* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Iza_MSthesis - Electrical and Computer Engineering

Power electronics wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Magnetic core wikipedia , lookup

Loudspeaker wikipedia , lookup

Crystal radio wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Radio transmitter design wikipedia , lookup

Valve RF amplifier wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Rectiverter wikipedia , lookup

Power MOSFET wikipedia , lookup

Index of electronics articles wikipedia , lookup

NORTHEASTERN UNIVERSITY

Graduate School of Engineering

Thesis Title: Design, Fabrication and Modeling of Microfabricated Inductively Coupled

Plasma Sources

Author: Felipe Iza

Department: Electrical and Computer Engineering

Approved for Thesis Requirement of the Master of Science Degree

______________________________________________________ _________________

Thesis Advisor: Jeffrey A. Hopwood

Date

______________________________________________________ _________________

Thesis Reader: Nicol E. McGruer

Date

______________________________________________________ _________________

Thesis Reader: Carey M. Rappaport

Date

______________________________________________________ _________________

Thesis Reader:

Date

______________________________________________________ _________________

Department Chair: Fabrizio Lombardi

Date

Graduate School Notified of Acceptance:

______________________________________________________ _________________

Director of the Graduate School: Yaman Yener

Date

NORTHEASTERN UNIVERSITY

Graduate School of Engineering

Thesis Title: Design, Fabrication and Modeling of Microfabricated Inductively Coupled

Plasma Sources

Author: Felipe Iza

Department: Electrical and Computer Engineering

Approved for Thesis Requirement of the Master of Science Degree

______________________________________________________ _________________

Thesis Advisor: J. A. Hopwood

Date

______________________________________________________ _________________

Thesis Reader: N. E. McGruer

Date

______________________________________________________ _________________

Thesis Reader: C. M. Rappaport

Date

______________________________________________________ _________________

Thesis Reader

Date

______________________________________________________ _________________

Department Chair: F. Lombardi

Date

Graduate School Notified of Acceptance:

______________________________________________________ _________________

Director of the Graduate School: Yaman Yener

Date

Copy Deposited in Library:

______________________________________________________ _________________

Reference Librarian

Date

DESIGN, FABRICATION AND MODELING OF MICROFABRICATED

INDUCTIVELY COUPLED PLASMA SOURCES

A Thesis Presented

by

Felipe Iza

to

The Department of Electrical and Computer Engineering

in partial fulfillment of the requirements

for the degree of

Master of Science

in

Electrical Engineering

in the field of

Electronic Circuits and Semiconductor Devices

Northeastern University

Boston, Massachusetts

July 2001

Design, Fabrication and Modeling of mICP Sources

Abstract

ABSTRACT

Microsystems that integrate mechanical and optical structures have been

fabricated for a wide range of applications in recent years. This thesis focuses on the

design, fabrication and performance of microfabricated inductively coupled plasma

(mICP) sources with the ultimate goal of integrating them in plasma-based microsystems.

Large ICP sources are extensively used in the semiconductor industry because of

their high efficiency, high ion density and plasma controllability. mICP sources,

however, present a poorer performance than their large system counterparts. It is the aim

of this thesis to investigate the factors that limit the performance of mICP sources in

order to obtain design guidelines for more efficient designs.

A typical mICP source consists of a planar spiral-like coil microfabricated on a

glass substrate. Using single-turn coils instead of spirals allow us to flip over the devices

such that the coil is adjacent to the plasma. This increases the coupling between the coil

and the plasma while keeping the fabrication process requirements down to one mask.

Previous mICP source experiments and models suggested that increasing the

frequency of operation would lead to better performance of mICP sources. Although this

is true at low frequencies, no efficiency improvement is observed at frequencies much

larger than the electron collision frequency (>3). A new model that incorporates the

effect of the electron inertia on the conductivity of the plasma seems to agree with the

experimental results.

ii

Design, Fabrication and Modeling of mICP Sources

Abstract

For mICP sources operating at ~1GHz the new model predicts maximum

efficiency at pressures of a few torr. The main factor limiting the efficiency of the device

at high frequency is the coil resistance, which is increased to ~20 times the DC value by

the proximity effect.

iii

To my fiancée, Myung Hee Kim,

and to my parents, Felipe Iza and Amparo Pérez,

for their love and support

iv

Design, Fabrication and Modeling of mICP Sources

Acknowledgements

ACKNOWLEDGMENTS

There are many people who in one way or another have helped me in coming to

Northeastern University and in completing this thesis. I would like to show them my

gratitude and thank all of them.

I want to express my deepest and sincere gratitude to my academic and thesis

advisor, Dr. J. A. Hopwood, for his guidance and support during these last two years. His

many helpful insights, suggestions and detail discussions have made the completion of

this work possible. Without his direction and motivation I would not have been able to

pursue this thesis in a field in which I had absolutely no background.

I would also like to express my gratitude to the rest of faculty, staff, and

colleagues at the Plasma Engineering Laboratory and the Microfabrication Laboratory

(MFL) Group at Northeastern University for their friendship, support and help. In

particular, I would like to thank Michael Miller for his not always appreciated work in

keeping the labs up and running, Weilin Hu for his practical suggestions working in the

lab, and Patricia Nieva, Xiaoqing (Vivian) Lu, Xiaoji Yang, and Juan Carlos Aceros for

their friendship and always interesting discussions.

I would also like to thank Claudia Costanzo, Program Director of the Commission

for Cultural, Educational and Scientific Exchange between the United States of America

and Spain, for giving me the opportunity to come to Boston under a Fulbright

scholarship, and her help and advice with the bureaucracy that is always hidden behind

v

Design, Fabrication and Modeling of mICP Sources

Acknowledgements

these scholarships. I would also want to thank ENDESA for sponsoring my studies

through the Fulbright Program.

Finally, I would like to express my deepest gratitude to Dr. Fernando Arizti for his

help and support when coming to the USA seemed almost impossible.

This project was also supported by the National Science Foundation under Grant

No. DMI-0078406.

vi

Design, Fabrication and Modeling of mICP Sources

Table of Contents

TABLE OF CONTENTS

ABSTRACT

ii

ACKNOWLEDGEMENTS

Error! Bookmark not defined.

