* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download 04_FINAL_AVR_2009 (PPTmin)

History of electric power transmission wikipedia , lookup

Electrification wikipedia , lookup

Voltage optimisation wikipedia , lookup

Audio power wikipedia , lookup

Electric power system wikipedia , lookup

Distribution management system wikipedia , lookup

Thermal copper pillar bump wikipedia , lookup

Power over Ethernet wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Alternating current wikipedia , lookup

Mains electricity wikipedia , lookup

Power engineering wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Printed circuit board wikipedia , lookup

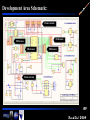

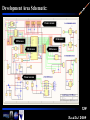

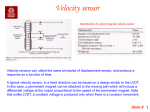

Command & Data Handling PCB Build Procedure RockOn! 2009 1 RockOn! 2009 What Are We Building? RockOn! 2009 2 RockOn! 2009 The C&DH PCB 1: 3 RockOn! 2009 The C&DH PCB 2: AVR Board Z-Accel. Board Data Board 4 RockOn! 2009 Organization: The boards may seem like an array of confusing electronics, but one can easily break the board into smaller subsystems of related components. This build is organized by different sub systems integral to the board. 5 RockOn! 2009 Integral Systems: -ATMega32 Microprocessor -2 MB Flash Memory -0-15 PSI Pressure Sensor -3-Axis Acceleration -Temperature Sensor -In-System-Programming -Power Regulation 6 RockOn! 2009 Safety/Background RockOn! 2009 7 RockOn! 2009 Board Safety: Caution: Many of the components used in this workshop are sensitive to electrostatic discharge (ESD). Please ensure that you are wearing your protective wrist strap at all times. There will be a warning slide when components are ESD and heat sensitive. Clipping leads can sometimes cause them to separate in a rapid manner that could cause injury. Please take caution when clipping leads. Wear your safety glasses at ALL TIMES! 8 RockOn! 2009 Reading a Resistor: The resistors in this workshop have already been organized by value. In the event that your resistors get mixed, please refer to the chart at the left to classify your resistors, or use your multimeter. If you are unsure, don’t hesitate to raise your hand and ask for assistance. 9 RockOn! 2009 Verifying Kit Contents RockOn! 2009 10 RockOn! 2009 Kit Contents—PCBs: PCBs: - One Main Board - One Data Board - One Z Accelerometer Board - One XY Accelerometer Board Note: All boards were tested in-house and are currently in working order. 11 RockOn! 2009 Kit Contents—Resistors: Resistors: - Two 1 KΩ Resistors - R8, R9 - Eight 10 KΩ Resistors - R1, R2 R3, R4, R5, R6, R10, R11 - One 3.3 KΩ Resistors - Indicator - One 100 KΩ Resistor - R7 12 RockOn! 2009 Kit Contents—Capacitors: Capacitors: - Eleven .1 μF Capacitors - C2, C3, C4, C5, C6, C7, C8, C9, CX, CY, CZ - One 1 μF Capacitor - C10 - One 10 μF Capacitors - C1 13 RockOn! 2009 Kit Contents - Connectors: Connectors: - One ISP Cable - Ten 2X1 Headers - One 3X1 Header - One 4X1 Header - Three 3X2 Right Angle Headers 14 RockOn! 2009 Kit Contents—LEDs: LEDs: - Two Red LEDs 15 RockOn! 2009 Kit Contents—Sockets/ICs/Pressure Sensors: 16 RockOn! 2009 Kit Contents—Sockets/ICs/Pressure Sensors: Sockets/ICs/Press. Sens.: - One AVR Socket AVR DIP - One AVR AVR - One Level Shifter (LS) Press. Sens - One LS Socket LS DIP LS - One Pressure Sensor - One DB9 Connector 17 RockOn! 2009 Kit Contents—Miscellaneous 1: 18 RockOn! 2009 Kit Contents—Miscellaneous 2: Miscellaneous: - One Red LED - One Green LED Green LED - One G-Switch Z-Acc. Conn. Jumper - One Jumper - One Z-Accelerometer Connector 19 RockOn! 2009 Kit Contents—Miscellaneous 3: Miscellaneous: - Wires: -Three Blue -Three Red Black Red Blue -Two Black 20 RockOn! 2009 Kit Contents—Transistors: Transistors: - One PNP Transistor - T1 - One NPN Transistor - T2 21 RockOn! 2009 Kit Contents—VREGS: VREGS: - One 5V VREG - One 3.3 VREG 22 RockOn! 2009 Kit Contents—Diodes: Diodes: - Three Diodes -D1, D2, D3 23 RockOn! 2009 Board Check: 1 2 - Check to ensure that your boards have: flash memory (1), a level shifter (2), and four accelerometers (3). - Please raise your hand if any components are missing. 24 RockOn! 2009 Board Schematic: - Check to ensure that your boards have: flash memory (1), a level shifter (2), and four accelerometers (3). - Please raise your hand if any components are missing. 25 RockOn! 2009 Schematic Overview – Part Highlighting: - Blue highlights mean parts will be added to the board in the current step. - Green highlights indicate components already on the board but relevant to the current step. - Red highlights show access points on the PCB where wires can be soldered. 26 RockOn! 2009 Schematic Overview – Coordinates (A1): Numbers across top Letters along side - All schematic close-ups include coordinates so they can be easily located in your schematic printout. - The coordinates correspond to the letters across the side of the schematic and the numbers across the top. 27 RockOn! 