* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download 9.5. Combined Methods: Electrochemical

Surface runoff wikipedia , lookup

Chemical thermodynamics wikipedia , lookup

X-ray photoelectron spectroscopy wikipedia , lookup

Diamond anvil cell wikipedia , lookup

Nanofluidic circuitry wikipedia , lookup

Rutherford backscattering spectrometry wikipedia , lookup

Thermal spraying wikipedia , lookup

Self-assembled monolayer wikipedia , lookup

Electrochemistry wikipedia , lookup

Surface tension wikipedia , lookup

Low-energy electron diffraction wikipedia , lookup

Sessile drop technique wikipedia , lookup

Surface plasmon resonance microscopy wikipedia , lookup

Ultrahydrophobicity wikipedia , lookup

Protein adsorption wikipedia , lookup

Nanochemistry wikipedia , lookup

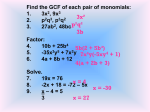

9. Chemical, Photochemical and Electrochemical Modification of Diamond 9. Chemical, Photochemical and Electrochemical Modification of Diamond Donald A. Tryk, Takeshi Kondo and Akira Fujishima 9.1. Introduction The attractive characteristics of electrodes based on conductive diamond films have led a number of research groups around the world to use these electrodes for electroanalytical applications. As a way to extend the analytical capabilities of diamond electrodes, researchers have also become interested in chemically modifying the diamond surface. One of the principal motivations is to impart selectivity for analytical purposes. Closely associated with this is the desire to impart electrocatalytic activity for specific electrochemical reactions, making use of diamond as a highly robust support. One of the more interesting recent applications of the modified diamond surface is the fabrication of DNA arrays. The reports that have appeared thus far can be classified into the following categories: 1) chemical modification; 2) photochemical modification; 3) electrochemical modification; 4) ion implantation techniques; and 5) combined methods, for example, electrochemical modification followed by chemical modification. All of these methods have their respective advantages and disadvantages, which we will examine in this chapter. 173 Another way to group the published reports on the covalent modification of the diamond surface is as follows: 1) conversion of the hydrogen termination to oxygen, chlorine or fluorine; 2) cycloaddition reactions of alkenes with the bare diamond surface, either after high temperature vacuum annealing or during UV illumination, resulting in carbon-carbon bonds; 3) reactions with functional group-specific reagents, such as those that react with either hydroxyl groups or carbonyl groups; and 4) radical reactions with reagents, directly without activation, or after either electrochemical or photochemical activation . In general, the features that are desired for the modification of the diamond surface include the following: Chemical or electrochemical selectivity for a particular species Chemical inertness Chemical stability Electrochemical stability Mechanical robustness Electrical contact (specifically for electrochemical applications) Ability to be patterned, particularly at the micrometer to nanometer scales Speed of modification 9.2. Chemical Modification Methods Some of the chemical modification methods have been investigated for many years, even though the analytical aspects were not envisaged initially. The simplest technique involves the treatment with an oxidizing acid solution such as nitric acid or chromic acid. 174 9. Chemical, Photochemical and Electrochemical Modification of Diamond This type of treatment can convert the hydrogen termination to oxygen termination. An additional benefit is that possible nondiamond carbon impurities, as well as metallic impurities, can be removed from the surface in this way. The chemical oxidation of diamond is closely related to electrochemical oxidation, discussed later, and which is also discussed in Chapters 8 and 10. The carbon-oxygen surface functional groups that are produced via chemical oxidation, irrespective of the details of the reaction, include carbonyl and ether groups, which can form predominantly on the diamond (100) surface, and hydroxyl groups, which can form predominantly on the (111) surface [1-12]. It has also been found that hydroxyl groups can be stabilized on the (100) surface, particularly if they are hydrogen-bonded to each other [5]. Thus, on this surface, the three principal types of functional groups can exist in various proportions, depending on the coverage; this uncertainty exists even if the (100) surface is crystallographically perfect. In many cases, chemical oxidation has been used as a standard preparation technique for certain types of experimental measurements, particularly those that involve semiconducting properties, because it removes hydrogen from the surface and/or subsurface, which can impart metallic conductivity [13]. There have been several reports in which the electronic properties of hydrogen-terminated vs. oxygen-terminated diamond have been compared [1, 3]. Briefly, the carbon-oxygen surface functional groups that are produced possess a strong dipole, in which the negative end points outward from the surface [14, 15]. Depending on the details of the 175 surface crystal structure and the coverage with various functional groups, this dipole can be as large as ~3.6 eV (carbonyl group) or 2.6 eV (ether group), which is enough to affect the placement of the energy band edges with respect to the vacuum level (Evac), i.e., pulling the conduction band (CB) edge below Evac. The dipole can also affect the electrochemical behavior significantly, leading to a sizable repulsion of anions, with an accompanying decrease in the electron transfer (ET) rate (see section on electrochemical oxidation). Oxidation can also be carried out via gas-phase reaction with various forms of oxygen, including molecular oxygen, singlet (molecular) oxygen, and atomic oxygen. The reaction with molecular oxygen has been studied extensively. It begins at around 500C and leads to the formation of carbonyl, ether, hydroxyl and carboxylic acid groups, but there can also be significant graphitization [2, 11]. The reaction with atomic oxygen takes place without thermal activation [1]. Initial oxidation can be used in conjunction with a subsequent chemical modification step. This is very similar to the approach discussed later for initial electrochemical oxidation followed by chemical modification. For example, Ushizawa et al. started with an oxidized diamond powder surface, containing carboxylic acid groups, and, via the acid chloride, made use of an esterification reaction with hydroxyl groups on ribose moieties attached to the DNA strands (16). Wenmackers et al. used this approach to attach DNA strands to diamond films (17). In another example, Krysinski et al. chemically oxidized a polycrystalline diamond film to produce hydroxyl groups, converted these to acid chlorides, and then used 176 9. Chemical, Photochemical and Electrochemical Modification of Diamond esterification to attach aminopyrene moieties (18). In connection with the latter work, there is an apparent discrepancy with other work, in that the surface coverage of oxygen is stated to be quite low. This is a question that requires further examination, because, for most purposes, it is desirable to maximize the surface coverage of both the oxygen-containing surface groups and the subsequently attached moieties. Halogenation reactions have also been studied for many years (19-31). Freedman found that molecular fluorine and chlorine do not react with the diamond surface without activation, whereas atomic fluorine and chlorine do react. The