TABLE OF CONTENTS

vii

1 .- INTRODUCTION

1

1.1 .- TYPES OF MICROPLASMA SOURCES

2

1.2 .- MICP SOURCES: PREVIOUS DESIGNS

4

1.3 .- WHAT IS PLASMA

7

1.3.1 .- Sheaths

8

1.3.2 .- Plasma Conductivity

11

2 .- NEW MICP SOURCE DESIGN

13

2.1 .- MICP SOURCE MODEL

13

2.2 .- FREQUENCY SELECTION

16

2.3 .- COUPLING COEFFICIENT IMPROVEMENTS

17

2.4 .- COIL PARAMETERS

21

2.4.1 .- Coil Resistance

21

2.4.2 .- Coil Inductance

22

2.5 .- PLASMA PARAMETERS

24

2.5.1 .- Plasma Resistance

24

2.5.2 .- Plasma Inductance

26

2.6 .- COIL WIDTH SELECTION

26

2.7 .- MATCHING NETWORK

27

3 .- FABRICATION

31

3.1 .- FABRICATION ISSUES

32

3.1.1 .- Photolithography

33

3.1.2 .- Gold Electroplating

34

vii

Design, Fabrication and Modeling of mICP Sources

Table of Contents

4 .- EXPERIMENT DESCRIPTION

36

4.1 .- SET UP

37

4.2 .- PROBES

39

4.2.1 .- Probe Design

42

5 .- PERFORMANCE OF THE NEW MICP SOURCE

5.1 .- ION DENSITY AND ELECTRON TEMPERATURE CALCULATION

44

44

5.1.1 .- Step 1: Plasma Potential

47

5.1.2 .- Step 2: Probes Potential

48

5.1.3 .- Step 3: Area Ratio

49

5.1.4 .- Step 4: Ion Current

49

5.1.5 .- Step 5: Electron temperature

51

5.1.6 .- Step 6: Ion density

52

5.2 .- FREQUENCY OF OPERATION AND MATCHING

52

5.3 .- ELECTRON TEMPERATURE

54

5.4 .- ION DENSITY

54

6 .- NEW MICP SOURCE MODEL

57

6.1 .- NEW PLASMA MODEL

57

6.2 .- NEW EFFICIENCY EXPRESSION

62

6.2.1 .- Efficiency As A Function Of The Frequency Of Operation

63

6.2.2 .- Efficiency As A Function Of The Power Absorbed By The Plasma

66

6.2.3 .- Efficiency As A Function Of Pressure

68

6.3 .- APPROXIMATION FOR LARGE AND MICROFABRICATED ICP SOURCES

71

6.3.1 .- Frequency Of Operation

73

6.3.2 .- Pressure And Power Absorbed By The Plasma

74

6.4 .- MODEL AND EXPERIMENTAL RESULTS AGREEMENT

76

7 .- LOSSES IN MICP SOURCES

77

7.1 .- SKIN EFFECT

77

7.2 .- PROXIMITY EFFECT

79

viii

Design, Fabrication and Modeling of mICP Sources

Table of Contents

7.3 .- CAPACITIVE COUPLING

85

7.4 .- EXPERIMENT RESULTS AND MODEL PREDICTIONS WITH LOSSES

86

8 .- CONCLUSIONS AND FUTURE WORK

87

9 .- REFERENCES

89

APPENDICES

91

APPENDIX I: MINIMUM GLASS THICKNESS

92

APPENDIX II: COUPLING COEFFICIENT

94

APPENDIX III: PROGRAM USED TO DESIGN THE NEW MICP SOURCES

95

APPENDIX IV: MATCHING NETWORK DESIGN

104

APPENDIX V: 5-MM SINGLE-TURN MICP SOURCE PARAMETERS

106

APPENDIX VI: FABRICATION PROCESS TRAVELER

107

APPENDIX VII: PROBE MEASUREMENT CURVE FITTING

109

APPENDIX VIII: PROXIMITY EFFECT IN A SINGLE TURN COIL

118

INDEX OF FIGURES

Figure 1.1 Voltage distribution in the plasma

9

Figure 1.2 Induced electric field in the plasma region

4

Figure 1.3 Ion density of three mICP sources made on copper clad epoxy board in

argon at 370mtorr, 1.3W [7]

5

Figure 1.4 Ion density created by different mICP sources @ 350mtorr, 1W

6

Figure 2.1 ICP source model

13

Figure 2.2 Equivalent ICP source model

14

Figure 2.3- Magnetic field in a mICP source

17

Figure 2.4 a) Multi-turn coil with cavity etched at the back of the wafer b) Single

turn coil flipped over

18

Figure 2.5 Multi-turn mICP source

19

Figure 2.6 Coupling coefficient as function of the separation between the coil and

the plasma

20

ix

Design, Fabrication and Modeling of mICP Sources

Table of Contents

Figure 2.7 Cross section of the coil

22

Figure 2.8 Wire loop

22

Figure 2.9 Wire loop approximation

23

Figure 2.10 Electric field and electron density distribution in the plasma region

25

Figure 2.11 Predicted power efficiency of a 5mm single loop mICP source

27

Figure 2.12 Matching network schematics

28

Figure 2.13 Single turn mICP source

29

Figure 3.1 mICP source on plastic substrate

32

Figure 3.2 Cracks in the photoresist

34

Figure 3.3 mICP sources fabricated a) DI water wet before electroplating b) Soapy

solution wet before electroplating

35

Figure 4.1 mICP source mounted on package and bonded to the glass tube

37

Figure 4.2 Experiment set up

38

Figure 4.3 Typical voltage-current characteristic for a single Langmuir

40

Figure 4.4 Typical voltage-current characteristic for a double probe measurement

41

Figure 4.5 Probes a) double probe b) coaxial probe

42

Figure 5.1 Typical voltage-current characteristic for a coaxial probe in the mICP

44

Figure 5.2 Coaxial probe schematic

46

Figure 5.3 Iterative process for calculating the electron temperature and the ion

density

47

Figure 5.4 Inner and outer conductor potential

49

Figure 5.5 Regions in the voltage-current characteristic of a coaxial probe

50

Figure 5.6 Ion current fitting

51

Figure 5.7 Ion density and the power reflection coefficient as function of frequency

for a constant amplitude input signal of –8dBm (~150mW) a) with the

25% additional tuning capacitor added b) without the additional tuning

capacitor. (Device in flipped over configuration)

53

Figure 5.8 Electron temperature a) Device I b) Device II (Flipped over)

54

Figure 5.9 Ion density generated by the new mICP sources

55

Figure 6.1 New ICP source model

58

x

Design, Fabrication and Modeling of mICP Sources

Table of Contents

Figure 6.2 Characteristic curves of a resistance inversely proportional to the power

it dissipates

59

Figure 6.3 Voltage across the plasma impedance

60

Figure 6.4 Equivalent circuit for the new ICP source model

60

Figure 6.5 ICP Source efficiency as function of the frequency of operation

64

Figure 6.6 Ion density vs. frequency of operation for 3 different mICP sources

operating in Argon at 300mtorr, 1.3W. From Hopwood et al. [7]

65

Figure 6.7 ICP Source efficiency as function of the power absorbed by the plasma

67

Figure 6.8 Efficiency as function of the power absorbed by the plasma and the

frequency of operation for a constant pressure

68

Figure 6.9 Equivalent Plasma Resistance

74

Figure 7.1 Non-uniform current distribution due to the skin effect

77

Figure 7.2 a) Current distribution in the coil b) Equivalent current distribution using

the skin depth

78

Figure 7.3 Eddy currents in the coil

80

Figure 7.4 Non-uniform current distribution due to the proximity effect

80

Figure 7.5 Coil Effective Resistance Decomposition

82

INDEX OF TABLES

Table 1.1 Comparison of different microplasma sources

4

Table 4.1 Test conditions

36

Table 6.1 Large and microfabricated ICP source comparison

72

Table 7.1 Coil resistance increment as function of frequency

79

Table 7.2 Efficiency loss due to the proximity effect when the frequency is

increased from 690 MHz to 818 MHz

84

xi

Design, Fabrication and Modeling of mICP Sources

Introduction

1.- INTRODUCTION

It was in 1965 when Gordon Moore, then Fairchild Semiconductor's R&D

director, made the famous observation that chip capacity doubles every 18 moths. Since

then the number of transistors on a chip has increased more than 3,200 times leaving

behind a knowledge and technology that in the last decades has been used to fabricate not

only transistors but also other structures in a micro-scale (micromachines).

The integration of microelectronic circuitry into micromachined structures brings

up the possibility of fabricating completely integrated systems (microsystems) that have

the same advantages of low cost, reliability and small size as traditional integrated

circuits. Microsystems that integrate mechanical and optical structures have been

fabricated for a wide range of applications including automotive, telecommunications,

biochemistry, bioengineering and consumer electronics.

This thesis focuses on the design, fabrication and performance of microfabricated

inductively coupled plasma (mICP) sources with the ultimate goal of integrating them in

a plasma-based microsystem. Although many large scale ICP sources use helical coils, 3dimensional structures are costly and hard to fabricate with conventional microfabrication

processes. Therefore planar structures are desirable for fabricating a cost effective

microplasma source. Plasma-based microsystems would find application in gas analyzers,

ion thrusters, sterilizers, plasma displays and pixel-addressable plasma processing.

Page - 1 -

Design, Fabrication and Modeling of mICP Sources

Introduction

ICP sources are typically modeled as air-core transformers. In this thesis we show

that the model used for large ICP systems is not appropriate to describe the performance

of microfabricated ICP sources operating at high frequencies. A new model that

incorporates the effects of the electron inertia and the power and pressure dependence of

the plasma impedance is presented in chapter 6. This new model agrees with the

experimental results obtained in this thesis as well as with the results from previous

generations of mICP sources.

