* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Introduction - Cornell - Seafood HACCP Alliance Internet Training

Survey

Document related concepts

Transcript

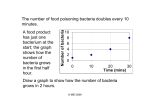

Seafood HACCP Alliance Training Course 2-1 Introduction This module will introduce you to the potential food safety hazards that can be associated with seafood products. Please refer to Chapter 2 (pages 11-26) in the 3rd edition of the blue HACCP Training Curriculum manual for additional information. There are 32 pages and 8 questions in this Module. Seafood HACCP Alliance Training Course 2-2 Food Safety Hazards HACCP is a food safety control program designed to prevent, eliminate or reduce food safety hazards to an acceptable level. In this module we will discuss the potential food safety hazards that can be associated with both seafood products and processing. Food safety hazards are categorized in three classes: BIOLOGICAL, CHEMICAL and PHYSICAL. Each one will be discussed separately in this module. Seafood HACCP Alliance Training Course 2-3 Definition of Food Safety Hazards Food safety hazards, if not properly controlled, can cause illness or injury to the person who eats the food. As previously mentioned, the hazards that are associated with food and food processing have been categorized in three classes: biological, chemical or physical hazards. Some hazards are species related because they are likely to be present in certain types of fish or shellfish. Other hazards are process related because the hazard may become incorporated into the product due to equipment or handling procedures. Types of Hazards Biological hazards include harmful bacteria, viruses or parasites. Chemical hazards include compounds that can cause illness or injury due to immediate and/or long-term exposure such as toxins found in fish or shellfish. Physical hazards include foreign objects that can cause harm when eaten such as metal or glass. Hazard Analysis Hazards are evaluated during what is called a hazard analysis. During the hazard analysis it's determined whether a particular hazard needs to be included in a HACCP plan. Only hazards that directly affect the safety of the product need to be included in a HACCP plan. This evaluation of hazards will be discussed in detail in Module 5. This module will, however, provide an overview of the kinds of hazards that are associated with seafood products and food processing, and will help you to recognize what is and is not appropriate to control with HACCP. Seafood HACCP Alliance Training Course 2-4 Undesirable conditions or contaminants that are NOT food safety hazards There are a number of conditions or contaminants that are undesirable in food, but do not necessarily represent a safety hazard. That's because they're not likely to cause illness or injury to the person who eats the food. These conditions can be controlled by a company's standard operating procedures (SOP's), and should NOT be included in a HACCP plan as they don't affect the safety of the food. Examples Some examples of these undesirable conditions that are not food safety hazards are: • Product quality or spoilage, unless the spoilage results in a food safety problem, • Hair, insects, or other filth, • Economic fraud or misrepresentation, and • Failure to meet other regulatory standards such as Good Manufacturing Practices and sanitation. Again, these conditions still need to be addressed and controlled by processors, but they don't need to be part of a HACCP plan system for controlling food safety. Seafood HACCP Alliance Training Course 2-5 Food Safety Hazards Now, let's cover the different categories of hazards, starting with biological. Definition: Biological hazards can be found in both raw and processed products. They're living microorganisms or parasites that can make people sick if they're present in food. Many types of microorganisms, those organisms that are too small to see with the naked eye, live everywhere in our environment. Microorganisms are classified into various groups. Some microorganisms can cause illness, while others spoil food. Some can even be beneficial in some foods. Some types of bacteria, yeast and molds actually grow in food and can produce certain chemicals or "by-products" that give some foods beneficial characteristics. Other microorganisms can cause spoilage. Some of their "by-products" can cause food to look, taste, and smell bad. Spoilage is undesirable but is normally NOT associated with safety. Other microorganisms are considered food safety hazards because they can cause infections or produce "by-products" called toxins that can make people sick. First let's take a look at some of the microorganisms that are considered beneficial. Seafood HACCP Alliance Training Course 2-6 Food Safety Hazards Beneficial microorganisms produce desirable properties and components in foods. These include: bacteria and fungi which can be either yeast or molds. Bleu Cheese made with mold Bacteria Cells Certain yeast, molds and bacteria are used to make foods that we eat everyday including beer, bread, wine, cheese, yogurt, soy sauce and salami. These foods couldn't be made without