2009 Let’s Begin! RockOn! 2009 28 RockOn! 2009 Current Sub System: Power Subsystem: Activation Power Regulation Sensor Subsystem: Temperature Sensor Pressure Sensor X & Y Axis Accelerometers Z Axis Accelerometers Geiger Counter Interface Command and Data Handling: AVR, Memory, & In-System Serial Programming (ISP) Data Retrieval 29 RockOn! 2009 Activation Schematic 1 (D2): Power from batteries - This circuitry allows power to the board to be switched on when the rocket launches. 30 RockOn! 2009 Activation Schematic 2 (D2): - The acceleration of launch closes the Gswitch. - If the G-switch is closed while the RBF Pin header is shorted, the system turns on. - T2 keeps T1 on even after the G-switch is released. - Everything stays on until the battery is removed. 31 RockOn! 2009 On LED Schematic (C2): 5V Power Bus - The ON LED indicates that the system is receiving power. - It will not turn on until after the next section (Power Regulation). - R9 prevents the LED from drawing too much power. 32 RockOn! 2009 RBF/G-Switch Headers: RBF Pin G-Switch - Solder two (2) of the 2X1 headers into the footprints labeled RBF Pin and G-Switch. - As always, ensure they are flush with the board. 33 RockOn! 2009 RDY On On and RDY Headers: - Solder two more (2) of the 2X1 headers into the footprints labeled On and RDY. - These headers will be used for indicator LEDs. 34 RockOn! 2009 Power Header 1: Power - Solder one (1) of the 2X1 headers into the footprint labeled Power. - This is the primary power header. 35 RockOn! 2009 Power Header 2: Power - There is a secondary power header on the opposite side of the board. DO NOT install this header. 36 RockOn! 2009 Pre-Bending: Pre-Bending 101: - Pre-bending is a technique that allows components to be easily inserted into a PCB. - Pre-bending also allows components to lay more flush with the board. - Bending components to the correct bend radius takes practice, but mastering the technique will reap rewarding benefits! 37 RockOn! 2009 Pre-Bending: Pre-Bending 101: - Start with the bending and prodding tool in the position shown in the top picture. - Choose a location along the length of the tool that will yield the appropriate bend radius. 90° - Use your thumb to bend the lead such that the component and lead are orthogonal. 38 RockOn! 2009 Diodes: Left: Diode as it comes in the kit. Right: Bent diode ready for installation. - Take three (3) diodes from your supplies and use the supplied bending and prodding tool to bend the leads at 90 degrees as shown above. 39 RockOn! 2009 Diodes (D1-D3): D2 D3 D1 Black and white overlay - Solder one (1) of the bent diodes into the footprint labeled D1 on the board. - Note: Diodes are polarized and the black line on the diode must overlay the white line on the footprint. 40 RockOn! 2009 Diodes (D1-D3): D2 D3 D1 - Solder one (1) of the bent diodes into the footprint labeled D2. - Check polarity. 41 RockOn! 2009 Diodes (D1-D3): D2 D3 D1 - Solder one (1) of the bent diodes into the footprint labeled D3. - Check polarity. 42 RockOn! 2009 ESD/Heat Concern: WARNING: ESD The following components are extremely ESD and heat sensitive! Q ESD is electrostatic discharge caused by built up charge on your person from not wearing your protective ESD wrist strap. When soldering heat sensitive components, use the guideline 2-3 on, 8-10 seconds off. 43 RockOn! 2009 Transistors: Bent power transistor, T1 Bent NPN transistor, T2 - Take the power transistor, T1, and the NPN transistor, T2, from the kit and use the bending and prodding tool to bend the leads as shown above. - Note: Advance to the next slide/page to place these transistors in their footprints to determine the bend location and radius. 44 RockOn! 2009 Transistors (T1): T1 - Solder the power transistor, T1, into its footprint and ensure that the bend allows it to lay flush with its heat sink. - Ensure that T1 is flush with the heat sink BEFORE soldering it into its footprint. - DO NOT solder T1 to the heat sink. 45 RockOn! 2009 Transistors (T2): T2 - Place and solder the bent NPN transistor, T2, into its footprint and ensure that the bend allows it to lay flush with the board. 46 RockOn! 2009 Resistors: - The next several steps install the resistors for the power sub system. There are four (4) different types of resistors for this sub system: 10K, 100K, 1K, and 3.3K. - The resistors will lay more flush with the board if the bending and prodding tool is used first to bend the resistors as shown above. 47 RockOn! 2009 Resistors (10K): R4 R3 R2 R10 - Bend four (4) of the 10K resistors in the kit as indicated previously and solder them into footprints R2, R3, R4, and R10. 48 RockOn! 2009 Resistors (1K): R8 - Bend one (1) of the 1K resistors in the kit as indicated previously and solder it into footprint R8. 