-3

Chapter 2 Installation

Installation and Operation Manual

Internal Jumpers

In order to avoid the possibility of electrical shock, always disconnect the

power cable from mains before opening the SPS-3S.

Warning

The SPS-3S main board has a number of internal jumpers. Refer to Figure 2-2 and

use the following descriptions of the more important jumpers.

INIT - NOR jumper, JP25

The JP25 jumper is used to select the default set of configuration parameters

stored in the unit. The jumper has two positions:

•

NOR – Normal operation. SPS-3S uses the parameters selected by the user

during the last configuration session.

•

INIT – Initialization. Upon turn-on, SPS-3S loads the default configuration

(determined by the factory and common to all the SPS-3S units). To select the

default configuration, refer to the RAD Packet Switching Guide.

The factory setting is NOR.

JP1

JP1 is not used. It is for future applications only.

The JP1 factory setting is NORMAL-NVRAM.

JP21, JP22

JP21 and JP22are not used. It is for future applications only.

The factory setting for JP21 and JP22 is RTS.

JP2

This jumper is used to set the unit when an IR-ETH or U-INT interface is used.

•

IR-ETH

JP2 is shorted to pins 2 and 3 (towards the front panel)

•

U-INT

JP2 is shorted to pins 1 and 2 (towards the back panel)

The factory setting for JP2 is U-INT.

BRG1, BRG2, BRG3, JP4, JP5, JP6

These jumpers are in use when working with the X.21 interface in the DCE mode.

To work the X.21 interface in the DCE mode, the jumper must be connected in

accordance with the interface in use.

For example, if you are using the X.21 interface in DCE mode, JP4 (BRG2) must be

connected to Link 2. To work with Link 1, connect JP5 (BRG1). To work with

Link 3, connect JP3.

When working with the X.21 interface in DTE mode, the jumper must be

disconnected.

2-4

Hardware Configuration

SPS-3S

Installation and Operation Manual

Chapter 2 Installation

Figure 2-2. SPS-3S Identification of Internal Jumpers

Interface Board

SPS-3S is available with four types of removable interface boards. Port 1 of the unit

is available as DDS for DDS CSU/DSU interface.

The interface board types are:

SPS-3S

•

V.24 (RS-232) interface

•

V.35 interface

•

RS-530 (V.36) interface

•

X.21 interface

•

IR-ETH

•

ISDN

•

DDS CSU/DSU interface.

Hardware Configuration

2-5

Chapter 2 Installation

Warning

Installation and Operation Manual

In order to avoid the possibility of electrical shock, always disconnect the

power cable from wall plug before opening the SPS-3S.

Each interface board can be configured as DCE or DTE by changing the main

jumper. The main jumper consists of multiple jumpers that must be changed

together. Each board is marked DCE DTE. The UI-X21 interface board is shown

in Figure 2-3.

Figure 2-3. UI-232 Interface Board

The interface board determines the physical layer configuration of a SPS-3S link.

When the board is set as DTE, the link must be used with a flat cable to connect to

a terminal. The link receives its clock from outside and the clock parameter must

be configured as external clock.

When the board is set as DCE, the link uses the internal clock, and the clock

parameter must be configured as internal clock (for more information, see the

RAD Packet Switching Guide).

Jumper Setting Procedure

In order to avoid the possibility of electrical shock, always disconnect the

power cable from the wall plug before opening the unit.

Warning

To access the printed circuit board of SPS-3S, loosen screws on the bottom of the

unit and remove the top cover.

Refer to Figure 2-2 or Figure 2-3and identify jumper locations and settings. Change

settings as required.

Replace the SPS-3S cover, gently push it down until it clips into place and fasten

screws.

2-6

Hardware Configuration

SPS-3S

Installation and Operation Manual

2.5

Chapter 2 Installation

Installation in 19" Racks

SPS-3S can be installed in 19" racks. Unit height corresponds to 1U (1.75"). The

width of the unit is slightly less than the available mounting width.

An adapter kit provides the hardware necessary for installation of the unit in 19"

racks. The paragraph below provides step-by-step instructions for this procedure.

