* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download relay - Weebly

Mains electricity wikipedia , lookup

Buck converter wikipedia , lookup

Alternating current wikipedia , lookup

Electric vehicle conversion wikipedia , lookup

Protective relay wikipedia , lookup

Light switch wikipedia , lookup

Automotive lighting wikipedia , lookup

Counter-IED equipment wikipedia , lookup

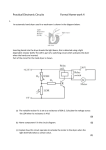

Resistive opto-isolator wikipedia , lookup

Presented By: Mahesh Kr. Gupta E.C.(Sem 7th ) Roll no. 0501031048 U.C.E.R Naini Alld. Auto Dipper is highly sophisticated electronic device that switches head lights of an automobile/vehicle to differ mode(low beam) automatically when the sharp light beam lights off an on coming vehicle falls on its windscreen . And it switches back from dipper mode (low beam) to main beam (high beam) automatically once the on coming vehicle passes off . This happens within a fraction of seconds . Relay Printed circuit board Optical sensor(LDR) Resistors Diodes Capacitors Transistor Lamp Switch 12V RELAY R1 22k L1 1mH 12V Lamp 12V Lamp L3 L2 D2 BY127 R2 100k ON\OFF D1 1N914 T1 SL100 S1 T2 2N3055 + + V1 R3 VR1 100K C1 47uF 12V 12V AUTO BATTER Voltage : Contact Current : Device Wattage : Sensitivity range : 12 Volts 20 Amps 1 watt (Adjustable from 0.5 lux to infinity) Auto dipper can be used for vehicle with headlight. : Rating upto 250 watts Relay : 12Volts , 300mA Coil LDRs or Light Dependent Resistors are very useful especially in light/dark sensor circuits. Normally the resistance of an LDR is very high, sometimes as high as 1000 000 ohms, but when they are illuminated with light resistance drops dramatically. Working Of LDR The animation opposite shows that when the torch is turned on, the resistance of the LDR falls, allowing current to pass through it. Example of a light sensor circuit : When the light level is low the resistance of the LDR is high. This prevents current from flowing to the base of the transistors. Consequently the LED does not light. However, when light shines onto the LDR its resistance falls and current flows into the base of the first transistor and then the second transistor. The LED lights. The preset resistor can be turned up or down to increase or decrease resistance, in this way it can make the circuit more or less sensitive. A relay is an electrical switch that opens and closes under the control of another electrical circuit. In the original form, the switch is operated by an electromagnet to open or close one or many sets of contacts. It was invented by Joseph Henry in 1835. Because a relay is able to control an output circuit of higher power than the input circuit, it can be considered, in a broad sense, to be a form of an electrical amplifier. When a current flows through the coil, the resulting magnetic field attracts an armature that is mechanically linked to a moving contact. The movement either makes or breaks a connection with a fixed contact. When the current to the coil is switched off, the armature is returned by a force approximately half as strong as the magnetic force to its relaxed position. Usually this is a spring, but gravity is also used commonly in industrial motor starters. Most relays are manufactured to operate quickly. In a low voltage application, this is to reduce noise. In a high voltage or high current application, this is to reduce arcing. 1. It keeps the head lamps in main beams if there is no vehicle from the opposite direction. Contd. 2. It dips the head lamps automatically on encountering another vehicle from the opposite direction and restores main beam at crossing points if the opposite driver also dips his head lamps. Contd. 3. It restores the main beam much before crossing if the oppostite driver does not dip his head lamps within the safe stopping sight distance of 100 meters. Contd. 4. It dips the head lamps of both the vehicles if fitted to both vehicles. 5. It maintains headlamps in main beams on encountering dense traffic from opposite direction on a dark road. The size of the device is about 2.5 inches cube . Auto dipper box can be installed anywhere near steering as per convenience so that "ON-OFF" switch on auto dipper box can be used easily. Sensor Eye is mounted near wiser position near the top edge of wind screen (inside the car) such that it receives the light of the approaching vehicle in proper position. Sensor position can be adjusted slightly by bending the sensor support. The device gets activated only when headlights are in "on" position. For truck & buses, Sensor Eye can be placed on lower side of wind shield inside close to the right hand of driver and for car and jeep etc. the Sensor Eye can be placed using the Sun wiser support screws. The device can be operated with the existing 12 volts battery of the vehicle. Salient Features: Main function is automatic control of headlamps beam This Intelligent device (AUTODIP) automatically understands the well Lit and Dark roads and functions accordingly and promptly Understands the type of roads including curves and straight Understands approaching traffic’s DIP and MAIN beams Device also understands the dipper switch position The head lamp ON/OFF status It is designed to withstand: Vibrating environment, Bumpy roads, sudden temperature variations, Salty and chemical environment, etc. AUTODIP is a very compact small size device and can easily be mounted and fitted easily anywhere inside in any automobile / vehicle or under the bonnet and sensor is concealed and mounted behind the windscreen by an auto electrician or by company-trained personnel. The entire process has only two steps physical installation and electrical integration. The whole process takes only 5 to 10 minutes. THANK YOU