introducing certain types of microorganisms that produce the "by-products" necessary for the characteristic flavor and texture that you would expect. Because these microorganisms do not cause illness, they are not considered a food safety hazard. But as we said earlier, some microorganisms do cause illness, let's take a look at those next. Seafood HACCP Alliance Training Course 2-7 Food Safety Hazards Microorganisms that can cause disease or illness are called pathogens—a word that means "disease-causing". Pathogens are biological food safety hazards that must be evaluated in a hazard analysis. If it's determined that a pathogen is reasonably likely to occur at a level that will cause illness, this hazard would need to be controlled in a HACCP plan. These biological hazards can be present in a food product that "appears" to be of good quality with no obvious visual signs or odors to indicate that the food is unsafe or "bad". There are three types of pathogenic organisms that can be potential food safety hazards. They are: bacteria, viruses and parasites. Let's take a look at each one, starting with bacteria. Seafood HACCP Alliance Training Course 2-8 Food Safety Hazards Bacteria are single celled microorganisms that are too small to see with the naked eye. Bacteria live everywhere: in the air, dirt, fresh and salt water, on your skin and hair and other body parts, and on both plants and animals. A few types of bacteria are food safety hazards because they can cause illness and disease. To control these bacteria we need to prevent them from getting into the food, and if they are present to prevent them from growing and/or eliminate them. To do this, you must understand their properties—how they grow, what they need to grow, how they get into food, and how they make you sick. Let's find out! Seafood HACCP Alliance Training Course 2-9 How do Bacteria grow? Bacteria do not grow and multiply the same way as animals or humans. They take in nutrients and reproduce by dividing – one bacteria splits and becomes two bacteria, two become four, four become eight and so on. Doubling can occur quickly if the conditions – enough nutrients, proper temperature, adequate moisture, etc. - are suitable. Each type of bacteria has its own preferred conditions for growth. Under ideal conditions, many types of bacteria can double every 20 minutes. Potentially, one bacteria can multiply to more than 30,000 in five hours and to more than 16 million in eight hours. Controlling the conditions needed for growth is an effective way to control many bacterial food safety hazards. Seafood HACCP Alliance Training Course 2-10 What do bacteria need to grow? Like all living things, bacteria need food, water and the proper environment to live and grow. The food product itself supplies the food and water needed for bacterial growth. Most seafood products provide an abundance of food and water for growth. The exact environmental requirements can vary from one type of bacteria to another. Most bacteria grow best within certain ranges of temperature, and have specific requirements related to their need for air, the proper amount of water, acid and salt. By controlling nutrients, water, temperature and time, air, acidity, and salt, you can eliminate, control, or reduce the rate at which bacteria grow. Spores Some types of bacteria have the ability to form spores when they are exposed to conditions that they "do not like". Once bacteria form spores to survive, they will not grow until conditions become favorable again. Spores are very resistant to conditions of high heat, acid, or other chemicals that would kill most bacteria in their normal state. These spores can create food safety hazards under certain conditions. Controlling the spores requires preventing favorable conditions for growth—keeping the temperature low or the acidity or salt content high will keep them as spores that aren't harmful. An example of a type of spore forming bacteria that is extremely hazardous is Clostridium botulinum, the bacteria that causes botulism. Optional If you would like to learn more about specific requirements for bacterial growth, the next 3 pages have more information on these requirements. What bacteria need to grow and multiply 1. Food (nutrients) 2. Water (moisture) 3. Proper temperature 4. Time 5. Air, no air, minimal air 6. Proper acidity (pH) 7. Salt levels Seafood HACCP Alliance Training Course 2-10A Food: Food is essential for ALL living organisms. Bacteria need protein, carbohydrates, vitamins and minerals - just like we do. Seafood is a great food source for bacteria - it contains all of these nutrients and plenty of water - a good environment for disease-causing bacteria to grow. Some food preservation methods such as smoking, drying, and freezing work by preventing the water and nutrients in food from being used by bacteria. Water or Moisture: All bacteria need moisture, or water, in a "useable" or "available" form to grow and reproduce. Bacteria use the water to take in food and to remove unwanted waste products. Water activity (aw) is one measure of the available water in a food. The water activity scale runs from 0 to 1.0. The