* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Active Suspension System Test Platform Bradley University

Solar micro-inverter wikipedia , lookup

Power engineering wikipedia , lookup

Flip-flop (electronics) wikipedia , lookup

Alternating current wikipedia , lookup

Voltage optimisation wikipedia , lookup

Mains electricity wikipedia , lookup

Control theory wikipedia , lookup

Power inverter wikipedia , lookup

Power MOSFET wikipedia , lookup

Negative feedback wikipedia , lookup

Analog-to-digital converter wikipedia , lookup

Oscilloscope history wikipedia , lookup

Schmitt trigger wikipedia , lookup

Distribution management system wikipedia , lookup

Buck converter wikipedia , lookup

Control system wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Switched-mode power supply wikipedia , lookup

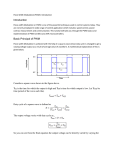

Immunity-aware programming wikipedia , lookup

Active Suspension System Test Platform Bradley University Department of Electrical & Computer Engineering By: Craig Chan & Olusegun Michael Abidoye Advisor: Steven Gutschlag 27 April 2005 Outline Project Summary Division of Labor Functional Description Block Diagrams Subsystems Test Results Parts List Questions? Project Summary Providing a test platform for active/passive suspension system Testing vehicle suspension system Actuator driven and micro-controller based Common feedback control applications CNC fabrication machines Aviation control Division of Labor Craig Design and build power electronics to drive a 115 Volt DC motor Microcontroller isolation circuitry H-Bridge design Control algorithm Testing and debugging Mike Microcontroller based feedback control system Control Algorithm A/D converter PWM (Timer 2) Testing and debugging Functional Description Microcontroller feedback system ensures proper output independent of load. The mode of operation will be determined by the user via a keypad on the micro-controller. Sinusoidal Step Triangular Flexibility in selecting desired speed and travel distance of the platform Overall Control Block Diagram Pe Pi Pa Perror = Pinput – Pactuator Output (Platform Position) System Block Diagram Analog Position Input Keypad Input (Desired Platform Motion) A/D Converter EMAC Micropac 535 Micro-Controller Interface POSITION FEEDBACK Display ( user input) Power Electronics Test Platform Output (Platform Motion) Hardware Subsystem Hardware Configuration Power MOSFETS 4N25 Phototransistor Optocouplers Infrared emitting diode driving a phototransistor Provides voltage isolation between the microcontroller and the IR2213 IR640N Power MOSFET’s Drain to Source Voltage Max = 200 Volts Continuous Drain Current Max = 18A IR2213 High & Low Side Driver Configuration Load supply voltage up to +1200 volts N-Channel MOSFETs (Faster & Cheaper) IR2213 High & Low Side Driver Decoupling Capacitors Charge Pump Bootstrap Circuit Decoupling Capacitor H-Bridge IR 2213 IR 2213 Vcc (Signal to MOSFETs) A (Signal to MOSFETs) B ON ON ON ON C Gnd D Software Subsystem Setup Module Initializes the microcontroller Setups interrupt vector tables Setups necessary peripherals Configures interrupt priority Jumps to main module Main Module Welcomes the user Prompts the user platform parameters Amplitude and frequency Waveform (single or continuous) Keypad Module EX1 interrupt handler Fetches keys pressed via kpad subroutine Translates keys to ASCII equivalent Performs necessary task for each key Key A = Single Step input Key B = Backspace Key C = Continuous waveform input Key D = Stop suspension Key E = Start suspension Lcd Module Displays prompts Displays user’s entries Timer 2 Module Configuration Auto reload , mode 0 Compare mode 1 (16 bits) Subroutines PWM Subroutine Timer 2 interrupt handler EX4 interrupt handler (when T2 register = CC1) EX5 interrupt handler (when T2 register = CC2) PWM Subroutine Generates two PWM signals at P4.1 and P4.2 Decides which one to turn on, via direction flag Generates three interrupts T2 interrupt (overflow) CC1 = T2 EX4 interrupt CC2 = T2 EX5 interrupt PWM Subroutine •Checking direction flag •Forward Pwm •Reverse Pwm Timer 2 interrupt handler EX4 interrupt handler Forward PWM EX5 interrupt handler Reverse PWM A/D Module Determines status of direction flag A/D_pi Fetches input signal from AN0 A/D_pa Fetches position feedback from AN2 Control Block Diagram Input Voltage Signal Representing the Desired Platform Motion (Provided by the Waveform Generator) Gain Old Duty Cycle Output (Platform Motion) Suspension Module DC_new = DC_old + K * Pe Pe = Pi – Pa (Pi > Pa, clr dir flag, forward PWM) DC_new = DC_old – K *Pe Pe = Pa – Pi (Pa > Pi, setb dir flag, reverse PWM) Test Platform Subsystem Rated DC Motor Specifications RPM Max 1725 Horse Power 1/3 Volts 115 Amps 3.4 Screw Jack Specifications (Nook Industries) 18 Inches of Stroke Length Gear Ratio 5:1 Turns of worm per inch travel = 10 Max Horse Power 1/3 Max load = 1000 Lbs Max worm speed at rated load = 868 RPM Max load at 1750 RPM = 496 lbs Assembled with a top plate Inch Ball Screw Jack Without Top Plate With Top Plate Preliminary Experimental Results Electrak mini actuator Pi = Input signal Pa = Actuator Position Sinusoidal Input Pi = Input signal Pa = Actuator Position Triangular Input Pi = Input signal Pa = Actuator Position Parts List Micro Pac 535 (EMAC Kit # 5) High and Low Side Driver (IR2213) Phototransistor (4N25) N-channel Power MOSFETS (IR640) Electrak mini actuator Screw Jack (0.5HL-BSJU) DC Motor (437698-AW) QUESTIONS ?