* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Development of Room Temperature Stable Formulation of

Survey

Document related concepts

Neuropharmacology wikipedia , lookup

Compounding wikipedia , lookup

Pharmacogenomics wikipedia , lookup

Nicholas A. Peppas wikipedia , lookup

Sol–gel process wikipedia , lookup

Pharmaceutical industry wikipedia , lookup

Drug design wikipedia , lookup

Prescription costs wikipedia , lookup

Drug interaction wikipedia , lookup

Prescription drug prices in the United States wikipedia , lookup

Pharmacognosy wikipedia , lookup

Drug discovery wikipedia , lookup

Transcript

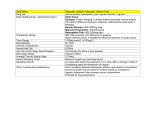

www.ijpsonline.com TABLE 3: VISCOSITY OF NASAL FORMULATION AT DIFFERENT TEMPERATURES Formulation F1 F2 Viscosity at 250 in cP Viscosity at 350 in cP Gelling point by graph (0) 25 51 839 1089 34 34 F3 88 1474 32 F4 107 1847 31 F5 129 2247 29 Viscosity by Brookfield viscometer cap 2000+ spindle No. 1 at 5 rpm of nasal formulation at different temperature 250 for solutions and 350 forgels Various solubilizers were tried during preformulation study. Propylene glycol and Transcutol were selected as solubilizers for further study. Poloxamer 407 gives gelation temperature in nasal temperature range 28 0 to 35 0 in 18% w/v concentration. Addition of bioadhesive polymer from 0.2% to 0.7% further lowered the gelation temperature from 34 0 to 29 0. Gelation temperatures obtained using two different methods (visual inspection and rheological method) did not vary more than ±10. The gelation temperature lowering effect of bioadhesive polymer might have caused in part by the increased viscosity after dissolution of mucosadhesive polymer. The pH values of all formulations were found in the range of 5.3 to 5.6. Formulation should posses’ mild acidic pH for activation of lysozyme (A natural antibacterial enzyme important for controlling nasal microbial count which becomes inactive at alkaline pH). The pKa of ondansetron hydrochloride is 7.4; so drug present in solubilised form in pH range 5 to 6.5 (ondansetron hydrochloride precipitate above 6.8). It was observed that the concentration of bioadhesive polymer increased from 0.2% to 0.7% showed retardation of ondansetron hydrochloride release, probable mechanism for such retardation of release may be reduction in number and dimensions of the channels in gel structure by increased viscosity of the formulation. From the study it can be concluded that the nasal in situ gels can be formulated of ondansetron hydrochloride using PF127 and bioadhesive polymer. ACKNOWLEDGMENTS We would like to thank Dr. Reddy’s Lab. and Signet Chemicals for supplying drug and polymer samples respectively. REFERENCES 1. 2. 3. 4. 5. 6. Cho E, Gwak H, Chun I. Formulation and evaluation of ondansetron nasal delivery systems. Int J Pharm 2008;349:101-7. Schmolka IR. Artificial skin: Preparation and properties of Pluronic F-127 gels for treatment of burns. J Biomed Mater Res 1972;6:571-82. Miller SC, Donovan MD. Effect of poloxamer 407 gels on the miotic activity of pilocarpine nitrate in rabbits. Int J Pharm 1982;5:142-52. Shinde JV, Mali KR, Dias RJ, Havaldar VD, Mahajan NS. In situ Mucoadhesive nasal gels of metaclopramide hydrochloride: preformulation & formulation studies. J Pham Res 2008;1:88-96. Yong CS, Choi JS, Quan QZ, Rhee JD, Kim CK. Effect of sodium chloride on gelation temperature, gel strength and bioadhesive force of poloxamer gels containing diclofenac sodium. Int J Pharm 2001;226:195-205. Zaki NM, Awad GA, Mortada ND, AbdelHady SS. Enhanced bioavailability of metaclopromide HCl by intranasal administration of a mucoadhesive in situ gel with modulated rheological and mucociliary transport properties. Eur J Pharm Sci 2007;32:296-307. Development of Room Temperature Stable Formulation of Formoterol Fumarate/Beclomethasone HFA pMDI D. PUROHIT*, A. TREHAN AND V. ARORA Research & Development Centre (R&D I), Ranbaxy Laboratories Limited, Plot No. 20, Sector 18, Udyog Vihar Industrial Area, Gurgaon-122 015, India Purohit et al.: Room Temperature Stable Formoterol Fumarate/Beclomethasone HFA pMDI The primary aim of present