lower the water activity, the less water is available in a form that can be used by bacteria. The water activity of pure water is 1.0—thus the water activity of all foods falls below this number. However, many food products, particularly meat, poultry, seafood and dairy products, have a water activity of 0.95–0.99. Unfortunately, this is the optimum range for many of the spoilage and disease-causing bacteria. Most fresh seafood products have a water activity above 0.98—perfect for bacterial growth!!! Pathogenic bacteria do not grow well or produce toxin below 0.85 and most require 0.92 or above. Freezing, drying, or salting are ways to reduce available water to bacteria, and slow down their growth. Temperature: Each type of bacteria grows best in a certain temperature range. Not all bacteria have the same temperature requirements, but most grow best between 40° F and 140° F, which is known as the TEMPERATURE DANGER ZONE. Unfortunately, a few very harmful disease-causing bacteria, like Listeria monocytogenes and Clostridium botulinum Type E, can also grow slowly at refrigerated temperatures. That's why proper refrigeration at temperatures as close to 32° F as possible for unfrozen product is important - not only for quality but for safety as well. Keeping products cold can stop some bacteria from growing, but only slows down the rate of growth for other bacteria. Freezing food and holding it at temperatures below 0° F can stop bacterial growth. Temperatures at the high end of the Danger Zone, above 140° F, can also be used to prevent bacterial growth. Heating food to temperatures above 145° F can be used to kill bacteria. Some type of bacteria may be more heat resistant than others. Cooking times and temperatures used in processing must be designed to provide internal product temperatures that ensure that pathogenic bacteria are killed. 140˚ 40˚ Seafood HACCP Alliance Training Course Time: Bacteria do not grow and multiply instantly. When enough food and water is available as well as the proper temperature for growth, they will multiply over time. This is why you need to consider both time and temperature controls to keep products safe and of high quality. While bacteria may differ in their optimum growth temperatures, a good rule is to cool products quickly and keep them cold to minimize the amount of time that food is held in the Danger Zone, the temperature range most favorable for bacterial growth. Air, No Air, or Minimal Air Bacteria can be placed into three groups depending on whether or not they need oxygen or air to grow. The first group must have oxygen to grow. The second group can grow with or without oxygen, and the third group cannot grow if oxygen is present. Bacteria like Bacillus cereus can only grow if oxygen or air is present. Many types of bacteria such as Listeria, Salmonella, Staphylococcus and Vibrio can grow with or without air. Others, like the sporeforming bacteria, Clostridium botulinium Type E, can only grow when no air is present. Since C. botulinum Type E is common in the marine environment and grows best in the absence of air, preservation techniques like vacuum-packing and modified atmosphere packaging can be particularly hazardous. Other controls that provide additional barriers to C. botulinium growth, like low temperatures and additives such as salt or nitrates, must be used to ensure that the bacteria that causes botulism does not grow. 2-10B Seafood HACCP Alliance Training Course 2-10C Acidity: The acidity of a food is also important for bacterial growth. Acidity is measured using what is known as the pH scale which Acidic Neutral Alkaline goes from 0 to14, where pH 7.0 is neutral, a pH less than 7 is 0 7 14 acidic and a pH greater than 7.0 is basic or alkaline. Foods with a pH close to 7.0 are ideal for most bacterial growth. Every pH Scale microorganism has a minimum, optimum and maximum pH for growth. The optimum growth range is about 6.0 to 7.5, but growth can occur slowly at lower or higher pH levels. A pH of 4.6 and below or a pH above 11 will prevent pathogen growth. A pH 4.6 is used as a divider between what we call acid and what we call low acid foods. Many fruits, such as peaches, oranges and apples are acid foods as their pH is below 4.6. Many vegetables, meats and fish have a pH above 4.6 making them low-acid foods. There are some exceptions, but most fresh seafood has a pH above 6.0 - putting it in the optimal range for bacterial growth. Some foods start out as a low acid food and are then processed in such a way that they become an acid food. An example is pickled fish which is produced by adding vinegar to lower the pH and slow down the growth of spoilage and disease causing bacteria. Fermented products like fish sauce depend on non-harmful microorganisms to produce acid to lower the pH and achieve the same effect. Salt: The amount of salt in food can also affect bacterial growth. For most types of bacteria, growth slows down as the salt content increases. However, there are some types of bacteria that can grow at high salt levels. A salt level of 10% or higher is needed to inhibit the growth of most types of bacteria that cause illness, although