* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Advantages of CAN and LIN in Networked Embedded Systems

Distributed operating system wikipedia , lookup

Airborne Networking wikipedia , lookup

Internet protocol suite wikipedia , lookup

Low-voltage differential signaling wikipedia , lookup

Low Pin Count wikipedia , lookup

Recursive InterNetwork Architecture (RINA) wikipedia , lookup

MIL-STD-1553 wikipedia , lookup

Bus (computing) wikipedia , lookup

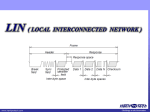

ID 210C: Introduction to CAN/LIN Solutions Renesas Electronics America Inc. Sridhar Lingam Product Marketing Manager 12 October 2010 Version 10 Sridhar Lingam Product Marketing Manager Renesas MCU CAN Solutions M16C/R32C, H8S/H8SX Product Families TFT-LCD solution for H8S and H8SX Education MSEE from the Clemson University, Clemson, SC Work Experience 16 years experience with semiconductor Industry with focus on Industrial applications Varied experience as Product Engineer, FAE and Product Marketing Responsible for definition and Marketing of Memory & MCU product families Previously worked at National Semiconductor, STMicroelectronics & Atmel 2 Renesas Technology and Solution Portfolio Microcontrollers & Microprocessors #1 Market share worldwide * ASIC, ASSP & Memory Advanced and proven technologies Solutions for Innovation Analog and Power Devices #1 Market share in low-voltage MOSFET** * MCU: 31% revenue basis from Gartner "Semiconductor Applications Worldwide Annual Market Share: Database" 25 March 2010 ** Power MOSFET: 17.1% on unit basis from Marketing Eye 2009 (17.1% on unit basis). 3 Renesas Technology and Solution Portfolio Microcontrollers & Microprocessors #1 Market share worldwide * Solutions for Innovation ASIC, ASSP & Memory Advanced and proven technologies Analog and Power Devices #1 Market share in low-voltage MOSFET** * MCU: 31% revenue basis from Gartner "Semiconductor Applications Worldwide Annual Market Share: Database" 25 March 2010 ** Power MOSFET: 17.1% on unit basis from Marketing Eye 2009 (17.1% on unit basis). 4 Microcontroller and Microprocessor Line-up Superscalar, MMU, Multimedia High Performance CPU, Low Power High Performance CPU, FPU, DSC Up to 1200 DMIPS, 45, 65 & 90nm process Video and audio processing on Linux Server, Industrial & Automotive Up to 500 DMIPS, 150 & 90nm process 600uA/MHz, 1.5 uA standby Medical, Automotive & Industrial Up to 165 DMIPS, 90nm process 500uA/MHz, 2.5 uA standby Ethernet, CAN, USB, Motor Control, TFT Display Legacy Cores Next-generation migration to RX General Purpose Up to 10 DMIPS, 130nm process 350 uA/MHz, 1uA standby Capacitive touch 5 Ultra Low Power Embedded Security Up to 25 DMIPS, 150nm process Up to 25 DMIPS, 180, 90nm process 190 uA/MHz, 0.3uA standby 1mA/MHz, 100uA standby Application-specific integration Crypto engine, Hardware security Microcontroller and Microprocessor Line-up Superscalar, MMU, Multimedia High Performance CPU, Low Power High Performance CPU, FPU, DSC Up to 1200 DMIPS, 45, 65 & 90nm process Video and audio processing on Linux Server, Industrial & Automotive Up to 500 DMIPS, 150 & 90nm process 600uA/MHz, 1.5 uA standby Medical, Automotive & Industrial Up to 165 DMIPS, 90nm process 500uA/MHz, 2.5 uA standby Ethernet, CAN, USB, Motor Control, TFT Display CAN MCU Solutions Legacy Cores R8C/R32C/SH/RX Next-generation migration to RX General Purpose Up to 10 DMIPS, 130nm process 350 uA/MHz, 1uA standby Capacitive touch 6 Ultra Low Power Embedded Security Up to 25 DMIPS, 150nm process Up to 25 DMIPS, 180, 90nm process 190 uA/MHz, 0.3uA standby 1mA/MHz, 100uA standby Application-specific integration Crypto engine, Hardware security Innovation 7 Our CAN/LIN Solution Renesas’ easy to design MCU CAN/LIN solutions provide highly reliable, expandable, and noise immune interfaces for industrial applications using chip to chip communications. 