investigation was to develop and formulate room temperature stable formulation of formoterol fumarate and beclomethasone dipropionate with extra fine part size of hydrofluoroalkane pressurized metered dose inhalers. Particle size distribution of hydrofluoroalkane pressurized metered dose inhalers was evaluated using Twin Stage Glass Impinger and Anderson Cascade Impactor. A tetrafluoroethane and/or heptafluoropropane were evaluated for preparation of hydrofluoroalkane pressurized metered dose inhalers. The fine particle fractions delivered from hydrofluoroalkane propellant suspension pressurized metered dose inhalers can be predicted on the November - December 2009 Indian Journal of Pharmaceutical Sciences 713 www.ijpsonline.com basis of formulation parameters and is dependent of metering chamber of valve and orifice size of actuators. The results presented in investigation showed the importance of formulation excipients with formulation of pressurized metered dose inhalers viz, canister, valve and actuators used in formulations. Key words: Impinger, aerosols, deposition of emitted dose, delivered dose uniformity dipropionate to be able to deliver the desired doses to the patient. Beclometasone dipropionate/formoterol fumarate in above formulation is characterized by an extra-fine particle size distribution which results in a more potent effect than individual formulation of beclomethasone available in market. The above combination is indicated for regular treatment of asthma where use of a combination product (inhaled corticosteroid and long-acting beta 2 -agonist) is appropriate. pMDIs were prepared by single step manufacturing process as given here: Introduction of active/ excipients into pressure vessel, Addition of required quantity of propellant to provide sufficient number of doses, Filling of drug/propellant mixture into precrimped aluminum canister (supplied by Presspart, UK). RESULTS AND DISCUSSION Delivered dose uniformity results obtained with a DF316/50 valve fitted with a 0.3 mm outlet orifice Delivered Dose Uniformity (DDU) To develop room temperature stable formulation of formoterol fumarate/beclomethasone dipropionate hydrofluoroalkane (HFA) pressurized metered dose inhalers (pMDI) for lung delivery. The HFA pMDI were prepared from ozone friendly propellants viz, tetrafluoroethane and/or heptafluoropropane. A HFA based formulation of formoterol fumarate/ beclomethasone dipropionate was developed to deliver 6 +100/200 µg per actuation over 120 doses. The present formulation comprises polyvinylpyrrolidone and/or polyethylene glycol in an amount sufficient to enhance the physical stability of suspension and provide extra fine particle size of formoterol fumarate/ beclomethasone dipropionate. Formoterol fumarate and beclomethasone dipropionate have different modes of action. Beclomethasone dipropionate, a synthetic glucocorticoid given by inhalation at recommended doses has an antiinflammatory action, which plays an important role in the efficacy of beclomethasone dipropionate in controlling symptoms and improving lung function in asthma. Inhaled beclomethasone dipropionate probably acts topically at the site of deposition in the bronchial tree after inhalation. Formoterol is a selective β2 adrenergic agonist that produces relaxation of bronchial smooth muscle in patients with reversible airways obstruction. In addition to its bronchodilator action, formoterol also inhibits mast cell mediator release, plasma exudation and may reduce sensory nerve activation. Thus these two classes of drug address complementary aspects of the pathophysiology of asthma and COPD that neither drug class is able to achieve alone. 