49 RockOn! 2009 R9 Resistors (1K): - Bend one (1) of the 1K resistors in the kit as indicated previously and solder it into footprint R9. 50 RockOn! 2009 Resistors (100K): R7 - Bend one (1) of the 100K resistors in the kit as indicated previously and solder it into footprint R7. 51 RockOn! 2009 Activation Schematic 1 (D2): Power from batteries - This circuitry allows power to the board to be switched on when the rocket launches. 52 Highlight your schematic RockOn! 2009 Activation Schematic 2 (D2): - The acceleration of launch closes the Gswitch. - If the G-switch is closed while the RBF Pin header is shorted, the system turns on. - T2 keeps T1 on even after the G-switch is released. - Everything stays on until the battery is removed. 53 Highlight your schematic RockOn! 2009 On LED Schematic (C2): 5V Power Bus - The ON LED indicates that the system is receiving power. - It will not turn on until after the next section (Power Regulation). - R9 prevents the LED from drawing too much power. 54 Highlight your schematic RockOn! 2009 Power System Test 1: 9V Supply, Flight Pin, RDY LED RockOn! 2009 1 hr, 20 min55 RockOn! 2009 Power System Test 1: - Take out the multimeter that was provided. - Insert the red plug into the port labeled VΩHz. - Insert the black plug into the port labeled COM. COM VΩHz 56 RockOn! 2009 Power System Test 1: - Turn on the multimeter. - Turn the dial to the 20V DC setting. - Place the red lead on the positive battery terminal. - Place the black lead on the negative battery terminal. - If you do not get a reading of above 9V, raise your hand. 57 RockOn! 2009 Power System Test 1: + - Set multimeter in continuity test mode. - Place red lead on the positive power terminal. - Place black lead on GND. - If a beep is heard, please raise your hand. 58 RockOn! 2009 Power System Test 1: NOTE: Red wire from LED connects to “+” on board Jumper - Connect your battery to the circuit (red wire is positive). - Connect the red LED to the “RDY” header. - Connect the jumper to “RBF Pin.” - If the red LED does not light, please raise your hand. - Final Step - Disconnect the battery from the board! 59 RockOn! 2009 Current Sub System: Power Subsystem: Activation Power Regulation Sensor Subsystem: Temperature Sensor Pressure Sensor X & Y Axis Accelerometers Z Axis Accelerometers Geiger Counter Interface Command and Data Handling: AVR, Memory, & In-System Serial Programming (ISP) Data Retrieval 60 RockOn! 2009 Power Regulation Schematic 1 (C1): 3.3V Output - Voltage regulators turn the 9 Volts provided by the battery into the 5 Volt and 3.3 Volt power supplies required by the digital components. 61 RockOn! 2009 Power Regulation Schematic 2 (A3): - Capacitors can be used to filter power supplies by storing energy when the voltage is slightly too high and releasing it when the voltage is too low. There is a capacitor for each power supply (5V, 3.3V, and 9V) and also at the power input pins of every chip. 62 RockOn! 2009 ESD/Heat Concern: WARNING: ESD The following components are extremely ESD and heat sensitive! Q ESD is electrostatic discharge caused by built up charge on your person from not wearing your protective ESD wrist strap. When soldering heat sensitive components, use the guideline 2-3 on, 8-10 seconds off. 63 RockOn! 2009 3.3V Voltage Regulator: 3.3 VREG Take one (1) 3.3 VREG from the kit (L69B) and solder it to the board. TIP: Place a large blob of solder (2 linear inches) onto the side of the soldering iron’s tip, and tack the large pad on first. Once the large pad is tacked, solder the remaining pads. 64 RockOn! 2009 5V Voltage Regulator: 5.0 VREG Using the technique described on the previous slide, solder one (1) 5.0 VREG onto the board as shown above. 65 RockOn! 2009 Capacitors (C1): 10μF(C1) Take one (1) 10μF capacitor from the kit and solder it into the footprint labeled C1. Note: These capacitors are not polarized 66 RockOn! 2009 Capacitors (C2, C6, C7): .1μF(C2) .1μF(C6) .1μF(C7) Take three (3) .1μF capacitors from the kit and solder them into the footprints labeled C2, C6, and C7. 67 RockOn! 2009 Power Regulation Schematic 1 (C1): 3.3V Output - Voltage regulators turn the 9 Volts provided by the battery into the 5 Volt and 3.3 Volt power supplies required by the digital components. 68 Highlight your schematic RockOn! 2009 Power Regulation Schematic 2 (A3): - Capacitors can be used to filter power supplies by storing energy when the voltage is slightly too high and releasing it when the voltage is too low. There is a capacitor for each power supply (5V, 3.3V, and 9V) and also at the power input pins of every chip. 69 Highlight your schematic RockOn! 2009 Power System Test 2: ON LED, 3.3 V Supply, 5.0 V Supply RockOn! 2009 1 hr, 50 min70 RockOn! 