Disconnect the units from AC power while performing the following

procedures.

Warning

Installation of the Unit

The rack adapter kit for the installation includes two long-arm brackets. The

brackets are fastened by means of screws to the two side walls of the case. The

installation of SPS-3S is shown in Figure 2-4.

To prepare the unit for rack installation, attach the two brackets to the side walls of

the unit. Each bracket is fastened by means of two screws (with flat washers),

which are inserted into the two front holes on the side wall (nuts are already in

place, on the inner side of the wall).

After attaching the brackets, the unit is ready for installation in the 19" rack. Fasten

the brackets to the side rails of the 19" rack by means of four screws (not included

in the kit), two on each side.

Figure 2-4. Installation of SPS-3S in 19" Rack

SPS-3S

Installation in 19" Racks

2-7

Chapter 2 Installation

Installation and Operation Manual

2.6

Cable Connections

General

SPS-3S has three connectors located on the rear panel that serve the synchronous

links, and an RJ-45 connector located on the front panel for the asynchronous data

channels.

Asynchronous Data Channel Connections

The SPS-3S channel interfaces are configured as data communication equipment

(DCE) interfaces, thereby allowing direct connection, via RS-232 port cables, to

data terminal equipment (DTE). When modems are used to extend the range (tailend circuits), cross-over cables are required. Channel interfaces are asynchronous,

therefore clock signals are neither supported, or required.

The Packet Switching Guide lists pin allocations in SPS-3S data channel connectors,

and provides typical wiring diagrams for straight-through and cross-over cables.

Synchronous Links Connection

Each interface board can be configured as DCE or DTE by changing the main

jumper. The main jumper consists of multiple jumpers that must be changed

together. Each board is marked DCE DTE. The X.25 link connectors type

depends on the SPS-3S interface:

•

V.24:

25-pin D-type, female connector

•

X.21:

25-pin D-type, female connector (via adapter cable)

•

V.35:

25-pin D-type, female connector (via adapter cable)

•

V.36:

25-pin D-type, female connector (via adapter cable)

•

RS-530:

25-pin D-type, female connector

•

IR-ETH:

10BaseT, UTP cable, RJ-45

•

ISDN

S-interface, UTP cable, RJ-45

•

DDS:

8-pin RJ-45, female connector.

Appendix A provides the pin allocations.

Note

The user data cables and the synchronous links cables should be shielded, in order

to comply with FCC rules. The SPS-3S and its data interfaces will work well even if

the cables are not shielded, but some radio interference may occur.

Power Connection

AC power should be supplied to the SPS-3S through the 5 feet (1.5m) power cable

terminated by a standard 3-prong plug. Connect the cable between the AC mains

connector on the SPS-3S rear panel and a standard grounded AC outlet.

2-8

Cable Connections

SPS-3S

Installation and Operation Manual

Warning

Chapter 2 Installation

BEFORE APPLYING POWER TO THIS UNIT, the protective earth terminals of

this instrument must be connected to the protective ground conductor of the

(mains) power cord. The mains plug should only be inserted in a socket outlet

provided with a protective earth contact. The protective action must not be

negated by use of an extension cord (power cable) without a protective

conductor (grounding).

Make sure that only fuses with the required rated current, as marked on the

SPS-3S rear panel, are used for replacement. The use of repaired fuses and

the short-circuiting of fuse holders must be avoided.

Whenever it is likely that the protection offered by fuses has been impaired,

the instrument must be made inoperative and be secured against any

unintended operation.

Any interruption of the protective (grounding) conductor (inside or outside the

unit) or disconnecting the protective earth terminal can make this unit

dangerous. Intentional interruption is prohibited.

SPS-3S

Cable Connections

2-9

Chapter 2 Installation

2-10

Cable Connections

Installation and Operation Manual

SPS-3S

Chapter 3

Operation

3.1

General

SPS-3S supports a wide range of applications. These include:

•

Connection of a bridge/router using HDLC encapsulation over Frame Relay

•

Encapsulating private X.25 over Frame Relay networks

•

Connecting SDLC/QLLC/LLC environment T-PADs and FEPs over X.25 or

Frame Relay Networks

•

Providing interfaces to DDS Networks

•

SLIP communication and IP encapsulation over Frame Relay or X.25 protocols.

