* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Fluid Mechanics - 上海交通大学工程力学教学基地

Cnoidal wave wikipedia , lookup

Magnetorotational instability wikipedia , lookup

Superfluid helium-4 wikipedia , lookup

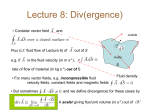

Stokes wave wikipedia , lookup

River engineering wikipedia , lookup

Countercurrent exchange wikipedia , lookup

Constructed wetland wikipedia , lookup

Particle image velocimetry wikipedia , lookup

Hydraulic machinery wikipedia , lookup

Nanofluidic circuitry wikipedia , lookup

History of fluid mechanics wikipedia , lookup

Blade element momentum theory wikipedia , lookup

Biofluid dynamics wikipedia , lookup

Flow measurement wikipedia , lookup

Lorentz force velocimetry wikipedia , lookup

Flow conditioning wikipedia , lookup

Derivation of the Navier–Stokes equations wikipedia , lookup

Bernoulli's principle wikipedia , lookup

Fluid Mechanics Lectuer:Sun Gang Introduction • 1-2 Definition of a Fluid • The solid object will no change inside the a closed container • The liquid will change its shape to conform to that of the container and will take on the same boundaries as the container up to the maximum depth of the liquid • • • Fluid mechanics:the behavior of fluids at rest and in motion A fluid is a substance that deforms continuously under the application of a shear(tangential) stress no matter how small the shear stress may be A solid deforms when a shear stress is applied does not continue to increase with the time F/A • Dye maker to outline a fluid element Introduction • The deformation of solid • Experience a Deformation • Finite(solid) • • • • Continuously increasing Shear stress is proportional To the rate of change of The deformation At the atomic and molecular level: Solid:the molecular are packed so closely together that their nuclei and electrons form a rigid geometric structure,”glued”together by powerful intermolecular forces. Liquid:the space between molecular is large,the intermolecular forces allow enough movement of the molecules to give the liquid its “fluidity” Gas:the spacing between molecular is much larger, the influence of the intermolecular forces is much weaker,and the motion of the molecules occurs rather freely throughout the gas Introduction • 1-4 Basic Equation • The ideal gas equation of state p RT • The Basic laws governing the flow motion include: • 1、The conservation of mass (1.1) • 2、Newton’s second law of motion • 3、The principle of angular momentum • 4、The first law of theromdynamics • 5、The second law of theromdynamics Introduction • 1-5 Methods of analysis • The system that you are attempting to analyze Basic mechanics : free-body diagram thermodynamics: closed system(terms: system and control volume) 1-5.1 System and Control Volume • A system is defined as a fixed, identifiable quantity of mass; the system boundaries separate the system from the surroundings(fixed or movable), no mass crosses the system boundaries. • A control volume is an arbitrary volume in space through which fluid flows. The geometric boundary of the comtrol volume is called the control surface.(include real or imaginary) 1-5.2 Differential versus Integral Approach • The basic laws can be formulated in terms of infinitesimal or finite systems and control volumes. • The first case the resulting equation are differential equation. • The integral formulations of basic laws are easier to treat analytically, for deriving the control volume equation , we need the basic laws of mechanics and thermodynamics ,formulated in terms of finite systems 1-5.3 Methods of Description • Use of the basic equations applied to a fixed , identifiable quantity of mass, keep track of identifiable elements of mass(in particle mechanics: the Lagrangian method of description) • Example: th eapplication of Newton’s second law to a particle of fixed mass • Consider a fluid to be composed of a very large number of particle whose motion must be described • With control volume analyses, the Eulerian on the properties of a flow at a given point in space as a function of time 1-6 Dimension and Unit • The physical quantities of engineering problems include units: length,time,mass, and temperature as dimension • The primary quantities(length,time,mass, and temperature as dimension )and secondary quantities (dimensions are expressible in terms of the dimension of the primary quantities) 1-6 Dimension and Unit • 1-6.1 System of Dimension • a) mass(M), length(L), time(t), temperature(T)(MLtT) • b) Force(F), length(L), time(t), temperature(T)(FLtT) • c) Force(F),mass(M) ,length(L), time(t), temperature(T) (FMLtT) 1-6.2 system of unit • a. SI, MLtT(primary) Secondary dimension unit of mass(kg) Force(N) length (meter) 1N=1kg. m/s2 time (second) s temperature (kelvin) Absolute metric system of unit 1dyne=1.g.cm/s2 • FLtT, British Gravitational system: • force(1bf); length(ft); • time(second);temperat ure(degree Rankine) • 1 slug = 1lbf.s2/ft • FMLtT (English Engineering system) • force(1bf) mass(lbm) length(foot) time (second) temperature (degree Rankine) • gc=32.2 ft.lbm/(lbf. S2) 4. State the three basic system of dimension 5. The typical units of physical quantities in the SI, British Gravitational, and English Engineering system of units FLtT: 1bf Mass: 1slug = 1lbf.s2/ft FMLtT: gc=32.2 ft.lbm/(lbf. S2) SI: 1N=1kg. m/s2 Chapter 2 Fundamental Concept Mechanics and thermodynamics 2-1 Fluid as a continuum • The average or macroscopic effects of many molecules……….continuum(classic fluid mechanics)(p, ,T,V is continuous function of position and time) • the mean free path of the molecules is same order of magnitude as the smallest significant characteristic dimension of the problem(rarefied gas flow) For determine the density at a point , In fig.2.1 point C(x,y,z)’s density is defined as mass per unit volume, the mean density within volume V would be given by = m/V, at point C m C lim V V V ' ( x, y, z, t ) (2 1) (2 2) 2-2 velocity field V V ( x, y , z , t ) Steady flow ( p, , V .....) 0 t V uiˆ vˆj wkˆ unsteady flow ( p, , V .....) 