some pathogens can grow at much higher salt levels. Flavor is a consideration when using salt as a preservative, and foods could get too salty to eat. Control of bacterial growth in foods is usually achieved by using lower levels of salt in combination with refrigeration or other barriers that inhibit the growth of bacteria. For example, with smoked products, minimum levels of salt (3.5%) in combination with smoking, cooling and cold storage are required to control pathogens that cause botulism and staphylococcus intoxication. Seafood HACCP Alliance Training Course 2-11 Sources of Bacteria Bacteria are found everywhere in the environment - air, soil, and water. Bacteria are on the outer surfaces and in the digestive tract of all fish and shellfish. Processing plants and all the equipment and utensils in them are prime areas for bacteria because of the abundance of nutrients and water. A big contributor for bacterial contamination are people - as bacteria is present on their skin, hands, hair and in their respiratory and digestive tract. Good sanitation practices including proper employee practices along with the use of high quality raw materials are used to minimize the potential for finished food products to become contaminated with bacteria. Processing procedures such as refrigeration, time/ temperature controls, cooking, adding salt, and drying or removing water, are used to minimize bacterial growth or to kill them altogether. Examples The following are some examples of how bacteria can contaminate food: • Bacteria may be naturally present on fish or shellfish when they are harvested. • Bacteria from the processing facility can contaminate fish or shellfish after they are harvested. • Cross contamination can occur when bacteria from food products or food contact surfaces are transferred to another product when the products touch, drip or splash onto each other. • Bacteria from the plant or dirty food handling equipment or utensils that are not properly cleaned and sanitized can contaminate products. • People can contaminate products because of poor personal hygiene practices, not washing hands properly, or using poor food handling practices. Seafood HACCP Alliance Training Course 2-12 How Bacteria Cause Illness Bacteria can cause illness in three ways: by infection, intoxication or toxicoinfection. A foodborne infection occurs when the microorganism itself is ingested with the food. The organism establishes itself in the host's body and multiplies. Since the infection is a consequence of growth in the body, the time from ingestion until symptoms occur is relatively long. A foodborne intoxication occurs when specific pathogenic bacteria grow in the food and release toxins into the food that is subsequently consumed. It is the toxin that makes the person sick. Since the illness is a consequence of absorption of the preformed toxin by the intestinal tract, and not microbial growth in the host's body, symptoms of intoxication have a much more rapid onset than foodborne infection. A third type is called toxicoinfection, which combines the two. Toxicoinfections are characterized by bacteria that are non-invasive and cause illness by producing toxins while growing in the human intestines. The times of onset are generally, but not always, longer than those for intoxications, but less than those for infections. Examples Examples of bacterial pathogens that have been associated with seafood products are: Clostridium botulinium (forms spores and a toxin) Listeria monocytogenes Salmonella Vibrio species Staphylococcus aureus Optional To see a table from the FDA Hazards and Controls Guide that summarizes the growth requirements for specific types of bacterial pathogens go to pages 279-283 in the third edition of the FDA Hazards Guide. To see in-depth information on bacterial pathogens in food from the FDA Bad Bug Book visit this web site: http://vm.cfsan.fda.gov/~mow/intro.html. To see in-depth information on bacterial pathogens and process controls from the Seafood HACCP Alliance Compendium visit this web site: http://www-seafood.ucdavis.edu/haccp/compendium/ compend.htm. Seafood HACCP Alliance Training Course 2-13 Food Safety Hazards Virus Hazards Like other microorganisms, viruses exist in many places in our environment, but unlike bacteria, they cannot grow in food. When viruses are in food, they are simply there and do not replicate or increase in number. Viruses are extremely persistent and may remain in a contaminated food for long periods of time. Many viruses can survive for a long time under harsh conditions such as freezing. To reproduce, viruses must invade a living cell – this means you!! Of the many different types of viruses in the environment, only some of them can infect humans. Seafood HACCP Alliance Training Course 2-14 Foods are contaminated with viruses in four major ways People who have been infected with viruses can carry them in their digestive tract for a long time with no signs of illness. They excrete the viruses when they go to the bathroom and can transmit them to food when they don't wash and sanitize their hands properly. Sewage polluted estuarine waters can