coverage of fluorine after treatment with atomic fluorine was about 0.75 of a monolayer, and this was stable at temperatures up to 700 K. The stabilities of the halogenated surfaces are experimentally less than predicted theoretically, as pointed out by Hukka et al. (23). Fluorination (22) and chlorination (21) of diamond powders were carried out by Ando et al. without thermal activation for fluorine and with thermal activation for chlorine. Comparing the work with diamond films with that for powders shows that there are definite differences in reactivity. This is to be expected, because the surfaces of nanoparticles (or even microparticles) present a variety of crystallographic planes, as well as edges and corners. A more efficient means of fluorinating the diamond surface is the plasma. Several groups have used CF4 as a fluorine source (27, 29-31). The electrochemical behavior of the resulting surface has been examined by these same groups. In an early report, there was no significant effect on the voltammetric background of the 177 fluorination compared to the as-deposited, hydrogen-terminated surface (27). However, recently, there has been renewed interest in this topic with the finding that heavily fluorinated surfaces provide a 5-V potential working range (29). At present, there is no explanation of the difference in potential window between the earlier and later reports, but the degree of fluorination may have been greater in the latter. The electrochemical behavior of the heavily fluorinated surfaces is interesting, because the rates of various redox reactions are affected quite differently from each other. For example, hydrogen evolution is shifted by about two volts, and the rate of ferrocyanide oxidation is decreased by three orders of magnitude, but the rates of reactions involving several aquo complexes are only decreased by factors of around five (30). Thus, it appears that the ET is sensitive to the intimate details of the approach of the redox species to the diamond surface. The halogenated diamond surface, specifically, the chlorinated surface, can be used for further chemical modification, for example, to produce amine-covered or thiol-covered surfaces. This approach has been developed for diamond powders (24), as well as for films; the latter will be described in more detail later, in the section on photochemical modification. The chemical reactions of the halogens with diamond are usually thermally activated in order to produce significant quantities of the halogen atoms, e.g., chlorine atoms. This is a recurring theme: the very low reactivity of the diamond surface often requires that reactions be initiated by radicals, as halogen atoms are. As already mentioned, the plasma is an efficient means of generating radicals. 178 As we shall see later, radicals can be 9. Chemical, Photochemical and Electrochemical Modification of Diamond generated photochemically. There has also been a sustained effort to make use of a solution-phase, ambient temperature approach to initiate radical reactions (32-38). This work has involved various types of organic peroxides as radical initiators. These workers have succeeded in attaching several different organic compounds, such as carboxylic acids, to the surfaces of diamond powders. Another solution-phase approach has been examined, with the use of sulfuryl chloride, a nucleophilic reagent (25). In this work, the surfaces of diamond powders were chlorinated and butylated. Next, we will treat cycloaddition reactions of alkenes with the bare diamond surface, after high temperature vacuum annealing, which results in the formation of carbon-carbon bonds (39-41). For example, if the diamond (100) surface is heated in vacuum to 1000C, hydrogen desorbs, leaving surface C-C dimers. These have appreciable double-bond character and can react with alkenes under conditions appropriate for the Diels-Alder cycloaddition reaction. Either the [2+2] or the [2+4] product can be formed, with the latter being the energetically favored pathway. This type of modification can also be carried out photochemically, and this approach is the one that is used more commonly, as discussed in the next section. 9.3. Photochemical Modification Methods There are two principal types of photochemical modification techniques: 1) cycloaddition reactions of alkenes with the bare diamond surface under UV illumination, resulting in carbon-carbon 179 bonds; and 2) radical reactions with reagents that are activated photochemically. As mentioned in the previous section, alkenes react with C-C dimers on the clean diamond (100) surface, which are produced during high temperature treatment in vacuum. This reaction can also be activated photochemically. This approach can be used to attach alkyl chains that are terminated with carboxylic acid or primary amine groups, for example, which are useful for further functionalization (42). These groups must be protected during the UV illumination and then subsequently deprotected. Hamers and coworkers have used this technique to attach DNA strands to the diamond surface, and they found that the stability of the attachment is excellent, much better than that to other surfaces, such as silicon or gold (43-45). UV illumination can be used to activate radical-type reactions, for example, chlorination, as first shown by Miller and Brown (46). They also showed that the chlorinated surface can be photochemically converted to an amine-covered surface (28, 46) and to a thiol-covered surface, the latter being accomplished also directly from the hydrogen-terminated surface (28). 9.4. Electrochemical Modification Methods Electrochemical modification methods include 1) anodic polarization in aqueous acid or base; and 2) radical reactions with reagents that are activated electrochemically. Both of these approaches can provide a surface that can be further functionalized. In addition, the electrochemical approach leads to the possibility of 180 9. Chemical, Photochemical and Electrochemical Modification of Diamond patterning the surface down to the nanometer scale through the use of scanning electrochemical microscopy (SECM) or of conductive atomic force microscopy (CAFM). One of the motivations for using electrochemical oxidation, compared to chemical oxidation, is that the oxidizing power can be immediately controlled over a wide potential range. Other motivations, compared to plasma oxidation, are that the process is simple to implement and, since it does not involve high kinetic energy, leads to negligible surface damage. In addition, the amount of charge that is passed in the oxidation process can be monitored. The electrochemical oxidation approach has been studied in detail by the Angus group (27), by the Fujishima group (47-55), by the Swain group (56, 57), as well as others (58-60). As with chemical oxidation, electrochemical oxidation of the polycrystalline surface produces a mixture of several types of carbon-oxygen functional groups, which can reasonably be expected to include the following: carbonyl, ether and hydroxyl on the (100) surface and principally hydroxyl on the (111) surface, based on the previously cited surface characterization and theoretical studies. The presence of the carbonyl group has been confirmed unambiguously by work with polycrystalline samples (52) and on single-crystal-like homoepitaxial samples (61). The presence of the hydroxyl group has also been confirmed unambiguously by work with polycrystalline samples (54) and homoepitaxial samples (58, 61). Just as in the case of fluorination, the oxygenation of the surface, due to the presence of the strong dipoles mentioned already, leads to a variety of effects on different redox couples. ET 