1.1.- TYPES OF MICROPLASMA SOURCES

Several microplasma sources operating by different principles have been reported

in recent years. In this section we look at the advantages and disadvantages of each

approach, and thereby justify our interest in mICP sources.

Direct current (DC) plasma sources have been fabricated for optical emission

detectors [2],[3]. Although the voltage applied between the electrodes can be reduced as the

dimensions get smaller, DC microplasma sources still require high voltages (~800V)

which for certain applications can be inconvenient and dangerous. However these devices

are easy to fabricate, compact and require simple electronics to operate them. The main

drawback of these devices is the electrode erosion due to the constant bombardment of

ions driven by the perpendicular electric field. This erosion limits the usage of the

devices to few hours of operation.

Capacitive coupled plasma sources,[4],[5] present a longer life than DC sources

Page - 2 -

Design, Fabrication and Modeling of mICP Sources

Introduction

because the electrodes can be protected with low sputtering yield materials even if these

are insulating. Capacitive coupled plasma sources are simple to fabricate and compact,

but they require more complicated electronics than DC sources to drive them. The fact

that the electric field is perpendicular to the electrodes limits the ion density achievable

with these devices. As the power applied to the device increases, so does the energy lost

by the ions accelerated in the sheath regions resulting in little ion density gain. Typically

capacitive coupled plasma sources, although more efficient than DC sources, produce ion

densities 10 times smaller than inductively coupled or microwave plasma sources.

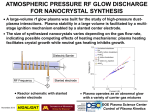

Large microwave plasma sources are popular due to their high efficiency.

However the dimensions of the device are strongly related to the frequency of operation.

A microfabricated plasma source of few millimeters would require frequencies of

operation of the order of 10 to 100 GHz, or by the same token, microwave sources

operating at ~1G would be of the order of several centimeters in size.[6]

Finally inductively coupled microplasma sources have been reported recently.[7],[8]

The schematic of a microfabricated inductively coupled plasma source is shown in Figure

1.1. A planar spiral like coil generates a magnetic field that induces an electric field in the

azimuthal direction. Since the electric field is parallel to the wall, increasing the power in

the device does not translate into a higher energy loss due to ions being accelerated in the

sheath region. Therefore, higher ion densities can be achieved than in DC and capacitive

coupled plasmas.

Page - 3 -

Design, Fabrication and Modeling of mICP Sources

Introduction

Coil

H

Glass wafer

Sea

l

Plasma

E

Glass tube

VACUUM REGION

Figure 1.1 Induced electric field in the plasma region

Table 1.1 summarizes qualitatively the pros and cons of different microplasma

sources in terms of their size, electronic complexity, plasma intensity and life of the

device.

Microplasma type

Size

Electronic

complexity

Plasma

density

Life

DC

Small

Simple

Low

Short

Capacitively coupled

Small

Medium

Medium

Medium

Inductively coupled

Medium

Medium

High

Long

Large

Complex

High

Long

Microwave

Table 1.1 Comparison of different microplasma sources

1.2.- MICP SOURCES: PREVIOUS DESIGNS

Several mICP sources have been developed at Northeastern University. This

section presents a review of these designs that help us to put the new design in

perspective and see the evolution in the performance of the mICP sources.

Page - 4 -

Design, Fabrication and Modeling of mICP Sources

Introduction

The first attempt to fabricate a miniaturized inductively plasma source was a

20-turn coil wound around a 6mm Pyrex tube. The performance of this device was

strongly limited by the losses in the coil, which is a concern in all mICP sources.

The next mICP sources were fabricated as planar spiral-like coils on a 1-oz copper

clad epoxy board. 3-turn 5-mm coils, 5-turn 10-mm coils and 6-turn 15-mm coils were

fabricated and tested. The planar structure of these devices makes them compatible with

microfabrication techniques. It was noticed that the efficiency of these devices increased

with the frequency of operation (See Figure 1.2), although the ion density obtained was

an order of magnitude lower than in large ICP sources.

1

.

2

e

+

1

0

1

.

2

e

+

1

0

1

.

0

e

+

1

0

IonDesity(cmIonDesity(cm -3 ) -3 )

1

.

0

e

+

1

0

8

.

0

e

+

9

8

.

0

e

+

9

6

.

0

e

+

9

6

.

0

e

+

9

4

.

0

e

+

9

4

.

0

e

+

9

2

.

0

e

+

9

2

.

0

e

+

9

0

.

0

0

0

.

0

0

1

0

0

1

0

0

2

0

0

3

0

0

2

0

0

3

0

0

F

r

e

q

u

e

n

c

y

(

M

H

z

)

1

5

m

m

c

o

i

l

1

0

m

m

c

o

i

l

1

5

m

m

c

o

i

l

5

m

m

c

o

i

l

1

0

m

m

c

o

i

l

5

m

m

c

o

i

l

4

0

0

5

0

0

4

0

0

5

0

0

F

r

e

q

u

e

n

c

y

(

M

H

z

)

Figure 1.2 Ion density of three mICP sources made on copper clad epoxy board in argon at

370mtorr, 1.3W [7]

Page - 5 -

Design, Fabrication and Modeling of mICP Sources

Introduction

This lower ion density is due to an increase in the surface to volume ratio of mICP

sources that leads to higher wall recombination. A low efficiency is also due to the losses

in the coils and perhaps due to a higher capacitive coupling between the coil and the

plasma. As mICP sources shrink down, these effects become more pronounced and lead

to worse efficiencies (lower ion densities for the same RF power).

The last generation of mICP sources is a 3-turn 5-mm spiral-like coil fabricated of

gold on a 700m thick glass wafer. It operates at ~450MHz and it can generate ion

densities of 1011cm-3 while consuming 3W.

Figure 1.3 shows the evolution in the efficiency of mICP sources including the

new design that is the subject of this thesis.

New mICP

source

IonDesity(cm -3 )

1

e

+

1

1

1

e

+

1

0

mICP source on

glass wafer

mICP source on

wound copper clad epoxy

on a Pyrex

board

tube

1

e

+

9Coil

1

e

+

8

01

0

02

0

03

0

04

0

05

0

06

0

07

0

08

0

09

0

0

F

r

e

q

u

e

n

c

y

(

M

H

z

)

Figure 1.3 Ion density created by different mICP sources @ 350mtorr, 1W

Page - 6 -

Design, Fabrication and Modeling of mICP Sources

Introduction

1.3.- WHAT IS PLASMA

Plasma, in the microfabrication context, is a weakly ionized gas in which free

electrons and ions move randomly in every direction. The term weakly ionized means

that the density of electrons and ions is much smaller than the density of neutral

molecules in the gas (typically less than 1%). Since free electrons are generated by

stripping electrons from neutral atoms, electron-ion pairs are generated and the number of

electrons and ions in the plasma is essentially the same. Therefore on average the plasma

can be considered neutral.

Energy is needed to strip electrons from neutrals in order to start and maintain the

plasma. This energy can be of various origins and in the case of mICP sources electrical

energy is used. If the energy flowing into the plasma is insufficient, the plasma

recombines into a neutral gas.

In a low pressure, electrically-driven plasma the electrons are much hotter than

the ions, and the plasma is said to be in non-thermal equilibrium. The high reactivity of

the ions generated in the plasma and the low temperature of the gas are used in the

semiconductor industry in many fabrication processes.

The next sections present basic relationships in plasma theory that will be needed

in future chapters. The expressions are not derived and the reader is referred to

reference [1] for a detailed explanation and derivation of these formulae.

Page - 7 -

Design, Fabrication and Modeling of mICP Sources

Introduction

1.3.1.- Sheaths

Although the plasma is essentially neutral, this is not true at plasma chamber walls

where the plasma forms a region called the sheath. In this region the ion density is larger

than the electron density. The formation of the sheath is due to the higher mobility of the

electrons that diffuse faster than the ions from the bulk of the plasma to the walls. As

electrons pile up at the walls, a potential is formed that repels additional electrons and

accelerates the ions toward the walls.