0 t • 2-2.1 one-,two-,and three-Dimensional flows 2-2.2 Timelines, Pathlines, streaklines, and Streamlines • Visual representation of a flow field: TL; PL, STKL, STML • Timeline:a number of adjacent fluid particles in the flow field are marked at given instant, they form a line in the field • Pathline: the path or trajectory traced out by moving fluid particle, the line traced out by the particle Streakline:a number of identifiable fluid particles in the flow passed through one fixed location in space , the line joining these fluid particles is defined as a streakline Streamline:are lines drawn in the flow field so that at a given instant they are tangent to the direction of flow at every point in the flow field. No flow across a streamline 2-3 Stress Field • Surface and body forces: • body force:gravitational body force gdV • Stress force (nine quantities)to specify the state of stress in a fluid • Imagine any surface within a flowing fluid, and consider the contact force applied to the fluid on one side by that on the other,surrounding point C, the surface A the unit normal vector outwardly , the force, n̂ , acting on F nay be resolved in two components, one normal to and the other tangent to the area. The A normal stress n and a shear stress n are then defined as: Fn n lim An 0 An Ft n lim A 0 A n n (2.6) (2.7) the rectangular coordinates the stress acting on the planes whose outwardly drawn normals are in the x,y, or z directions, The first subscript indicate the plane on which the stress acts. The second one indicates the direction in which the stress acts Fx A 0 A x Fy xy lim A 0 A x xx lim x x Fz xz lim A 0 A x x (2.8) The stress at a point is specified by the nine components xx yx zx xy yy zy xz yz zz stress denote the normal stress and shear 2-4 viscosity • We have defined a fluid as a substance that continues to deform under the action of a shear stress. Consider the behavior of a fluid element between the two infinite plates yx Fx dFx lim A 0 A dAy y y d deformation rate lim t 0 t dt l ut l y u d du t y dt dy 2-4.1 Newtonian fluid Fluid as water,air, and gasoline are Newtonian fluid du yx dy The different Newtonian fluid will deform at different rates under the action of the same applied shear stress; the water, glycerin exhibits a much larger resistance to deformation than water Newton’s law of viscosity is given for one-dimensional flow by yx du dy The dimension, [F/L2],du/dy are [1/t], [Ft/L2]; in the SI system, the unit of viscosity are kg/(ms) or Pas( 1Pas = 1Ns/m2)(page 26) The kinematic viscosity( / )[L2/t]is represented. Viscosity data for a number of common Newtonian fluid are given in Appendix A. Note that for gases, viscosity increases with temperature, whereas for liquids, viscosity decreases with increasing temperature. 2-4.2 Non-Newtonian fluids • Fluids in which shear stress is not directly proportional to deformation rate are nonNewtonian flow: toothpaste and Lucite paint yx du n du n 1 du du k( ) k( ) dy dy dy dy (2.11,12) 2-5 surface Tension • Surface tension is the apparent interfacial tensile stress(force per unit length of interface) that acts whenever a liquid has a density interface, such as when the liquid contacts a gas, vapor,second liquid, or solid • Contact angle between the liquid and solid is defined When the contact angle is less than 900, the liquid tends to wet the solid surface as shown in fig2.10a, and the tensile stress due to surface tension tends to pull the liquid free surface up near the solid, forming a curved meniscus. The contact angle>90, the liquid can not wet the solid; surface tension tend sto pull the liquid free surface down along the solid. The magnitude and direction of surface tension against a solid surface depend on the liquid and solid 2-6 Description and classification of fluid motions • Continuum fluid mechanics • Inviscid-(compressible and incompressible) • Viscous-laminar(internal and external) • -turbulent(internal and external) •2-6.1 Viscosity and Inviscid flow yx du dy 2-6.2 Laminar and Turbulent flows • The basis of flow structure • Smooth motion in laminae or layers • Random, three-D motions of fluid particles in addition to the mean motion 2-6.3 Compressible and Incompressible Flows • The variations in density are negligible are termed incompressible(liquid) • Density variations within a flow are not negligible, the flow is called compressible(gas) • M=V/c; M<0.3, M>0.3 2-6.4 Internal and External Flows • Flows completely bounded by solid surfaces called internal or duct flows. Flows over bodies immersed in an unbounded fluid are termed external flows. • The incompressible flow through a pipe, the nature of the flow(laminar and turbulent) is determined by the Reynolds number:the ratio between inertial force and viscous force Re V D / • Incompressible flow through pipe • Laminar flow: Re<2300 • The flow over a semi-infinite flat plate, laminar:Re<500000 Chapter 3 Fluid Static Absence of shear stresses, fluid either at rest or in “rigidbody” motion are able to sustain only normal stresses, fluid element do not deform. 3-1 The Basic equation of fluid statics • Newton’s second law to a fluid element of mass dm= dV • Body forces(gravity) and surfaces forces are applied to fluid element(no shear stress, include pressure force) d F g dm g dV g dxdydz • The body force is B • Pressure is scalar field, p=p(x,y,z),using Taylor series expansion, the pressure of left face of the element is: p p dy PL p ( yL y ) p ( ) y y 2 • The right face: p p dy ( yR y) p y y 2 p p ˆ p ˆ dFs ( iˆ j k )dxdydz x y z PL p The gradient of a scalar field gives a vector field dFs gradp(dxdydz) pdxdydz dF dFB dFs (p g )dV dF p g dV For a static fluid, (3.1) (3.2) a 0 dF ma 0 p g 0 (3.3) p p 0 0 x y dp g dz p g z (3.5) (3.6) Restriction (1) Static fluid (2) Gravity is the only body force (3) The z axis is vertical and upward 3-2 The standard atmosphere 3-3 Pressure variation in a static fluid dP g dz 3-3.1 incompressible liquid:Manometers p p0 z dp gdz z0 z h z0 p p0 g ( z0 z ) p p0 gh (3.7) Incompressible liquid:manometers • p A pB 1 gh1 pB pC 2 gh2 p A pC 2 gh2 1 gh1 3-3.2 Gases (compressible fluid) The pressure varies with altitude or temperature T T0 mz pg pg dp gdz dz dz RT R(T0 mz) mz g / mR T g / mR p p0 (1 ) p0 ( ) T0 T0 (3.8) 3-5 Hydrostatic force on submerged surfaces Determine the resultant force acting on a submerged surface we must specify: (1) The magnitude of the force (2) The direction of the force (3) The line of action of the force 3-5.1 hydrostatic force on a plane submerged surface The hydrostatic force on any element of the surface must act normal to the surface dF pdA (3.9) The resultant force acting on the surface is found by summing the contributions of the infinitesimal forces over the entire area. FR pdA (3.10) A dp g dh h p p0 gdh p0 gh h y sin 0 The point of application of the resultant force(the center of pressure) must be such that the moment of the resultant force about any axis is equal to the moment of the distributed ' force about the same axis, the position vector isdesignatedas r ' r FR r dF r pdA (3.11) ' r x 'iˆ y ' ˆj r xiˆ yˆj Substitute into Eq.