* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Self -Excited DC Motor

History of electric power transmission wikipedia , lookup

Stray voltage wikipedia , lookup

Brushless DC electric motor wikipedia , lookup

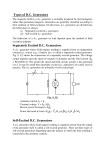

Voltage optimisation wikipedia , lookup

Mains electricity wikipedia , lookup

Power engineering wikipedia , lookup

Resonant inductive coupling wikipedia , lookup

Skin effect wikipedia , lookup

Three-phase electric power wikipedia , lookup

Buck converter wikipedia , lookup

Rectiverter wikipedia , lookup

Transformer wikipedia , lookup

Electrification wikipedia , lookup

Electric motor wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Alternating current wikipedia , lookup

Induction motor wikipedia , lookup

Commutator (electric) wikipedia , lookup

Electric machine wikipedia , lookup

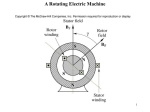

UNIT-4 DC MACHINES 2 marks What is the principle of a dc generator? Answer: A generator is a device which converts mechanical energy into electrical energy. There are two types of generators. They are a) AC Generator and b) DC Generator. An ac generator produces alternating voltage and a dc generator produces direct voltage. They work on the principle of Faraday’s law of electromagnetic induction (shortly referred as EMI). According to this law, when a conductor moves in a magnetic field it cuts magnetic lines force and there is rate of flux linking the conductor due to which an Emf is induced in the conductor. The magnitude of this induced Emf depends upon the rate of change of flux (magnetic line force) linkage with the conductor. This Emf will cause an current to flow if the conductor circuit is closed. 2. Explain the concept of excitation of a dc machine? Answer: An electric generator or electric motor consists of a rotor spinning in a magnetic field. The magnetic field may be produced by permanent magnets or by field coils. In the case of a machine with field coils, a current must flow in the coils to generate the field, otherwise no power is transferred to or from the rotor. The process of generating a magnetic field by means of an electric current is called excitation of a dc machine. Thus the magnetic field in a dc machine is produced by even excitation. 3. What is the main purpose of laminating the core of a dc generator? We = Bm2F2V2t Answer: During the operation of a dc generator small currents flow in the core material which are termed as eddy currents. The loss because of these current is termed as Eddy current loss. It is given by, Where We= Eddy current loss Bm = max flux density F = Supply frequency V = volume of core t=thickness of core So as Eddy current losses are directly proportional to area of armature or more precisely the path of motion. To minimise these eddy current losses core is laminated. In laminated armature eddy current losses are reduced to very less or '0' quantity. That is why armature of DC machines (either motor or generator) is laminated. 4. Explain the principle of a dc motor? Answer: A DC motor is a machine which converts electrical energy into mechanical energy. The operating principle of a dc motor is , when a current carrying conductor is placed in magnetic field it experiences force. The direction force is formed by using Flemings’ left hand rule. 5. Explain separately excited dc motor? Answer: When the field winding of a dc machine is supplied from an external source, it is termed as a separately excited dc motor. Vt= Eb +IaRa+Vbrushes Ia=Il Ia=Il Ia=armature current, Ra=armature resistance, Vbrushes=voltage across brushes. Vt=terminal voltage, Il =load current, Induced Emf = ǾPNZ/60*A 3 Marks What are the different types of dc generators? Answer: Based on the excitation dc Generators are classified into two types. They are i) separately excited dc generator ii) Self excited dc generator The self-excited dc generators are further classified as DC shunt generator DC series generator DC compound generator Again the DC compound generators are divided into long shunt and short shunt dc generators. 2. What are the losses in a dc machine? Answer: Losses in a dc machine are classified into three types. They are Iron loss Copper loss Mechanical losses The Iron loss in a machine is due to the material of the core and further divided into two types. They are hysteresis and Eddy current losses. The copper loss is because of resistance of the conductor used in the machine. Mechanical losses constitute of friction and windage losses. 3. Explain the concept of back Emf in a dc motor? Answer: When the armature of a d.c. motor rotates under the influence of the driving torque, the armature conductors move through the magnetic field and hence e.m.f. is induced in them as in a generator. The induced e.m.f. acts in opposite direction to the applied voltage V (Lenz’s law) and in known as back or counter e.m.f. Eb. The back emf Eb= PΦZN/60 A is always less than the applied voltage V, although this difference is small when the motor is running under normal conditions. 