The potential difference between the walls (floating potential Vf) and the plasma

(plasma potential Vp) is such that the number of electrons reaching the wall balances out

with the number of ions so no net current flows. Between the sheath and the bulk of the

plasma there exists a region called the presheath where a small electric field exists to

match the boundary conditions in between the sheath and the bulk of the plasma (See

Figure 1.4).

Assuming that electrons follow the Boltzmann distribution, the electron flux to the

wall is given by:

1

e n es v e e

4

q(Vp Vf )

kTe

1

8 k Te

n es

e

4

π me

q(Vp Vf )

kTe

Eq. 1.1

where nes is the electron density at the edge of the sheath, v e the average electron

velocity, Te the electron temperature, me the electron mass, q the electron charge and k

Page - 8 -

Design, Fabrication and Modeling of mICP Sources

Introduction

the Boltzmann’s constant.

On the other hand, ions are accelerated by the field in the presheath to the Bohm

velocity and do not follow a Boltzmann distribution. The ion flux to the wall in terms of

the Bohm velocity (uB) is given by:

i nis u B nis

kTe

Mi

Eq. 1.2

where nis is the ion density at the edge of the sheath, and Mi the ion mass.

Sheath

Pre

sheath

Plasma Bulk

(ne ni)

Pre

sheath

Sheath

nes = nis

ni

ni

ne

ne

Wall

Wall

Sheath

Plasma

Potential

(Vp)

Floating

Potential

(Vf)

Pre

sheath

Plasma Bulk

(Vp)

Pre

sheath

Sheath

e

e

i

i

Wall

Wall

Figure 1.4 Voltage distribution in the plasma

An expression for the difference between the plasma potential and the floating

Page - 9 -

Design, Fabrication and Modeling of mICP Sources

Introduction

potential in terms of the electron temperature can be found by setting the electron flux

equal to the ion flux:

(Vp Vf )

1 k Te M i

ln

2 q

2 π me

Eq. 1.3

The ion and electron density at the edge of the sheath is related to the ion and

electron density in the bulk of the plasma:

n es n e e

1

2

n is n i e

1

2

Eq. 1.4

The Debye length is a characteristic length scale in a plasma. It is a measure of the

distance that the potential of a charged object penetrates into the plasma and is

proportional to the sheath thickness.

λ De

ε o Te

q ne

Eq. 1.5

where o is the vacuum permittivity.

For a biased body the sheath thickness (s) can be calculated using Child’s law:

2Vp V 4

2

s

λ De

3

Te

3

where V is the potential of the biased body.

Page - 10 -

Eq. 1.6

Design, Fabrication and Modeling of mICP Sources

Introduction

1.3.2.- Plasma Conductivity

Another important characteristic of the plasma that will be needed in future

chapters is the plasma conductivity. The plasma conductivity is given by:

σ

ε oω2pe

jω ν

Eq. 1.7

where pe is the electron plasma frequency, is the frequency of operation and the

electron-neutral collisional frequency.

The electron plasma frequency is the fundamental characteristic frequency of the

plasma and represents the frequency at which the electron cloud oscillates with respect to

the ion cloud. It is given by:

ω 2pe

q2ne

ε o me

Eq. 1.8

Combining Equation 1.6 and 1.7 we find another expression for the plasma

conductivity:

σ

q2ne 1

jω ν me

Eq. 1.9

This expression shows the dependence of the plasma conductivity on the electron

density. At low frequencies the plasma can be considered a poor conductor with

Page - 11 -

Design, Fabrication and Modeling of mICP Sources

Introduction

conductivity proportional to the electron density. However at high frequencies the

conductivity becomes complex and the plasma behaves inductively.

Page - 12 -

Design, Fabrication and Modeling of mICP Sources

New mICP Source Design

2.- NEW MICP SOURCE DESIGN

In this chapter we describe the motivation and the procedure followed to design

the new mICP source.

2.1.- MICP SOURCE MODEL

Modeling is a useful technique to understand the behavior of a system and

identify the parameters that affect its performance. Inductively couple plasma sources are

typically modeled as an air-core transformer with the coil (source) acting as the primary

of the transformer and the plasma (single current loop) as the secondary (Figure 2.1).

This model is a direct representation of the physical phenomena occurring in an

ICP source. Rc represents the coil resistance, Lc the coil inductance, Lp the inductance of

the plasma due to the single loop of current induced by the coil, Rp the plasma resistance

due to the collisions of the electrons within the current loop, and k the coupling

coefficient between the coil and the plasma.

Rc

I

1

V

Coil

Mk L c L p

Lc

I

Rp

Lp

2

Plasma

Figure 2.1 ICP source model

Page - 13 -

Design, Fabrication and Modeling of mICP Sources

New mICP Source Design

Simple manipulations of the circuit in Figure 2.1 lead to the following equivalent

circuit:

Rc

I

1

R eq R p

Req

R 2p ω2 L2p

L’ = Lc + Leq

R’

V

k 2ω 2 L p Lc

Leq L p

k 2ω 2 L p Lc

R 2p ω2 L2p

Figure 2.2 Equivalent ICP source model

where Req and Leq are the equivalent plasma resistance and inductance referred to the

primary of the transformer.

The power efficiency of an ICP source can then be calculated as the ratio of the

equivalent plasma resistance divided by the total resistance of the circuit in Figure 2.2:

η

R eq

R c R eq

k 2ω2 L p Lc R p

Eq. 2.1

R c R 2p ω 2 L2p R c k 2 ω 2 L p L c R p

This expression can be simplified for the case of a mICP source and a large ICP

system as follows:

η

R eq

R c R eq

k 2ω 2 L p Lc R p

R c R 2p k 2ω2 L p Lc R p

For R p ω L p

(mICP)

Eq. 2.2-a) b)

η

R eq

R c R eq

Page - 14 -

2

k Lc R p

R c L p k 2 Lc R p

For R p ω L p

(Large ICP)

Design, Fabrication and Modeling of mICP Sources

New mICP Source Design

It is clear that although the efficiency of a large ICP source does not depend on

the frequency of operation (a well-known experimental observation), for a mICP source

the efficiency depends on the square of the frequency. This fact had been reported in

previous mICP sources and will be further investigated in this work.

It should also be noted that the efficiency of both large and micromachined ICP

sources depends on the square of the coupling coefficient. Therefore the model predicts

that a relatively small improvement on the coupling coefficient and a small increase in

the frequency of operation can lead to much more efficient mICP sources since the

efficiency depends on the square of these two parameters.

The rest of the parameters that affect the efficiency do have a smaller impact than

the coupling coefficient and the frequency of operation although they should also be

taken into account during the design. Equation 2.2-a can be rewritten as :

η

R eq

R c R eq

1

For R p ω Lp

1 Rc Rp

1 2 2

k ω Lp Lp

(mICP)

Eq. 2.3

As we might expect, the efficiency gets better as the ratio between the resistance

and the inductance decreases. Therefore the coil should be designed to maximize the

inductance while minimizing the resistance. The same is true for the plasma, although its

parameters depend on the type of gas and the power supplied to the mICP source and

therefore they are not design variables.

Page - 15 -

Design, Fabrication and Modeling of mICP Sources

New mICP Source Design

The new mICP source is designed and tested to corroborate these predictions and

obtained more intense plasmas with a more efficient design.

2.2.- FREQUENCY SELECTION

Increasing the frequency of operation of mICP sources leads to better

performance. However, the frequency of operation is limited by three factors:

Physical: The operating frequency should be lower than the self-resonance

frequency of the coil.

Economical: High frequency electronics for a power supply might get too

expensive as the frequency increases and eventually limit the viability of a

plasma-based microdevice.

Practical: The signal generator used for the testing of the new mICP source

(HP8656A) and the power amplifier (EIN603L) do not go beyond 1GHz.