(3.11) gives y ' FR ypdA A dA dAkˆ and x ' FR xpdA(3.12) A 1. The resultant force is the sum of the infinitesimal forces (3.10) 2. The moment of the resultant force about any axis is equal to the moment of the distributed force about the same axis(3.12) In evaluating the hydrostatic force acting on a plane submerged surface, the resultant force and moment is: 1. The magnitude of FR is given by FR FR pdA (3.13) 2. The direction of FR is normal to the surface 3. For a surface in the xy plane, the line of FR passes through the point x,y ( the center of pressure), where y ' FR ypdA A and x' FR xpdA A 3-5.2 Computing equation for pressure force and point of application on a plane submerged surface The pressure distribution on the lower surface is uniform ambient pressure p0 , on the upper surface is given by p p0 gh The magnitude of the resultant force on the upper surface is FR pdA p0 A g sin ydA A A The yc is the y coordinate of the centroid of the area A thus FR p0 A g sin yc A ( p0 ghc ) A pC A (3.14) To find the expressions for coordinates of the center of pressure , the moment of the resultant force about any axis must be equal to the moment of the distributed force about the same axis yFR ypdA A yg sin yc A yghdA g sin y 2 dA A I xx y dA 2 A I xˆxˆ I xˆxˆ y yc Ayc A (3.15a) Is the second moment of the area about the centroid x̂ axis The same ruler: x xc I xˆyˆ Ayc (3.15b) 3-5.3 Hydrostatic force on a curved submerged surface dF pdA (3.9) FR pdA (3.10) A ˆ FR iˆFRx ˆjFRy kFRz (3.16) FRx FR iˆ dF iˆ pdA iˆ pdAx A Ax In general in the l direction the component of resultant force is: FRl pdAl Al With the free surface at atmospheric pressure, the vertical component of the resultant hydrostatic force on a curved submerged surface is equal to the total weight of the liquid directly above the surface. FRZ FV pdAZ p gh FV ghdAZ gdV gV Basic equation in integral form for a control volume 4-1 Basic laws for a system 4-1.1 Conservation of mass dM system 0 dt (4.1a ) M system dm M system M system dV (4.1b) 4-1.2 Newton’s second law ( Conservation of momentum ) dP F dt system Psystem Vdm M system M system (4.2a) VdV (4.2b) 4-1.3 The angular Momentum principle dH T dt system H system r Vdm r VdV M system H system T r Fs r gdm Tshaft (4.3a) (4.3b) (4.3a) M system 4-1.4 The first of thermodynamics Q W dE dE Q W dt system Esystem edm M system V2 eu gz 2 Vsystem (4.4a) edV (4.4c) (4.4b) 4-1.5 The second Law of Thermodynamics dS Q T dS 1 Q dt system T (4.5a) S system sdm M system Vsystem sdV (4.5b) 4-2 Relation of system derivatives to the control volume formulation M 1 P V N system H r V dv V system E e S s The control volume is fixed in space relative to coordinate system xyz,during t+dt-t time the system has been chosen so that the mass within region I enters the control volume during interval dt, and the mass in region III leaves the control volume during the same interval. ( N cv N I N III )t0 t N cv t0 dN lim dt system t 0 t (4.8) N cv )t0 t N cv t0 dN lim lim t 0 dt system t 0 t N III )t0 t t lim t 0 N I )t0 t t The surface of control volume include: surface of the flow enter the control volume and the surface of the flow leaves the control volume and he surface no flow pass it dN dV (l cos dA) l lim V t 0 t (4.9) dN N cs V dA cos dt s t s dN CV dV cs V dA dt s t (4.11) 4-3 Conservation of mass:(N=m; 1 ) dN CV dV cs V dA dt s t dM CV dV cs V dA dt s t (4.11) (4.12) conservation dV V dA 0 cs t CV (4.13) 4-3.1 special cases incompressible, nondeformable control volume of fixed size and shape V dA 0 cs The integral of V dA over a section of the control surface is commonly called the volume flow rate or volume rate of flow. For incompressible flow , the volume flow rate into a fixed control volume must be equal to the volume flow rate out of the control volume AV dA Q V dA 0 cs V Q A (4.16) At a section, uniform flow, density is constant An V dA nVn An 4-4 momentum equation for inertial control volume N P dN CV dV cs V dA dt s t dP VdV VV dA cs dt s t CV V (4.11) (4.17) Newton’s second law for a system moving relative to an inertial coordinate system dP F FS FB dt s The sum of all forces (surface and body) acting on a nonaccelerating control volume is equal to the sum of the rate of change of momentum inside the control volume and the net rate of flux of momentum out through the control surface We denote the body force per unit mass as B FB Bdv CV FS pdA A Fx FS x FBx udV uV dA cs t CV Fy FS y FB y vdV vV dA cs t CV Fz FS z FBz wdV wV dA cs t CV 4-4.1 Differential Control volume analysis Application of the basic equations to a differential control volume leads to differential equations describing the relationships among properties in the flow field (property variations) For the case Steady, incompressible, frictionless flow along a streamline, integration of one such differential equation leads to a useful relationship among speed, pressure, and elevation in a flow field, The control volume is bounded by streamlines, flow across the bounding surfaces occurs only at the end section, p, ,Vs , A a. Continuity equation p dp, ,Vs dVs , A dA Assumption: Steady,no flow across bounding streamlines, incompressible flow Basic equation: dV V dA 0 cs t CV (4.13) | Vs A | | (Vs dVs )( A dA) | 0 Vs dA AdVs dAdVs 0 Vs dA AdVs 0 b. Streamwise component of the momentum equation Assumption: No friction, pressure forces only Basic equation: FS s FBs cs VV dA us V dA cs dp FS s pA ( p dp)( A dA) ( p )dA 2 Where Fsb is the pressure force acting in the s direction on the bounding stream surface of the control volume dp FS s dpA dA 2 FBs g s dV ( g sin )( A dA / 2)ds where dz sin ds FBs g ( A dA / 2)dz The momentum flux will be CS us VdA Vs ( | Vs A |) (Vs dVs )( | (Vs dVs )( A dA) |) Vs AdVs Where : continuity | Vs A | | (Vs dVs )( A dA) | 0 1 1 Adp dpdA gAdz gdAdz Vs AdVs 2 2 dpdA and dAdz are negligible compared with the remaining term Vs d ( ) gdz 0 2 dp (4 24) For incompressible flow p V2 gz C 2 (4.25) For an infinitesimal stream tube control volume, steady, incompressible flow without friction. We can get formation(4.25) , the