8 Agenda CAN in Embedded Networks What is CAN & it’s benefits? Can Basics What is LIN and it’s benefits? Renesas MCU CAN Solutions Q&A 9 Key Takeaways Reasons for using CAN and LIN Benefits of CAN and LIN Basics of CAN and LIN General differences between CAN and LIN 10 What is CAN ? Controller – Area – Network Developed in 1983 by Robert Bosch To solve the networking issues in automotive Main Benefits Economical Reliable Real Time response Scalable Standards CAN 2.0A (ISO11519) Can 2.0B(ISO11898) 11 CAN-Leading Choice for Embedded Networking The main Reasons are Economical – Low Wiring Cost – Low Hardware Cost Reliability – Error Free Communication – Immune to EMI/EMS Availability – Several 8/16/32 bit MCU available in the market – Standard development tools Scalability 12 Question Please give 3 reasons for the growing popularity of CAN in embedded applications Reliability (works well in noisy environment) Economical ( Have low wiring costs) Scalability Availability 13 Features and Benefits of CAN 14 Multiple Master Hierarchy Redundant Intelligent Systems 1 Mbps of Data transfer rate Real Time Response 0-8 Bytes of User Data Simplifies design requirements Unique mail box Identifiers Flexibility in System Design Acceptance Filtering by nodes Arbitration & Prioritization Provides Error Detection Ensures high Reliability Fault Confinement measures Keeps the traffic undisturbed Auto re-transmit if corrupted Accurate communication link CAN and the 7-layer model ISA/OSI Reference Model 7. Application Layer 6. Presentation Layer 5. Session Layer 4. Transport Layer Partially implemented by higher-level CAN protocols (CANOpen) 3. Network Layer 2. Data Link Layer 1. Physical Layer 15 Standard CAN implementation Managed in Hardware. Dramatic Real-time advantage to System Design Data Flow in CAN Transmitting Node Node Configured to receive identifier Node not Configured to receive identifier MCU Firmware MCU Firmware MCU Firmware Identifier [id_n] Identifier [id_n] Data [values_x] Data [values_x] Tx Mail Box [id_n] Rx Mail Box [id_c] Rx Mail Box [id_d] Data [values_x] Rx Mail Box [id_b] Rx Mail Box [id_b] Rx Mail Box [id_c] Rx Mail Box [id_n] Rx Mail Box [id_c] Rx Mail Box [id_b] Data [values_x] Rx Mail Box [id_a] CAN Peripheral CAN Peripheral CAN Peripheral CAN Transceiver CAN Transceiver CAN Transceiver Data Frame is broadcast to the bus [ id_n][value_x] 16 Data Frame Identifier Rem Req 1 11/29 1 ID extend S O F Control Data (Bytes) C R C A C K E O F 1 4 0-8 bytes 15 1 7+ Start of Frame – 1-bit Arbitration Field – 11-bits/29-bits Control Field – 6 bits (2 reserved, 4 representing number of Data Field bytes) Data Field – 0 to 8 BYTES CRC – 15-bits ACK Field – 1-bit/variable End of Frame – 7-bits (recessive) 17 Question Why do most CAN applications use CAN 2.0A (11-bit identifiers) and not CAN 2.0B (29-bit identifiers)? Overall data bandwidth decreases Decrease in reliability Increase in worse case delay 18 CAN Bus Characteristics Dominant bits (0’s) override recessive bits (1’s) on the CAN bus. Node 1 Backs OffNode 1 100 0 Node 2 Backs OffNode 2 101 Node 3 000 LSB…MSB 19 Maintaining Synchronization ‘Bit Stuffing’ is applied to keep the bus synchronized Five bits of consecutive dominant or recessive bits inserts a bit of the opposite polarity Resulting signal edge is used to establish timing synchronization at all nodes Stuffed bits are managed by hardware 20 Bus Access and Arbitration The CAN protocol handles bus accesses according to the concept of “Carrier Sense Multiple Access with Collision Detection” For a collision, messages are NOT destroyed! No bandwidth is wasted on collisions! The message with the higher priority wins bus access – NDA – “Non-destructive Arbitration” Each message