For more detailed configuration information, refer to the RAD Packet Switching

Guide and RAD Packet Switching Applications Guide.

3.2

Controls, Indicators and Connectors

Front Panel

Table 3-1 lists the functions of the SPS-3S front panel indicators and connectors.

The numbers under the heading “Item” refer to the identification numbers in

Figure 3-1.

Figure 3-1. SPS-3S Front Panel

SPS-3S

Controls, Indicators and Connectors

3-1

Chapter 3 Operation

Installation and Operation Manual

Table 3-1. SPS-3S Controls, Indicators and Connectors

Item

Control, Indicator or

Connector

Function

1

PWR Indicator

Lights up when SPS-3S is powered.

2

Main Links Activity Indicators

Indicators, one for each main link, light up

when the corresponding link is active

(receives or transmits frames).

3

Channel Activity Indicator

Indicator lights up when the channel is

active (receives or transmits data).

4

SYN Indicators

Indicators, one for each main link, indicate

synchronization status.

Condition:

Indication:

Off

SPS-3S is not powered

On

SPS-3S is powered and

synchronized with the

corresponding peer.

Flashing

SPS-3S is powered but

(Continuous) not synchronized with

the corresponding

peer.

3-2

5

ERR Indicator

Lights up when a hardware malfunction is

detected during the self-test automatically

performed upon power-up, or after

pressing the RESET push-button.

6

OVF Indicator

Lights up when the SPS-3S buffers are full.

In a properly designed system, this

condition usually indicates that one of the

units connected to the unit does not

respond to the flow control commands

sent by SPS-3S, a condition that could be

caused by incorrect configuration of the

unit.

7

TEST Indicator

Lights up to indicate that SPS-3S is in

diagnostics mode (one of the test loops

active). In either case, traffic is interrupted.

8

Channel Connector

Connection to the SPS-3S channel.

Controls, Indicators and Connectors

SPS-3S

Installation and Operation Manual

Chapter 3 Operation

Rear Panel

Table 3-2 lists the functions of the SPS-3S rear panel controls and connectors. The

numbers under the heading “Item” refer to the identification numbers in

Figure 3-2.

Figure 3-2. SPS-3S Rear Panel Controls and Connectors

Table 3-2. SPS-3S Rear Panel Controls and Connectors

Item

Control or Connector

Function

1

Power Connector

AC power connector with integral

fuse

2

Synchronous Links Connectors

Connection to synchronous link

3.3

Operating Instructions

General

After being prepared for operation as explained above, SPS-3S normally operates

unattended. Operator intervention is only required when the unit is set up for the

first time or must be adapted to new operational requirements.

Note

SPS-3S configuration is stored in a non-volatile memory, and is not affected when

power is turned off.

Power-On

Connect the power cable to the unit's rear power connector; the PWR indicator

should light up. All the indicators on SPS-3S should flash, according to the default.

Check that after a short interval (during which SPS-3S performs self-test), the ERR,

OVF and TEST indicators are extinguished.

SPS-3S

Operating Instructions

3-3

Chapter 3 Operation

Installation and Operation Manual

Normal Operation

During normal operation, the PWR and SYNC indicators should light up

continuously and the TEST, OVF and ERR indicators must remain off.

Channel activity indicators flash according to the traffic load, and are extinguished

when the channel is idle.

Power-Off

To turn off the unit, disconnect its power cable from the mains.

3.4

What to do in Case of Malfunction

Preliminary Checks

In case a problem occurs, the following actions will help you return the to normal

operation.

•

Check that the unit is powered (PWR indicator should light up).

•

Check that cables are properly connected.

•

Check that the equipment connected to the unit is powered and operates

normally.

•

Check the LED indicators.

•

Check the configuration of SPS-3S and that of the remote PAD or switch

correspond to the requirements of the equipment connected to its channels.