Bernoulli equation 4-4.2 Control volume moving with constant velocity The previous equation based on the stationary control volume. A control volume (fixed relative to reference frame xyz) moving with constant velocity reference frame XYZ, is also inertial , since it has no acceleration with respect to XYZ dN CV dV cs Vxyz dA dt s t (4.26) F FB FS Vxyz dV Vxyz Vxyz dA cs t CV (4.27) 4-5 Momentum equation for control volume with rectilinear acceleration For an inertial control volume (having no acceleration relative to a stationary frame of reference xyz) F FB FS Vxyz dV Vxyz Vxyz dA (4.27) cs t CV dP F dt system Psystem Vdm M system Vsystem (4.2a) VdV (4.2b) If we denote the inertial reference frame by XYZ,for accelerating control volume (4.27) is not right dPXYZ F dt d dVXYZ dt M system VXYZ dm M system dt dm The velocity with respect to the inertial (XYZ) and the control volume coordinate(xyz) are related by the relative-motion Eq. VXYZ Vxyz Vrf (4.30) Where V is the velocity of the control volume reference frame. dVxyz dVrf dVXYZ XYZ xyz rf (4.31) dt dt dt dPxyz F )s (4.32) rf dm M system dt Linear momentum of the system, to derive the control volume formulation of Newton’s second law dP dt t s CV VdV VV dA cs (4.17) F rf dV FB FS rf dV CV CV Vxyz dV Vxyz Vxyz dA cs t CV (4.34) FS x FBx wxyz Vxyz dA udV uV dA CS cs t CV FS y FB y v xyz Vxyz dA vdV vV dA CS cs t CV FS z FBz u xyz Vxyz dA wdV wV dA CS cs t CV (4.35) 4-8 The first law of thermodynamics dE Q W dt system Esystem edm M system V2 eu gz 2 Vsystem (4.4a) edV (4.4b) (4.4c) M 1 P V N system H r V dv V system E e S s dE CV edV cs eV dA dt s t (4.54) Since the system and the control volume coincide at t0 [Q W ]system [Q W ]controlvolume Q W edV eV dA cs t CV (4.55) 4-8.1 rate of work done by a control volume W W s Wnormal W shear Wother 1:Shaft work 2. Normal stresses at the control surface w F ds W lim lim F V t 0 t t 0 dt Wnormal nnV dA cs 3. shear stresses at the control surface dF dA W shear VdA cs Can be expressed as three terms(shaft; solid ports surface) 4 other work W Ws cs nnV dA Wshear Wother (4.56) 4-8.2 control volume equation Q W s W shear Wother edV eV dA nnVdA cs cs t CV nn p Q W s W shear Wother V2 edV (u pv gz ) V dA CV cs t 2 4-9 the second law of thermodyhamics dS 1 Q dt system T Ssystem sdm M system M system sdV (4.5a) (4.5b) M 1 P V N system H r V dv V system E e S s dS CV sdV cs sV dA dt s t 1 Q sdV sV dA dA cs cs T t CV A (4.58) (4.59) Introduction to differential analysis of fluid motion The chapter 4 describe the basic equation in integral form for control volume. This chapter present the differential equations in terms of infinitesimal systems and control volume 5-1 Conservation of mass 5-1.1 rectangular coordinate system the control volume chosen is an infinitesimal cube with sides of length dx,dy,dz as shown in Fig5.1. The parameter of flow, density,velocity,pressure etc. is defined at center O point V iˆu ˆjv kˆw To evaluate the properties at each of the six faces of the control surface, we use a Taylor series expansion about point O, at right If we define: x dx / 2 x 2 1 dx 2 2 ( ) x 2 x 2! 2 Neglecting higher order term x dx / 2 x x 2 At the left face u x dx / 2 u x dx / 2 x x 2 u x x 2 u x dx / 2 u x u x 2 Statement of conservation of mass is Net rate of mass flux out Rate of change of mass through the control surface inside the control volume 0 The first term in Eq. We must consider the mass through each flux of the six surfaces of the control surface: cs V dA The net rate of mass flux out through the control surface is given by u v w x y z dxdydz The mass inside the control volume at any instant is the product of the mass per unit volume and the volume, dxdydz. The rate of Change of mass inside the control volume is given by dxdydz t u v w 0 x y z t (5.1a) ˆ ˆ ˆ i j k x y z V 0 t (5.1b) 5-1.2 Cylindrical Coordinate System A suitable differential control volume for cylindrical coordinate is in Fig.5.2, also define desity, velocity, at the control volume center O V eˆrVr eˆV kˆVz cs V dA The mass flux through each of the six faces of control surface, from the Taylor series expansion about point O. The net rate of mass flux out through the control surface is given by Vr V Vz Vr r r r z drddz The mass inside the control volume at any instant is the product of the mass per unit volume and the volume rddrdz The rate of change of mass inside the control volume is given by rddrdz t 1 (rVr ) 1 V Vz 0 r r r z t eˆr (5.2) 1 ˆ ˆ e k r r z V 0 t 5-2 Stream function for 2-D incompressible flow Relation between the streamlines and the statement of conservation of mass, for 2-D incompressible flow in the xy plane u v 0 x y If a continuous function , ( x, y, t ) , called the stream function, is defined such that u y and v x (5.4) The streamline ,at given instant, it tangent to the direction of flow at every point in the flow field, V dr 0 (iˆu ˆjv) (iˆdx ˆjdy ) kˆ(udy vdx) udy vdx dx dy d 0 x y Where the time is defined at t0, the volume flow rate, Q, between streamlines and can be evaluated by consider the flow across AB or across BC. For a unit depth, the flow rate across AB Is: y2 y2 y1 y1 Q udy dy y d dy y y2 Q d 2 1 y1 Along BC, d / xdx it is same as the side AB For a 2-D, imcompressible flow in the cylindrical coordinate, conservation of mass, (rVr ) V 0 r streamfunction 1 Vr V r r 5-3 Motion of a fluid element(kinematics) 5-3.1Fluid translation:Acceleration of a fluid particle in a velocity field V p |t V p ( x, y, z , t ) and a p Vp V p ( x dx, y dy, z dz , t dt ) t t V V V V dV p dx p dy p dz p dt x y z t V V V V ap dx p / dt dy p / dt dz p / dt x y z t V V V V u v w x y z t DV V V V V ap u v w Dt x y z t It include: total acceleration of a particle, convective acceleration, and local acceleration V V V (V )V u v w x y z DV V a p (V )V Dt t (5.10) 5-3.2 Fluid Rotation A fluid particle moving may rotate about the axes, iˆx ˆj y kˆz The oa and ob rotate to the position shown during the interval dt v va vo x x / x oa lim lim t 0 t t 0 t v xt x v oa x Similar, the angular velocity of line ob u ob y The rotation of the fluid element about z axis is the average angular velocity of the two mutually perpendicular line elements 1 v u z ( ) 2 x y 1 w v x ( ) 2 y z 1 u w y ( ) 2 z x 1 ˆ w v u w v u [i ( ) ˆj ( ) kˆ( )] 2 y z z x x y 1 V 2 (5.13) (5.14) to be twice the rotation The vorticity is defined as 2 V (5.15) In cylindrical coordinates the vorticity