contaminate fish and shellfish. Oysters, clams and mussels, which are filter feeders, entrap the viruses from the water in their mucous membranes and transfer them to their digestive tract. If the shellfish is consumed whole and raw, so are the viruses. This is the reason why certified shellfish harvest areas are evaluated for sources of sewage pollution or fecal contamination caused by run-off from the land. Contaminated irrigation water can deposit viruses on the surface of fruits and vegetables. Again, people become infected when they consume contaminated foods raw. Viruses can be introduced if contaminated drinking water is used to wash or transport food, or is used as an ingredient in the food, or if you just drink it! And last, viruses can be added to food by infected food handlers with fecal material on their hands - a result of poor personal hygiene practices. Examples Examples of common seafood-related viral pathogens are: Hepatitis A Virus and Norwalk-Like Agent Optional To see additional information about viruses from the Seafood HACCP Alliance training manual, turn to page 183 in the Seafood HACCP Alliance training manual "Blue Book". To see additional information about viruses from the FDA Bad Bug Book visit this web site: http://vm.cfsan.fda.gov/~mow/intro.html Seafood HACCP Alliance Training Course 2-15 Food Safety Hazards Parasite Hazards Parasites are organisms that need to live on or within a host to survive. There are thousands of different kinds of parasites, but less than 100 different kinds are known to infect people. Two kinds of parasites are known to infect people through food and water: worms and protozoa. Parasitic worms can vary in size from not visible to several feet long. Parasitic protozoa are single celled animals that cannot be seen without a microscope. Some types of parasites, like parasitic worms, occur naturally in certain species of fish. As a result, humans get infected when they eat food that contains a living parasite. Other parasites are transmitted through food or water that is contaminated by fecal material that is shed by infected hosts. Parasites can contaminate food directly from infected people who do not follow good personal hygiene or hand washing practices. Contamination can also occur through water that has been contaminated with parasites from fecal material because of improper disposal of waste, insufficiently treated sewage, or runoff from the land. Seafood HACCP Alliance Training Course 2-16 Control of Parasites Some fish species are excellent hosts for parasites. For these species you can expect that they are likely to be present and if the product is eaten raw, there is a good chance of becoming infected. Parasites can be controlled in two ways: by heat or proper freezing. For heating, it is reasonable to assume that normal cooking will kill the parasites. FDA recommends three freezing options to kill parasites; freezing at -4° F or below for 7 days OR freezing at -31° F or below until solid and then holding for 15 hours OR freezing at -31° F or below until solid and them holding at -4° F or below for 24 hours. Examples Examples of common parasitic worms in seafood include: Roundworms such as cod worm (Pseudoterranova) and herring worm (Anasakis) Tapeworms Examples of parasitic protozoa that could contaminate seafood products from water or other sources include: Giardia lamblia Cryptosporidium parvum Entamoeba histolitica Optional To find out which species of fish are likely to have a parasite hazard go to pages 16-37 in the third edition of the FDA Fish and Fishery Products Hazards and Controls Guide or click here. To learn more about the hazard of parasites and proper controls go to page 65 in the third edition of the FDA Fish and Fishery Products Hazards and Controls Guide. To learn more about the hazard of parasites and proper controls from the FDA Bad Bug Book visit this web site: http://vm.cfsan.fda.gov/~mow/intro.html To learn more about the hazard of parasites from the Seafood HACCP Alliance Compendium of Processing Methods visit this web site: http://www-seafood.ucdavis.edu/haccp/compendium/ compend.htm Seafood HACCP Alliance Training Course 2-17 Check Your Knowledge 1 Now you need to return to Module 2 via the Internet. Click through the text pages until you get to the Check Your Knowledge page (page 2-17). Submit your answers before moving on to page 2-18. Good Luck! Seafood HACCP Alliance Training Course 2-18 Food Safety Hazards What Are Chemical Hazards? Chemical contamination of food products can occur at any stage of food processing. Certain chemicals can be considered food safety hazards, but not all chemicals are hazardous. For example, when pesticides are used properly on fruits and vegetables they are helpful in eliminating unwanted pests and protecting crops. But if these same pesticides are not used properly or unapproved pesticides are used, they can become a potential risk to the consumer. The presence of a chemical may not always mean there is a hazard as the amount of the chemical may determine whether it's a hazard or not. Exposure to some chemicals may cause immediate symptoms and other chemicals may require