* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Pathogen Removal in Constructed Wetlands

Survey

Document related concepts

Transcript

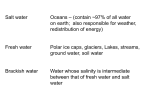

Lecture 6b Sewage Treatment & Constructed Wetlands http://agen521.www.ecn.purdue.edu/AGEN521/epadir/wetlands/graphics.html Using Wetlands for sewage treatment. By Jennie Swenson & Terry Cooper On Site Sewage Treatment Systems – Septic Tank Systems • • • The wastes generated by some 60% of the U.S. population are collected in sewer systems and carried along by some 14 billion gallons of water a day. Some 10% is allowed to pass untreated into rivers, streams, and the ocean. The rest receives some form of treatment to improve the quality of the water (which makes up 99.9% of sewage) before it is released for reuse. 1855-First U.S. sewage treatment system Untreated sewage discharge is a persistent problem that seems to be getting worse in an era of regulatory neglect. http://enr.construction.com/features/_gallery/050817/050817-5.asp Sewage Treatment Technology • Saved more lives than any other technological development • A sewage treatment plant is nothing more than a LARGE MICROBIAL CULTURE FLASK • The result of this process converts most of the nutrients to chemicals like carbon dioxide, nitrate, sulfate, phosphate; i.e., minerals • Raw sewage is rich in organic nutrients such as human excrement, and food and industrial wastes. • Since microbes grow and utilize nutrients most efficiently under AEROBIC CONDITIONS, sewage treatment plants are designed to provide excess OXYGEN for the microbes. Hong Kong Sewage Treatment Plant Land Spreading • Finally, there is always some material that can not be easily degraded by microbes which SETTLES OUT at various stages in the treatment process. • This material is called SLUDGE and it must also be disposed of as part of the sewage treatment process. Ocean Dumping Mirfield Sewage Sludge Incinerator -UK Fertilizer Alternative Sewage Technology • Constructed Wetlands – Engineered system – Utilize natural processes – Treat wastewater Constructed wetlands are small artificial wastewater treatment systems consisting of one or more shallow treatment cells, with herbaceous vegetation that flourish in saturated or flooded cells. They are usually more suitable to warmer climates. In these systems wastewater is treated by the processes of sedimentation, filtration, digestion, oxidation, reduction, adsorption and precipitation. 3-System Designs 1) Subsurface Flow System 2)Free Water Surface 3)Aquatic Plant System The Water holding structure is constructed in basin or channel. Some form of subsurface barrier limits seepage in first basineven a wet soil can be used. Subsurface Flow System (SFS) •Water flows below media- No water on soil surface but subsoil is saturated •Sand, gravel, rock •Grasses, trees •Minimal land Subsurface Flow System Free Water Surface (FWS) •Water flows over soil media •Water <18” •Sedges, reeds, rushes •Land intensive Free Water Surface Aquatic Plant System (APS) •Similar to FWS •Water >18” •Water hyacinth, duckweed, pennywort •Fish Aquatic Plant System Constructed Wetland Scales Subsurface Flow Free Water Surface Major Mechanisms of Pathogen Removal • Sedimentation Bacteria -> • Predation Viruses -> • Adsorption • Inactivation Percent Removal Fecal Coliform # 29 8 4 Type Range Subsurface 99.9 - 78.2 Free Water 99.9 - 81.6 Aquatic Plant 98.5 - 43.2 Avg 97.6 91.8 79.5 Reasons Cited for High Removal Rates • Long retention time • Low effluent loading rate • Vegetation – Increase microbial population – Root excretions – Aeration of media Reason Cited for Low Removal Rates • Insufficient sunlight • Lack of maturity • Excessive wildlife • High turbidity – Resuspension of solids – Water soluble humic substances Spring Hill’s Wastewater System – Innovative Technology • Description: The City of Spring Hill, population 77, had nonconforming septic tanks connected by a community sewer that ultimately discharged to the Sauk River without further treatment. • The unauthorized discharge needed to be corrected, but the cost of compliance was of great concern. • Solution: Spring Hill’s new wastewater treatment system consists of a subsurface flow constructed wetland followed by disposal by drip irrigation. The treatment system is capable of treating 9,200 gallons per day of domestic wastewater. • The construction cost of the treatment and disposal system was approximately $285,000. The sewage collection system, designed by the city engineer, added another $310,000 to the total capital cost of the system. • The original Preliminary Engineering Report recommended regionalization at a capital cost of $805,000 plus approximately $200,000 of improvements at the regional pond system. The cost of the original plan, at over $25,000 per connection, was beyond the City’s financial capability. • With the application of constructed wetland technology, the costs became affordable. Cross section of Spring Hill wetland treatment cell plan List of plants include: broadleaf cattail (Typha latifolia), hardstem bulrush (Scirpus acutus), river bulrush (Scirpus fluviatilis), duck potato (Sagittaria latifolia), wild iris (Iris versicolor), big bluestem (Andropogan gerardi), switchgrass (Panicum virgatum), gravel mulch Inflow from septic tanks rock Wetland Cell Typical Cross Section Outflow to lift station and drip irrigation adaped from Widseth Smith Norlting and Associates report dated 11/98 Dyad Problem: • • • • Calculate the amount of soil erosion from this 3 acre field in tons per acre. BD = Mass/Vol BD soil = 1.33 g/cc Area of soil measured = 30 ft x 40 feet. The soil was 8 inches thick over this area. • • Solution 1.33 x 62.4lbs/ft3 = 83lbs/ft3 & 30x40x8/12 = 800ft3 • • 83s/ft3 = wt/800ft3 = wt = 83x800 = 66400 lbs/3acres = 22133 lbs./acre or ÷2000lbs/ton = 11 tons/acre or 2 x sustainable rate- of 5 tons / acre note: some soil did leave the field and was not in our calculation, I wonder how much???