4. Explain why the speed of dc shunt motor is constant? Answer: In dc shunt motor flux produced by field winding is proportional to field current(Ish). Here the input voltage is constant so field current and flux is also constant. Therefore, dc shunt motor is also called a constant flux or constant speed motor 10 Marks Derive the Emf equation of a dc generator? Answer: In a dc generator, for one revolution of the conductor, Let, Φ = Flux produced by each pole in weber (Wb) P = number of poles in the DC generator. therefore, Total flux produced by all the poles is ΦP Time taken to complete one revolution is 60/N Where, N = speed of the armature conductor in rpm. Now according to Faraday’s law of induction, the induced Emf of the armature conductor is denoted by “e” which is equal to rate of cutting the flux. Therefore, Induced Emf of one conductor is Derivation for Induced EMF for DC Generator Let us suppose there are Z total numbers of conductor in a generator, and arranged in such a manner that all parallel paths are always in series. Here, Z = total numbers of conductor A = number of parallel paths Then, Z/A = number of conductors connected in series We know that induced emf in each path is same across the line Therefore, Induced emf of DC generator E = emf of one conductor × number of conductor connected in series. Induced emf of DC generator is For a Simple wave wound generator Numbers of parallel paths are only 2 = A Therefore, Induced emf for wave type of winding generator is Simple lap-wound generator Here, number of parallel paths is equal to number of conductors in one path i.e. P = A Therefore, Induced emf for lap-wound generator is 2. What are the different types of DC generators and explain them briefly. Answer: The behavior of a dc generator on load depends upon the method of field excitation adopted. Separately Excited D.C. Generators A dc generator whose field magnet winding is supplied from an independent external d.c. source (e.g., a battery etc.) is called a separately excited generator. Figure shows the connections of a separately excited generator. The voltage output depends upon the speed of rotation of armature and the field current (Eg = φZNP/60 A). The greater the speed and field current, greater is the generated e.m.f. It may be noted that separately excited d.c. generators are rarely used in practice. The d.c. generators are normally of self excited type. Armature current, Ia = IL Terminal voltage, V = Eg - IaRa Electric power developed = EgIa Power delivered to load = EgIa - I R = I E - I R = VIa Self-Excited D.C. Generators A d.c. generator whose field magnet winding is supplied current from the output of the generator itself is called a self-excited generator. There are three types of self-excited generators depending upon the manner in which the field winding is connected to the armature, namely; i. Series generator ii. Shunt generator iii. Compound generator Series generator In a series wound generator, the field winding is connected in series with armature winding so that whole armature current flows through the field winding as well as the load. Figure shows the connections of a series wound generator. Since the field winding carries the whole of load current, it has a few turns of thick wire having low resistance. Series generators are rarely used except for special purposes e.g., as boosters. Armature current, Ia = Ise = IL = I(say) Terminal voltage, V = EG - I(Ra + Rse) Power developed in armature = EgIa Power delivered to load Shunt generator In a shunt generator, the field winding is connected in parallel with the armature winding so that terminal voltage of the generator is applied across it. The shunt field winding has many turns of fine wire having high resistance. Therefore, only a part of armature current flows through shunt field winding and the rest flows through the load. Fig. (1.34) shows the connections of a shuntwound generator. Shunt field current, Ish = V/Rsh Armature current, Ia = IL + Ish Terminal voltage, V = Eg - IaRa Power developed in armature = EgIa Power delivered to load = VIL Compound generator In a compound-wound generator, there are two sets of field windings on each pole - one is in series and the other in parallel with the armature. A compound wound generator may be: • Short Shunt in which only shunt field winding is in parallel with the armature winding. • Long Shunt in which shunt field winding is in parallel with both series field and armature winding. Long shunt Series field current, Ise = Ia = IL + Ish Shunt field current, Ish = V/Rsh Terminal voltage, V = Eg - Ia(Ra + Rse) Power developed in armature = EgIa Power delivered to load = VIL Short shunt Series field current, Ise = IL Shunt field current, Terminal voltage, V = Eg - IaRa - IseRse Power developed in armature = EgIa Power delivered to load = VIL 3. What are the losses in a dc machine? Answer: The various losses in a DC machine whether it is a motor or a generator are classified into three groups as: (a) Copper losses (b) Iron or core losses (c) Mechanical losses (a) Copper losses: The copper losses are the losses taking place due to the current flowing in a winding. Armature copper loss = Where = Armature winding resistance Armature current Shunt field copper loss = Where = Shunt field winding resistance = Shunt filed current Series field copper loss = Where = Series field winding resistance = Series field current Iron or core Losses: These losses are also called magnetic losses. These losses include hysteresis loss and eddy current loss. The hysteresis is proportional to the frequency and the maximum flux density in the air gap and is given by, Hysteresis loss = Where watts = Steinmetz hysteresis coefficient V = Volume of core in f = frequency