is 1 Vz V Vr Vz 1 rV 1 Vr ˆ ˆ ˆ V er ( ) e ( ) k( ) r z z r r r r (5.16) The circulation is defined as the line integral of the tangential velocity component about a closed curve fixed in the flow V ds C (5.17) For closed curve oacb ux (v v u x)y (u y )x vy x x v u ( )xy 2 z xy x x V ds 2 z dA ( V ) z dA c A A 5-3.3 fluid Deformation a. Angular deformation:The angular changes between two mutually perpendicular line segments in the fluid. Fig.5.9 in the xy plane the rate of decrease of angle between lines oa and ob 900 ( ) d d d dt dt dt d / x v / x)xt / x v lim lim ( ) t 0 t 0 dt t t x d u dt y d v u The rate of angular deformation in the xy plane is dt x y b. Linear deformation The element change length in the x direction only if du/dx=0, dv/dy, dw/dz, changes in the length of the sides may produce changes in volume of the element. Volume dilation rate = u v w V x y z For incompressible flow, the rate of volume dilation is zero 5-4 momentum equation dP F dt system Psystem Vdm M system M system (4.2a) VdV (4.2b) dV DV V V V V dF dm dm dm( u v w )(5.22) dt system Dt t x y z 5-4.1 forces acting on a fluid particle xx dx dx )dydz ( xx xx )dydz x 2 x 2 yx dy yx dy ( yx )dxdz ( yx )dxdz x 2 x 2 dz dz ( zx zx )dxdy ( zx zx )dxdy x 2 x 2 xx yx zx ( )dxdydz x x x dFs x ( xx xx yx zx dFx dFBx dFS x ( g x )dxdydz x x x yy xy zy dFy dFBy dFS y ( g y )dxdydz x x x xz yz zz dFz dFBz dFS z ( g z )dxdydz x x x 5-4.2 differential momentum equation (5.23a) (5.23b) (5.23c) xx yx zx u u u u g x ( u v w ) (5.24a) x x x t x y z xy yy zy v v v v g y ( u v w ) (5.24b) y y y t x y z xz yz zz w w w w g z ( u v w ) (5.24c) y y y t x y z 5-4.3 Newtonian fluid :N-S equation For a Newtonian fluid the viscous stress is proportional to the rate of shearing strain(angular deformation rate). The stresses may be expressed in terms of velocity gradients and fluid properties in rectangular coordinates as follow: v u xy yx ( ) x y w v yz zy ( ) y z u w zx xz ( ) z x 2 u xx p V 2 3 x 2 v yy p V 2 3 y 2 w zz p V 2 3 z (5.25a ) (5.25b) (5.25c) (5.25d ) (5.25e) (5.25 f ) If the expression for the stresses are introduced into the differential equations of motion(eqs 5.24) we obtain Du p u 2 u v g x [ (2 V )] [ ( )] Dt x x x 3 y y x w u [ ( )] z x z Dv p v 2 u v g y [ (2 V )] [ ( )] Dt y y y 3 x y x v w [ ( )] z z y Dw p w 2 v w g z [ (2 V )] [ ( )] Dt z z z 3 y z y w u [ ( )] x x z Chapter 6 Incompressible inviscid flow Many flow cases is reasonable to neglect the effect of viscosity , no shear stresses are present in inviscid flow, normal stress are considered as the negative of the thermodynamic pressure -p 6-1 momentum equation for frictionless flow: Euler’s equations p u u u u g x ( u v w ) (6.1a) x t x y z p v v v v g y ( u v w ) (6.1b) y t x y z p w w w w g z ( u v w ) (6.1c) y t x y z V V V V g p ( u v w ) t x y z V g p ( (V )V ) (6.2) t DV g p (6.3) Dt p Vr Vr Vr Vr V g r ( Vr V Vz ) (6.4a) r t r z r V V V VrV 1 p 1 V g ( Vr V Vz ) (6.4b) r t r r z r p Vz Vz 1 Vz Vz g z ( Vr V Vz ) (6.4c) z t r r z 2 6-2 Euler’s equation in streamline coordinates The motion of a fluid particle in a steady flow, “streamline coordinates” also may be used to describe unsteady flow streamline in unsteady flow give a graphical representation of the instantaneous velocity field. p ds p ds (p )dndx ( p )dndx g sin dsdndx as dsdndx s 2 s 2 p g sin as s p z g as s s as DV V V V Dt t s p z V V g V s s t s p V V s s (6.5a) (6.5b) p dn p dn (p )dsdx ( p )dsdx g cos dsdndx an dsdndx n 2 n 2 p g cos an n p z g an n n V2 an R p z V 2 g n n R p V 2 n R (6.6a) (6.6b) 6-3 Bernoulli equation-integration of Euler’s equation along a streamline for steady flow For incompressible inviscid flow 6-3.1 Derivation using streamline coordinates Along streamline: 1 p z V g V s s s dp gdz VdV dp V 2 2 gz C c p V2 gz C 2 (6.8) (6.9) 6-3.3 Static, Stagnation, and Dynamic Pressure The static pressure is that pressure which would be measured by an instrument moving with flow. The stagnation pressure is obtained when a flowing fluid is decelerated to zero speed by a frictionless process. Neglecting elevation difference, p V2 C 2 p0 p The dynamic pressure 1 V 2 2 V 2 2 V 2( p 0 p ) Q Q dm Q Q m dt dm dt dm Incompressible v1 v2 1 / V12 p2 V22 Q gz1 gz2 (u2 u1 ) 2 2 dm p1 (6.15) 6-5 unsteady Bernoulli equation-integration of Euler’s equation along a streamline p DV DV ˆ gk ds Dt Dt (6.3) DV DV p V V ˆ ds gk ds ds ds V ds ds Dt Dt s t p ds dp (the change in pressure along kˆ ds dz (the change in z along s ) V ds dV (the change in V s V gdz VdV ds t dp along (6.19) s) (6.18) s) 2 V dp V22 V12 g ( z2 z1 ) ds 0 1 2 t (6.20) 2 V V12 p2 V22 gz1 gz2 ds 1 2 2 t (6.21) 2 1 p1 Restrictions (1) incompressible (2) Frictionless flow (3) Flow along a streamline 6-6 irrotational flow The fluid element moving in the flow field without any rotation 1 V 0 2 w v u w v u 0 (6.22) y z z x x y 1 Vz V Vr Vz 1 rV 1 Vr 0 r z z r r r r 6-6.1 Bernoulli equation applied to irrotational flow p1 2 V1 gz1 C 2 (6.23) p gkˆ (V )V (6.10) 1 (V )V (V V ) V ( V ) 2 1 p 1 gkˆ (V V ) (V 2 ) 2 2 1 p 2 ˆ dr gk dr (V ) dr 2 dp 1 gdz dV 2 2 p V2 gz C 2 (6.24) (6.25) Since the dr was an arbitrary displacement Eq.6.25 is valid between any two points in a steady, incompressible, inviscid flow that is also irrotational. 6-6.2 Velocity potential We formulated the stream function which relates the streamlines and mass flow rate in 2-D , incompressible flow. we can formulate a relation called the potential function for a velocity field that is irrotational. curl(grad ) = = 0 V (6.26) (6.27) u v w (6.28) x y z 1 ˆ ˆ ˆ er e ez (3.21) r r z 1 Vr V Vz (6.29) r r z The velocity potential exists only for irrotational flow. The stream function satisfies the continuity equation for incompressible flow; the stream function is not subject to the restiction of irrotational flow. 6-6.3 stream function and velosity potential for 2-D , irrotational , incompressible flow: Laplace’s equation u v (5.4) y x u v (6.28) v u 0 (6.22) x y x y Irrotational flow 2 2 2 0 (6.30 2 x y continuity equation u v 0 (5.3) x y 2 2 2 0 2 x y (6.31) Along streamline c Along a line of constant , d = 0 We see that the slope of a constant streamline at any point is the negative reciprocal of the slope of constant velocity potential line at that point; lines of constant stream and constant velocity potential are orthogonal 6-6.4 Elementary Plane Flow A variety of potential flows can be constructed by