With this three factors in mind the frequency of operation for the new mICP

source was chosen to be 900MHz. This frequency is below the self-resonance frequency

of previous multi-turn coils and therefore should be well below the self-resonance of the

new mICP source which is based on a single loop coil. Moreover ~1GHz is in the

frequency range at which mobile phones and other telecommunication equipment work,

and therefore a final power supply design could take advantage of the electronics already

available at these frequencies. And finally, 900MHz is a frequency at which we can test

the devices, having some margin of error for mismatches than can occur during the

Page - 16 -

Design, Fabrication and Modeling of mICP Sources

New mICP Source Design

fabrication process.

2.3.- COUPLING COEFFICIENT IMPROVEMENTS

The coupling coefficient (k) of equation 2.1 is a measure of how much of the

magnetic field generated by the coil actually intersects the plasma region. Figure 2.3

shows a schematic of the plasma source and the plasma region in which magnetic field

(H) lines have been sketched. It is easy to see that as the coil is separated from the plasma

region fewer and fewer lines reach the plasma, and therefore the coupling coefficient

tends to zero. On the other hand if the coil comes in intimate contact with the plasma, all

the lines generated by the coil will intersect the plasma and the coupling coefficient

becomes 1.

H

Coil

Glass wafer

Seal

Plasma

VACUUM REGION

Glass tube

Figure 2.3- Magnetic field in a mICP source

In a mICP source, the coupling coefficient is limited by two factors: the thickness

of the glass substrate (wafer) where the device is fabricated and the sheath width of the

Page - 17 -

Design, Fabrication and Modeling of mICP Sources

New mICP Source Design

plasma. The sheath of the plasma can not be ignored as the glass substrate gets thin and

there is not much to do to minimize it other than making the plasma more intense (See

equation 1.6). It is possible to use thinner substrates to increase the coupling coefficient.

However, the thickness will eventually be limited by the mechanical strength needed to

withstand the pressure difference between the plasma region (in vacuum) and the outer

world (atmospheric pressure). The maximum coupling coefficient can be achieved by

etching a cavity at the back of the wafer only under the coil (Figure 2.4-a). However,

even in this case the thickness cannot be reduced beyond ~200m. The minimum

thickness calculation can be found in Appendix I.

Wire Bond

One-turn coil

Coil

Glass

wafer

Plasma

Cavity

Glass

Tube

Thin

protective film

Glass

Tube

Plasma

Figure 2.4 a) Multi-turn coil with cavity etched at the back of the wafer b) Single turn coil flipped

over

A way to get rid of the separation due to the glass wafer is flipping over the

device (Figure 2.4-b). Since no substrate separates the plasma region from the coil, it is

Page - 18 -

Design, Fabrication and Modeling of mICP Sources

New mICP Source Design

necessary to electrically isolate the coil and the plasma as well as protect the coil from

being sputtered by the plasma.

This protective/insulating layer can be very thin because the mechanical strength

required to withstand the pressure difference between the plasma region (in vacuum) and

the outer world (atmospheric pressure) is provided by the substrate which can be as thick

as needed. Since the new device is to be tested in argon, a layer of photoresist can be used

as a protective/insulating layer. However a protective layer more resistant to oxygen

containing gases can be obtained by using other substances such as spin-on-glass.

Wire bond

Figure 2.5 Multi-turn mICP source

Multi-turn coils (spirals) need a wire bond to connect the center of the coil with

one of the pads (Figure 2.5). This wire bond does not allow us to flip over the device

because it is not insulated and makes the sealing of the plasma chamber difficult. For this

reason the new mICP source is designed as a single-loop coil which keeps the fabrication

process simple and allows us to flip over the device to investigate the effect of the

coupling coefficient in the overall performance of the device.

Page - 19 -

Design, Fabrication and Modeling of mICP Sources

New mICP Source Design

By approximating the coil and the plasma by two coaxial circular conductors, it is

possible to calculate the coupling coefficient between these two. The coupling coefficient

between two circular loop conductors can be calculated using the Neumann’s formula

[9]

for the mutual inductance of two circular loop conductors. The calculation involves

elliptical integrals and the details can be found in Appendix II. Figure 2.6 shows the

variation of the coupling coefficient as function of the separation between the two coils,

or in our case, the coupling coefficient as function of the separation between the coil and

the plasma.

By flipping over the device we can reduce the separation from ~850m (glass

wafer + plasma sheath) down to ~400m (plasma sheath only) and therefore improve the

coupling coefficient by a factor of ~1.7.

1

.

0

0

.

8

0

.

6

CouplingCoeficnt(k)

0

.

4

0

.

2

0

.

0

0

2

0

0

4

0

0

6

0

0

8

0

0

1

0

0

0

S

e

p

a

r

a

t

i

o

n

(

u

m

)

Figure 2.6 Coupling coefficient as function of the separation between the coil and the plasma

Page - 20 -

Design, Fabrication and Modeling of mICP Sources

New mICP Source Design

2.4.- COIL PARAMETERS

The new mICP source uses a 5-mm single turn coil to create a plasma. The reason

for the single turn (instead of a spiral as in previous designs) is explained in the previous

section. The diameter was chosen to be the same as in the previous design so designs can

be compared under similar conditions.

The new mICP source is made of gold. Although copper and silver have lower

resistivity, experience shows that they oxidize quickly while gold circuits do not present

any degradation in performance even after several months. Silver or copper devices may

be reconsidered for the flipped over devices since these devices do require a protective

layer. A new fabrication process would need to be developed however.

The thickness of the coil is chosen to be ~10m as in previous designs. Thicker

films would not reduce the resistance of the coil significantly due to the skin effect but

would be substantially more difficult to fabricate.

Given the number of turns, the outer diameter of the coil, its thickness and the

electrical properties of the gold, the coil should be designed to maximized the power

efficiency of the source. The only parameter left to be determined is the width of the coil.

We therefore need to express all the parameters in the mICP model in terms of this

parameter so the optimum width can be found.

2.4.1.- Coil Resistance

The coil resistance can be calculated as function of the coil width using:

Page - 21 -

Design, Fabrication and Modeling of mICP Sources

Rc ρ

New mICP Source Design

2 π rave

A effec

Eq. 2.4

where is the resistivity of gold at the operating temperature, rave is the average radius of

the coil, and Aeffec is the effective cross section area of the coil that incorporates the skin

effect. Figure 2.7 shows the effective area in a cross section schematic of the coil.

A effec w h (w 2 δ)(h 2 δ)

rout

rave

h

...where δ the skin depth and is given by :

δ

Aeffec

w

1

f πσμ

Figure 2.7 Cross section of the coil

2.4.2.- Coil Inductance

It is not trivial to find an analytical closed form expression for the inductance of a

rectangular cross section loop. For this reason we need to use an approximation in order

to estimate the actual value of the inductance. Two methods have been used to predict the

inductance, both leading to similar values:

Wire approximation:

A wire loop self-inductance is typically calculated as: [9]

r

d

8r

L c μ r ln 2

d

Figure 2.8 Wire loop

Page - 22 -

Eq. 2.5

Design, Fabrication and Modeling of mICP Sources

New mICP Source Design

where is the permittivity of the gold, r is the average radius and d is the

diameter of the wire.

In order to use this expression we need to approximate the coil by a wire using

the average radius (rave) and a wire diameter equal to the height of the coil (h)

as shown in Figure 2.9.

rave

h

Figure 2.9 Wire loop approximation

Semiempirical formula by Sunderarajan et al.: [10]

Several semiempirical equations have been developed for the calculation of

different geometry spirals. One of them is the equation developed by

Sunderarajan et al. which can be particularized for a single turn coil:

Lc

di

n

w

μ n 2 d avg c1 c 2

2

ln

c3 ρfill c4 ρfill Eq. 2.6

2

ρfill

...where for a single turn coil:

c1 ,c 2 ,c3 ,c 4 are constants

n 1

dout

ρfill

d out 2 rout w

d out 2 rout w

d avg d out w

Page - 23 -

Design, Fabrication and Modeling of mICP Sources

New mICP Source Design

Both methods give similar values of inductance and provide us with an expression

for calculating the inductance as function of the coil width (w).