of magnetic reversals. This loss is basically due to reversal of magnetization of the armature core. The eddy currents loss exists due to eddy currents. When armature core rotates, it cuts the magnetic flux and e.m.f. gets induced in the core. This induced e.m.f. sets up eddy currents which cause the power loss. This loss is given by, Eddy currents = Where watts K = Constant t = Thickness of each lamination V = Volume of core f = Frequency of magnetic reversals The hysteresis loss is minimized by selecting the core material having low hysteresis coefficient. While Eddy current loss is minimized by selecting the laminated construction for the core. (c) Mechanical losses: These losses consist of friction and windage losses. Some power is required to overcome mechanical friction and wind resistance at the shaft. Thus for a DC machine, Total losses = constant losses + variable losses 4.Explain the construction of dc machine( generator or motor)? Answer: The dc generators and dc motors have the same general construction. In fact, when the machine is being assembled, the workmen usually do not know whether it is a dc generator or motor. Any dc generator can be run as a dc motor and vice-versa. All dc machines have five principal components (i) Field system (ii) Armature core (iii) Armature winding (iv) Commutator (v) Brushes The diagram given below represents the various parts of a DC machine. Field system: The function of the field system is to produce uniform magnetic field within which the armature rotates. It consists of a number of salient poles (of course, even number) bolted to the inside of circular frame (generally called yoke). The yoke is usually made of solid cast steel whereas the pole pieces are composed of stacked laminations. Field coils are mounted on the poles and carry the dc exciting current. The field coils are connected in such a way that adjacent poles have opposite polarity. The m.m.f. developed by the field coils produces a magnetic flux that passes through the pole pieces, the air gap, the armature and the frame. Practical d.c. machines have air gaps ranging from 0.5 mm to 1.5 mm. Since armature and field systems are composed of materials that have high permeability, most of the m.m.f. of field coils is required to set up flux in the air gap. By reducing the length of air gap, we can reduce the size of field coils (i.e. number of turns). ii) Armature core: iii) The armature core is keyed to the machine shaft and rotates between the field poles. It consists of slotted soft-iron laminations (about 0.4 to 0.6 mm thick) that are stacked to form a cylindrical core as shown in Fig. The laminations (See Fig.) are individually coated with a thin insulating film so that they do not come in electrical contact with each other. The purpose of laminating the core is to reduce the eddy current loss. The laminations are slotted to accommodate and provide mechanical security to the armature winding and to give shorter air gap for the flux to cross between the pole face and the armature “teeth”. Armature winding: The slots of the armature core hold insulated conductors that are connected in a suitable manner. This is known as armature winding. This is the winding in which “working” e.m.f. is induced. The armature conductors are connected in series-parallel; the conductors being connected in series so as to increase the voltage and in parallel paths so as to increase the current. The armature winding of a d.c. machine is a closed-circuit winding; the conductors being connected in a symmetrical manner forming a closed loop or series of closed loops. iv) Commutator: A commutator is a mechanical rectifier which converts the alternating voltage generated in the armature winding into direct voltage across the brushes. The commutator is made of copper segments insulated from each other by mica sheets and mounted on the shaft of the machine. The armature conductors are soldered to the commutator segments in a suitable manner to give rise to the armature winding. Depending upon the manner in which the armature conductors are connected to the commutator segments, there are two types of armature winding in a d.c. machine viz., (a) lap winding (b) wave winding. Great care is taken in building the commutator because any eccentricity will cause the brushes to bounce, producing unacceptable sparking. The sparks may bum the brushes and overheat and carbonise the commutator. v) Brushes: The purpose of brushes is to ensure electrical connections between the rotating commutator and stationary external load circuit. The brushes are made of carbon and rest on the commutator. The brush pressure is adjusted by means of adjustable springs If the brush pressure is very large, the friction produces heating of the commutator and the brushes. 