* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Power Requirements - Rockwell Automation Knowledgebase

Solar micro-inverter wikipedia , lookup

Electrification wikipedia , lookup

Electrical substation wikipedia , lookup

Stray voltage wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Opto-isolator wikipedia , lookup

Power over Ethernet wikipedia , lookup

Power inverter wikipedia , lookup

Power factor wikipedia , lookup

Chirp spectrum wikipedia , lookup

Electric power system wikipedia , lookup

History of electric power transmission wikipedia , lookup

Audio power wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Utility frequency wikipedia , lookup

Power engineering wikipedia , lookup

Voltage optimisation wikipedia , lookup

Buck converter wikipedia , lookup

Distribution management system wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Power electronics wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Mains electricity wikipedia , lookup

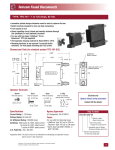

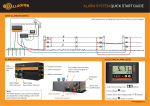

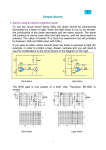

INFORMATION CONCERNING THE DIGITAL METERING SYSTEM 'DMS' CUTLER HAMMER I/Q 4130 Updated 1/25/2000 NOTE: The “I/Q DP-4000” is similar to the “I/Q Data Plus” (Used until late 1997) both electrically (Same Input devices required, although connection points may be different and it provides some extra features) and mechanically (Same mounting dimensions), and it can be used as a direct substitute. 01) The meter is a Cutler-Hammer (Westinghouse) 'IQ DP-4130'. 02) The meter used in MCC’s (2190-B_C-_-86KCXXX) is A-B part number 22996-011-02. 1) Designed for operation from 110 to 600 volts, (110, 120, 208, 220, 240, 380, 416, 460, 480, 577 and 600) 50/60 HZ and 3 or 4 wire via external “DIP” switches. (10VA power requirement) 2) Designed to operate with 3 current inputs of 5 amp. Current Transformer with ratio's from 5/5 to 12800/5 can be used. Ratio's are set via external “DIP” switches. 3) A front panel read-out supplies: A) AC line currents. (Phase A, B & C) B) AC line to line voltages. (Phase A-B, B-C, C-A) C) AC line to neutral voltage. (Four-Wire Systems) D) Watts. E) Vars. F) Power Factor. G) VA. H) Frequency. I) Watt-Hours. J) Var-Hours. K) VA-Hours. L) Percent Total Harmonic Distortion (%THD) for Amps and Volts. M) Demand Current, Watts, Vars and VA. N) Minimum Current, Volts, Watts, Vars, VA, Power Factor and Frequency. O) Maximum Current, Volts, Watts, Vars, VA, Power Factor and Frequency. 4) Alarm 1/Alarm 2 contacts are brought out to rear mounted terminal block. (Resistive rating 10A/115VAC-30VDC) Contact operation is set-up via external mounted “DIP” switches: (Alarm 1/Alarm 2 Can be set to monitor the following) A) Phase loss a) Voltage.(any phase - 50% of normal) b) Current. (smallest phase is 6.25% of largest phase) B) Phase unbalance. (line voltage +/- nominal in ranges from 5 to 40%, set via "dip" switches.) C) Phase reversal. (A-B-C or C-B-A Rotation Set by “dip” switches, Absolute Monitoring) D) Under voltage. (95% to 60%, set by “DIP” switches.) E) Over voltage. (105% to 140%, set by “DIP” switches.) 5) Alarm 1/Alarm 2 contact: A) Can be set for manual/auto reset after an alarm. B) Operate independent of each other. C) Can be set for an alarm delay of 1 to 20 seconds. D) Can be set for a reset delay of 1 to 120 seconds. E) Auto reset mode: Will automatically reset the alarm when the fault condition is cleared. An “Alarm Data” Button on the front panel provides viewing of last alarm trip condition. 1 of 4 INFORMATION CONCERNING THE DIGITAL METERING SYSTEM 'DMS' CUTLER HAMMER I/Q 4130 Updated 1/25/2000 03) When the meter ships from Cutler-Hammer it is a 1 piece unit, consisting of a removable power module and chassis, or read-out module: (face plate) 1) A-B Packaged Control Products Division installs the power module separately on a stationary mounting plate.(3 phase Power connect to this part of unit.) 2) The chassis is mounted to the door. (C.T. Connections, Alarm 1/Alarm 2 contacts or external options connect to this part of the unit.) 3) Power module and chassis are connected together with a 36" ribbon cable, A-B part number 22996-011-03. 2 of 4 INFORMATION CONCERNING THE DIGITAL METERING SYSTEM 'DMS' CUTLER HAMMER I/Q 4130 Updated 1/25/2000 04) Pushbutton Operation: 1) Reset: After an alarm event, the Reset pushbutton allows you to reset the alarms. 