2009 ON LED Test: Connections: 9 V Batt. ON LED RDY LED Jumper - Connect the LEDs: -Red to RDY -Green to ON - Connect the G-Switch - Connect the jumper to RBF Pin - Connect the battery G-Switch NOTE: Red wires from LEDs connect to “+” on board 71 RockOn! 2009 ON LED Test 2: Expected Results: - The red LED should be illuminated, but not the green LED 9 V Batt. ON LED RDY LED - Click the G-Switch Jumper - The green LED should illuminate G-Switch - Raise your hand if you do not see these results 72 RockOn! 2009 3.3 VREG Test: Connections: - Place the multimeter in 20V mode. - Touch the black terminal to the large pad of the 3.3 VREG (Ground) - Touch the red terminal to pin closest to the label Vreg3.3 73 RockOn! 2009 3.3 VREG Test: Expected Results: - The multimeter should read 3.3 ± 0.1 Volts. - If you do not see these results, please raise your hand. 74 RockOn! 2009 5.0 VREG Test: Connections: - Place the multimeter in 20V mode. - Touch the black terminal to the large pad of the 5.0 VREG (Ground) - Touch the red terminal to pin closest to the label Vreg5.0 75 RockOn! 2009 5.0 VREG Test: Expected Results: - The multimeter should read 5.0 ± 0.1 Volts. - If you do not see these results, please raise your hand. Final Step - Disconnect the battery 76 RockOn! 2009 Current Sub System: Power Subsystem: Activation Power Regulation Sensor Subsystem: Temperature Sensor Pressure Sensor X & Y Axis Accelerometers Z Axis Accelerometers Geiger Counter Interface Command and Data Handling: AVR, Memory, & In-System Serial Programming (ISP) Data Retrieval 77 RockOn! 2009 Temperature Sensor Schematic (C5): Filter capacitor - The temperature sensor outputs an analog voltage which is proportional to the temperature. A filter capacitor on the power supply reduces the noise in the output signal. 78 RockOn! 2009 ESD/Heat Concern: WARNING: ESD The following components are extremely ESD and heat sensitive! Q ESD is electrostatic discharge caused by built up charge on your person from not wearing your protective ESD wrist strap. When soldering heat sensitive components, use the guideline 2-3 on, 8-10 seconds off. 79 RockOn! 2009 Temperature Sensor: Temp. Sens. - The assistants will now give you a temperature sensor. - Use a similar technique used on the Vregs to solder the temperature sensor to its pads - TIP: Have one of your partners hold it in place with the provided tweezers while a pin is tacked in place. 80 RockOn! 2009 Capacitor (C8): Take one (1) .1μF capacitor from the kit, and solder the capacitor into the footprint labeled C8. 81 RockOn! 2009 Temperature Sensor Schematic (C5): Filter capacitor - The temperature sensor outputs an analog voltage which is proportional to the temperature. A filter capacitor on the power supply reduces the noise in the output signal. 82 Highlight your schematic RockOn! 2009 Temperature Sensor Test RockOn! 2009 83 RockOn! 2009 Temperature Sensor Test 1: Connections: - Connect the LEDs: -Red to RDY -Green to ON - Connect the G-Switch - Connect the jumper to RBF Pin - Connect the battery - Click/Activate the G-Switch 84 RockOn! 2009 Temperature Sensor Test 2: Connections 2: - Place the multimeter in 2V mode. - Place the black terminal on the large temperature sensor pad. - Place the red terminal on the pin nearest “p” in Temp. 85 RockOn! 2009 Temperature Sensor Test 2: Expected Results: - If the multimeter does not display a voltage of 0.7 ± 0.1 Volts, please raise your hand. - Ensure that your partner has his/her ESD band on and have him/her place his/her finger on the sensor. - If you do not see an increase in voltage, raise your hand. Final Step - Disconnect the battery 86 RockOn! 2009 Current Sub System: Power Subsystem: Activation Power Regulation Sensor Subsystem: Temperature Sensor Pressure Sensor X & Y Axis Accelerometers Z Axis Accelerometers Geiger Counter Interface Command and Data Handling: AVR, Memory, & In-System Serial Programming (ISP) Data Retrieval 87 RockOn! 2009 Development Area Introduction: - The development area, also known as the breadboard, allows additional components to be added to the board. It makes the board more reusable and versatile. I/O Access points - The development area gives access to all the microcontroller input and output (I/O) pins as well as 3.3V, 5V, and 9V power. 88 RockOn! 2009 Development Area Schematic: Power access I/O Access I/O Access I/O Access I/O Access Power access 89 RockOn! 2009 Development Area Tips: - When using the breadboard, keep in mind that other parts will use it later, so make sure that the wires crossing the breadboard are not so tight that the area underneath them is unusable. - For wires, use the convention that red is power, black is ground, and blue and white are data. 90 RockOn! 2009 ESD/Heat Concern: WARNING: ESD The following components are extremely ESD and heat sensitive! Q ESD is electrostatic discharge caused by built up charge on your person from not wearing your protective ESD wrist strap. When soldering heat sensitive components, use the guideline 2-3 on, 8-10 seconds off. 91 RockOn! 