exposure over prolonged periods to have a toxic effect. Seafood HACCP Alliance Training Course 2-19 Chemical Hazards Can Be Controlled by As important as it is to understand chemical hazards, it's equally important for you to know how to control those hazards. Four of the most common ways to control chemical hazards are by: • Controlling the type and amount of chemicals added to foods. • Preventing accidental contamination or spills. • Using food or ingredients not contaminated with chemicals. • Preventing conditions that allow chemical hazards to develop in food. Seafood HACCP Alliance Training Course 2-20 Food Safety Hazards Types of Chemical Hazards In order for you to identify the chemical hazard and the appropriate control it is important to understand what a chemical hazard is. Chemical hazards can be separated into three category's: Naturally occurring chemicals; Intentionally added chemicals; and Unintentionally or incidentally added chemicals. Let's take a look at each one. Seafood HACCP Alliance Training Course 2-21 Food Safety Hazards Finfish Toxins Shellfish Toxins Naturally Occurring Chemicals (including allergens) Naturally occurring chemicals, including allergens, are normally found in a variety of different plants, animals or microorganisms. They can be present in food or food ingredients prior to harvest - or they can develop in foods after they are harvested. Even though some naturally occurring chemical toxins are created by microorganisms and are therefore biological in origin, the toxins are traditionally categorized as chemical hazards. Allergens are naturally occurring chemicals present in food that cause an allergic reaction in some people after the food is eaten. There are two (2) types of naturally occurring chemicals in seafood: Finfish toxins and shellfish toxins. Here's what you need to know about each type. Seafood HACCP Alliance Training Course 2-22 Food Safety Hazards Finfish Toxins Shellfish Toxins Finfish Toxins There are two types of toxins that may be considered a chemical hazard in certain types of finfish. Ciguatera toxin is considered a naturally occurring toxin as it occurs naturally in some fish species that live in tropical reef areas. Scombrotoxin is not considered a naturally occurring toxin, but is still considered a chemical hazard. Scombrotoxin or histamine can form in some fish species when they aren't cooled down properly after harvest or held properly during processing and storage. Let's take a look at each one separately. Seafood HACCP Alliance Training Course 2-23 Ciguatera toxin is a chemical hazard associated with tropical reef fish species such as barracuda, jacks, king, mackerel and large groupers and snappers that results in a fish poisoning syndrome known as ciguatera fish poisoning (CFP). The toxin is produced when naturally occurring marine algae accumulates in the fish. Ciguatera toxin can't be eliminated either from the environment or from the fish. Therefore, the hazard is controlled by harvesting the fish in waters that have not been associated with a natural toxin problem. Barracuda Grouper Optional To learn more about the Ciguatera toxin hazard go to pages 73–74 in the third edition of the FDA Fish and Fishery Products Hazards and Controls Guide. To find out which species of fish are susceptible to this hazard go to pages 16-37 in the third edition of the FDA Fish and Fishery Products Hazards and Controls Guide. To learn more about the hazard of ciguatera fish poisoning and proper controls from the FDA Bad Bug Book visit this web site: http://vm.cfsan.fda.gov/~mow/intro.html To learn more about the hazard of ciguatera fish poisoning from the Seafood HACCP Alliance Compendium of Processing Methods visit this web site: http://www-seafood.ucdavis.edu/haccp/ compendium/compend.htm Seafood HACCP Alliance Training Course 2-24 Scombrotoxin is a chemical hazard associated with fish species such as tuna, mackerel, bluefish, mahi-mahi, amberjack, herring, and escolar. Scombrotoxin formation in these fish is a result of time/temperature abuse anywhere from harvesting to the consumer. Scrombrotoxin can't be eliminated once the fish has been time/temperature abused. Therefore, the hazard is controlled by rapid chilling after death and then keeping the fish cold throughout processing and to the consumer. Bluefish Mackerel Tuna Optional To learn more about the Scombrotoxin (Histamine) hazard go to page 83 in the third edition of the FDA Fish and Fisheries Products Hazards and Controls Guide. To find out which species of fish are susceptible to this hazard go to pages 16-37 in the third edition of the FDA Fish and Fishery Products Hazards and Controls Guide. To learn more about the hazard of histamine or scombrotoxin and proper controls from the FDA Bad Bug Book visit this web site: http://vm.cfsan.fda.gov/~mow/intro.html To learn more about the hazard of histamine or scombrotoxin from the Seafood HACCP Alliance Compendium of Processing Methods visit this web site: http://www-seafood.ucdavis.edu/haccp/ compendium/compend.htm Seafood HACCP Alliance Training Course 2-25 Food Safety Hazards Shellfish Toxins Finfish Toxins Shellfish Toxins There are