* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download thermo grill illusion of pain

Survey

Document related concepts

Transcript

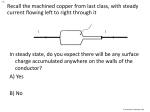

Probing The Of Experience Pain Team Members Jeff Swift Anna Karas Stacey Hoebel Advisor Prof. Willis Tompkins Client Dr. Christopher Coe UW-Madison Dept. of Psychology Abstract Our client, a psychologist at UW, wanted a method to study pain disorders without actually inflicting pain on patients. The “thermal grill illusion” accomplishes this by tricking the brain into feeling pain due to alternating hot and cold components. Our device employs solid copper rods as the cold component (20°C) and strips of stainless steel foil heated electrically as the warm component (40°C). Problem Statement Design a device to test pain sensitivity in patients with generalized pain disorders. The alternating warm and cool components of the device activate sensory receptors and neurological thermal pathways to create the illusion of pain. Background FIBROMYALGIA Chronic musculoskeletal pain and fatigue disorder Cause of the disease is still unknown Associated sleep disorder called the alpha-EEG anomaly Treatments THERMO GRILL ILLUSION OF PAIN Pain and temperature have intersecting neural pathways Previous Design Created by A.D. Craig (Univ. of Arizona) Alternating warm (40°C) and cool rods (20°C) About 8” x 8” with 0.5” diameter thermal rods Presumed to be electric Ominous Looking Design Constraints Consistent temperature components – Warm: 40°C Cool: 20°C Reach temperatures in 1 sec. Safe Reusable Non threatening appearance Easy to operate Materials and Cost Material Use Cost St. Steel Foil Copper Bars Wood (scrap) Heater Cool Component Insulator for heater, Platform $24.00 $65.00 ---------- Resistors & Wires Breadboard Wood Screws Circuitry Circuitry Secure Copper Bars Circuitry $1.00 ---------$2.00 Power Amplifier $40.00 TOTAL $132.00 Temperature Controlling Circuit •Temperature remains constant 40° C •Rapid heating •No temperature overshoot Warm Component Stainless Steel foil strips heat when voltage is applied by power supply As temperature changes, the resistance of the stainless steel feeds back to the circuit If the resistance of the foil, when heated, balances the wheatstone bridge, the voltage supply is stopped and temperature is held constant Warm Component Material Selection Platinum – Ideal resistivity and temperature coefficient of resistivity – Very high cost Stainless Steel – – – – Large temperature coefficient of resistivity Large resistivity Inexpensive Available in appropriate thickness Material Selection Resistivity (micro ohm*cm) Electrical resistivity vs Temperature for Stainless Steel 321 140 120 100 80 y = -3E-10x4 + 4E-07x3 - 0.0003x2 + 0.1474x + 69.166 R2 = 1 60 40 20 0 0 200 400 600 Temperature (C) 800 1000 Material Selection Calculations for foil dimensions: – Want total resistance of heaters Rs = 2.5Ω – Heaters to be connected in series so resistance of each of 6 heaters = 0.42Ω – Thickness of foil = 5.08 x 10-5 m Length of foil strip = 0.2032 m Resistivity of steel at 40°C = 7.46 x 10-7 Ω-m – R=ρ*L/A width of foil strip = 0.7 cm Cool Component Copper bars – Heat transfer equation: Q=A * k * ΔT T=(m * Cp * ΔT) / Q – Time to change 1ºK = 6.4 sec Heat sink – Adds thermal mass (absorbs heat) – Adds surface area (dissipates heat) Prototype Construction Cool Component – Cut copper bar into six smaller bars (8” long) – Drilled holes in ends of each copper bar – Used a countersink to accommodate screw heads – Hammered wood screw through copper hole and into plywood platform Prototype Construction Warm Component – Cut wood blocks to same size as copper bars (8” x 1” x ½”) – Cut stainless steel foil strips to size for optimal heating control (8” x ¼”) – Tacked foil and wire to wood at ends Prototype Testing Verified total resistance of foil heaters Tested prototype with feedback circuit: – Power Source: +/- 20V and 1 amp – Resulted in overload of power source – Failure Analysis Tested prototype without feedback circuit: – Applied direct voltage of 3V to foil – Resulted in successful heat generation Assessment of Cool Component – Advantages Simple operator interface Easy to manufacture Constant temperature Reusable Aesthetically pleasing– conductive paint – Disadvantages Remains at the room temperature Assessment of Warm Component – Advantages: Quickly heats up to 40°C (1-2 sec) Remains at constant temperature No temperature overshoot No risk of burning patient Easy to manufacture – Disadvantages: Somewhat primitive in appearance Improvement of control circuitry necessary Ethics Inducing pain in human subjects Adequate testing to assure engineering temperature controls are reliable and safe Future Work Improve the aesthetics of device Develop and test circuitry to control temperature – Order 3W resistors for power amp Look into possibilities of creating a switch operated device Use an aluminum sheet to serve as a heat sink for the cold copper bars Replace wood blocks with ceramic as the thermal insulator for stainless steel heater Special Thanks Prof. Willis Tompkins Prof. John Webster Prof. Jay Martin