5. Derive the expression for torque in a dc motor? Answer: Torque Equation of a DC Motor: When armature conductors of a DC motor carry current in the presence of stator field flux, a mechanical torque is developed between the armature and the stator. Torque is given by the product of the force and the radius at which this force acts. Torque T = F × r (N-m) …where, F = force and r = radius of the armature Work done by this force in once revolution = Force × distance = F × 2πr circumference of the armature) (where, 2πr = Net power developed in the armature = word done / time = (force × circumference × no. of revolutions) / time = (F × 2πr × N) / 60 (Joules per second) . But, F × r = T and 2πN/60 = angular velocity ω in radians per second. Net power developed in the armature = P = T × ω (Joules per second) Armature Torque (Ta): The power developed in the armature can be given as, Pa = Ta × ω = Ta × 2πN/60 The mechanical power developed in the armature is converted from the electrical power, Therefore, mechanical power = electrical power That means, Ta × 2πN/60 = Eb.Ia We know, Eb = PΦNZ / 60A Therefore, Ta × 2πN/60 = (PΦNZ / 60A) × Ia Rearranging the above equation, Ta = (PZ / 2πA) × Φ.Ia (N-m) The term (PZ / 2πA) is practically constant for a DC machine. Thus, armature torque is directly proportional to the product of the flux and the armature current i.e. Ta ∝ΦIa Shaft Torque (Tsh): Due to iron and friction losses in a dc machine, the total developed armature torque is not available at the shaft of the machine. Some torque is lost, and therefore, shaft torque is always less than the armature torque. Shaft torque of a DC motor is given as, Tsh = output in watts / (2πN/60) ....(where, N is speed in RPM) 6. What are the different types of DC motors and explain with diagrams? Answer: Separately Excited DC Motor As the name suggests, in case of a separately excited DC motor the supply is given separately to the field and armature windings. The main distinguishing fact in these types of DC motor is that, the armature current does not flow through the field windings, as the field winding is energized from a separate external source of DC current Self -Excited DC Motor In case of self -excited DC motor, the field winding is connected either in series or in parallel or partly in series, partly in parallel to the armature winding, and on this basis its further classified as:Shunt wound DC motor. Series wound DC motor. Compound wound DC motor. Let’s now go into the details of these types of self -excited DC motor. Shunt Wound DC Motor In case of a shunt wound DC motor or more specifically shunt wound self excited DC motor, the field windings are exposed to the entire terminal voltage as they are connected in parallel to the armature winding Series Wound DC Motor In case of a series wound self excited DC motor or simply series wound DC motor, the entire armature current flows through the field winding as its connected in series to the armature winding. The series wound self excited DC motor is diagrammatically represented below for clear understanding. Compound Wound DC Motor The compound excitation characteristic in a dc motor can be obtained by combining the operational characteristic of both the shunt and series excited dc motor. The compound wound self excited DC motor or simply compound wound DC motor essentially contains the field winding connected both in series and in parallel to the armature winding as shown in the figure below: The excitation of compound wound DC motor can be of two types depending on the nature of compounding. Cumulative Compound DC Motor When the shunt field flux assists the main field flux, produced by the main field connected in series to the armature winding then its called cumulative compound DC motor. Differential Compound DC Motor In case of a differentially compounded self excited DC motor i.e. differential compound DC motor, the arrangement of shunt and series winding is such that the field flux produced by the shunt field winding diminishes the effect of flux by the main series field winding. Short Shunt DC Motor If the shunt field winding is only parallel to the armature winding and not the series field winding then its known as short shunt DC motor or more specifically short shunt type compound wound DC motor. Long Shunt DC Motor If the shunt field winding is parallel to both the armature winding and the series field winding then it’s known as long shunt type compounded wound DC motor or simply long shunt DC motor. Short shunt and long shunt type motors have been shown in the diagram below. 7. What is efficiency and derive the condition for maximum efficiency of dc generator? Answer: Efficiency is simply defined as the ratio of output power to the input power. Ŋ=output/input=output/(output + losses) There are 3 types of losses in a dc machine. Copper loss: This loss is because of the resistance of armature winding and shunt or series field winding. Units:watts Wcu=Ia2Ra+Ish2Rsh+Ise2Rse b)Iron loss: This loss is because of the core material and is classified into two types: i)Hysterisis loss: Wh=Bm1.6fv Bm=max flux density F=frequency V= volume of core This is because of reversal of magnetization ii)Eddy current loss: During the operation of dc machine small currents flow in the core material. The loss because of these current is eddy current loss. It is given by We=Bm2f2V2t t=thickness of core iii)Mechanical loss: A dc machine consist of moving parts so the losses in the moving parts are frictionless loss and windage loss and these are termed as mechanical losses. Iron loss and mechanical loss together are termed as constant losses and copper loss is termed as variable loss. Maximum efficiency of dc machine is attained when copper loss is equal to constant loss. Ղ=VtIL/VtIL+Wc+Wcu Ղmax=when Wc=Wcu Output of a dc generator is VtIL Ia=Ish+IL and Ia=IL(approx) 2 2 2 And losses=Wcu+Ia Ra+Ish Rsh+Ise Rse 2 Ղ= VtIa/VtIa+Wcu+Ia Ra When dՂ/dIa=0 we get max efficiency on further calculation, We get Wc=Ia2Ra