four recognized food poisoning syndromes in the United States that are associated with shellfish toxins. They are paralytic shellfish poisoning (PSP), neurotoxic shellfish poisoning (NSP), diarrhetic shellfish poisoning (DSP), and amnesic shellfish poisoning (ASP). The toxins are produced by naturally occurring marine algae that concentrates in filter feeding shellfish such as clams, oysters, and mussels. The toxins cannot be eliminated if they have accumulated in the shellfish. Therefore, the hazard is most commonly controlled by harvesting the shellfish from waters that have not been closed because of a natural toxin problem. Optional To learn more about Shellfish toxin hazards go to pages 73-74 in the third edition of the FDA Fish and Fishery Products Hazards and Controls Guide. To find out which species of shellfish are susceptible to this hazard go to pages 38-44 in the third edition of the FDA Fish and Fisheries Products Hazards and Controls Guide. To learn more about the hazard of shellfish toxins and proper controls from the FDA Bad Bug Book visit this web site: http://vm.cfsan.fda.gov/~mow/intro.html To learn more about the hazard of shellfish toxins from the Seafood HACCP Alliance Compendium of Processing Methods visit this web site: http://www-seafood.ucdavis.edu/haccp/compendium/ compend.htm Seafood HACCP Alliance Training Course 2-26 Intentionally Added Chemicals Food Safety Hazards Intentionally added chemicals are those added to food at some point during food processing, or distribution. They can serve a variety of important functions such as helping to preserve the food, maintaining or adding color, or enhancing the foods nutritional composition. Intentionally added chemicals are safe if they are used at established levels but can be dangerous when those levels are exceeded. Intentionally added chemicals are typically controlled through proper food labeling to alert consumers who are sensitive to avoid them. Let's take a look at food and color additives. Seafood HACCP Alliance Training Course 2-27 Types of Intentionally Added Chemicals Food Safety Hazards Allergens and Additives Certain food and color additives can cause an allergic-type reaction in consumers and are thus considered a potential food safety hazard. Therefore, additives must be approved before they can be used in foods and food processors should review the appropriate regulations for its status and any limitations before using a food additive. This chemical hazard is controlled by properly labeling food to inform consumers that food and color additives are present, and by controlling the amount that is added to food. Examples of Allergens and Additives Used in Seafood Products • Sulfites: Sulfites are used in foods to prevent color changes that can occur in the pigments in certain foods. Sulfiting agents are sometimes used in the on-board handling of shrimp and lobster tails to prevent the formation of "black spot" a quality defect caused by the oxidation of pigments in their shells. • Color Additives: In some food products additives are used to add color to the product. An example of an approved color additive is FD&C Yellow No. 5. • Preservatives like sodium nitrite are used to prevent microbial growth in some food products like smoked fish and bacon. • Nutritional supplements like Vitamin A are sometimes added to food to enhance their nutritional quality or to replace nutrients lost during processing. Optional To learn more about allergens and additives go to page 237 in the third edition of the FDA Fish and Fishery Products Hazards and Controls Guide. To see a partial list of prohibited substances (Part 189 of Title 21 of the Code of Federal Regulations - "Substances Prohibited from Use in Human Food") visit this web site: http:// www.access.gpo.gov/nara/cfr/waisidx_99/21cfr189_99.html Seafood HACCP Alliance Training Course 2-28 Food Safety Hazards Unintentionally or Incidentally Added Chemicals Chemicals can become part of a food without being intentionally added. These incidental chemicals might already be in a food product or ingredient when it's received. For example, certain seafood may contain small but legal residues of approved antibiotics or environmental chemical contaminants like PCBs or mercury. Packaging materials that are in direct contact with ingredients or the product can be a source of incidental chemicals, such as sanitizers or inks. Most incidental chemicals have no effect on food safety, and others are only a concern if they are present in too high an amount. Incidental chemicals also include accidental additions of prohibited substances such as poisons or insecticides that may not be allowed at any level. Examples of Incidental or Unintentional Added Chemical Contaminants Environmental Pollutants Environmental pollutants like PCBs, mercury, cadmium etc. and agricultural chemicals like pesticides and herbicides may accumulate in certain species of fish or shellfish harvested from contaminated areas. Federal tolerances, action levels, and guidance levels are established for some of the most toxic and persistent contaminants in fish. These levels are used by states to determine health risks