* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download T06_11

Survey

Document related concepts

Transcript

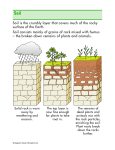

Alternative Materials for Landfill Liners and Covers IGC 2009, Guntur, INDIA ALTERNATIVE MATERIALS FOR LANDFILL LINERS AND COVERS M.R. Patil Asst. Prof, Department of Civil Engg, BVBCET , Hubli–580 031, India. E-mail: [email protected] S.S. Quadri Professor, Department of Civil Engg., BVBCET, Hubli–580 031, India. E-mail: [email protected] Lakshmikantha H. Environmental Officer, Karnataka State Pollution Control Board, Bangalore–560 001, India. E-mail: [email protected] ABSTRACT: An engineered landfill is a facility designed for the safe disposal of solid wastes. The bottom liner and a top cover, of the landfill are considered as the most critical components. These components are typically composite layers, made up of geomembrane overlying a compacted clay liner. Similarly landfill cover also consists of compacted clay layer to prevent the entry of surface water into the landfill. The main factor affecting the quality of compacted clay liners/covers is its permeability which should not be greater than 1.0 × 10 –9 m/sec. Due to non-availability of suitable soil, it is necessary to develop alternative material for liners and covers. In the present study Kolar soil and Granite polish wastes are used as basic materials. The properties of these materials are altered by adding sodium bentonite to achieve the required properties of a competent material for landfill liners and covers. Also, the performance of these materials is tested under different physicochemical environments. The results of the study show that addition of sodium bentonite brings the permeability to the required range to use as an alternative material for landfill liners and covers. 1. INTRODUCTION Solid wastes are the by products of human activities. Due to increase in population, change in life style, urbanization, advent of technology and industrialization, there has been radical change in quantity as well as quality of the solid waste produced. These wastes have become more hazardous to human being and environment and demands careful disposal practices. Historically, landfill has been the most common practical method for disposal of solid wastes. Hence an engineered landfill is a facility designed for the safe and environmental friendly disposal of solid waste instead of open, unengineered dumps. Engineering landfill basically consists of bottom liner and a top cover. These components play very important role in reducing the leachate quantity and minimizing the ground water pollution. Hence these are considered as the most critical components of an engineered landfill facility. Bottom liner and top covers are composite layers made up of geomembrane overlying a compacted clay liner of hydraulic conductivity not greater than 1.0 × 10–9 m/sec. These composite layers woks as a hydraulic barrier layer in liner and cover system. In recent years, geomembrane and geosynthetic clay liners have been used to replace compacted clay liners. But these liners are vulnerable to accidental puncture and create a potential problem with interface shear between their surfaces. Hence composite clay liners are preferred. The liners/covers of engineered landfill are multilayered systems consisting of hydraulic barrier layer as an important component. The function of this layer is to minimize percolation of water through the cover system by directly blocking water and by indirectly promoting drainage or storage of water in the overlying layers. Furthermore, hydraulic barrier layer prevents landfill gasses from escaping into the atmosphere. Such gases are shown to be major sources of air pollution and ozone depletion. Also this layer prevents the percolation of leachate into the ground and reduces underground water pollution. The hydraulic barrier layer for municipal solid waste landfills has consisted typically of a composite layer made up of a geomembrane overlying a compacted clay layer having a hydraulic conductivity not greater than 1.0 × 10−9m/sec. (Danial, 1993). Compacted clay layers are of low cost, large leachate attenuation capacity and resistance to damage. Due to non-availability of suitable soil at a site/to prevent