has an identifier that determines the priority Each node defined by unique identifier to avoid collisions AMP – “Arbitration by Message Priority” 21 CAN and EMI Node A Node B V CAN_H U diff CAN_L (dominant level) CAN_H + CAN_L - + - EMI CAN-Bus (Differential Serial Bus) 22 t Node C CAN Baud Rate vs. Bus Length 1000 500 Bus lines assumed to be an electrical medium (e.g. twisted pair) 200 Bit Rate [kbps] 100 50 20 10 5 0 10 40 100 200 1000 CAN Bus Length [m] 23 10,000 Error Detection in CAN Error statistics depend up on the entire environment Total number of nodes Physical Layout EMI Disturbance CAN application example running at 2000 hours/year, 500 Kbps, 25% Bus load Results in one undetected error in 1000 years 24 CAN Controller Physical Layer Physical CAN Bus (Differential, e.g Twisted Pair) CAN_Txd CAN_Rxd CAN_Txd Differential CAN_Rxd Transceiver CAN_Txd CAN_Rxd Optical Transceiver Optical Fiber 25 Cables and Connectors CAN does not specify the physical media Common Wire Twisted pair Shielded twisted pair If optional power is needed: additional twisted pair – A pair of “shielded twisted pair” Application specific Common Connector 26 9-pin Dsub 5-pin mini style Terminal blocks Application specific (e.g. telephone jacks) What is LIN ? Local Interconnect Network A slower & low cost alternative to CAN Developed by LIN Consortium in 2002 Developed as a sub-network of CAN to reduce the Bus Load Applications Automotive, White Goods, Medical – for sensors and actuators 27 Features & Benefits of LIN Complementary to CAN Extends CAN to sub-nets Single Wire Implementation Reduce harness costs Speed up to 20Kbps Improves EMI response Single Master/Multiple Slave No arbitration necessary Based on common UART/SCI Reduces risk of availability Self Synchronization No external crystal Guaranteed latency times Deterministic & Predictable 28 Typical LIN Network ECU & Gateway CAN 5V CAN phys SCI IF LIN phys IF Simplex 12V Operation 29 Node A Node B Node C Node D SCI XCVR SCI XCVR SCI XCVR SCI XCVR LIN Message Frame message header synch break 13 bit Synchronization Frame message response synch field identifier Identifier Byte Synchronization Field 30 0 to 8 data fields checksum Message LIN Physical Interface Usually managed by a transceiver LIN Control Unit Bus Voltage VBAT 8...18V master: 1k slave: 30k UART Rx 60% Bus 40% Tx GND Example capacitances master: 2.2nF slave: 220pF 31 recessive logic ‘1’ controlled slope ~2V/µs dominant logic ‘0’ Time Sense voltage Taking account of Ground-Shift Data timing 32 LIN Baud Rate Requirements (1)The pre-synchronization accuracy in rev. 1.3 is ±15%, but this is tightened to 14% in LIN 2.0 33 Question What are the reasons when LIN is preferred over CAN? To save the bandwidth of another main bus Size of Network is 16 nodes or less When lower speed is acceptable Economical Single Master with multiple slaves 34 LIN versus CAN LIN versus CAN 35 Access Control Single Master Multiple Master Max Bus Speed 20 Kbps 1 Mbps Typical # nodes 2 to 16 4 to 20 Message Routing 6-bit Identifier 11/29-bit Identifier Data byte/frame 2,4,8 bytes 0-8 bytes Error detection 8-bit checksum 16-bit CRC Physical Layer Single-wire Twisted-pair Renesas CAN/LIN Solutions 36 Renesas MCU CAN Solutions SH7216 200MHz@3/5V High End Up to 1 MB Flash 1-2 CAN 176 pin Single CAN Multi CAN RX600 100MHz@3V New SH7264/62 144MHz@3V SH7286 100MHz@3/5V Mid End Up to 1 MB Flash 1-2 CAN 100/144/176 pin R32C/117 With FPU 64MHz@3/5V R32C/118 With FPU CAN API Compatible 64MHz@3/5V M16C/29 20MHz@3/5V Low End Up to 128 KB Flash 1 CAN 48-64 pin 37 www.america.renesas.com/CAN R8C/2x 20MHz@3/5V Implementation of CAN in Renesas MCU RX TX CAN 2.0A / CAN 2.0B Protocol Engine Up to 1Mbps data rate 16/32 Message Buffers INTs Message Buffer Clock Data Control CPU Interface Acceptance