and to close waters to commercial harvesting or issue consumption advisories to sport fishermen. This chemical hazard is primarily a concern for fish harvested in fresh waters or near shore coastal waters, and is not likely to be a concern for fish harvested in deeper off shore ocean waters. Consumer health risks are associated with long term exposure to these contaminants. The hazard is controlled by harvesting or growing fish in waters that are not contaminated. Cooking and other processing procedures cannot be used to control this hazard. Optional To learn more about environmental chemical contaminants go to page 105 in the third edition of the FDA Fish and Fisheries Products Hazards and Controls Guide. To find out which species of fish and shellfish may be susceptible to this hazard go to pages 16-44 in the third edition of the FDA Fish and Fisheries Products Hazards and Controls Guide. Seafood HACCP Alliance Training Course 2-29 Aquaculture Drugs Aquaculture drugs are sometimes used to treat or prevent disease, stimulate reproduction, or tranquilize fish. Drugs must be approved before they can be used, and they must be used according to instructions. Unregulated drugs or drug use can be a potential human health hazard. The hazard is controlled by assuring that growers use only approved drugs and the drugs are used properly. Optional To learn more about aquaculture drugs go to page 127 in the third edition of the FDA Fish and Fisheries Products Hazards and Controls Guide. Cleaning and Maintenance Chemicals Cleaning and maintenance chemicals like acids, caustics, sanitizers, lubricants, paints etc. can cause chemical burns or may be toxic if present in food. These chemicals would be most likely to pose a hazard as a result of accidents, spills or inadequate maintenance of equipment or facilities. Sanitation procedures that address the use and proper storage of chemicals and the construction and maintenance of facilities and equipment used in food handling or processing operations are generally used to control this type of chemical hazard. Optional To see the current Good Manufacturing Practices (Part 110 of Title 21 of the Code of Federal Regulations) see page 259 of the Seafood HACCP Alliance training manual "Blue Book". Seafood HACCP Alliance Training Course 2-30 Check Your Knowledge 2 Now you need to return to Module 2 via the Internet. Click through the text pages until you get to the Check Your Knowledge page (page 2-30). Submit your answers before moving on to page 2-31. Good Luck! Seafood HACCP Alliance Training Course 2-31 Food Safety Hazards What are Physical Hazards? Physical hazards include any potentially harmful extraneous matter not normally found in food. When a consumer mistakenly eats the foreign material or object, it can cause choking, injury or other adverse health effects. Physical hazards are the most commonly reported consumer complaints because the injury occurs immediately or soon after eating, and the source of the hazard is often easy to identify. Physical Hazards can be controlled by: • Preventing foreign objects from getting into food. • Using metal detectors or other techniques to detect hazards in food. Types of materials that can be physical hazards in foods. Metal or metal fragments can get into food from food processing or handling equipment like saws or mixers that have metal blades, wire mesh conveyor belts, screens, can openers and portion control equipment. Other sources of metal fragments can come from buckshot, wire, staples, building materials, and employees. Metal fragments can cause a variety of injuries to consumers such as cuts, punctures, or broken teeth. This hazard is controlled by preventing or minimizing equipment malfunctions and using monitoring tools such as metal detectors when necessary. Glass and other foreign material can get into food from containers like glass jars, light bulbs that explode, or other objects from the plant or plant workers. Glass and other materials can physically harm consumers by causing cuts, bleeding, or choking. Preventing contamination is the most effective way to control these hazards. Bones in fish are generally considered a quality defect rather than a food safety hazard even though they can cause physical injury to the consumer. The reason is that bones are a normal part of the product and not a foreign material like metal or glass that is not normally part of the product. Processors have a responsibility to minimize uncontrollable quality defects but under normal conditions they cannot be completely eliminated. Optional To learn more about the physical hazard of metal inclusion go to page 249 in the third edition of the FDA Fish and Fisheries Products Hazards and Controls Guide. To learn more about the physical hazard of glass inclusion go to page 259 in the third edition of the FDA Fish and Fisheries Products Hazards and Controls Guide Seafood HACCP Alliance Training Course 2-32 Check Your Knowledge 3 Now you need to return to Module 2 via the Internet. Click through the text pages until you get to the Check Your Knowledge page (page 2-32). Submit your answers before moving on to Module 3. Good Luck!