2.5.- PLASMA PARAMETERS

In the model presented in section 2.1, the plasma is modeled with an inductor (Lp)

and a resistor (Rp) as a single loop coil. The diameter of this imaginary coil is set by the

diameter of the mICP source coil that induces the electric field in the plasma region.

2.5.1.- Plasma Resistance

The plasma resistance is harder to predict than the coil resistance because the

plasma conductivity and the electric field vary across the plasma. The plasma

conductivity depends on the electron density which is not constant across the plasma. The

electron density is maximum at the center of the tube and zero at the walls as a result of

the diffusion process of the electrons within the plasma. Typically the radial electron

density distribution within a cylindrical chamber volume can be considered a type-1

Bessel function.

On the other hand, the electric field induced in the plasma is zero at the center of

the tube, reaches a maximum somewhere under the coil and decreases as we move

towards the glass tube. For these calculations the electric field has been approximated by

a sinusoidal. Figure 2.10 shows a qualitative graph of the ion density and the electric field

in the plasma as function of the radius.

Page - 24 -

Design, Fabrication and Modeling of mICP Sources

New mICP Source Design

Electron density (ne)

Electric field (E)

r=0

r

center of the tube

radius of the tube

Figure 2.10 Electric field and electron density distribution in the plasma region

The plasma resistance can then be calculated as a parallel connection of

differential cylinders, each having a constant electron density, and therefore constant

conductivity.

r

d

r

Glass

Tube

rtube

1

h σ(r)

dr

0

RP

2 π r E(r)

h

Eq. 2.7

...where is the conductivity of the plasma

E is the electric field

Plasma

differential

element

h is the plasma length

Rp the plasma resistance

The conductivity as function of the electron density is given by Equation 1.8, and

therefore it is possible to perform the integral knowing the variation of the electric field

and the electron density as function of the radius r. The peak value of the electric field

and the ion density depend on the power absorbed by the plasma.

Page - 25 -

Design, Fabrication and Modeling of mICP Sources

New mICP Source Design

Sheaths have been neglected in this calculation and the exponential variation of

the electric field along the longitudinal axis of the tube has been approximated by a

constant field within an effective plasma length (h).

It might seem that the plasma resistance is not calculated accurately and actually it

is true. However, we can vary the power absorbed by the system to control the electron

density and, therefore, the resistance of the plasma. Notice that we are not trying to

estimate the plasma resistance accurately, but rather we are developing a model to

perform an analysis that leads us to the best possible coil design. And the best coil design

is independent of the plasma characteristics, although the actual efficiency will depend on

the plasma resistance.

2.5.2.- Plasma Inductance

Since the current flowing in the plasma also forms a single loop, the plasma

inductance is approximately the same as the coil inductance.

2.6.- COIL WIDTH SELECTION

The expressions developed in sections 2.4 and 2.5 can be used in equation 2.1 to

calculate the efficiency of the mICP as function of coil width. A MATLAB program that

performs this calculation can be found in Appendix III. The efficiency as function of the

width is presented in Figure 2.11.

The plot suggests that the thicker the coil the better the performance of the mICP

Page - 26 -

Design, Fabrication and Modeling of mICP Sources

New mICP Source Design

source gets. Although the result also suggests that the efficiency would be maximum

when the coil becomes a disk, this result is not accurate as the inductance formula used

for this calculation was derived only for coils (coil width << coil radius). Therefore that

part of the graph is ignored and the coil width is chosen to be half the radius (1.25 mm).

1

.

0

0

.

8

0

.

6

Eficeny(%)

0

.

4

0

.

2

0

.

0

0

5

0

0 1

0

0

01

5

0

02

0

0

02

5

0

03

0

0

0

C

o

i

l

W

i

d

t

h

(

u

m

)

Figure 2.11 Predicted power efficiency of a 5mm single loop mICP source

2.7.- MATCHING NETWORK

Once the coil width is selected the values of the coil resistance, coil inductance,

plasma resistance and plasma inductance in our model are determined. These values lead

to a coil-plasma equivalent circuit that presents an arbitrary input impedance. However, it

is desired that the input impedance of the mICP source equals the output impedance of

the power supply at the frequency of operation, so the power transfer from the power

Page - 27 -

Design, Fabrication and Modeling of mICP Sources

New mICP Source Design

supply into the mICP source is maximized.

To achieve this, a matching network consisting of two capacitors is used (Figure

2.12). The input impedance equals the power supply impedance (typically Rsupply = 50 )

for the following values of capacitance:

Ct

Input

impedance

Rc

Cm

Matching

network

Ct

Rp

M

Lc

Coil

Lp

Ct

Cm

Matching

network

L' ω

R

supply

L' ω

R’

L’

R' R' ω

Plasma

Cm

Input

impedance

1

1

Ct ω

2

1

2

ω

R' L' ω

C

ω

t

Coil

+

Plasma

Figure 2.12 Matching network schematics

The derivation of these expressions for the required capacitances can be found in

Appendix IV. Note that the matching can be achieved only if Rsupply > R’, which holds

true for a mICP source.

The matching network is implemented by two interdigital capacitors fabricated in

gold. The digits of the capacitors are 10m wide, 8m high and they are separated by

Page - 28 -

Design, Fabrication and Modeling of mICP Sources

New mICP Source Design

10m wide gaps. The product “length x number of digits” was calculated extrapolating

data from previous designs and assuming that in a first approximation the capacitance is

proportional to the number of digits and their length.

Once the product is calculated, small aspect ratio modifications were made to

guarantee that the ohmic loses in the capacitors are negligible. The results obtained for a

5mm single turn coil mICP source can be found in Appendix V.

Two additional capacitors were fabricated next to the device to shift the frequency

of operation and investigate the performance of the device at different frequencies. The

capacitance of these additional capacitors is 25% of the tuning and the matching

capacitor respectively (Figure 2.13).

Single turn coil

Matching Capacitor

Cm

Tuning Capacitor

100m

Ct

Digits of the Interdigital

Capacitor

Additional capacitors

Figure 2.13 Single turn mICP source

Page - 29 -

Design, Fabrication and Modeling of mICP Sources

New mICP Source Design

Finally, the single turn coil and the matching network are arranged such that

parasitic loops are minimized. The two capacitors share a base and the connections to the

coil are very compact. Figure 2.13 shows a picture of an actual device and a close-up

view of the interdigital capacitor.

Page - 30 -

Design, Fabrication and Modeling of mICP Sources

Fabrication

3.- FABRICATION

A traveler for the fabrication of the mICP source can be found in Appendix VI.

The single turn mICP source can be fabricated as follows:

Sputtering

TiW

Glass Wafer

Au

Cr

Beginning with a 700m glass wafer, a 1000 Å seed

layer of gold is deposited over a 300 Å chrome

adhesion layer. Then a 300 Å TiW layer is

deposited on the gold film to improve the

photoresist adhesion.

Photolithography:

Two coats of AZ®P4620 photoresist are spun to get

a ~15m layer. The photoresist is then exposed and

developed.

TiW plasma etch

The TiW layer is plasma etched in O2+SF6 where it

has been revealed after the photoresist developing.

Gold electroplating

The device is electroplated to a thickness of ~8m

using the photoresist as a mold.

Photoresist strip

Once the device is grown, the photoresist is

stripped.

TiW, Au & Cr etch

Finally, the metal layers are stripped, TiW and gold

in a wet etch and Cr in a O2+CF4 plasma.

Alternatively, the three metal layers can be

physically removed using an ion beam etcher.

Page - 31 -

Design, Fabrication and Modeling of mICP Sources

Fabrication

Protective film

If the device is to be flipped over, the next step is to

apply a protective layer. In the experiments

described in the next chapters a coat of AZ®P4620

has been used as a protective layer.