181 to anions, such as the members of the ferro/ferricyanide redox couple, is often slowed down considerably, compared to the hydrogen-terminated surface, while it is either speeded up or there is little effect for cations (50, 55-57, 62). For neutral compounds, the effects are subtler, probably involving dipole-dipole interactions as well as other types of interactions. The selective inhibition of ET due to electrochemical preoxidation can lead to enhanced selectivity in the analytical determination of components of mixtures. One example is the determination of dopamine (DA) in the presence of ascorbic acid (AA) (47, 48), which is important for patients with Parkinson’s disease and the determination of uric acid (UA) in the presence of AA (53). Unfortunately, the determination of DA in the presence of AA at oxidized diamond can only be carried out successfully at low pH values (0-2), where DA is protonated and thus positively charged. Thus, in vivo analysis is not possible. In the case of UA, this is not a drawback, and electrochemical sensors for UA in urine have been developed. Surface dipole-related effects can be accentuated if there are insufficient charge carriers near the diamond surface, either due to a somewhat low intrinsic boron doping level (<1019 cm-3) or to a passivation of the existing boron dopant. The latter can occur as a result of hydrogen donors compensating boron acceptors. In either case, the relatively small number of charge carriers cannot support a normal level of ET to species that are at a distance from the electrode surface, particularly those that are sensitive to the number of charge carriers or the density of states (DOS) at the Fermi level, such as ferrocyanide. 182 9. Chemical, Photochemical and Electrochemical Modification of Diamond There are other examples in which analytical determinations have been enhanced with the use of the electrochemically oxidized surface: 1) the determination of chlorophenols (63); and the determination of sulfur-containing organic compounds (64, 65). In the latter case, the negatively charged surface attracts the cationic disulfide compound. In both cases, the use of the oxidized surface is convenient, because electrochemical oxidation is actually used periodically to clean the surface, which can slowly become fouled with polymeric oxidation products of the analytes. The fouling process proceeds much more slowly than it does on glassy carbon, but it can still occur. These topics will be treated in greater detail in subsequent chapters (12 and 15). The electrochemical oxidation approach has also been carried out at the nanometer scale on homoepitaxial films, through the use of conductive AFM (51, 66-69). With this technique, although there is not a conventional electrochemical cell involved, there is a small amount of water present from the ambient air, and this condenses at the gold-coated AFM tip. If the tip is biased negative with respect to the diamond surface, by 2 to 3 volts, oxidation of the diamond surface occurs. The actual presence of carbon-oxygen functional groups has not been confirmed yet, due to the extremely small scale of the modification, however. The principal effect is that the conductivity of the homoepitaxial film is effectively decreased, by several orders of magnitude. In the work of the Fujishima group (51, 69, 70), the films were boron-doped, in the 1019 cm-3 region; in work of the Kawarada group, the films were undoped crystals, but these contained hydrogen on or near the surface, due to treatment in a hydrogen plasma (67, 68, 71-73). In 183 both cases, the CAFM polarization serves to remove hydrogen, leading to extremely low conductivity. In the case of the borondoped films, the conductivity may also be quite low, due to the passivation phenomenon mentioned earlier. In any case, the principal application of this technique at present is the fabrication of nanoscale electronic devices, as reported by the Kawarada group (68). In the future, it may be quite interesting to try to expand the range of electronic devices that can be fabricated. The other major electrochemical modification approach has been that in which aromatic diazonium salts in an electrolyte solution are reduced at a diamond electrode; this leads to the formation of an aryl radical, which can then attach to the diamond surface (74). This work is based on a series of papers in which the same technique was applied to the surface modification of glassy carbon and highly ordered pyrolytic graphite (HOPG) (75-78). This approach may also be quite fruitful for the covalent modification of diamond surfaces, if the attachment is as robust as it is on glassy carbon surfaces. 9.5. Combined Methods: Electrochemical/ Chemical methods Although there are other examples of combined methods, such as photochemical–chemical, which have already been mentioned briefly, as in the case of the photochemical–chemical attachment of DNA strands, we shall focus on that of electrochemical–chemical method. This combined approach has been used recently to attach a protein to the diamond surface (59), using first electrochemical 184 9. Chemical, Photochemical and Electrochemical Modification of Diamond oxidation to produce hydroxyl groups, followed by esterification to attach biotin, with subsequent attachment of streptavidin. Even though these workers used electrochemical oxidation, they found that chemical oxidation with singlet oxygen was more effective in achieving high hydroxyl coverage. We shall continue by discussing in greater detail a recent study, in which we made use of electrochemical oxidation of singlecrystal-like homoepitaxial films and then used specific reagents to bind to the resulting carbonyl and hydroxyl groups (61). In this study, we found that the diamond (100) surface contains a mixture of carbonyl and hydroxyl groups, while the (111) surface contains mainly hydroxyl groups. The presence of other types of groups has not examined. In previous modification of work, carbonyl 2,4-dinitrophenylhydrazine (C=O) groups (52) (DNPH) and 3- aminopropyltriethoxysilane (APTES) modification of hydroxyl (-OH) groups (54) were carried out on oxidized polycrystalline diamond electrodes. The latter is particularly important for possible applications, because the terminal amino group can be used to form a covalent bond, e.g., via amidization, with a variety of functional species, including examples already mentioned, such as DNA and proteins. In this study, the surface functional groups generated by anodic treatment on (100) and (111) homoepitaxial single-crystal boron-doped diamond electrodes were first examined with X-ray photoelectron spectroscopy (XPS). Subsequently, DNPH and APTES modifications of the anodically treated surfaces were carried out and were characterized again with XPS, as well as with cyclic voltammetry and electrochemical impedance measurements. 