Filter Control Registers Common Control/Status Registers 38 Renesas M16C LIN Roadmap R32C Dedicated LIN Hardware M16C Platform M32C M16C M16C/Tiny R8C/3x 39 UART LIN Common LIN API Support for all M16C Products Renesas CAN Development Kit CAN Development Kits for R8C & R32C– CAN-D Kit R32C CAN-D kit now availabl e Two R8C/23 or R32C/118 Renesas Starter Boards Systec CAN protocol Analyzer included in the kit E8/E30a Debug Interface Up to 3 CAN interfaces with 32 mailboxes each Time-triggered CAN support All board specific APIs and drivers available in included CD Extensive third-party middleware support available Sample projects and evaluation software – CAN API – LIN API Common API for all Renesas CAN MCU Solutions www.america.renesas.com/CAN RCDK8C (R8C), MSRP: $495 YRCDK32C (R32C), MSRP: $550 40 Innovation 41 Questions? 42 Feedback Form Please fill out the feedback form! If you do not have one, please raise your hand 43 Thank You! 44 Appendix 45 Serial Communications CAN, LIN, RS-485, RS-232, SPI, I2C, etc. are all serial communications Advantages No line-to-line timing skew Fewer wires lowering cable, connector, and design costs Saves on board space and power consumption per bit Disadvantages Generally point-to-point Overhead above actual data payload that uses bandwidth Higher signal rates shorten transmission distances 46 Transmission Topologies Point-to-Point (Simplex) One transmitter and one receiver per line Transmission is possible only in one direction, i.e. unidirectional. Multidrop (Distributed Simplex) point-to-point configuration with one transmitter and many receivers Only unidirectional transfer is possible. 47 Transmission Topologies Multipoint (Multiplex) Many transmitters and many receivers per line. Transmission is possible in either direction, i.e. bidirectional. 48 Number of CAN Nodes Built ~Over 2 Billion Nodes Shipped YTD!!!* CAN Nodes Built 800 700 600 500 Millions 400 Millions of Units 300 200 100 0 1998 2000 2002 2004 2006 2008 2010 Year Source: CiA (CAN-in-Automation): http://www.can-cia.org*; REA estimates 49 A Typical 2-channel CAN Solution 2-channel CAN MCU CPU CAN CAN Lighting System Motion Sensor Monitor HVAC CAN CAN Transceiver Transceiver Temp Sensor 50 Motor Control CAN Bus 1 CAN Bus 2 Low-Speed High-Speed RS-485 vs. CAN CAN equals RS-485? Similar costs Similar distances Similar electrical immunity Similar chip availability Similar connectors Same 32 nodes (loads) standard Duplex (4 wire) or Half-Duplex (2 wire) options available RS-485 is used primarily due to Legacy. Remember 8051? 51 RS-485 and the 7-layer model ISA/OSI Reference Model 7. Application Layer 6. Presentation Layer 5. Session Layer 4. Transport Layer Partially implemented by higher-level RS-485 protocols (i.e. MODBUS) 3. Network Layer 2. Data Link Layer Standard RS-485 implementation 1. Physical Layer Only Low Layer specification 52 Managed by CPU in Software CAN Protocol Versions Two CAN protocol versions are available: V2.0A (Standard) - 11 bit Message ID’s - 2048 ID’s available V2.0B (Extended) - 29 bit Message ID’s - more than 536 Million ID’s available 53 Termination Settings High-Speed CAN (125Kbps+) For High-Speed CAN, both ends of the pair of signal wires (CAN_H and CAN_L) must be terminated ISO 11898 requires a cable with a nominal impedance of 120 ohms – 120 ohm resistors should be used for termination Only the devices on the ends of the cable need termination resistors 54 Termination Settings Low-Speed CAN (Up to 125Kbps) Each device on the network needs a termination resistor for each data line: R(RTH) for CAN_H and R(RTL) for CAN_L Requires termination on the transceiver rather than on the cable The resistance of each resistor is calculated through several formulas 55 An example of LIN Implementation 56 Renesas Electronics America Inc.