Finally the wafer is diced and each device placed in a plastic substrate that acts as

a package. A SMA connector is also mounted on the same plastic substrate and the

device is wire bonded to the connector. Figure 3.1 shows a mICP source mounted in the

plastic substrate with a photoresist protective layer on the coil region.

SMA connector

Plastic substrate

Photoresist protective layer

Figure 3.1 mICP source on plastic substrate

3.1.- FABRICATION ISSUES

The fabrication process of a single turn mICP source is fairly simple. However

problems might arise during the photolithography process and the gold electroplating.

Page - 32 -

Design, Fabrication and Modeling of mICP Sources

Fabrication

3.1.1.- Photolithography

The photolithography process is probably the most delicate part of the process

since the photoresist is going to act as a mold later during the electroplating step. Any

defect in the photoresist will translate later into a defect in the final device. Sometimes

these defects are tolerable, but some others are fatal. In general defects due to particles

sitting in the photoresist translate in broken digits in the capacitor since gold will not

grow in that particular spot during the electroplating process. A broken digit does not

have a significant effect on the overall performance of the device as long as the number

of broken digits is small.

The real problems are normally due to cracks and adhesion failures in the

photoresist layer. More often than not, the photoresist layer cracks during the baking

process after the developing step. Reducing the photoresist layer thickness seems to help,

but since the photoresist acts as a mold it cannot be made thinner. Gold seed layers of 600

Å and 1200 Å have been tried to see if they translated into underlying films of lower

stress, but in both cases the photoresist did crack.

Fortunately most of the cracks end in the outer part of the device and do not

propagate across the devices (See Figure 3.2). A more subtle defect in the photoresist

layer occurs when the photoresist does not adhere completely to the TiW layer and forms

a cavity underneath the photoresist digits. These cavities do get filled with gold during

the electroplating process, short-circuiting the capacitor and ruining the device.

Page - 33 -

Design, Fabrication and Modeling of mICP Sources

Fabrication

Figure 3.2 Cracks in the photoresist

3.1.2.- Gold Electroplating

During the electroplating process the defects in the photoresist layer translate into

defects in the actual device. Those defects need to be addressed during the

photolithography process. However, there is an additional issue during the gold

electroplating process which is gas bubbles being trapped in between photoresist digits.

This effect is more prevalent near the bases of the capacitors, and as a result, the gold

plating does not occur in these areas. Figure 3.3-a shows a device from a previous

generation of mICP sources in which most of the digits are damaged due to bubbles

trapped near the bases of the capacitors during the electroplating process.

It was found that dipping the wafer in a soapy solution before starting the

electroplating process wets the photoresist, changes the surface tension and significantly

reduces the number of bubbles that get trapped in between the digits of photoresist

(Figure 3.3-b).

Page - 34 -

Design, Fabrication and Modeling of mICP Sources

a)

Fabrication

b)

Figure 3.3 mICP sources fabricated a) DI water wet before electroplating b) Soapy solution wet

before electroplating

Page - 35 -

Design, Fabrication and Modeling of mICP Sources

Experiment Description

4.- EXPERIMENT DESCRIPTION

Two identical 5-mm single-turn mICP sources have been tested using four

different conditions to investigate the effect of frequency of operation and coupling

coefficient on the source efficiency. These conditions are summarized in the Table 4.1:

Device

Coupling

coefficient

Frequency

Condition 1

I

Low

High

Condition 2

I

Low

Low

Condition 3

II

High

High

Condition 4

II

High

Low

Table 4.1 Test conditions

The first device (Device I) was tested facing outwards from the vacuum chamber

(tube) with the glass substrate in between the coil and the plasma region (in similar

fashion to previous designs). On the other hand, Device II was flipped over to bring the

coil as close as possible to the plasma region to improve the coupling coefficient. Each

device was tested at two different frequencies of operation as the resonant frequency was

varied by adding an additional capacitor to Ct as described in section 2.7.

For each of these conditions the mICP source maintained argon plasmas at 100,

200, 300 and 400 mtorr and the RF power was swept from 200 to 1000 mW for each

pressure. Although the device is capable of sustaining the plasma at pressures of at least

Page - 36 -

Design, Fabrication and Modeling of mICP Sources

Experiment Description

12 torr, the probe theory used to diagnose the plasma assumes non-collisional sheaths

which limit the validity of the calculations to pressures under 400 mtorr.

4.1.- SET UP

Once the device has been fabricated, mounted in the plastic package and wire

bonded to the SMA connector, it is attached to a glass tube that acts as vacuum chamber

(Figure 4.1). The glass tube is terminated in a metal flange that attaches the tube to a

body where the gas inlet, the mechanical pump and pressure gauges are connected.

Figure 4.1 mICP source mounted on package and bonded to the glass tube

A signal generator and a RF amplifier are used to supply power to the mICP

source. A dual directional coupler, a RF switch and a RF power meter are used to

measure the forward and reflected power. Figure 4.2 shows a schematic and actual

pictures of the experiment set up.

The gas used for the experiment is argon, which is fed through the gas inlet, and a

mechanical pump is used to create vacuum in the chamber. A capacitive pressure gauge

Page - 37 -

Design, Fabrication and Modeling of mICP Sources

Experiment Description

1. Single turn mICP source

2. 5/16” Glass tube (vacuum

chamber)

7

1

6

8

2

3. Signal generator

HP8656A (.1 - 990MHz)

4. RF Power amplifier

EIN603L (+30dB)

5

4

5. RF coupler

Pasternack PE2217-20

30dB

3

818.000

-

7.3

6. RF Switch

919C70200

11

13

M

M

K

MK

KSSS

0.53

7. RF Power Sensor

HP8482H

8. RF Power meter HP435A

12

9. Gas inlet (Argon)

10. Needle Valve (SS4)

10

11. Pressure gauge

MKS390HA (10 torr)

9

12. Signal Conditioner

MKS270B

13. Gas outlet (to pump)

14

14. Electrostatic plasma probe

Controller HIDEN ESP004

8

12

3

4

11

9

10

9

2

5

1

7

8

10

7

Figure 4.2 Experiment set up

Page - 38 -

6

13

Design, Fabrication and Modeling of mICP Sources

Experiment Description

measures the pressure in the chamber and a needle valve at the inlet allows us to vary the

pressure by altering the gas flow.

The plasma is diagnosed using a thin Langmuir probe that is discussed in

following sections. An electrostatic plasma probe controller drives the probe and

measures the voltage-current characteristic of the plasma. A computer is used to store the

data for future analysis.

4.2.- PROBES

One of the most commonly used methods for measuring the ion density in a

plasma is by means of Langmuir probes. This plasma diagnosis technique consists of

introducing a metallic probe in the plasma. When the probe is biased to different

voltages, current flows through it and a voltage-current characteristic curve that depends

on the ion density and the electron temperature in the plasma can be obtained.

As the probe is introduced in the plasma, a sheath forms around the probe and the

probe is driven to the floating potential. The probe size needs to be small so the plasma is

not significantly perturbed by the probe. When the probe is at the floating potential the

flux of electrons reaching the probe equals the flux of ions being collected and the net

result is a zero current flowing through the probe.

However if the probe is externally driven to a voltage different than the floating

potential, the electron and ion fluxes are no longer in equilibrium and a net current does

Page - 39 -

Design, Fabrication and Modeling of mICP Sources

Experiment Description

flow through the probe. Figure 4.3 shows a typical voltage-current characteristic for a

single Langmuir probe.

I

I

Plasma

V

V

Figure 4.3 Typical voltage-current characteristic for a single Langmuir

When the probe is driven negatively with respect to the floating potential,

electrons see a higher barrier to reach the probe and the electron flux decreases. On the

other hand, the ion flux does not change with the applied voltage (it is limited by the

Bohm velocity) and the overall result is an ion current being collected by the probe.