superposing elementary flow patterns, five elementary 2-D flows-----a uniform flow, a source, a sink, a vortex, and a doublet----are summaried in Tablet 6.1 6-6.5 superposition of elementary plane flows Both stream function and velocity potential satisfy Laplace’s equationfor flow that is both incompressible and irrotational . Sincer Laplace’s equation is a linear, homogeneous partial differential equation , solution may be superposed to develop more complex and interesting patterns of flow Chapter 7 Dimensional Analysis And Similitude The real physical flow situation is approximated with a mathematical model that is simple enough to yield a solution, then experimental measurements are made to check the analytical results. Experimental measurement is very time-consuming and expensive. When experimental testing of a full-size prototype is either impossible or prohibitively expensive. The model flow and the prototype flow must be related by known scaling laws. 7-1 Nature of dimensional analysis The physical parameters can write the symbolic equation: F f ( D, V , , ) We need do many experiments for determining the parameter (diameter, velocity,density,fluid viscosity), through the use of dimensional analysis, we can get very useful formulation ( example 7.1) F VD f1 ( ) 2 V D The Buckingham Pi Theorem is a statement of the relation between a function expressed in terms of dimensional parameters and a related function expressed in terms of nondimensional parameter 7-2 Buckingham Pi Theorem The dependent parameter is a function of n-1 independent parameters, we may express the relationship among the variables in functional form as q1 f (q1 , q2 ,..., qn ) g (q1 , q2 , q2 ,..., qn ) 0 F f ( D, V , , ) g ( F , D, V , , ) 0 The n parameters may be grouped into n-m independent dimensionless ratios, or II parameters, expressible functional form by G (1 , 2 ,...., n m ) 0 or 1 G1 ( 2 , 3 ,...., n m ) The number m is usually equal to the minimum number of independent dimensions required to specify the dimensions of all the parameters 21 13 / 4 5 or 6 2 2 3 3 7-3 Determining the II groups The six steps listed below outline a recommended procedure for determining the II parameters Step1. List all the dimensional parameters involved Step 2. Selected a set of fundamental dimensions MLt .. Step 3. List the dimensions of all parameters in terms of primary dimensions Step 4. Select a set of r dimensional parameters that include all the primary dimensions Step 5. Set up dimensional equations, combining the parameters selected in step 4 with each of the Other parameters in turn , to form dimensionless group Step 6. Check to see that each group obtained is dimensionless 7-4 Significant Dimensionless groups in fluid mechanics In flow field, we use physical force such as interia, viscous, pressure, gravity, surface tension, and compressibility Viscous force Pressure force Gravity force du V 2 A A L VL dy L (p) A (p) L2 mg gL3 Surface tension force L V D V D VL VL Re Re Re No. Pressure coefficient: p Cp 1 V 2 2 Cavitation phenomena, the pressure express as cavitation number: p pv 1 V 2 2 Froude number was significant for flows with free surface effects which may be interpreted as the ratio of inertia force to gravity forces. V Fr gL V 2 V 2 L Fr gL gL3 2 The Weber number is the ratio of inertia forces to surface tension forces V 2 L We Compressibility effects M V V V c dp Ev d M2 V 2 L2 Ev L2 As a ratio of inertia forces to forces due to compressibility 7-5 Flow similarity and model studies Geometric similarity..model and prototype have same shape and both flow are kinematically similar Kinematically similar: velocities at corresponding points are in the same direction and are related in magnitude by a constant scale factor, the streamline patterns related by a constant scale factor Kinematic similarity requires that the regimes of flow be the same for model and prototype. VD VD mod el prototype Re mod el Re prototype Then the dependent parameter is duplicated between model and prototype F F 2 2 2 2 V D mod el V D prototype And the result determined from the model study can be used to predict the drag on the full-scale prototype. As long as the Reynolds numbers are matched. The actual force on the object due to the fluid have the value of its dimensionless group. Effects are absent from the model test. F VD Re mod el Re prototype f ( ) 1 2 2 V D The prototype condition Vp = 8.44 ft/s Re p Vp Dp p Dynamically similar Vm Re m 4.99 105 Re m m Dm Vm Dm m 4.99 105 157 ft / s F F 2 2 2 2 V D mod el V D prototype p V p2 D p2 Fp Fm 53.9lbf 2 2 m Vm Dm 7-6 Nondimensionalizing the basic differential equation Use the Buckingham Pi theorem , a more rigorous and broader approach to determine the conditions under which two flows are similar is to use the governing differential equations and boundary conditions. Two physical phenomena are governed by differential equations and boundary conditions that have the same dimensionless forms. Dynamic similarity is guaranteed by duplicating the dimensionless coefficients of the equations and boundary conditions between prototype and model. Nondimensionalizing the basic differential equation, steady incompressible 2-D flow in the xy plane u v 0 x y (7.7) 2u 2u u u p u v 2 2 y x y x x (7.8) 2v 2v v v p u v g 2 2 y y y x x (7.9) The pressure nondimensional by dividing by V2 x x L * y y L * u u V * v v V * p p V2 * V u * V v* 0 * * L x L y V2 * V2 * (7.11) * u * V2 p * V * u u v 2 * * * L x y L x L 2u * 2u * (7.12) 2 2 * x* y * v* V2 p* V * v u v g 2 * * * L x y L y L u * v* * 0 * x y 2 v* 2v* (7.13) 2 2 x* y * (7.14) * * u * p * 2u * 2u * * u u * v (7.15) 2 2 * * * * y x V L x y x * * v* gL p * 2 v* 2 v* * v u 2 * v (7.16) 2 2 * * * * y V y V L x y x The differential equations for two flow system will be 2 identical if the quantities / V L and gL / V Are the same for both flows. Thus , model studies to determine the drag force on a surface ship require duplication of both the Froude number and the Reynolds number to ensure dynamically similar flows. Emphasize that in addition to identical nondimensional equation, the nondimensional boundary conditions also must be identical if the two flow are to be kinematically similar . The periodicbc flowdefine the velocity on the u V sin t boundary: Nondimensionalize time: t* t V L V V ubc bc sin t * * u L Duplication of the boundary condition requires that parameter L / V be the same between the two flows. This parameter is the Strouhal number St L V Chapter 8 Internal incompressible viscous flow Flow completely bounded by solid surfaces are called internal flows: pipes, nozzles, diffusers, sudden contractions and expansions, valves, and fittings. Laminar and turbulent flow, some laminar flow may be solved analytically, the case of turbulent flow we must rely heavily on semi-empirical theories and on experimental data. The flow regime is primarily a function of the Reynolds number. 