* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download DN290 - Monitor Network Compliant -48V Power Supplies

Ground (electricity) wikipedia , lookup

Studio monitor wikipedia , lookup

Electrification wikipedia , lookup

Electrical ballast wikipedia , lookup

Power over Ethernet wikipedia , lookup

Power engineering wikipedia , lookup

Power inverter wikipedia , lookup

Current source wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Electric power system wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Electrical substation wikipedia , lookup

Schmitt trigger wikipedia , lookup

Power MOSFET wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Power electronics wikipedia , lookup

History of electric power transmission wikipedia , lookup

Three-phase electric power wikipedia , lookup

Stray voltage wikipedia , lookup

Voltage regulator wikipedia , lookup

Alternating current wikipedia , lookup

Earthing system wikipedia , lookup

Buck converter wikipedia , lookup

Surge protector wikipedia , lookup

Fuse (electrical) wikipedia , lookup

Voltage optimisation wikipedia , lookup

Power supply wikipedia , lookup

Opto-isolator wikipedia , lookup

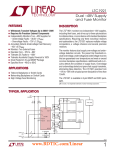

advertisement Monitor Network Compliant – 48V Power Supplies – Design Note 290 Brendan Whelan Introduction Reliability is a top priority for the designers of modern telephone and communication equipment. Designers take extra care to protect circuitry from failure-causing temperature and voltage changes, employing redundancy whenever possible, especially for power supplies. The power supplies are monitored to obtain early warning of impending failure. Often complicated circuitry that can include a voltage reference, comparators, voltage regulator and several precision resistor dividers is used. Designers may also use discrete components to monitor and indicate the state of power supply fuses. The resulting circuitry can be expensive in terms of component cost, board space and engineering time. The LTC1921 replaces the complicated monitoring circuitry with a simple integrated precision monitoring system contained entirely in an 8-lead MSOP package. Features The LTC1921 is the only integrated solution that can monitor two independent – 48V power supplies, plus associated fuses and drive up to three optoisolators or LEDs to indicate status. The required external components are three resistors and optocouplers or LEDs, as shown by the simple circuit in Figure 1. The LTC1921 can withstand ±100V DC at the supply and fuse input pins and tolerates ±200V transients. The LTC1921 monitors supply voltages by dividing the voltage internally and comparing to an internal precision reference. Since no critical precision external components are required, component cost, board space and design time are minimized while accuracy is maximized. The LTC1921 comes with telecom industry accepted preset voltage thresholds, including undervoltage (–38.5V), undervoltage recovery (–43V) and overvoltage (–70V). The overvoltage threshold has a 1.3V hysteresis that defines the overvoltage recovery threshold. These thresholds are trimmed to meet exacting requirements. This eliminates the messy worst-case threshold tolerance error calculation required when using discrete comparators, resistors and a separate voltage reference. , LTC and LT and are registered trademarks of Linear Technology Corporation. Hot Swap is a trademark of Linear Technology Corporation. 