2009 Pressure Sensor 1: Notched PWR Pin - Remove one (1) pressure sensor from the kit. - Find the notched pin (shown above) that will be connected to 5 Volts DC. 92 RockOn! 2009 Pressure Sensor 2: NC NC Ground NC Data NC Power NC Power Goes Here. - Carefully insert the pressure sensor into the breadboard. - The row of NC pins should be in column 8. - The notched power pin should be in row 4, column 2. 93 RockOn! 2009 Pressure Sensor 3: - Now turn the board over and solder all 8 pins. - Note: DO NOT KEEP THE IRON ON ANY PIN LONGER THAN 2-3 SECONDS WITHOUT ALLOWING 10 SECONDS OF COOLING TIME. 94 RockOn! 2009 Bridging 1: Bridging 101: - Building in a bread board section usually calls for a technique called “bridging.” - If you are unfamiliar with bridging, it is used to make electrical connection between components when pre-printed traces do not already exits. 95 RockOn! 2009 Bridging 2: Good Bridge Bridging 101: - To bridge, a good technique calls for bending leads and wire over each other before clipping them. - Once leads and/or wires are in contact, apply a generous amount of solder to create a solder bead between the leads of interest. See the pictures above. 96 RockOn! 2009 Pressure Sensor 4: PWR Bridge - Strip both ends of one (1) 1.5 inch red wire. - Insert one end of the wire into a 5V source. - Insert the other end into row 4, column 1 (next to power pin). - Bridge the red wire to the power pin on the pressure sensor. 97 RockOn! 2009 Pressure Sensor 5: GND Bridge - Strip both ends of one (1) 1.5 inch black wire. - Insert one end of the wire into GND. - Insert the other end into row 2, column 1 (next to ground pin). - Bridge the black wire to the ground pin on the pressure sensor. 98 RockOn! 2009 Pressure Sensor 6: Data Bridge - Strip both ends of one (1) 1.5 inch blue wire. - Insert one end of the wire into A7. - Insert the other end into row 3, column 1 (next to data pin). - Bridge the blue wire to the data pin on the pressure sensor. 99 RockOn! 2009 Development Area Schematic: Power access I/O Access I/O Access I/O Access I/O Access Power access 100 Highlight your schematic RockOn! 2009 Pressure Sensor Test RockOn! 2009 2 hr, 50 min101 RockOn! 2009 Pressure Sensor Test: Connections 1: - Connect the LEDs: -Red to RDY -Green to ON - Connect the G-Switch - Connect the jumper to RBF Pin - Connect the battery - Click/Activate the G-Switch 102 RockOn! 2009 Pressure Sensor Test: Connections 2: - Place the multimeter in 20V mode. - Place the black terminal on GND. - Place the red terminal at A7 (blue wire). 103 RockOn! 2009 Pressure Sensor Test: Expected Results: - Your multimeter should read between 4.3 to 4.5 Volts (sea level). - If you do not see these results, please raise your hand for assistance. 104 RockOn! 2009 Pressure Sensor Test: Expected Results: Straw - You should also find a red coffee stirring straw in your kit. - Place one end over the pressure sensor and suck on the other end. <DO NOT BLOW> - You should see the voltage drop. - If your results vary, please raise your hand. Final Step - Disconnect the battery 105 RockOn! 2009 Current Sub System: Power Subsystem: Activation Power Regulation Sensor Subsystem: Temperature Sensor Pressure Sensor X & Y Axis Accelerometers Z Axis Accelerometers Geiger Counter Interface Command and Data Handling: AVR, Memory, & In-System Serial Programming (ISP) Data Retrieval 106 RockOn! 2009 X & Y Axis Accelerometer Socket Schematic (A6): - The accelerometers output analog voltages proportional to the acceleration they feel in a particular axis. - Low range accelerometers have much higher precision than high range accelerometers, but will saturate if the acceleration is too great. 107 RockOn! 2009 X & Y Axis Accelerometers Schematic (B5): - The accelerometers are very sensitive and difficult to solder, so they have been provided on a socket which can be soldered to the board. - To reduce noise there are capacitors on the power supply and analog outputs of the accelerometers. 108 RockOn! 2009 X & Y Accelerometers 1: - Take out four (4) of the 2X1 headers from the kit. Share pliers with your neighbors, and break one (1) 2X1 header into two 1X1 headers. 109 RockOn! 2009 X & Y Accelerometers 2: 2X1 2X1 2X1 1X1 - Place and solder the three (3) 2X1 headers into the 2X1 holes in the ACC footprint. - Place and solder the one (1) 1X1 header into the 1X1 hole in the ACC footprint. 110 RockOn! 2009 X & Y Accelerometers 3: - Place and solder the provided X&Y accelerometer board onto the headers added in the previous step. - Caution: When clipping these leads, ensure that you have your safety glasses on. Hold the leads while clipping them. 111 RockOn! 