125 120 115 110 105 100 95 90 85 80 75 1 4 MATERIALS AND METHODS 7 Beclomethasone Excipients selected for evaluation were polyethylene glycol (at levels of 0.05 to 2.5% w/w, supplied by Clariant, India) and polyvinylpyrrolidone (at levels of 0.002 to 0.5% w/ w, supplied by Signet, India). The amount of micronised formoterol fumarate and beclomethasone dipropionate were mixed in a pressure vessel in a way to get the appropriate dose of formoterol fumarate and beclomethasone *Address for correspondence E-mail: [email protected] 714 10 Dose number Formoterol Fig. 1: Delivered dose uniformity of the formulation using 0.3 mm actuator Delivered dose uniformity of the formulation containing (──) formoterol and (──) beclomethasone at initial conditions using a 0.3 mm actuator fitted on a DF316/50 valve. TABLE 1: DEPOSITION OF EMITTED DOSE BY TSLI Drug Beclomethasone dipropionate Formoterol fumarate 0.3 mm Actuator 0.48 mm Actuator 40.23% 49.89% 56.81% 69.03% Values are in terms of % of Label Claim Indian Journal of Pharmaceutical Sciences November - December 2009 Delivered Dose Uniformity (DDU) www.ijpsonline.com fumarate was selected by using HFA propellants closely matching the density of the micronised actives. 125 120 115 110 105 100 95 90 85 80 75 1 4 7 10 Dose number Beclomethasone Formoterol Fig. 2: Delivered dose uniformity of the formulation using a 0.48 mm actuator Delivered dose uniformity of the formulation containing (──) formoterol and (──) beclomethasone at initial conditions using a 0.48 mm actuator fitted on a DF316/50 valve. diameter actuator are shown in fig. 1 and those obtained with a DF316/50 valve fitted with a 0.48 mm outlet orifice diameter actuator are shown in fig. 2. Deposition of emitted dose by TSLI results are summarized in Table 1. During this study, Polyethylene glycol at levels less than 0.5% w/w was found to ensure good product performances and valve functioning throughout the MDI units’ life. The level of polyvinylpyrrilodone selected also helped to decrease the settling of particles and prevents agglomeration of actives. This formulation was readily re-dispersible and avoiding invariability dosing of the drug. The stable suspension of particulate beclomethasone/ formoterol In conclusion, the novel combination of formoterol fumarate and beclomethasone dipropionate is a suspension based HFA pMDI product. The combined characteristics of room temperature stable formulation with good deposition of both drugs in lung provides unique characteristics to the above fixed dose combination, highly attractive in terms of patient usage requirements and commercial supply. ACKNOWLEDGEMENTS The authors would like to thank Valois, France & Presspart, UK for supplying canisters and valves for development trials. REFERENCES 1. 2. 3. 4. Purewal T. Formulation of metered dose inhalers, Metered dose inhalers technology, Buffalo Grove: Interpharm Press; 1998, p. 1-8. Vervaet C, Byron PR. Drug-surfactant-propellant interactions in HFAformulations. Int J Pharm 1999;186:13-30. Hickey AJ. Inhalation Aerosols, Physical and Biological Basis for Therapy, 2nd ed. In; Lenfant C. Editors. Lung Biology in Health and Disease. Vol. 221. Boca Raton: In-forma Health Care; 2007. Murnane D, Martin GP, Marriott C. Investigations into the Formulation of Metered Dose Inhalers of Salmeterol Xinafoate and Fluticasone Propionate Microcrystals. Pharm Res 2008;25:2283-91. Brain-Targeted Nasal Clonazepam Microspheres J. SHAJI*, A. PODDAR AND S. IYER Prin. K. M. K. College of Pharmacy, Colaba, Mumbai-400 005, India Shaji et al.: Nasal Clonazepam Microspheres Gelatin-chitosan mucoadhesive microspheres of clonazepam were prepared using the emulsion cross linking method. Mirospheres were evaluated using the in vitro and ex vivo drug release patterns. In vivo CNS drug distribution studies were carried out in rats by administering the clonazepam microspheres intra-nasally and clonazepam solution intravenously. From the drug levels in plasma and CSF, drug targeting index and drug targeting efficiency were calculated. Results obtained indicated that intranasally administered clonazepam microspheres resulted in higher brain levels with a drug targeting index of 2.12. Gelatin-chitosan cross linked mucoadhesive microspheres have the potential to be developed as a brain-targeted drug delivery system for clonazepam. Key words: Gelatin-chitosan cross linked microspheres, mucoadhesive microspheres, clonazepam, brain-targeted drug delivery, drug targeting index *Address for correspondence E-mail: [email protected] November - December 2009 Indian Journal of Pharmaceutical Sciences 715