the use of fertile soil for these layers, it is sometimes necessary to blend imported clay materials with local non-productive soils 301 Alternative Materials for Landfill Liners and Covers and industrial process wastes to achieve a suitable blended material. The most common blend is a combination of on site material/industrial process waste with sodium bentonite which can lower hydraulic conductivity as much as several orders of magnitude. Compacted clay layers of liners and covers are of low cost, large leachate attenuation capacity and resistance to damage. But strong acids and bases can dissolve the solid materials in the soil, form channels and increase the hydraulic conductivity. Hence lechate/pore fluid with pH < 3 or >11 are usually of the most concern. Table 1: Geotechnical Properties of Study Materials S. No Datta et al. (1999) studied the influence of additives on compaction characteristics and permeability. To achieve the low permeability in alluvial soils are blended with fly ash and clay. Tiwari & Srivastava et al. (2000) studied the influence of additives such as fly ash and sodium bentonite and reported that the compression index (Cc) increases with increase in fly ash and bentonite and substantial decrease in permeability with both fly ash and bentonite additives. 3. EXPERIMENTAL PROGRAMME Granite polish waste is the waste slurry, coming out from the polishing process of natural granite slabs, to give them fine finish. As many industries are in operation in the granite available area throughout the world, considerably large quantity of this waste is being generated and creating heaps of this waste which faces disposal problem. Ilakal town in Bagalkot district is one such place which faces such problem. Similarly a natural soil from Kolar district which is a nonfertile soil and has limited usage for many other works is identified for the study. Hence in the present study granite polish waste from Ilkal in Bagalkot District and natural soil called Kolar soil from Kolar district of Karnataka State, India, are used as basic materials for landfill liner and cover. The geotechnical properties of these soils are determined and reported in Table 1. Ilakl granite polish waste and Kolar soil are individually mixed with different percentages of sodium bentonite and their change in the permeability is observed with distilled water. Also the effect of pH on the hydraulic conductivity of these materials is studied. Ilkal granite polish waste 0.42 Natural Content Moisture 3.50 2. Atterberg Limits Liquid Limit (%) Plastic Limit (%) Shrinkage Limit (%) Plasticity Index (%) 28.30 20.06 9.69 8.24 Non-plastic Non-plastic 32.08 Non-plastic Grain size Analysis Gravel (%) Sand (%) Silt (%) Clay (%) 0.90 54.40 43.20 1.50 Nil 1.00 93.00 6.00 3. Sivapullaiah et. al. (2003) studied the geotechnical properties of stabilized Indian red earth and reported that red earth blended with bentonite, stabilized with lime can be used as liner material. Kolar soil 1. 2. LITERATURE REVIEW Blending of imported clay material with a local soil/ industrial process waste to reduce the permeability is a popular practice in the construction of landfills. Many researchers have worked on this approach and following are few studies. Properties 4. Specific Gravity 2.58 2.5 5. (a) OMC (%) (b) MDD (g/cc) 16.20 1.71 26 1.46 6. 2.68 × 10–8 Permeability (m/sec) 2.26 × 10– 8 4. RESULTS AND DISCUSSIONS 4.1 Kolar Soil and Effect of Sodium Bentonite The properties of Kolar soil show that, it belongs to clayey sands soil with permeability 2.68 × 10–8 m/sec. Addition of sodium bentonite shows that, there is a decrease in permeability as the percentage of sodium bentonite increases. However the decrease in permeability is marginal even with addition of 10% of sodium bentonite. The results of the tests are shown in Table 2. Table 2: Kolar Soil and Effect of Sodium Bentonite Property Kolar soil Coeff. of permeability (m/sec) 2.68 × 10–8 1% 2.31 × 10–8 Kolar soil + % Sodium bentonite 3% 5% 7% 1.55 1.32 1.00 × × × 10–8 10–8 10–8 10% 0.9 × 10– 9 4.2 Ilkal Granite Polish Waste and Effect of Sodium Bentonite The properties of Ilkal granite polish waste show that, it belongs to silty soil having its permeability 2.26 × 10–8. Similar to the Kolar soil, there is a decrease in permeability as the percentage of sodium bentonite increases and addition of 4% bentonite decreases the permeability of the soil as per the desired limit. The results of the tests are shown in Table 3. 