185 The original work can be consulted for the experimental details, which will be given here briefly. The single-crystal-like boron-doped homoepitaxial diamond films were prepared by microwave plasma-assisted chemical vapor deposition on synthetic high pressure-high temperature single-crystal substrates (3-4° offaxis polished). Hydrogen-terminated surfaces were prepared from as-deposited or oxidized surfaces by heating to 900 °C in hydrogen ambient for 1 h. For the anodic treatment, a single positive potential sweep (0 to +3 V vs. Ag/AgCl), with sweep rate 100 mV s -1 in 0.1 M sulfuric acid, was used unless otherwise noted. The procedures used for the surface modification with DNPH and APTES were the same as those in described in the previous references. First, the XPS spectra for the oxidized surfaces will be presented. Figure 9.1 shows the C 1s spectra for the hydrogenterminated, anodically treated and oxygen-plasma treated (100) and (111) surfaces. For the hydrogen-terminated surfaces (a and b), the main peak is assigned to carbon in the diamond bulk; its binding energy was found to be 285.0 ± 0.2 eV, and this was used as the binding energy shift (BES) reference. The small peaks found at ca. +1.6 and +1.8 eV BES for the (100) and (111) surfaces are similar to those that have been assigned to carbon bonded to multiple hydrogens (79) or to subsurface hydrogen (80). There is negligible oxygen present on the hydrogen-terminated surfaces. For the oxidized surfaces (both anodic and plasma treatment), shoulder-like peaks at ca. +2 eV appeared (c-f). These peaks are assigned to carbon singly bonded to oxygen (11, 81, 82). For the anodically treated (100) diamond surface, another shoulder-like 186 9. Chemical, Photochemical and Electrochemical Modification of Diamond peak, at ca. +4 eV BES, was observed (c). This peak is assigned to doubly bonded carbon-oxygen (11, 83). b (100) Intensity / cps Intensity / cps a Binding Energy Shift / eV Binding Energy Shift / eV d (100) Intensity / cps Intensity / cps c Binding Energy Shift / eV (111) Binding Energy Shift / eV f (100) Binding Energy Shift / eV Intensity / cps e Intensity / cps (111) (111) Binding Energy Shift / eV Fig. 9.1. XPS C 1s spectra for (a, b) hydrogen-terminated, (c, d) anodically-treated and (e, f) oxygen-plasma treated (100) and (111) single-crystal diamond thin films. 187 For the anodically oxidized (100) surface (c), both singly and doubly bonded C-O are present, whereas, for the (111) surface (d), only singly bonded oxygen appears to be present. As already mentioned above, the possible oxygen-containing surface functional groups for diamond (100) include the hydroxyl group (C-OH), the ether structure (C-O-C) and the carbonyl (C=O) group (4-7, 9). The hydroxyl group is the only one that could reasonably exist on the unreconstructed (111) surface (10, 84). The results for the XPS C 1s peak fittings for the homoepitaxial surfaces are summarized in Table 9.1, together with previously reported results for the polycrystalline surfaces. It can be concluded from these results that the polycrystalline surfaces consisted of a slightly greater amount of (111) than (100) faces for the first electrode and just the reverse for the second electrode. From the areas of the O 1s and C 1s peaks in the XPS survey spectra (not shown), corresponding to Fig. 9.1, the overall O/C ratios have been estimated; these are summarized in Table 9.2. For the (100) surface, the O/C ratios tend to be in the 0.1 to 0.2 range, while those for (111) tend to be around 0.2. The latter value is probably rather close to a full monolayer, based on the following argument: the sampling depth is expected to lead to an enhancement in the carbon spectrum of between a factor of 3.0 and a factor of 8.8, depending on the specific model used, (85) for the present conditions (Mg K radiation, X-ray incidence angle, 45), so that we have chosen a compromise value of five. 188 9. Chemical, Photochemical and Electrochemical Modification of Diamond Table 9.1. Atomic concentration on modified single-crystal diamond surface estimated from XPS analysis. N/C ratio at DNPH-modified N/O ratio at APTES- surface modified surface (100) 0.015-0.025 0.16 (111) negligible 0.45 Table 9.2. Estimated ratio of surface functional groups to the total surface oxygen on anodically-treated single-crystal diamond surfaces. C=O C-OH poly 0.05a 0.6b (100) 0.19 0.48 (111) negligible ~1 Notsu et al., J. Electroanal. Chem., 492 (2000) 31; Electrochem. Solid-State Lett., 4 (2001) H1. a b Notsu et al., For oxygen-plasma treated surfaces (e and f), a shoulder at ca. +2 eV was observed for both the (100) and (111) single-crystal diamond surfaces, with no evidence of a peak at +4 eV on the (100) surface. This result suggests that the higher kinetic energy involved with the oxygen plasma treatment somehow leads to a surface on which there is little carbonyl coverage. Direct evidence for the effect of the plasma treatment is found in the significantly enlarged shoulders at -1.8 to -2.0 eV; for spectra a-d, the peaks in this position can be assigned to carbon dimers (79) or to crystal defects (82). For spectra d and f, the most reasonable assignment is surface graphite (79), which can be produced by the energetic oxygen atoms. 189 In the original paper, linear sweep voltammograms (LSV) are shown for the hydrogen-terminated (100), (111) single-crystal and polycrystalline diamond electrodes in 0.1 M sulfuric acid. The potentials found for the anodic peaks were ca. +1.5 V for the (100) surface and +1.65 vs. Ag/AgCl for (111) surface. In addition, for the polycrystalline surface, both peaks were observed in a single LSV. At +1.8 V vs. Ag/AgCl, current for oxygen evolution reaction began to be seen. These anodic peaks could be seen in the first positivegoing potential sweep but not in further sweeps. These peaks were assigned to the formation of oxygen-containing groups on the electrode surface. These results were compared to those reported by Martin et al. (27) Differences in the LSV behavior for the (100) and (111) surfaces were also reported by these authors. However, they observed anodic currents during the first sweep that were on the order of 1 to 2 µA cm-2, whereas those observed in the later work were on the order of 100-200 µA cm-2 (61). At present, there is no clear explanation for this large difference in the oxidation currents. Based on an integration of the experimental currents and comparison with the theoretically calculated ones, it can be concluded that the LSV curves correspond to conversion of the hydrogen-terminated surfaces to nearly fully oxygen-terminated surfaces. For the theoretical estimates, we made the assumption that the (100) surface was initially (21): H, and the (111) surface was initially (11):H. Furthermore, as a result of anodic oxidation, we assumed that every carbon atom on the (100) surface produces a carbonyl (C=O) group, and every carbon on the (111) surface produces a hydroxyl (C-OH) group. Thus, the anodic oxidation of 190 9. Chemical, Photochemical and Electrochemical Modification of Diamond the (100) (21):H surface to a (11):O surface would require three electrons per oxygen atom, yielding 7.64 10-4 C cm-2, based on a spacing of 2.508 Å between surface carbon atoms. For one (100) sample (A), the oxidation charge was less than this value, but for sample B, the charge was slightly greater, but still in good agreement. For the (111) (11):H surface, oxidation to (11):OH requires two electrons per OH group, yielding a value of 7.84 10-4 C cm-2, (2.508 Å spacing). In this case also, the integrated charge was slightly greater, but still in good agreement. 30000 Intensity / cps 25000 A C 1s 20000 15000 O 1s N 1s 10000 5000 0 1000 800 600 400 200 0 Intensity / cps 20000 15000 B C 1s O 1s 10000 5000 0 1000 800 600 400 200 0 Binding energy / eV Fig. 9.2. XPS survey spectra for DNPH-modified single-crystal diamond surfaces: (A) (100) and (B) (111) homoepitaxial boron-doped diamond films. 