2009 Capacitors (C5, CX, CY): C5 CX CY - Solder three (3) of the .1μF capacitors into the footprints labeled CX, CY, and C5. - Note: These capacitors are located near the accelerometers that were just mounted. 112 RockOn! 2009 X & Y Axis Accelerometer Socket Schematic (A6): - The accelerometers output analog voltages proportional to the acceleration they feel in a particular axis. - Low range accelerometers have much higher precision than high range accelerometers, but will saturate if the acceleration is too great. 113 Highlight your schematic RockOn! 2009 X & Y Axis Accelerometers Schematic (B5): - The accelerometers are very sensitive and difficult to solder, so they have been provided on a socket which can be soldered to the board. - To reduce noise there are capacitors on the power supply and analog outputs of the accelerometers. 114 Highlight your schematic RockOn! 2009 Current Sub System: Power Subsystem: Activation Power Regulation Sensor Subsystem: Temperature Sensor Pressure Sensor X & Y Axis Accelerometers Z Axis Accelerometers Geiger Counter Interface Command and Data Handling: AVR, Memory, & In-System Serial Programming (ISP) Data Retrieval 115 RockOn! 2009 Z Axis Accelerometer Schematic (C6): - There is one high range and one low range Z axis accelerometer. - Since the Z axis accelerometers must be mounted vertically, they are on a separate board, which connects to the main board with four wires. - As before, power supply and output filter capacitors reduce noise in the data. 116 RockOn! 2009 Z Accelerometer Header: - Solder one (1) 4X1 header into the footprint next to the pressure sensor. - Note: This header will connect the Z accelerometer board to the main board. 117 RockOn! 2009 Z Accelerometer Cable: - Strip and solder the four (4) wire Z Accelerometer Connector into the Z Accelerometer board. - White goes to “L”, Black to “-”, Red to “+”, and Blue to “H”. 118 RockOn! 2009 Z Accelerometer Cable: - Now that the wires have been soldered in, make sure that the leads are clipped as close to the board as possible to prevent shorting on the structural mount that will be added later. 119 RockOn! 2009 Capacitors (CZ and C9): Solder two (2) .1μF capacitors into the footprints labeled C9 and CZ on the Z accelerometer board. 120 RockOn! 2009 Capacitors (CZ and C9): - Now that the capacitors have been soldered in, make sure that the leads are clipped as close to the board as possible to prevent shorting on the structural mount that will be added later. 121 RockOn! 2009 Z Axis Accelerometer Schematic (C6): - There is one high range and one low range Z axis accelerometer. - Since the Z axis accelerometer must be mounted vertically, it is on a separate board, which connects to the main board with four wires. - As before, power supply and output filter capacitors reduce noise in the data. 122 Highlight your schematic RockOn! 2009 Accelerometer Test: X, Y, and Z Axis RockOn! 2009 123 RockOn! 2009 A Summary: At this point, you should be able to match the picture below. To complete the accelerometer tests, make the following connections. Connections 1: - Connect the LEDs: -Red to RDY -Green to ON - Connect the G-Switch - Connect the jumper to RBF Pin - Connect z-axis accel. board Blue wire to “H”, red to “+” - Connect the battery - Click/Activate the G-Switch 124 RockOn! 2009 Accelerometer Test 1: Connections 2: - Place the multimeter in 20V mode. - Place the black terminal on GND or the 3.3 VREG’s largest pad. - Place the red terminal in A0. Expected Results: - You should read 2.5 ± 0.2 Volts. - Raise your hand if you do not get these results. 125 RockOn! 2009 Accelerometer Test 2: Connections 3: - Ensure that one partner has an ESD strap on. - Have this partner hold the Z Accelerometer board flat against the static mat. - Keep black terminal on GND - Move red terminal from A0 through A5. Expected Results: - If you do not read 2.5 ± 0.2 Volts on all pins, please raise your hand. 126 RockOn! 2009 Accelerometer Test 3: Pin Summary: A0: X-Low Range A1: Y-Low Range A2: Z-Low Range A3: X-High Range A4: Y-High Range A5: Z-High Range Sanity Check: - Have your ESD safe partner reorient the Z Accelerometer board and main board. - Measure voltages on A0-A5 - If you do not see voltages other than 2.5 Volts, raise your hand. 127 RockOn! 2009 ESD/Heat Concern: WARNING: ESD The following components are extremely ESD and heat sensitive! Q ESD is electrostatic discharge caused by built up charge on your person from not wearing your protective ESD wrist strap. When soldering heat sensitive components, use the guideline 2-3 on, 8-10 seconds off. 128 RockOn! 2009 Accelerometer Test 4: Tilt Test 1: - You will notice that the XY accelerometer board has an axis definition on it. Axis - Have your ESD safe partner rotate the board so that the X axis points to the ceiling. - Now check the voltages on pins A0 and A3. -You should see an increase in voltage (above 2.5 Volts) on both, but the change will be smaller on A3. 