302 Alternative Materials for Landfill Liners and Covers Table 3: Ilkal Granite Polish Waste and Effect of Sodium Bentonite Property Coeff. of permeability (m/sec) 5. CONCLUSIONS To safeguard ground water effectively and economically; the landfill liner and cover should be made with locally available materials, which can attain low permeability and high strength by addition of some additives. Ilkal granite Ilkal granite polish waste + polish waste % Sodium bentonite added 1% 2% 3% 4% 2.26 1.80 2.012 1.07 4.98 × 10–8 × 10–6 × 10–9 × 10–9 × 10–10 Following are the major conclusions drawn from the present investigations. 4.3 Effect of pH on Kolar Soil and Sodium Bentonite Additive To study the performance of Kolar soil-sodium bentonite mixture, leachate as a pore fluid, the permeability of this mixture is tested under different physico-chemical environments. It is found that, permeability of the mixture is increased under acidic and alkaline environments. However substantial change is observed in alkaline environment. It is observed that addition of 4% bentonite will reduce the permeability well within the desirable limit. The results of the test are shown in Table 4. Table 4: Effect of pH Kolar Soil and Sodium Bentonite Mixture Material Kolar soil + 10% Sodium bentonite Kolar soil + 12% Sodium bentonite Kolar soil +14% Sodium bentonite Coeff. of permeability In neutral In acidic In alkaline condition environment environnent m/sec m/sec m/sec –9 –9 0.9 × 10 1.45 × 10 1.72 × 10–9 – 1.05 × 10–9 1.15 × 10–9 – 0.85 × 10–9 1.00 × 10–9 REFERENCES 4.4 Effect of Different Physicochemical Environment on Ilkal Granite Polish Waste and Sodium Bentonite Additive It is found that, addition of 4% sodium bentonite will reduce the permeability even under alkaline condition. The test results of the study are shown in Table 5. Table 5: Effect of Physico-chemical Environments on Permeability of Ilkal Granite Polish Waste and Sodium Bentonite Mixture Material Ilkal granite polish waste + 4% sodium bentonite Coeff. of Coeff. of Coeff. of permeability permeability permeability in neutral in acidic in alkaline condition environment environment in m/sec in m/sec in m/sec 4.98 × 10–10 9.06 × 10–10 Granite polish waste is fine grained non-plastic, light, weight material with low permeability Kolar soil is clayey sands with medium weight material having low permeability. It has been observed that the permeability of these materials decreases with increase in sodium bentonite. Ilkal granite polish waste with 4% sodium bentonite added and Kolar soil with 10% of sodium bentonite will reduce the permeability of these soils to the desired value to use as a material for landfill liner and cover when water (pH = 7) is used as a pore fluid. It has been observed that permeability changes with change in pH value. It is found that increase in permeability is high in alkaline medium for both the study materials. But increase in the permeability of Ilkal granite polish waste is marginal. It is due to inertness of the material to the change in pH. However the increase in the permeability of Kolar soil is slightly more this may be due to change in structure Recommended quantity of sodium bentonite to be added to Ilkal granite polish waste is 4% and that for Kolar soil is 14% to use them as a competent material for landfill liner and cover. Daniel David E. (1993). Geotechnical Practices for Waste Disposal, St. Edumundsdury Press Durystedmundds. Dutta M., Parida B., Guha B. and Shreekrishnan T.K. (1999). “Industrial Solid Waste Management and Land Filling Practice”, Narosa Publishers, Delhi. Manual on Municipal Solid Waste Management (first edition), (2002). Govt. of India, Ministry of Urban Development. Sivapullaiah and Lakshmikantha H., et al. (2003). “Geotechnical Properties of Stabilized Indian Red Earth”, Jr. of Geotechnical & Geological Engineering, 399–415. Tiwari R.P. and Srivastava et al. (2000). “Utilization of Industrial Waste (Fly ash) in Landfill Barrier”, IGC-2000, IIT Bombay, Mumbai: 207–210. 9.18 × 10–10 303 Alternative Materials for Landfill Liners and Covers 304