2) Up/Down: The Up/Down pushbuttons step through the items that the IQ DP-4000 monitors. If you press the up and Down buttons at the same time, the “INCOM” network address for your unit appears in the display window (If present). It monitors the following items: A) IA Amps B) IB Amps C) IC Amps D) VA-B Volts E) VB-C Volts F) VC-A Volts G) VA-N Volts H) VB-N Volts I) VC-N Volts J) Watts K) Vars L) VA M) Power Factor (Apparent and Displacement) N) Frequency O) Watt-Hours P) Var Hours Q) VA-Hours Each time you push the UP or DOWN Pushbuttons, the LED to the left of the selected item illuminates. At the same time, the present operating value corresponding to that item is in the display window. 3) Alarm Data: The Alarm Data pushbutton allows you to toggle between Alarm 1, Alarm 2 and the present metered values. A blinking LED indicates you are viewing the snapshot (Data saved at the time an alarm condition occurred for that particular alarm.)An LED that is constantly illuminated indicates an active alarm condition for that particular alarm. (NOTE: The alarm LED will always blink when being viewed, Even for an active alarm.) If you push the Alarm Data button before there has been an alarm condition, no light appears beside the alarm. 4) Monitor Pushbuttons: A) Metered: The metered pushbutton displays the metered value for all the parameters on the Operator Panel. (Will work with Minimum and Maximum to display Minimum and Maximum metered values.) B) %THD: This button displays Percent Total Harmonic Distortion for the amps and volts for each phase. (Will work with Minimum and Maximum to display Minimum and Maximum metered values.) C) Demand: The Demand button displays the current for each phase, as well as the demand Watts, Vars and VA. (Will work with Minimum and Maximum to display Minimum and Maximum metered values.) D) Minimum: This button displays the minimum values for all currents and voltages as well and Watts, Vars, VA, Power Factor, and Frequency. E) Maximum: This button displays the maximum values for all currents and voltages as well as Watts, Vars, VA, Power Factor and Frequency. 5) Pushbutton Combinations: 3 of 4 INFORMATION CONCERNING THE DIGITAL METERING SYSTEM 'DMS' CUTLER HAMMER I/Q 4130 Updated 1/25/2000 A) Reset and Metered: Holding both buttons for 3 to 4 seconds will reset the Min./Max. values for all metered parameters. B) Reset and %THD: Holding both buttons for 3 to 4 seconds will reset Max. value for all %THD Parameters. C) Reset and Demand: Holding both buttons for 3 to 4 seconds will reset the Max. values for the Demand Parameters. D) Up and Down: Holding both buttons will display the “INCOM” Address if present. E) Minimum and Maximum: Holding both buttons will display the revision of firmware the device is currently using. 05) Programming is Via an External mounted 8 bank “DIP” switch, Miniature 15 position selector switch, program (SAVE) button and “LED” Program Bank, all located on the back of the meter. Programming is accomplished by setting the selector switch to the proper position, setting Each of the 8 “DIP” switches to the proper position and holding the program button for 3 to 5 seconds or until the program light (Tenth “LED”) on the program “LED” bank indicate. (NOTE: All “DIP” switches must be set to the proper position for each selector switch setting.) FUNCTION SPECIFICATION PT burden (3 Phase Power Module) 10VA PT Burden (Separate Source Power Module) 0.02 VA CT Burden 0.003 VA 50/60 HZ Nominal Line +/- 20% -20 to +70 Deg “C” (-4 to + 158 Deg “F”) -30 to +85 Deg “C” (-22 to +185 Deg “F”) 5 to 95% RH non-condensing ¼ Amp ¾ Amp, 6000Volt Buss type KTK-R-3/4 (3 required) 10 Amps @ 1240/240 VAC (Resistive) 10 Amps @ 30 VDC (Resistive) Power Requirements Frequency Line Characteristics Operating Temperature Storage Temperature Humidity Fuses Alarm Contact Rating METERING SPECIFICATIONS Item Displayed Through IMPACC Local Display AC Amperes Phase A, B , C +/- 0.3% +/- 0.3% +/- 1 Digit AC Voltage Phase A-B, B-C, C-A, A-N, B-N, C-N +/- 0.3% +/- 0.3% +/- 1 Digit Watts +/- 0.6% +/- 0.6% +/- 1 Digit Vars +/- 0.6% +/- 0.6% +/- 1 Digit VA +/- 0.6% +/- 0.6% +/- 1 Digit Watt-Hours +/- 0.6% +/- 0.6% +/- 1 Digit Var-Hours +/- 0.6% +/- 0.6% +/- 1 Digit VA-Hours +/- 0.6% +/- 0.6% +/- 1 Digit Power Factor +/- 1% +/- 1% Frequency +/- 0.1 HZ +/- 0.1 HZ %THD Through th 31ST Harmonic NOTE: Accuracy is maintained from 3 to 250% of the full sales of the device. 4 of 4