129 RockOn! 2009 Accelerometer Test 5: Tilt Test 2: - You will notice that the XY accelerometer board has an axis definition on it. Axis - Have your ESD safe partner rotate the board so that the Y axis points to the ceiling. - Now check the voltages on pins A1 and A4. -You should see an increase in voltage (above 2.5 Volts) on both, but the change will be smaller on A4. 130 RockOn! 2009 Accelerometer Test 6: Axis Tilt Test 3: - You will notice that the Z accelerometer board has an axis definition on it. - Have your ESD safe partner rotate the board so that the Z axis points to the ceiling. - Now check the voltages on pins A2 and A5. -You should see an increase in voltage (above 2.5 Volts) on both, but the change will be smaller on A5. Final Step - Disconnect the battery 131 RockOn! 2009 Current Sub System: Power Subsystem: Activation Power Regulation Sensor Subsystem: Temperature Sensor Pressure Sensor X & Y Axis Accelerometers Z Axis Accelerometers Geiger Counter Interface Command and Data Handling: AVR, Memory, & In-System Serial Programming (ISP) Data Retrieval 132 RockOn! 2009 Geiger Counter Interface: - We will use more of the development area for this interface. - We will use power and ground from the power access - Data will be sampled on D2 133 RockOn! 2009 Development Area Schematic: Power access I/O Access I/O Access I/O Access I/O Access Power access 134 RockOn! 2009 Geiger Header 1: - Solder one (1) 3X1 header into the bread board section of the board. - The left most pin should be in row1, column 11. 135 RockOn! 2009 Geiger Header 2: Power (9V) - Strip both ends of one (1) 1.5 inch red wire. - Insert one end of the wire into a 9V source. - Insert the other end into row 2, column 12. - Bridge the red wire to the middle pin on the header as shown above. 136 RockOn! 2009 Geiger Header 3: GND - Strip both ends of one (1) 1.5 inch black wire. - Insert one end of the wire into GND. - Insert the other end into row 2, column 13. - Bridge the black wire to the right most pin on the header as shown above. 137 RockOn! 2009 Geiger Header 3: Data - Strip both ends of one (1) 1.5 inch blue wire. - Insert one end of the wire into D2. - Insert the other end into row 0, column 11. - Bridge the blue wire to the pin closest to the pressure sensor on the header as shown above. 138 RockOn! 2009 Development Area Schematic: Power access I/O Access I/O Access I/O Access I/O Access Power access 139 Highlight your schematic RockOn! 2009 Current Sub System: Power Subsystem: Activation Power Regulation Sensor Subsystem: Temperature Sensor Pressure Sensor X & Y Axis Accelerometers Z Axis Accelerometers Geiger Counter Interface Command and Data Handling: AVR, Memory, & In-System Serial Programming (ISP) Data Retrieval 140 RockOn! 2009 AVR Microcontroller Schematic 1 (B3): - The AVR is the computer that controls the system. PD6 - PA0 through PA7 are analog inputs, used to sample the sensors. Filter capacitor - PD6 will be used to control an LED 141 RockOn! 2009 AVR Microcontroller Schematic 2 (B3): - PB4 through PB7 are a data bus used to talk to the flash memory. UART - PD0 and PD1 are a Universal Asynchronous Receiver / Transmitter (UART) which can send data to a computer. 142 RockOn! 2009 Flash Memory Schematic (A1): Filter capacitor Flash Memory - The flash memory holds two megabytes of data. - A level shifter allows the AVR, which runs on 5V, to communicate with the 3.3V flash memory. 143 RockOn! 2009 In-System Programming Schematic (B2): - Using the ISP header with an AVRISP, which will be introduced later, allows the AVR to be programmed without removing it from the circuit. 144 RockOn! 2009 AVR Socket: Notches - Solder one (1) AVR DIP into the “AVR” footprint. - Warning: Make sure that the notches are aligned as indicated above and socket is flush with the board. - Tip: It works well to tack two corners on the back side to ensure it is mounted correctly before soldering all 40 pins. 145 RockOn! 2009 Capacitors (C3 and C4): C3 C4 - Solder two (2) .1μF capacitors into the footprints labeled C3 and C4. - Note: The footprints are located directly below the AVR Dip that was installed in the previous step. 146 RockOn! 2009 Resistors (R1, R5, R6): R6 R5 R1 - Solder three (3) 10K resistors from the kit into the footprints labeled R1, R5, and R6. 147 RockOn! 2009 ISP ISP Header: - Solder one (1) right angle header into the footprints labeled ISP. - The bent pins should be the ones that are soldered. - Caution: When clipping these leads, ensure that you are wearing your eye protection and holding the leads. 148 RockOn! 2009 Indicator LED 1: - Solder one (1) 3.3K resistor into bread board section as indicated above. - The right most lead of the resistor should be in row 1, column 15. - The left most lead of the resistor should be in row 1, column 19. 149 RockOn! 