8-1 introduction The pipe flow regime(laminar or turbulent) is determined by the Reynolds number, the qualitative For laminar flow, the entrance length,L, is the function of Reynolds number, L V D 0.06 D Part A Fully Developed Laminar Flow 8-2 Fully developed laminar flow between infinite parallel plates 8-2.1 Both plates stationary Boundary at y=0 u=0; y=a u=0. u=u(y)(v=w=0) For analysis we select a differential control volume of size dV=dxdydz and apply the x component of the momentum equation Assumption (1) steady flow (2) fully developed flow (3) FBx = 0 Basic equation FS x cs uV dA (4.19a) For fully developed flow, the net momentum flux through the control surface is zero. FSx = 0 The next step is to sum the forces acting on the control volume in the x direction. We recognize that the normal forces(pressure forces) act on the left and right aces and tangential forces(shear forces) act on the top and bottom faces faces. dFL dFR dFB dFT p dx (p )dydz x 2 p dx ( p )dydz x 2 d yx dy ( yx )dxdz dy 2 d yx dy ( yx )dxdz dy 2 p d yx 0 (8.3) x dy d yx p p C yx y c1 dy x x du du p yx y c1 dy dy x 1 p 2 c1 u y c2 2 x According to boundary condition 2 a 2 p y y u ( ) 2 x a a (8.4) (8.5) Shear stress distribution yx p y 1 a( ) x a 2 Volume flow rate (8.6a) a 1 p Q V dA ( y 2 ay )dy A 0 2 x Q 1 p 3 (8.6b) a l 12 x Flow rate as function of pressure drop p p2 p1 p x L L Q a 3p (8.6c) L 12L Average velocity Q 1 p a 3l 1 p 2 V a A 12 x la 12 x (8.6d ) Point of maximum velocity du a 2 p 2 y 1 ( ) dy 2 x a a du 1 p 2 3 0 y a / 2 umax ( )a V dy 8 x 2 Transformation of Coordinates Transform from y=0 at bottom to y=0 at centerline (8.6e) 2 a p y 1 u ( ) 2 x a 4 2 (8.7) 8-2.2 Upper plate moving with constant speed, U The boundary condition u=0 at y=0; u=U at y=a (8-4) is equally valid for the moving plate case , velocity distribution is given by 1 p 2 c1 u y c2 2 x From BC. We have (8.4) y0 u 0 c2 0 ya u U 1 p 2 c1 U 1 p U a a a c1 2 x a 2 x Uy a 2 p y 2 y u (8.8) ( ) ( ) a 2 x a a Shear stress distribution yx U p y 1 a( ) a x a 2 Volume flow rate (8.9a) a Q V dA uldy A 0 a Uy Q 1 p 2 [ ( y ay )dy 0 l a 2 x Q Ua 1 p 3 a l 2 12 x (8.9b) Average Velocity Q Ua 1 p a 3l U 1 p V l[ ] / la a(8.9c) A 2 12 x la 2 12 x Point of Maximum velocity du U a 2 p 2 y 1 ( ) 2 dy a 2 x a a du a U /a 0 y dy 2 (1 / )(p / x) 8-3 Fully developed laminar flow in a pipe For a fully developed steady flow, the x component of momentum equation applied to the differential control volume, reduce to FS x 0 On the control volume in the x direction. Normal forces (pressure surface) acting on the left and right ends of the control volume, and that tangential forces(shear forces) act on the inner and outer cylindrical surfaces as well Pressure force on dFL p 2rdr the left Pressure force on the right Shear force on the inner cylindrical On the outer cylindrical p dFR ( p dx)2rdr x dFl rx 2rdx d rx dFO ( rx dr )2 (r dr )dx dr p rx d rx 1 d (r rx ) (8.10) x r dr r dr 1 d rx p r 2 p C r rx c1 r dr x 2 x du du r p c1 rx dr dr 2 x r r 2 p c1 u ln r c2 4 x (8.11) Boundary condition u=0 r=R, and the physical considerations that the velocity must be finite at r=0, the only way that this can be true is for c1 to be zero r 2 p R 2 p u c2 c2 4 x 4 x velocity 2 R 2 p r u 1 4 x R (8.12) r p yx ( ) (8.13a) Shear stress distribution 2 x R 1 p 2 2 Q V d A ( r R )2rdr Volume flow A 0 4 x rate R 4 p Q (8.13b) 8 x Flow rate as a function pf pressure drop p p2 p1 p x L L pD 4 Q (8.13c) 128L The average velocity Q R 2 p V 2 R 8 x The maximum velocity is on the point (8.13d ) du r p ( ) dr 2 x du R 2 p 2 0 r 0 umax U ( )a 2V dr 4 x (8.13e) The velocity profile(8.12) can be written in terms of the maximum velocity as u r 1 ( )2 U R (8.14) Part B Flow in Pipes and Ducts This section is to evaluate the pressure changes from the flow velocity and from friction. To develop relations for major losses due to friction in constant-area ducts, 8-4 Shear stress distribution in fully developed pipe flow In fully developed steady flow in a horizontal pipe, be it laminar or turbulent, the pressure drop is balanced only by shear forces at the pipe wall. Assumption: Horizontal pipe, FBx 0 Steady flow, incompressible flow, Fully developed flow The x component of the momentum equation: Fx FS x FBx udV uV dA cs t CV The shear stress on the fluid varies linearly across the pipe, from zero at the centerline to a maximum at the pipe wall, at the surface of the pipe w [ rx ]r R R p 2 x (8.16) To relate the shear stress field to the mean velocity field, we could determine analytically the pressure drop over a length of pipe for fully developed flow for laminar flow. In turbulent flow, no simple relation exists between the shear stress field and the mean velocity field. For fully developed turbulent pipe flow, the total shear stress is: du lam turb uv dy (8.17) The profile fits the data close to the centerline, it fails to give zero slope there. It give adequate results in many calculation. For Re>2x104 : n=-1.7+1.8logReU V Q/ A and Q V dA A (8.23) The ratio of the average velocity to the centerline velocity V 2n 2 U (n 1)(2n 1) (8.24) 8-6 Energy considerations in pipe flow By applying the momentum equation for a control volume with the formulation of conservation of mass, we have derived all the results. About conservation of energy-the first law of the thermodynamics, we can get insight into the nature of the pressure losses in internal viscous flows can be obtained from energy equation Q W s W shear Wother edV (e pv) V dA(4.57) cs t CV V2 eu gz 2 5-6.1 kinetic Energy Coefficient Use as the Kinetic energy coefficient A V2 V dA 2 A A V2 V2 2 V dA m V dA 2 m V 2 (8.26b) For laminar flow in a pipe, = 2.0 V2 2 (8.26a) In turbulent pipe flow, the velocity profile is quite flat(fig.8.11), substitute the power-law velocity profile into(8.26b) 3 2n 2 U (8.27) V (3 n)(3 2n) 8-6.2 head loss Using the definition of , the energy equation can be written 2 2 V V Q m (u2 u1 ) m ( ) m g ( z2 z1 ) m ( 2 2 1 1 ) 2 2 p2 p1 p1 1V1 2 p2 2V22 Q ( gz1 ) ( gz2 ) (u2 u1 ) (8.28) 2 2 dm 2 V p ( gz ) 2 Q (u 2 u1 ) dm The mechanical energy per unit mass at a cross section The difference in mechanical energy per unit mass between section(1) and (2), it represents the conversion of mechanical energy at section (1) to unwanted thermal energy(u2-u1)and the loss of energy via heat transfer. We identify this group of terms as the total energy loss per unit mass and designate it by the symbol hl p1 1V1 p2 V ( gz1 ) ( gz2 ) hl (8.29) 2 2 2 2 2 2 For incompressible, frictionless flow, there is no conversion of mechanical energy ( p V gz ) to 2 internal energy 2 For viscous flow in a pipe, one effect of friction may be to increase the internal energy of the flow Eq.