Troubleshooting

In case the preliminary checks do not correct the problem, press RESET or turn the

unit off, and then turn it on again. If the problem repeats, refer to the RAD Packet

Switching Guide for additional operations.

3-4

What to do in Case of Malfunction

SPS-3S

Appendix A

Connector Pinouts

This appendix provides information needed for the SPS-3S interface connections.

The information presented in this appendix includes a description of the Control

connector, connector pin functions and where applicable – the recommended

wiring for relevant adapter cables.

A.1

Interface Connectors

X.21 Port Pinouts

V.24 Port Pinouts

SPS-3S

Interface Connectors

A-1

Appendix A Connector Pinouts

Installation and Operation Manual

V.35 Port Pinouts

V.36 Port Pinouts

A-2

Interface Connectors

SPS-3S

Installation and Operation Manual

Appendix A Connector Pinouts

RS-530 Port Pinouts

A.2

Control Connector

The control connector of SPS-3S is an RJ-45 8-pin female connector with a serial

RS-232 DCE interface, intended for connection to an ASCII-based terminal.

Connector pin functions are listed in Table A-1.

•

To connect a supervision terminal having a 9-pin connector to the control

connector, use the appropriate adapter cable (CBL-RJ45/D9/F/STR or

CBL-RJ45/D9/M/STR, supplied). Figure A-1 shows the wiring diagram of this

cable.

Table A-1. RJ-45 Control Connector Pin Functions

Pin

Function

1

GND

2

Not connected

3

Receive Data (RXD) from terminal

4

Not connected

5

Transmit Data (TXD) to terminal

6

Not connected

7

GND

8

Not connected

Terminal Control Table

The terminal control port cable has an 8-pin RJ-45 connector on one side, and a

9-pin, D-type, female connector on the other side.

SPS-3S

Control Connector

A-3

Appendix A Connector Pinouts

Installation and Operation Manual

Figure A-1. Wiring RJ-45 to DB-9 Adapter Cable (CBL-RJ45/DB9/F/STR)

A-4

Control Connector

SPS-3S

24 Raoul Wallenberg St., Tel Aviv 69719, Israel

Tel: +972-3-6458181, Fax: +972-3-6483331, +972-3-6498250

E-mail: [email protected], Web site: www.rad.com

Customer Response Form

RAD Data Communications would like your help in improving its product documentation.

Please complete and return this form by mail or by fax or send us an e-mail with your

comments.

Thank you for your assistance!

SPS-3S

Manual Name: ______________________________________________________________

159-200-10/06

Publication Number: __________________________________________________________

Please grade the manual according to the following factors:

Installation instructions

Operating instructions

Manual organization

Illustrations

The manual as a whole

Excellent

Good

Fair

Poor

Very Poor

What did you like about the manual?

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

Error Report

Type of Error(s)

Incompatibility with product

or Problem(s):

Difficulty in understanding text

Regulatory information (Safety, Compliance, Warnings, etc.)

Difficulty in finding needed information

Missing information

Illogical flow of information

Style (spelling, grammar, references, etc.)

Appearance

Other _________

Please list the exact page numbers with the error(s), detail the errors you found (information missing,

unclear or inadequately explained, etc.) and attach the page to your fax, if necessary.

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

Please add any comments or suggestions you may have.

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

You are:

Distributor

End user

VAR

Other ________________________

Who is your distributor?

_______________________________

Your name and company: ___________________________________________________________

Job title: __________________________________________________________________________

Address: __________________________________________________________________________

Direct telephone number and extension: _______________________________________________

Fax number: ______________________________________________________________________

E-mail: _____________________________________________________________________

www.rad.com

INTERNATIONAL HEADQUARTERS:

24 Raoul Wallenberg Street, Tel Aviv 69719, Israel, Tel: 972-3-6458181

Fax: 972-3-6498250, 972-3-6474436, Email: [email protected]

NORTH AMERICA HEADQUARTERS:

900 Corporate Drive, Mahwah, N.J. 07430, Tel: (201) 529-1100

Toll Free: 1-800-444-7234, Fax: (201) 529-5777, Email: [email protected]

Publication No. 159-200-10/06