191 9500 10500 Intensity / cps Intensity / cps 10000 A 9000 8500 8000 7500 405 403 401 399 397 10000 B 9500 9000 8500 8000 405 395 403 Intensity / cps Intensity / cps 397 395 397 395 10000 11000 C 10000 9500 9000 8500 405 399 Binding energy / eV Binding energy / eV 10500 401 403 401 399 397 395 9500 D 9000 8500 8000 7500 405 Binding energy / eV 403 401 399 Binding energy / eV Fig. 9.3. XPS N1s spectra for single-crystal diamond surfaces: (A, B) before and (C, D) after DNPH-modification; (A, C) (100) and (B, D) (111) homoepitaxial boron-doped diamond films. The XPS survey spectra obtained after the DNPH modification are shown in Fig. 9.2. In spectrum a (100), there is a small N 1s peak, whereas, in spectrum b (111), there is no discernable peak. The N 1s region is shown in detail in Fig. 9.3; from these results, it is rather clear that the (100) surface was partially modified with DNPH, indicating the presence of carbonyl groups, but the (111) surface was not, indicating their absence. The N/C atomic ratio for the DNPH-treated single-crystal diamond (100) surface was estimated to be 0.015-0.025 (Table 9.3). These values can be compared to values that would be obtained if DNPH were at full 192 9. Chemical, Photochemical and Electrochemical Modification of Diamond coverage. For a vertical orientation, the DNPH molecule would occupy approximately 30 Å2, compared to the area occupied by one carbon atom on the (100) surface (6.29 Å2), so that one DNPH would cover 4.77 surface carbons (see Fig. 9.4). Assuming some disorder, one could assume that a limiting coverage might be one DNPH per 10 surface carbons. The N/C ratio for this situation should be 0.071, taking into account the number of carbon and nitrogen atoms (6 and 4, respectively) for an attached DNPH molecule and the fact that several layers of carbon atoms underlying the surface are also being sampled (so that the carbon signal is enhanced by a factor of four to five) (52, 85). Thus, the experimentally obtained N/C ratios would correspond to 21-35% of “full” coverage. This level of coverage seems reasonable, since the surface oxygens on the anodically treated (100) face are expected to include a mixture of carbonyl, hydroxyl and ether groups. In fact, the experimental XPS results (Fig. 9.1c) indicated that approximately 19% of the surface oxygens (at essentially one full monolayer) were carbonyl groups for the unmodified anodically treated (100) surface. On the other hand, the N/C ratios correspond to only one DNPH to every 30-50 surface carbons, which means that only 10-17% of the carbonyl groups reacted with DNPH. Table 3. Atomic concentration ratios on modified single-crystal diamond surfaces estimated from XPS analysis. Surface (100) (111) N/C ratio (DNPHN/O ratio (APTESmodified) modified) 0.015-0.025 0.16 negligible 0.45 193 top side Fig. 9.4. Representation of the attachment of DNPH moieties to the diamond (100) surface. 194 9. Chemical, Photochemical and Electrochemical Modification of Diamond The APTES coverage can also be estimated from the atomic concentrations obtained by XPS, shown in Fig. 9.5. For a diamond surface fully covered by APTES, the N/O atomic ratio would be 0.33, assuming one APTES molecule reacts with three hydroxyl groups on the surface (see Fig. 9.6). In the present study, the N/O ratios for the (100) and (111) APTES-modified diamond surface were estimated to be 0.16 and 0.45, respectively. Given the uncertainty in the results, they indicate that the coverage of hydroxyl on the (100) surface is around 50%, while that on the (111) surface is around 100%. It was also seen in the C 1s spectrum for anodically treated (100) diamond (Fig. 9.1c) that the surface could contain well over 50% hydroxyl groups. 40000 35000 Intensity / cps Intensity / cps 40000 A 30000 25000 20000 405 403 401 399 397 35000 30000 25000 20000 405 395 B 403 C 25000 20000 15000 405 399 397 395 35000 Intensity / cps Intensity / cps 35000 30000 401 Biding energy / eV Biding energy / eV 403 401 399 Biding energy / eV 397 395 30000 D 25000 20000 15000 405 403 401 399 397 395 Biding energy / eV Fig. 9.5. XPS N1s spectra for single-crystal diamond surfaces: (A, B) before and (C, D) after APTES-modification; (A, C) (100) and (B, D) (111) homoepitaxial boron-doped diamond films. 195 Fig. 9.6. Representation of the attachment of APTES moieties to the diamond (111) surface. Taken together with the earlier results for polycrystalline diamond electrodes (54), the APTES coverage versus oxygen on the diamond surface exhibits a trend of (111) > polycrystalline (N/O = 0.15—0.25) > (100). This is quite reasonable, because the polycrystalline surface contains a mixture of the two crystal faces. From the results of the covalent surface modification of the singlecrystal diamond surfaces, we can conclude that anodically treated diamond (100) surfaces consist of a mixture of carbonyl and hydroxyl groups, although the presence of ether groups is not ruled out. On the diamond (111) surface, the hydroxyl group appears to be present at around 100%. We should emphasize that the ether structure (C-O-C) is also possible on the (100) diamond surface, given the predominance of singly bonded oxygen on this surface indicated by the C 1s 196 9. Chemical, Photochemical and Electrochemical Modification of Diamond spectrum. In fact, even though most of the work that has appeared concerning the oxidation of the (100) surface has discussed mainly ether and carbonyl functionalities (4, 6, 7, 9), it has been shown theoretically that a hydroxyl-covered diamond (100) surface can be greatly stabilized if these groups exist side-by-side on C-C dimers and can undergo hydrogen bonding.(5) We now turn to the electrochemical behavior. Figure 9.7 shows cyclic voltammograms (CVs) obtained for the Fe2+/3+ redox couple at subsequently hydrogen-terminated, DNPH-modified (100) anodically and (111) treated, and single-crystal diamond electrode surfaces. It has been reported that the electrontransfer rate for this redox couple tends to be affected by surface termination (50, 86). For polycrystalline diamond electrodes, the electron-transfer rate is larger at oxygen-terminated surfaces than at hydrogen-terminated ones. In the present case, the electrontransfer rate became greater after anodic treatment of the electrode surfaces, as evidenced by decreases in the CV anodiccathodic peak separations (Ep) (Fig. 9.8). Following DNPH treatment, the Ep value obtained for the (100) electrode surface was found to be greater than that for the corresponding anodically treated surface, but, in contrast, that for the (111) surface showed almost no change. These results support the presence of carbonyl groups on the (100) surface and their absence on the (111) surface. For glassy carbon electrodes, it has been reported that carbonyl groups on the surface, possibly in the form of quinones, can act as catalysts for the Fe2+/3+ couple (50, 52, 86). Given the fact that graphitic carbon is essentially not present on the diamond surfaces being studied, there could be few quinone groups. 197 Current density / A cm-2 a Potential / V vs. Ag/AgCl Current density / A cm-2 b Potential / V vs. Ag/AgCl Fig. 9.7. CVs for 1 mM Fe(ClO4)2 in 0.1 M H2SO4 at (a) (100) and (b) (111) single-crystal diamond electrodes; dotted line, hydrogenterminated; dashed line, anodically-treated; and solid line, DNPHmodified after anodic treatment. On the oxidized surface of polycrystalline diamond, carbonyl groups can certainly exist, but they are of an aliphatic type, which behave quite differently from the quinone type. Indeed, this type of 198 9. Chemical, Photochemical and Electrochemical Modification of Diamond carbonyl also appears to accelerate the ET for the Fe2+/3+ couple, but this is due to the previously mentioned attraction of the positively charged ions to the negatively charge electrode surface. The DNPH molecule reacts selectively with surface carbonyl groups, effectively blocking them. Therefore, for electrode surfaces containing carbonyl groups, DNPH treatment should cause a decrease in the ET rate for the Fe2+/3+ couple, whereas, for surfaces containing no carbonyl groups, this treatment should not produce any effect. Thus, we can conclude that the anodically treated (100) diamond surface does include a significant coverage of carbonyl groups, but that the anodically treated (111) surfaces contain essentially no carbonyl groups. This conclusion is consistent with the XPS results. Ep / mV ■ (100) ● (111) Hydrogenterminated Anodically -treated DNPHmodified Fig. 9.8. Variation of peak separations (Ep) of CVs in Fig. 9.7. For the APTES modification, the surfaces were characterized by recording the CVs for the Fe(CN)63-/4- redox couple (Fig. 9.9). From the variation of Ep, it was found that the ET behavior was nearly reversible at the hydrogen-terminated diamond electrode 199 surfaces, but, at the corresponding oxygen-terminated surfaces, it became much more irreversible, i.e., with a tendency opposite to that for Fe2+/3+. This is also likely to be due to an electrostatic effect, in which the surface dipoles of the C-O functional groups tend to repel the negative charges of both members of the redox couple (50, 55, 87). 