Following the sign convention of Figure 4.3 this corresponds to a negative current. When

the voltage applied is negative enough (V >> Te / q) the electron flux is negligible and the

current flowing through the probe is approximately constant. This corresponds to the ion

saturation current and the slight increase as the voltage becomes more negative is due to

an increase in the ion collecting area due to larger sheaths.

Similarly, when the probe is driven positively with respect to the floating

potential, more electrons have enough energy to reach the probe and the electron flux

increases. Since the ion flux is independent of the applied voltage as long as the applied

voltage is smaller than the plasma potential (V<Vp), the net result is electrons being

Page - 40 -

Design, Fabrication and Modeling of mICP Sources

Experiment Description

collected by the probe. Following the sign convention of Figure 4.3 this corresponds to a

positive current. As the voltage continues increasing the ion current becomes negligible

and the current increases exponentially until electron saturation current is reached.

In the new mICP source the plasma is generated in a glass chamber where no

voltage reference is available. This makes it impossible to use a single probe to diagnose

the plasma as the applied voltage will simply drive the plasma potential which is

otherwise floating.

Therefore, a double probe scheme as shown in Figure 4.4 is needed.

V

I

I

A1

A2

Plasma

V

Figure 4.4 Typical voltage-current characteristic for a double probe measurement

In a double probe scheme each probe behaves as a single probe. When no voltage

is applied between the two probes, both probes sit at the floating potential and no current

flows through the probes. When a voltage V is applied between the probes, one probe is

driven positively and the other one negatively with respect to the floating potential. The

voltage of each probe will be such that their difference is the applied voltage V and the

Page - 41 -

Design, Fabrication and Modeling of mICP Sources

Experiment Description

net ion current collected by the negative driven probe equals the net electron current

collected by the positive driven probe. If both probes are identical, a symmetric voltagecurrent characteristic is obtained as shown in Figure 4.4. The current at large positive and

negative voltages is limited by the ion saturation current of the probes.

4.2.1.- Probe Design

Due to the reduced dimensions of the plasma (5-mm in diameter) it is very

important to use very small probes to perturb the plasma as little as possible. Two probes

(See Figure 4.5) have been used to test the devices, both of them following the double

probe scheme.

Probe 1

Probe 2

a)

b)

Figure 4.5 Probes a) double probe b) coaxial probe

The first design is a symmetrical double probe consisting of two silver-coated

wires 0.008” in diameter, 3mm long. The two wires are separated forming a U shape to

Page - 42 -

Design, Fabrication and Modeling of mICP Sources

Experiment Description

prevent their sheaths from overlapping. The second design consists of a coaxial cable in

which the inner conductor (silver-coated 0.008” in diameter) acts a one of the probes and

the outer conductor (copper 0.034” in diameter) as the other probe. The first probe is

2mm long whereas the length of the second probe depends on the plasma length.

The symmetrical double probe has the advantage of symmetry, however, it

perturbs the plasma more significantly than the coaxial probe. The main limitation of the

symmetrical double probe comes from the fact that the ion density in the plasma changes

along the radius of the chamber (See Figure 2.10). Since the two probes need to be

separated ~1.5mm to guarantee that their sheaths do not overlap when a voltage is

applied, the ion density around each probe is quite different for this small plasma and the

probe theory that assumes that both probes see the same plasma cannot longer be used.

On the other hand the coaxial probe is asymmetric, but it perturbs the plasma less

than the symmetrical double probe and it is not affected by the ion density changes along

the radius of the chamber.

The results presented in the next sections were obtained with a coaxial probe

described above.

Page - 43 -

Design, Fabrication and Modeling of mICP Sources

Performance Of The New mICP Source

5.- PERFORMANCE OF THE NEW MICP SOURCE

Probe measurements where recorded for the conditions described in section 4.

Each voltage-current curve is obtained by sweeping the voltage across the probes from

-50 to +50V in intervals of one half volt and measuring the current flowing through the

probes at each voltage.

5.1.- ION DENSITY AND ELECTRON TEMPERATURE CALCULATION

A typical voltage-current characteristic of the coaxial probe is shown in Figure

5.1. It can be seen that it is clearly asymmetric compared to Figure 4.4 and this is due to

the fact that in the coaxial cable the probes have different areas.

4

0

0

3

0

0

2

0

0

Probecurnt(A)

1

0

0

0

1

0

0

2

0

0

6

0

4

0

2

0

0

2

0

4

0

6

0

A

p

p

l

i

e

d

V

o

l

t

a

g

e

(

V

)

Figure 5.1 Typical voltage-current characteristic for a coaxial probe in the mICP

Page - 44 -

Design, Fabrication and Modeling of mICP Sources

Performance Of The New mICP Source

The current flowing through each probe is determined by the probe potential with

respect to the plasma potential and it is the net result of two process: electrons reaching

the probe and ions being collected by the probe. Therefore the current in each probe can

be separated in two components, namely an ion current and an electron current.

Assuming that electrons follow the Boltzmann distribution, the electron current in

the probe is given by:

1

I e q A n es v e e

4

q(Vp V)

kTe

Eq. 5.1

where A is the probe area including the sheath around the probe and the rest of

parameters are as described for equation 1.1.

On the other hand since ions are accelerated to the Bohm velocity (uB) by the field

in the presheath, the ion current is given by:

Ii q A nis u B

Eq. 5.2

When there is no voltage applied in between the two probes, both of them are

driven to the floating potential and no net current flows through the probes.

I Ii Ie

0 q A n is

n is

Page - 45 -

q(Vp Vf )

1

u B q A n es v e e kTe

4

1

u B n es v e e

4

q(Vp Vf )

kTe

Eq. 5.3

Design, Fabrication and Modeling of mICP Sources

Performance Of The New mICP Source

So the final expression for the net current in each probe as function of the probe

potential is:

I

qVp

1

I q A n es v e e kTe

4

V

Plasma

Vf

qV

kT

kTe

e

e e

Eq. 5.4

From Figure 5.2 it is clear that the current that flows through the probes (inner and

outer conductors of the coaxial probe) and that in the power supply need to be the same

as the three are connected in series. Therefore it is possible to find a relationship between

the voltage applied in between the probes (V) and the current flowing through the

probes (I) as function of the area ratios of the probes and the ion currents of each probe.

I I 2 I1

A1

A2

I1

Plasma

I1 I1i I1e

I 2 I 2i I 2e

I2

Coaxial

Probe

V

I

V1 Vp

1

I1e q A1 n e v e exp

4

Te

V2 Vp

1

I 2e q A 2 n e v e exp

4

Te

V V1 V2

Figure 5.2 Coaxial probe schematic

Page - 46 -

V

I I1i A1 Te

e

I 2i I A 2

Eq. 5.5

Design, Fabrication and Modeling of mICP Sources

Performance Of The New mICP Source

The experimental data (voltage-current characteristic) can be fitted with this

expression and thereby obtain the electron temperature and the ion density of the plasma.

A MATLAB program that solves the fitting problem can be found in Appendix VII.

1

2

3

4

5

6

Initial

guess

Plasma

potential

Guess

2 Area

ratio

Probes’

potential

Area

ratio

Ion

4

current

Electron

temperature

Te=3eV

Vp

A1/A2

V 1, V 2

A1/A2

Ii1, Ii2

Te

5

Ion

density

ni

Ion

curre

A1/ temperature and the ion density

Figure 5.3 Iterative process for calculating the electron

nt

A2

Ii1, Ii2

Figure 5.3 shows a flow chart of the iterative fitting process followed to calculate

Ion

the electron temperature and the ion density from the experimental

data. It starts with an

curre

nt

initial guess for the electron temperature and iterates until the value of the electron

A1/

A2

Ii1, Ii2

temperature converges. Normally no more than three iterations are required. In each

Ion

iteration an inner iteration is performed to calculate the areacurre

ratio and the potential of the

nt

probes at each applied voltage. The next sections describe each

Ii1, Ii2of the steps greater detail.

5.1.1.- Step 1: Plasma Potential

A1/

A2

Taking the floating potential (Vf) as the voltage

Ion

curre