* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Computer organized measurements

Oscilloscope history wikipedia , lookup

Analog-to-digital converter wikipedia , lookup

Wien bridge oscillator wikipedia , lookup

Lego Mindstorms wikipedia , lookup

Integrating ADC wikipedia , lookup

Thermal runaway wikipedia , lookup

Nanogenerator wikipedia , lookup

Night vision device wikipedia , lookup

Power MOSFET wikipedia , lookup

Voltage regulator wikipedia , lookup

Operational amplifier wikipedia , lookup

Radio transmitter design wikipedia , lookup

Schmitt trigger wikipedia , lookup

Valve audio amplifier technical specification wikipedia , lookup

Lumped element model wikipedia , lookup

Power electronics wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Valve RF amplifier wikipedia , lookup

Transistor–transistor logic wikipedia , lookup

Rectiverter wikipedia , lookup

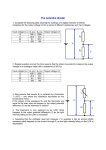

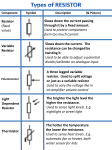

Current mirror wikipedia , lookup

Computer organized measurements A typical sequence of operations during the measurement experiment is as follows: a) proposition of physical and mathematical model of observable fact or object, b) conversion of the measured values into electrical signals, c) conditioning of signals (linearization, amplification, filtering, etc.), d) acquisition of the data (multiplexing, conversion to digital form), e) processing of the data signals, assessment of uncertainty, f) visualization of the results or transmission the data via the network. • Describe the three ways of how to do computer organized measurement! • Names and functions of the parts. (sensor, transducer, etc..) Simple Input/Output System using Sound Transducers Transducer: changes the from of the energy Common Transducers Quantity being Measured Input Device (Sensor) Output Device (Actuator) Light Level Light Dependant Resistor (LDR) Photodiode Phototransistor Solar Cell Lights & Lamps LED's & Displays Fibre Optics Temperature Thermocouple Thermistor Thermostat Resistive temperature detectors (RTD) Heater Fan Force/Pressur e Strain Gauge Pressure Switch Load Cells Lifts & Jacks Electromagnetic Vibration Position Potentiometer Encoders Reflective/Slotted Opto-switch LVDT Motor Solenoid Panel Meters Speed Tacho-generator Reflective/Slotted Opto-coupler Doppler Effect Sensors AC and DC Motors Stepper Motor Brake Sound Carbon Microphone Piezo-electric Crystal Bell Buzzer Loudspeaker Thermocouple used to produce an Analogue Signal Light Sensor used to produce an Digital Signal • Find out how they are working! • Why one is analogue, another is digital? Potentiometer Construction The output signal (Vout) from the potentiometer is taken from the centre wiper connection as it moves along the resistive track, and is proportional to the angular position of the shaft. Example of a simple Positional Sensing Circuit The Linear Variable Differential Transformer. operate under the electrical principle of Faradays Law of inductance. is shown below. Example of a simple Incremental coded disc. Example of a simple 4-bit circular binary coded disc. Typical application of absolute position encoders are in computer hard drives and CD/DVD drives were the absolute position of the drives read/write heads are monitored or in printers/plotters to accurately position the printing heads over the paper. The Bi-metallic Thermostat. The Thermistor. A Thermistor on the other hand is a THERM-ally sensitive res-ISTOR which changes its physical resistance with temperature. They are generally made from ceramic type semiconductor materials such as oxides of nickel, manganese or cobalt coated in glass which makes them easily damaged. Most types of thermistor's have a Negative Temperature Coefficient of resistance or (NTC), that is their resistance value goes DOWN with an increase in the temperature but some with a Positive Temperature Coefficient, (PTC), their resistance value goes UP with an increase in temperature are also available. Their main advantage is their speed of response to any changes in temperature, accuracy and repeatability. Example No1 The following thermistor has a resistance value of 10KΩ at 25o C and a resistance value of 100Ω at 100oC. Calculate the voltage drop across the thermistor and hence its output voltage (Vout) for both temperatures when connected in series with a 1kΩ resistor across a 12v power supply. by changing the fixed resistor value of R2 (in our example 1kΩ) to a potentiometer or preset, a voltage output can be obtained at a predetermined temperature set point for o example, 5v output at 60 C and by varying the potentiometer a particular output voltage level can be obtained over a wider temperature range. Resistive Temperature Detectors (RTD). Resistance Temperature Detectors or RTD´s are precision temperature sensors made from high-purity conducting metals such as platinum, copper or nickel wound into a coil and whose electrical resistance changes with temperature similar to that of the thermistor. Also available are thin-film RTD´s, where a thin film of platinum paste is deposited onto a white ceramic substrate. They have positive temperature coefficients (PTC) but unlike the thermistor their output is extremely linear producing very accurate measurements of temperature. However, they have poor sensitivity, that is a change in temperature only produces a very small output change for example, 1Ω/oC. The more common types of RTD´s are made from platinum and are called Platinum Resistance Thermometer orPRT´s with the most commonly available of them all the Pt100 sensor, which has a standard resistance value of 100Ω at 0oC. However, Platinum is expensive and one of the main disadvantages of this type of device is its cost. used as the temperature sensor and this is shown below. The principle of operation is that the junction of the two dissimilar metals produce a "thermo-electric" effect that produces a constant potential difference of only a few millivolts (mV) between and which changes as the temperature changes. application. The British colour thermocouples is given below. code for standard Thermocouple Sensor Colour Codes Extension and Compensating Leads The output voltage from a thermocouple is very small, a few millivolts (mV) for a 10oC change in temperature difference and because of this small voltage output some form of amplification is generally needed. The type of amplifier, either discrete or in the form of an Operational Amplifier needs to be carefully selected, because good drift stability is required to prevent recalibration of the thermocouple at frequent intervals. This makes the "Chopper type" of amplifier preferable for most temperature sensing applications. Code Type Conductors (+/-) Sensitivity E Nickel Chromium / Constantan -200 to 900oC J Iron / Constantan 0 to 750oC K Nickel Chromium / Nickel Aluminium -200 to 1250oC N Nicrosil / Nisil 0 to 1250oC T Copper / Constantan -200 to 350oC U Copper / Copper Nickel Compensating for "S" and "R" 0 to 1450oC British BS 1843:1952 Photo-emissive Cells - These are photodevices which release free electrons from a light sensitive material such as caesium when struck by light. Photo-conductive Cells - These photodevices vary their electrical resistance when subjected to light. The most common photoconductive material is Cadmium Sulphide Photo-voltaic Cells - These photodevices generate an e.m.f. in proportion to the radiant light energy received. The most common photovoltaic material is Selenium. Photo-junction Devices - These photodevices are mainly semiconductor devices such as the photodiode or phototransistor which use light to control the flow of electrons and holes across their PN-junction. The Light Dependant Resistor Cell One simple use of a Light Dependant Resistor, is as a light sensitive switch as shown below. This basic light sensor circuit is of a relay output light activated switch. A potential divider circuit is formed between the photoresistor, LDR and the resistor R1. When no light is present ie in darkness, the resistance of the LDR is very high in the Megaohms range so zero base bias is applied to the transistor TR1 and the relay is de-energised or "OFF". As the light level increases the resistance of the LDR starts to decrease causing the base bias voltage at V1 to rise. At some point determined by the potential divider network formed with resistor R1, the base bias voltage is high enough to turn "ON" the transistor TR1 and thus activate the relay which inturn is used to control some external circuitry. As the light level falls back to darkness again the resistance of the LDR increases causing the base voltage of the transistor to decrease, turning the transistor and relay "OFF" at a fixed light level determined again by the potential divider network. Photo-diode Construction and Characteristics Photo-transistor Construction and Characteristics Characteristics of a typical Photovoltaic Solar Cell. Input Devices or Sensors Sensors are "Input" devices which convert one type of energy or quantity into an electrical analog signal. The most common forms of sensors are those that detect Position, Temperature, Light, Pressure and Velocity. The simplest of all input devices is the switch or pushbutton. Some sensors called "Self-generating" sensors generate output voltages or currents relative to the quantity being measured, such as thermocouples and photo-voltaic solar cells and their output bandwidth equals that of the quantity being measured. Some sensors called "Modulating" sensors change their physical properties, such as inductance or resistance relative to the quantity being measured such as inductive sensors, LDR's and potentiometers and need to be biased to provide an output voltage or current. Not all sensors produce a straight linear output and linearization circuitry may be required. Signal conditioning may also be required to provide compatibility between the sensors low output signal and the detection or amplification circuitry. Some form of amplification is generally required in order to produce a suitable electrical signal which is capable of being measured. Instrumentation type Operational Amplifiers are ideal for signal processing and conditioning of a sensors output signal. Output Devices or Actuators "Output" devices are commonly called Actuators and the simplest of all actuators is the lamp. Relays provide good separation of the low voltage electronic control signals and the high power load circuits. Relays provide separation of DC and AC circuits (i.e. switching an AC current path via a DC control signal or vice versa). Solid state relays have fast response, long life, no moving parts with no contact arcing or bounce but require heatsinking. Solenoids are electromagnetic devices that are used mainly to open or close pneumatic valves, security doors and robot type applications. They are inductive loads so a flywheel diode is required. Permanent magnet DC motors are cheaper and smaller than equivalent wound motors as they have no field winding. Transistor switches can be used as simple ON/OFF unipolar controllers and pulse width speed control is obtained by varying the duty cycle of the control signal. Bi-directional motor control can be achieved by connecting the motor inside a transistor H-bridge. Stepper motors can be controlled directly using transistor switching techniques. The speed and position of a stepper motor can be accurately controlled using pulses so can operate in an Open-loop mode. Microphones are input sound transducers that can detect acoustic waves either in the Infra sound, Audible sound or Ultrasound range generated by a mechanical vibration. Loudspeakers, buzzers, horns and sounders are output devices and are used to produce an output sound, note or alarm.