200 Current density / A cm-2 9. Chemical, Photochemical and Electrochemical Modification of Diamond a Current density / A cm-2 Potential / V vs. Ag/AgCl b Current density / A cm-2 Potential / V vs. Ag/AgCl c Potential / V vs. Ag/AgCl Fig. 9.8. CVs for 1 mM K3Fe(CN)6 in 0.1 M H2SO4 at (a) polycrystalline, (b) (100) and (c) (111) single-crystal diamond electrodes; dotted line, hydrogen-terminated; dashed line, anodically-treated; and solid line, APTES-modified after anodic treatment. It should pointed out that the shapes of the CVs for the anodically-treated single-crystal electrodes in Fig. 9.9 were 201 asymmetric, i.e., the cathodic peak currents were either significantly smaller than the anodic peak currents, on the (111) surface (c), or could not be observed at all, on the (100) surface (b). This behavior may be due to semiconductor-type behavior. As mentioned above, the surface dipole effects are accentuated in cases in which the carrier concentrations fall below the 1019 cm-3 level. We have also shown that the acceptor density near the surface for as-deposited, hydrogen-terminated diamond electrodes can be much higher than that expected from the boron doping level, and can decrease to a density lower than the doping level after surface oxidation (62). The differences in the electrical properties are also reflected in the ET behavior on the electrode surface. Thus, in the case of the hydrogen-terminated (100) single-crystal diamond electrode, the ET for Fe(CN)63-/4- (Fig. 9.9b) showed reversible character, which may be due to higher accepter density in the near-surface region than that expected based on the doping level. Similar behavior has been reported for lightly-doped polycrystalline diamond electrodes.(55). It should also be noted that the voltammetric behavior for the Fe2+/3+ redox couple (Fig. 9.7) did not exhibit significant asymmetry. This difference is probably due to the fact that this redox couple is not as sensitive to the number of charge carriers as is the ferro/ferricyanide couple. For the oxidized and subsequently APTES-treated polycrystalline (Fig. 9.9a) and (111) single-crystal diamond electrodes (Fig. 9.9c), the CV shapes for the ferro/ferricyanide couple became almost the same as those for the respective hydrogen-terminated surfaces. The result for the APTES-modified 202 9. Chemical, Photochemical and Electrochemical Modification of Diamond polycrystalline diamond electrode is similar to that previously reported by Notsu et al. (54). In that paper, it was proposed that the protonated amino group of the APTES moiety was responsible for electrostatically attracting the anionic redox species. For the diamond (100) surface (Fig. 9.9b), the shape of the CV for the APTES-modified surface did not return to that for the hydrogenterminated surface, but the anodic peak potential shifted significantly negative of that for the anodically treated surface. The fact that it did not return to the initial behavior is probably due to the fact that the doping level for the (100) epitaxial film was lower than those for the polycrystalline and (111) films (55, 62). In the original paper, electrochemical AC impedance measurements were also carried out, and these results also tend to support those obtained in the cyclic voltammetry. Thus, in this study, by use of XPS in conjunction with chemical surface modification techniques, new information was obtained on the surface functional groups generated on oxidized diamond surfaces. In particular, it was found that the variation of oxygen-containing surface functional groups strongly depends on the exposed crystal face, as well as on the type of oxidative treatment, e.g., anodic or oxygen plasma. To understand the dependence of the coverages of oxygen-containing surface functional groups on treatment and crystal face is especially important, for two reasons: one is that the oxygen termination can include various types of surface functional groups, and thus a variety of functional surfaces can be created by utilizing these groups. The other is that diamond electrode surfaces typically become oxidized during practical use as an electrode material, because, as we have seen, only a single positive- 203 going potential sweep may be enough to completely oxidize the diamond. 9.6. Metal and Metal Oxides on Diamond Surfaces As a separate topic, we now discuss metals and metal oxides deposited on diamond surfaces. The topic of metals on diamond has been studied for a number of years from the standpoint of semiconductor devices (3, 88-105). Many of these papers discuss the effect of hydrogen vs. oxygen termination and the resulting surface dipoles. As mentioned above, this work has received attention over the years due to the great interest in electron emission. However, electrochemical our interest here characteristics. is more The related often-cited to the intrinsic electrochemical characteristics of diamond, including extreme stability, low background current and large potential working range, are also advantages for the fundamental study of the electrochemical characteristics of solid materials. The electroanalytical applications of electrochemical metal deposition will be treated in Chapter 16. The materials of interest in the present chapter are those with applications as battery electrodes, capacitor electrodes and electrocatalysts. There may even be cases in which diamond can play a role as a practical support material. We begin with electrocatalysts. Platinum has been deposited on diamond surfaces electrolytically and then examined with various techniques (106-109). The Pt deposit has been found to be quite stable on the polycrystalline diamond surface during 204 9. Chemical, Photochemical and Electrochemical Modification of Diamond potential cycling, more so than on conventional carbon or graphite substrates. This is most likely due to stability of the diamond substrate itself, particularly at highly positive potentials, at which graphitic carbon undergoes irreversible oxidation. Other metals that have been of interest include copper (110) and nickel (111). These have been studied due to their electrocatalytic activity for glucose oxidation. The copper was deposited electrochemically, whereas the nickel was deposited via ion implantation. The behavior of these metals in the form of nanoparticles on diamond is highly attractive in terms of glucose determination, because the current for glucose oxidation is increased dramatically without increasing the background current substantially. There has been some interest in the possibility that diamond electrodes could be intercalated or inserted with lithium, because there are still problems associated with graphitic materials in terms of stability. Li et al. showed that there is essentially no “underpotential deposition” of lithium on homoepitaxial diamond (111) surfaces under highly controlled conditions, particularly the absence of sp2 carbon-containing grain boundaries (112). In work of Pleskov and coworkers, they also concluded that there is neglibible Li intercalation into diamond nanoparticles (113). However, there is recent work that does suggest that significant insertion of Li into a diamond film grown on carbon is possible (114). One of the first metal oxides to be examined electrochemically on a diamond substrate was ruthenium dioxide (115, 116). This material is important both for electrochemical capacitor and 205 electrocatalytic applications (chlorine evolution). Another example is cobalt hydrous oxide, which has catalytic activity for oxygen evolution (117). A very recent example is lead dioxide (118). A metal oxide (V2O3) has also been supported on particulate diamond as a catalyst for an organic gas-phase reaction (119). 