2009 Flat Side Indicator LED 2: Bridge - Solder one (1) red LED into bread board section as indicated above. - Make sure that the flat side of the LED is adjacent to the resistor. - The left lead will go in row 1, column 20. - The right lead will go in row 1, column 21. - Turn the board over and bridge the flat side lead to the resistor. 150 RockOn! 2009 Bridge Indicator LED 3: - Strip both ends of one (1) 1.5 inch blue wire. - Solder one end of the wire into row 1, column 14 adjacent to the resistor. - Solder the other end into D6. - Bridge the blue wire and resistor on the backside of the board as indicated above. 151 RockOn! 2009 Bridge Indicator LED 4: 5V PWR - Strip both ends of one (1) 1.5 inch red wire. - Solder one end of the wire into row 1, column 22 adjacent to the LED. - Solder the other end into a 5 Volt source. - Bridge the wire and LED on the backside of the board as indicated above. 152 RockOn! 2009 AVR Microcontroller Schematic 1 (B3): - The AVR is the computer that controls the system. - PA0 through PA7 are analog inputs, used to sample the sensors. PD6 Filter capacitor - PD6 will be used to control an LED 153 Highlight your schematic RockOn! 2009 AVR Microcontroller Schematic 2 (B3): - PB4 through PB7 are a data bus used to talk to the flash memory. UART - PD0 and PD1 are a Universal Asynchronous Receiver / Transmitter (UART) which can send data to a computer. 154 Highlight your schematic RockOn! 2009 Flash Memory Schematic (A1): Filter capacitor Flash Memory - The flash memory holds two megabytes of data. - A level shifter allows the AVR, which runs on 5V, to communicate with the 3.3V flash memory. 155 Highlight your schematic RockOn! 2009 In-System Programming Schematic (B2): - Using the ISP header with an AVRISP, which will be introduced later, allows the AVR to be programmed without removing it from the circuit. 156 Highlight your schematic RockOn! 2009 Current Sub System: Power Subsystem: Activation Power Regulation Sensor Subsystem: Temperature Sensor Pressure Sensor X & Y Axis Accelerometers Z Axis Accelerometers Geiger Counter Interface Command and Data Handling: AVR, Memory, & In-System Serial Programming (ISP) Data Retrieval 157 RockOn! 2009 Level Shifter Board Schematic (D4): - The level shifter board allows the AVR, which runs on 5V, to communicate with a computer serial port, which uses +/- 12V. 158 RockOn! 2009 Data Header: - Solder one (1) right angle header into the footprints labeled Data on the Main Board. - The bent pins should be the ones that are soldered. - Caution: When clipping these leads, ensure that you are wearing your eye protection. 159 RockOn! 2009 Data Header 2: Data - Solder one (1) right angle header into the footprints labeled Data on the Data Board. - The bent pins should be the ones that are soldered. - Caution: When clipping these leads, ensure that you are wearing your eye protection. 160 RockOn! 2009 Level Shifter Socket: - Solder one (1) level shifter socket into the footprint labeled Level Shifter. - Tip: It works well to tack two corners on the back side to ensure it is mounted correctly before soldering all pins. 161 RockOn! 2009 DB9 Serial Connector: - Solder one (1) DB9 serial connector into the data transfer board. - Make sure that the connector is flush with the board and the prongs are securing the board before you begin soldering. 162 RockOn! 2009 Resistors (R11): - Solder one (1) 10k resistor into the footprint labeled R11. 163 RockOn! 2009 Capacitors (C10): C10 Solder one (1) 1μF capacitor into the footprint labeled C10. 164 RockOn! 2009 Data LED: - Solder one (1) red LED into the footprint labeled ON. - Note: LEDs are polarized. The flat side of the LED is the negative side and should be placed in the footprint accordingly. 165 RockOn! 2009 ESD/Heat Concern: WARNING: ESD The following components are extremely ESD and heat sensitive! Q ESD is electrostatic discharge caused by built up charge on your person from not wearing your protective ESD wrist strap. When soldering heat sensitive components, use the guideline 2-3 on, 8-10 seconds off. 166 RockOn! 2009 Level Shifter Insertion: Notch Notch LS - Remove the level shifter from the ESD foam. - Align the notch from the level shifter with the one on the level shifter dip on the board, and GENTLY work the level shifter into the socket. - Take your time with this, bent leads are extremely difficult to straighten. 167 RockOn! 2009 AVR Insertion: Notch AVR Notch - Remove the AVR from the ESD foam. - Align the notch from the AVR with the one on the AVR socket on the board, and GENTLY work the AVR into the socket. - Take your time with this, bent leads are extremely difficult to straighten. 168 RockOn! 2009 Final Products: AVR Board Z-Accel. Board Data Board 169 RockOn! 2009 Congratulations! The board is now complete and ready for software and testing. RockOn! 2009 170 RockOn! 2009