47k 5V FUSE STATUS –48V RETURN R1 100k MS8 U A L SIZ E A CT R2 100k MOC207 3 RTN 1 8 OUT F VA 5V SUPPLY A STATUS VB LTC1921 2 47k 4 FUSE B OUT A OUT B SUPPLY A –48V SUPPLY B –48V F1 D1 F2 D2 5V SUPPLY B STATUS 5 6 DN290 F01 MOC207 R3 47k 1/4W SUPPLY A STATUS 0 0 1 1 SUPPLY B STATUS 0 1 0 1 OK: WITHIN SPECIFICATION OV: OVERVOLTAGE UV: UNDERVOLTAGE MOC207 FUSE A 47k 7 VA VB OK OK OK UV OR OV UV OR OV OK UV OR OV UV OR OV –48V OUT FUSE A = VA = VA ≠ VA ≠ VA FUSE B = VB ≠ VB = VB ≠ VB FUSE STATUS 0 1 1 1* 0: LED/PHOTODIODE ON 1: LED/PHOTODIODE OFF *IF BOTH FUSES (F1 AND F2) ARE OPEN, ALL STATUS OUTPUTS WILL BE HIGH SINCE R3 WILL NOT BE POWERED = LOGIC COMMON Figure 1. The LTC1921 Requires Few External Components for Monitoring Two Supplies 07/02/290 www.BDTIC.com/Linear The LTC1921 is designed to indicate proper supply status across a wide variety of conditions. In order to accomplish this, the internal architecture is symmetrical. The LTC1921 is powered via the supply monitor input pins, VA and VB. Supply current can be drawn from either or both pins so the device can operate properly as long as one supply is within the operating range. Since power is not drawn from a combined supply (such as would be available with a diode OR), the LTC1921 will function properly even if the fuses or diodes are not functional. In addition, the LTC1921 has a low voltage lockout. If both supply voltages are very low, all three outputs of the LTC1921 lock into a fault indication state, thus communicating to supervisory systems that there is a problem even though there is not enough power for the LTC1921 to maintain accuracy. The LTC1921 can communicate supply and fuse status by controlling external optocouplers or LEDs. This allows for intelligent system monitoring despite high isolation voltage requirements. Control of the LEDs or optocouplers is accomplished by connecting the LTC1921 outputs in parallel with the LEDs or photodiodes. During normal supply and fuse conditions, the LTC1921 outputs are high impedance; current flows through the external diodes continuously. If a fuse opens or a supply voltage falls outside of the allowed window, then the proper LTC1921 output shunts the current around the diode, thus indicating a fault. The outputs may be ORed to reduce the number of required optoisolators. Application Example Figure 2 shows an LTC1921 and an LT®4250 Hot SwapTM controller comprising a complete power system solution. The LTC1921 monitors both –48V supply inputs from the power bus, as well as the supply fuses. The status signals may be wired off the board via optoisolators to an isolated microprocessor or microcontroller to control system performance and warning functions. Resistors R9 and R10 pull up the fuse pins so that damaged fuses can be detected. The LT4250L controls the combined –48V supply during hot swapping and low supply conditions, and monitors the combined supply voltage. The PWRGD pin drives an optoisolator signalling the status of the LT4250’s switched output. The device monitors fuses by comparing the voltage potentials on each side of each fuse. If a significant difference (about 2V) is sensed, the LTC1921 signals that a fuse has opened. The voltage difference across the damaged fuse may be reduced by diode reverse leakage, making it difficult to detect a damaged fuse. Weak pull-up resistors (R1 and R2 in Figure 1) ensure that the LTC1921 can detect an open fuse circuit. The value of the pull-up resistors used is a function of the reverse leakage current of the OR’ing diodes used. – 48V RTN R9 10k 1W R10 10k 1W MOC207 3 RTN 1 8 VA OUT F 7 C8 100nF 100V MOC207 SUPPLY A STATUS R4 549k 1% FUSE A OUT A OUT B 3A – 48V A R7 51k 5% 8 VDD VB FUSE B R8 100Ω 4 LTC1921 2 FUSE STATUS R5 6.49k 1% 5 6 MOC207 R11 47k 1/4W 3A SUPPLY B STATUS PWRGD 3 2 R6 10k 1% LT4250L OV GATE VEE * * DIODES INC. SMAT70A – 48V B DRAIN UV 7 6 + C2 15nF 100V SENSE 5 4 R1 0.02Ω 5% LUCENT JW050A1-E MOC207 1 C1 470nF 25V VIN R3 1k 5% R2 10Ω 5% C3 0.1µF 100V 1N4003 VOUT 1 LUCENT FLTR100V10 VIN– 2 + C4 0.1µF 100V + C5 100µF 100V VOUT– CASE C6 0.1µF 100V 4 VIN+ VOUT+ SENSE + TRIM ON/OFF SENSE – VOUT– VIN– 9 5V 8 7 + C7 100µF 16V 6 5 CASE 3 DN290 F02 Q1 IRF530 = DIODES INC. B3100 Figure 2. Network Switch Card Monitor with Hot Swap Control Data Sheet Download http://www.linear.com/go/dnLTC1921 Linear Technology Corporation For literature on our Supply Monitors, call 1-800-4-LINEAR. For applications help, call (408) 432-1900, Ext. 2525 dn290f LT/TP 0702 316.5K • PRINTED IN THE USA 1630 McCarthy Blvd., Milpitas, CA 95035-7417 (408) 432-1900 ● www.BDTIC.com/Linear FAX: (408) 434-0507 ● www.linear.com LINEAR TECHNOLOGY CORPORATION 2002