9.7. Conclusions The highly attractive characteristics of conductive diamond electrodes continue to bring attention. Recently, it has also become clear that the possibilities for chemical modification can take advantage of these fundamental characteristics and build upon them, imparting novel selectivity and catalytic activity. The possible applications are as diverse as those for all other types of electrodes, because diamond can be a useful substrate for all. Moreover, all of the modification techniques that have been worked out over the past several years for other surfaces, such as carbon and gold, can now be transplanted onto diamond. Now is just the beginning of the blossoming of this field. Acknowledgements The authors would like to express their appreciation to the students and researchers who have participated in this research. The APTES figure was drawn by Mr. Hiroyuki Ito, and the DNPH 206 9. Chemical, Photochemical and Electrochemical Modification of Diamond figure was drawn by Mr. Shinsuke Aoshima, both of the Tokyo Science University. The research has been supported by the Ministry of Education, Science, Sports and Culture of Japan, the National Aeronautics and Space Administration, the U.S. Army Office of Research, and the National Science Foundation. References 1. R. E. Thomas, R. A. Rudder, and R. J. Markunas, J. Vac. Sci. Technol. A 10, 2451 (1992). 2. T. Ando, M. Ishii, M. Kamo, and Y. Sato, J. Chem. Soc., Farad. Trans. 89, 1783 (1993). 3. J. van der Weide and R. J. Nemanich, Phys. Rev. B 49, 13629 (1994). 4. J. L. Whitten, P. Cremaschi, R. E. Thomas, R. A. Rudder, and R. J. Markunas, Appl. Surf. Sci. 75, 45 (1994). 5. S. Skokov, B. Weiner, and M. Frenklach, Phys. Rev. B 55, 1895 (1997). 6. M. Z. Hossain, T. Kubo, T. Aruga, N. Takagi, T. Tsuno, N. Fujimori, and M. Nishijuma, Surf. Sci. 436, 63 (1999). 7. P. E. Pehrsson and T. W. Mercer, Surf. Sci. 460, 49 (2000). 8. P. E. Pehrsson and T. E. Mercer, Surf. Sci. 460, 74 (2000). 9. H. Tamura, H. Zhou, K. Sugisako, Y. Yokoi, S. Takami, M. Kubo, K. Teraishi, A. Miyamoto, A. Imamura, M. N.-Gamo, and T. Ando, Phys. Rev. B 61, 11025 (2000). 10. K. P. Loh, X. N. Xie, S. W. Wang, and J. C. Zheng, J. Phys. Chem. B 106, 5230 (2002). 207 11. P. John, N. Polwart, C. E. Troupe, and J. I. B. Wilson, J. Amer. Chem. Soc. 125, 6600 (2003). 12. A. Laikhtman, A. Lafosse, Y. L. Coat, R. Azria, and A. Hoffman, J. Chem. Phys. 119, 1794 (2003). 13. Y. V. Pleskov, Russ. Chem. Rev. 68, 381 (1999). 14. M. J. Rutter and J. Robertson, Phys. Rev. B 57, 9241 (1998). 15. J. Robertson and M. J. Rutter, Diamond Rel. Mater. 7, 620 (1998). 16. K. Ushizawa, Y. Sato, T. Mitsumori, T. Machinami, T. Ueda, and T. Ando, Chem. Phys. Lett. 351, 105 (2002). 17. S. Wenmackers, K. Haenen, M. Nesladek, P. Wagner, L. Michiels, M. vandeVen, and M. Ameloot, Phys. Status Solidi A 199, 44 (2003). 18. P. Krysinski, Y. Show, J. Stotter, and G. J. Blanchard, J. Am. Chem. Soc. 125, 12726 (2003). 19. A. Freedman and C. D. Stinespring, Appl. Phys. Lett. 57, 1194 (1990). 20. A. Freedman, J. Appl. Phys. 75, 3112 (1994). 21. T. Y. Ando, Kazuo; Suehara, Shigeru; Kamo, Matsukazu; Sato, Yoichiro; Shimosaki, Shinji; Nishitani-Gamo, Mikka, J. Chin. Chem. Soc. (Taipei) 42, 285 (1995). 22. T. Ando, K. Yamamoto, M. Kamo, Y. Sato, Y. Takamatsu, S. Kawasaki, F. Okino, and H. Touhara, J. Chem. Soc., Farad. Trans. 91, 3209 (1995). 23. T. I. Hukka, T. A. Pakkanen, and M. P. D'Evelyn, J. Am. Chem. Soc. 99, 4710 (1995). 24. T. Ando, Nishitani-Gamo, M. Rawles, R. E., K. Yamamoto, M. Kamo, and Y. Sato, Diamond Rel. Mater. 5, 1136 (1996). 208 9. Chemical, Photochemical and Electrochemical Modification of Diamond 25. Y. Ikeda, T. Saito, K. Kusakabe, S. Morooka, H. Maeda, Y. Taniguchi, and Y. Fujiwara, Diamond Rel. Mater. 7, 830 (1998). 26. B. K. Ohtani, Young-Ho; Yano, Takashi; Hashimoto, Kazuhito; Fujishima, Akira; Uosaki, Kohei, Chem. Lett., 953 (1998). 27. H. B. Martin, A. Argoitia, J. C. Angus, and U. Landau, J. Electrochem. Soc. 146, 2959 (1999). 28. J. B. Miller, Surf. Sci. 439, 21 (1999). 29. S. Ferro and A. DeBattisti, Anal. Chem. 75, 7040 (2003). 30. S. Ferro and A. DeBattisti, J. Phys. Chem. B 107, 7567 (2003). 31. G. Sine, L. Ouattara, M. Panizza, and C. Comninellis, Electrochem. Solid-State Lett. 6, D9 (2003). 32. T. H. Tsubota, Osamu; Ida, Shintaro; Nagaoka, Shoji; Nagata, Masanori; Matsumoto, Yasumichi, Diamond Rel. Mater. 11, 1360 (2002). 33. T. Tsubota, O. Hirabayashi, S. Ida, S. Nagaoka, M. Nagata, and Y. Matsumoto, Diamond Rel. Mater. 11, 1374 (2002). 34. T. H. Tsubota, Osamu; Ida, Shintaro; Nagaoka, Shoji; Nagata, Masanori; Matsumoto, Yasumichi, Phys. Chem. Chem. Phys. 4, 806 (2002). 35. T. I. Tsubota, Shintaro; Hirabayashi, Osamu; Nagaoka, Shoji; Nagata, Masanori; Matsumoto, Yasumichi, Phys. Chem. Chem. Phys. 4, 3881 (2002). 36. T. T. Tsubota, Shunsuke; Ida, Shintaro; Nagata, Masanori; Matsumoto, Yasumichi, Phys. Chem. Chem. Phys. 5, 1474 (2003). 37. S. Ida, T. Tsubota, S. Tanii, M. Nagata, and Y. Matsumoto, Langmuir 19, 9693 (2003). 209 38. S. T. Ida, Toshiki; Hirabayashi, Osamu; Nagata, Masanori; Matsumoto, Yasumichi; Fujishima, Akira, Diamond Rel. Mater. 12, 601 (2003). 39. D. R. Fitzgerald and D. J. Doren, J. Am. Chem. Soc. 122, 12334 (2000). 40. J. S. Hovis, S. K. Coulter, R. J. Hamers, M. P. D'Evelyn, J. N. Russell, Jr., and J. E. Butler, J. Am. Chem. Soc. 122, 732 (2000). 41. G. T. Wang, S. F. Bent, J. N. Russell, Jr., and J. E. Butler, J. Amer. Chem. Soc. 122, 744 (2000). 42. T. Strother, T. Knickerbocker, J. N. Russell, Jr., J. E. Butler, L. M. Smith, and R. J. Hamers, Langmuir 18, 968 (2002). 43. W. Yang, O. Auciello, J. E. Butler, W. Cai, J. A. Carlisle, J. E. Gerbi, D. M. Gruen, T. Knickerbocker, T. L. Lasseter, J. John N. Russell, L. M. Smith, and R. J. Hamers, Nature Mat. 1, 253 (2002). 44. T. Knickerbocker, T. Strother, M. P. Schwartz, J. N. Russell, Jr., J. Butler, L. M. Smith, and R. J. Hamers, Langmuir 19, 1938 (2003). 45. W. Yang, J. E. Butler, J. N. Russell, Jr., and R. J. Hamers, Langmuir 20, 6778 (2004). 46. J. B. Miller and D. W. Brown, Langmuir 12, 5809 (1996). 47. H. Notsu, I. Yagi, T. Tatsuma, D. A. Tryk, and A. Fujishima, Electrochem. Solid-State Lett. 2, 522 (1999). 48. E. Popa, H. Notsu, T. Miwa, D. A. Tryk, and A. Fujishima, Electrochem. Solid-State Lett. 2, 49 (1999). 49. I. Yagi, K. Tsunozaki, D. A. Tryk, and A. Fujishima, Electrochem. Solid-State Lett. 9, 457 (1999). 50. I. Yagi, H. Notsu, T. Kondo, D. A. Tryk, and A. Fujishima, J. Electroanal. Chem. 473, 173 (1999). 210 9. Chemical, Photochemical and Electrochemical Modification of Diamond 51. M. Yanagisawa, H. Tai, I. Yagi, D. A. Tryk, A. Fujishima, and L. Jiang, in "Sixth International Symposium on Diamond Materials, Extended Abstracts, Joint Meeting of the Electrochemical Society and the Electrochemical Society of Japan". The Electrochemical Society, Honolulu, Hawaii, 1999. 52. H. Notsu, I. Yagi, T. Tatsuma, D. A. Tryk, and A. Fujishima, J. Electroanal. Chem. 492, 31 (2000). 53. E. Popa, Y. Kubota, D. A. Tryk, and A. Fujishima, Anal. Chem. 72, 1724 (2000). 54. H. Notsu, T. Fukuzawa, T. Tatsuma, D. A. Tryk, and A. Fujishima, Electrochem. Solid State Lett. 4, H1 (2001). 55. D. A. Tryk, K. Tsunozaki, T. N. Rao, and A. Fujishima, Diamond Rel. Mater. 10 (2001). 56. M. C. Granger and G. M. Swain, J. Electrochem. Soc. 146, 4551 (1999). 57. M. C. Granger, M. Witek, J. Xu, J. Wang, M. Hupert, A. Hanks, M. D. Koppang, J. E. Butler, G. Lucazeau, M. Mermoux, J. W. Strojek, and G. M. Swain, Anal. Chem. 72, 3793 (2000). 58. H. B. Martin and J. Philip W. Morrison, Electrochem. Solid-State Lett. 4, E17 (2001). 59. D. Delabouglise, B. Marcus, M. Mermoux, P. Bouvier, J. ChaneTune, J.-P. Petit, P. Mailley, and T. Livache, Chem. Commun., 2698 (2003). 60. W. C. Poh, K. P. Loh, W. D. Zhang, S. Triparthy, J.-S. Ye, and F.-S. Sheu, Langmuir 20, 5484 (2004). 61. T. Kondo, K. Honda, D. A. Tryk, and A. Fujishima, J. Electrochem. Soc., in press (2004). 211 62. T. Kondo, D. A. Tryk, and A. Fujishima, Electrochim. Acta 48, 2739 (2003). 63. C. Terashima, T. N. Rao, B. V. Sarada, D. A. Tryk, and A. Fujishima, Anal. Chem. 74, 895 (2002). 64. O. S. Chailapakul, W.; Sarada, B. V.; Terashima, C.; Rao, Tata N.; Tryk, D. A.; Fujishima, A.;, Analyst (Cambridge, U.K.) 127, 1164 (2002). 65. C. Terashima, T. N. Rao, B. V. Sarada, Y. Kubota, and A. Fujishima, Anal. Chem. 75, 1564 (2003). 66. We should note that the nanolithographic AFM modification of diamond was apparently discovered independently and nearly simultaneously by the Fujishima and Kawarada groups. 67. M. Tachiki, T. Fukuda, K. Sugata, H. Seo, H. Umezawa, and H. Kawarada, Jpn. J. Appl. Phys. 39, 4631 (2000). 68. M. Tachiki, H. Seo, T. Banno, Y. Sumikawa, H. Umezawa, and H. Kawarada, Appl. Phys. Lett. 81, 2854 (2002). 69. T. Kondo, M. Yanagisawa, L. Jiang, D. A. Tryk, and A. Fujishima, Diamond Rel. Mater. 11, 1788–1796 (2002). 70. M. Yanagisawa, L. Jiang, D. A. Tryk, K. Hashimoto, and A. Fujishima, Diamond Rel. Mater. 8, 2059 (1999). 71. M. Tachiki, T. Fukuda, K. Sugata, H. Seo, H. Umezawa, and H. Kawarada, in "Third International Symposium on the Control of Semiconductor Interfaces", p. 578, Karuizawa, Japan, 1999. 72. H. Seo, M. Tachiki, T. Banno, Y. Sumikawa, H. Umezawa, and H. Kawarada, Jpn. J. Appl. Phys., Part I 41, 4980 (2002). 73. K. Sugata, M. Tachiki, T. Fukuda, H. Seo, and H. Kawarada, Jpn. J. Appl. Phys., Part I 41, 4983 (2002). 212 9. Chemical, Photochemical and Electrochemical Modification of Diamond 74. T.-C. Kuo, R. L. McCreery, and G. M. Swain, Electrochem. Solid- State Lett. 2, 288 (1999). 75. M. Delamar, R. Hitmi, J. Pinson, and J. M. Saveant, J. Am. Chem. Soc. 114, 5883 (1992). 76. C. Bourdillon, M. Delamar, C. Demaille, R. Hitmi, J. Moiroux, and J. Pinson, J. Electroanal. Chem. 336, 113 (1992). 77. P. Allongue, M. Delamar, B. Desbat, O. Fagebaume, R. Hitmi, J. Pinson, and J.-M. Saveant, J. Am. Chem. Soc. 119, 201 (1997). 78. C. Saby, B. Ortiz, G. Y. Champagne, and D. Belanger, Langmuir 13, 6805 (1997). 79. R. Graupner, F. Maier, J. Ristein, L. Ley, and C. Jung, Phys. Rev. B 57, 12397 (1998). 80. K. Bobrov, A. Mayne, G. Comtet, G. Dujardin, L. Hellner, and A. Hoffman, Phys. Rev. ) 68, 195416 (2003). 81. T. N. Rao, D. A. Tryk, K. Hashimoto, and A. Fujishima, J. Electrochem. Soc. 146, 6870 (1999). 82. C. H. Goeting, F. Marken, A. Gutierrez-Sosa, R. G. Compton, and J. S. Foord, Diamond Relat. Mater. 9, 390 (2000). 83. C. D. Wagner, A. V. Naumkin, A. Kraut-Vass, J. W. Allison, C. J. Powell, and J. R. Rumble, Jr.; U. S. Department of Commerce, 2000. 84. F. K. de Theije, M. F. Reedijk, J. Arsic, W. J. P. van Enckevort, and E. Vlieg, Phys. Rev. B 64, 085 (2001). 85. C. J. Powell and A. Jablonski, in "NIST Standard Reference Database 82". National Institute of Standards and Technology, Gaithersburg, MD, 2000. 86. P. Chen, M. A. Fryling, and R. L. McCreery, Anal. Chem. 67, 3115 (1995). 213 87. T. Kondo, Y. Einaga, B. V. Sarada, T. N. Rao, D. A. Tryk, and A. Fujishima, J. Electrochem. Soc. 149, E179 (2002). 88. G. S. Gildenblat, S. A. Grot, C. R. Wronski, A. R. Badzian, T. Badzian, and R. Messier, Appl. Phys. Lett. 53, 586 (1988). 89. M. C. Hicks, C. R. Wronski, S. A. Grot, G. S. Gildenblat, A. R. Badzian, T. Badzian, and R. Messier, J. Appl. Phys. 65, 2139 (1989). 90. S. A. Grot, G. S. Gildenblatt, C. W. Hatfield, C. R. Wronski, A. R. Badzian, T. Badzian, and R. Messier, IEEE Electron Dev. Lett. 11, 100 (1990). 91. G. S. Gildenblat, S. A. Grot, and A. R. Badzian, Proc. IEEE 79, 647 (1991). 92. Y. Mori, H. Kawarada, and A. Hiraki, Appl. Phys. Lett. 58, 940 (1991). 93. K. Miyata, D. L. Dreifus, and K. Kobashi, Appl. Phys. Lett. 60, 480 (1992). 94. T. Tachibana, J. T. Glass, and R. J. Nemanich, J. Appl. Phys. 73, 835 (1993). 95. M. Aoki and H. Kawarada, Jpn. J. Appl. Phys. 33, L708 (1994). 96. H. Kiyota, E. Matsushima, K. Sato, H. Okushi, T. Ando, M. Kamo, Y. Sato, and M. Iida, Appl. Phys. Lett. 67, 3596 (1995). 97. H. Kawarada, M. Itoh, and A. Hokazono, Jpn. J. Appl. Phys. 35, L1165 (1996). 98. P. K. Baumann, S. P. Bozeman, B. L. Ward, and R. J. Nemanich, Diamond Rel. Mater. 6, 398 (1997). 99. P. K. Baumann and R. J. Nemanich, in "The 24th Conference on the Physics and Chemistry of Semiconductor Interfaces", Vol. 15, 214 9. Chemical, Photochemical and Electrochemical Modification of Diamond p. 1236. AVS, Research Triangle Park, North Carolina (USA), 1997. 100. K. Hayashi, S. Yamanaka, H. Watanabe, T. Sekiguchi, H. Okushi, and K. Kajimura, J. Appl. Phys. 81, 744 (1997). 101. P. K. Baumann and R. J. Nemanich, Diamond Rel. Mater 7, 612 (1998). 102. P. K. Baumann and R. J. Nemanich, J. Appl. Phys. 83, 2072 (1998). 103. A. Deneuville, C.R. Acad. Sci., Ser. IV, 81 (2000). 104. R. Zeisel, C. E. Nebel, and M. Stutzmann, Diamond Relat. Mater. 9, 413 (2000). 105. J. E. Gerbi, O. Auciello, J. Birrell, D. M. Gruen, B. W. Alphenaar, and J. A. Carlisle, Appl. Phys. Lett. 83, 2001 (2003). 106.J. Wang, G. M. Swain, T. Tachibana, and K. Kobashi, Electrochem. Solid-State Lett. 3, 286 (2000). 107. K. Honda, M. Yoshimura, T. N. Rao, D. A. Tryk, A. Fujishima, K. Yasui, Y. Sakamoto, K. Nishio, and H. Masuda, J. Electroanal. Chem. 514, 35 (2001). 108. O. Enea, B. Riedo, and G. Dietler, Nano Letters 2, 241 (2002). 109. J. Wang and G. M. Swain, Electrochem. Solid-State Lett. 5, E4 (2002). 110.R. Uchikado, T. N. Rao, D. A. Tryk, and A. Fujishima, Chem. Lett., 144 (2001). 111. K. Ohnishi, Y. Einaga, H. Notsu, C. Terashima, T. N. Rao, S.-G. Park, and A. Fujishima, Electrochem. Solid-State Lett. 5, D1 (2002). 112. L.-F. Li, D. Totir, B. Miller, G. Chottiner, A. Argoitia, J. C. Angus, and D. Scherson, J. Am. Chem. Soc.; 119, 7875 (1997). 215 113. T. L. Kulova, Y. E. Evstefeeva, Y. V. Pleskov, A. M. Skundin, V. G. Ral’chenko, S. B. Korchagina, and S. K. Gordeev, Phys. Solid State 46, 726–728 (2004). 114. N. G. Ferreira, L. L. Mendonca, V. J. T. Airoldi, and J. M. Rosolen, Diamond Rel. Mater. 12, 596–600 (2003). 115. A. DeBattisti, S. Ferro, and M. D. Colle, J. Phys. Chem. B 105, 1679 (2001). 116. S. Ferro and A. DeBattisti, J. Phys. Chem. B 106, 2249 (2002). 117. N. Spataru, C. Terashima, K. Tokuhiro, I. Sutanto, D. A. Tryk, S.M. Park, and A. Fujishima, J. Electrochem. Soc. 150, E337 (2003). 118. M. E. Hyde, R. M. J. Jacobs, and R. G. Compton, J. Phys. Chem. B 108, 6381 (2004). 119. K. Okumura, K. Nakagawa, T. Shimamura, N. Ikenaga, M. Nishitani-Gamo, T. Ando, T. Kobayashi, and T. Suzuki, J. Phys. Chem. B 107, 13419 (2003). 216