(8.28) As the empirical science of hydraulics developed, it was common practice to express the energy balance in terms of energy per unit weight of flowing liquid rather than energy per unit mass hl p1 1V1 2 p2 2V22 ( z1 ) ( z2 ) H l (8.30) g 2 g g 2 g g Equation(8.29) and (8.30) can be used to calculate the pressure difference between any two points in a piping system, provided the head loss. hl (or H l ) 8-7 Calculation of head loss hl total head loss is regarded as the sum of major loss, hl , due to frictional effects in fully developed flow in constant-area tubes, and minor losses hlm due to entrances , fittings, area changes, and so on 8-7.1 Major losses: friction factor V 2 For fully developed flow hl = 0 and C 2 m Eq.(8.29) becomes p1 p2 If the pipe is horizontal g ( z2 z1 ) hl (8.31) p1 p2 p hl (8.32) Since head loss represents the energy converted by frictional effects from mechanical to thermal energy , head loss for fully developed flow in a constant-area duct depends only on the details of the flow through the duct. Head loss is independent of pipe orientation. a. Laminar flow pD 4 Q 128L (8.13c) 128QL 128LV (D 2 / 4) L V p 32 4 4 D D D D L V 64 L V 2 hl 32 (8.33) D D Re D 2 b. Turbulent flow The pressure drop can not be evaluate, we get it from the experimental results and use dimensional analysis. The pressure drop in fully developed turbulent flow due to friction is depended on pipe diameter, D, pipe length, L, pipe roughness, e, average flow velocity, V, fluid density, and fluid viscosity p1 p2 p hl (8.32) hl L e (Re, , ) 2 V D D V2 L Hl f (8.35) 2g D The friction factor is determined experimentally(Fig 8.13) To determine head loss for fully developed flow with known conditions, the Reynolds number is evaluated first, Roughness, e, is obtained from Table8.1 the friction factor f is read from the appropriate curve in Fig8.13,at the known values of Re and e/D. For laminar flow, the friction factor from (8.33) and (8.34) 2 LV2 64 L V hl f D 2 Re D 2 64 f la min ar (8.36) Re e/D>0.001 Re>Re(transition), the friction factor is greater than the smooth pipe value. In general, the Re number is increased, the friction factor decreases as long as the flow remain laminar. At transition f increases sharply. In the turbulent flow regime, the friction factor decreases gradually and finally levels out at a constant value for large Reynolds number . The Colebrook formula for friction factor 1 e/ D 2.51 2.0 log( ) 0.5 0.5 f 3.7 Re f e / D 5.74 2 f 0 0.25[log( 0.9 )] 3.7 Re (8.37a) (8.37b) For turbulent flow in smooth pipes, the Blasius correlation 0.316 f 0.25 Re (8.38) The wall shear stress is obtained as w 0.0332 V ( 2 ) 0.25 (8.39) RV 8-7.2 Minor losses(K:loss coefficient from experiments) Le V 2 V2 hlm K (8.40a) hlm f (8.40b) 2 D 2 Where Le is an equivalent length of straight pipe. a. Inlets and Exits b.Enlargements and Contraction Fig 8.15 gives the results for sudden expansion and constraction Losses in diffusers depend on a number of geometric and flow variables. Diffuser data are in terms of a pressure recovery coefficient defined as the static pressure rise to inlet dynamic pressure p2 p1 Cp (8.41) 1 V1 2 2 If the gravity is neglected and 1 2 1 p1 V1 2 p2 V22 ( ) ( ) hl hlm 2 2 A1V1 A2V2 V1 2 hlm 2 A1 2 (1 ( ) C p A2 V1 2 hlm 2 1 (1 ( AR) 2 C p For frictionless flow (8.42) hlm 0 1 Cpi 1 2 AR (8.43) Applying the Bernolli equation with the mass conservation for frictionless flow through the diffuser, the head loss for flow through an actual diffuser maybe written V1 2 hlm (C pi C p ) (8.44) 2 c.pipe Bends d. Valves and Fittings Table 8.4(p367) 8-7.3 Noncircular Ducts If the square or rectangular cross section may be treated if the ratio of height to width is less than about 3 or 4. The correlation for turbulent pipe flow are extended for use with noncircular geometries by introducing the hydraulic diameter, defined as 4A Dh P (8.45) A is cross-sectional area, and P is wetted perimeter. For a rectangular duct of width b and height h, A=bh and P=2(b+h), and the aspect ratio ar=h/b, then 2h Dh 1 ar 8-8 solution of pipe flow problem From the total head loss, pipe flow problem can be solved using the energy equation Eq.8.29 . Consider single-path pipe flow problem. 8-8.1 single-path system The pressure drop through a pipe system is a function of flow rate,elevation change,and total head loss.(1. Major losses due to friction in constant-area section(Eq.8.34) and minor losses due to fittingd,area changes, and so forth (Eq.8.40). The pressure drop p 3 ( L, Q, D, e, z, system configuration , , ) For the fixed pipe flow(incompressible,roughness,elevation change) p 4 ( L, Q, D) (8.46) (a) L,Q,and D known, p unknown friction factor from fig8.13, the total head loss is computed from Eqs.8.34 and 8.40, Eq.29 used to calculate the p (Example 8.5) (b) p,Q, and D known, L unknown Eq8.29 for head loss. Friction factor calculate from Re and e/D, Eq.8.34 for unknown length(Example8.6) © p , L,and D known, Q unknown (8.29) and lead loss; the result is an expression for average V(or Q) in terms of the friction factor f (see P369) (d) p, L,and Q known, D unknown the problem is to determine the smallest pipe size that can deliver the desired flow rate. Since the pipe diameter is unknown, neither the Reynolds number nor relative roughness can be computed directly, and an iterative solution is required. Example8.8 2 p V Q W s edV (u gz ) V dA CV cs t 2 p2 p1 Win Ws (u2 )m (u1 )( m ) Q p2 p1 p2 p1 Win m (u2 u1 )m Q m losses The losses are determined in terms of the pump efficiency losses (1 )Win 1 p2 p1 1 V Ap Win m ( p2 p1 )V A Win 36800hp 8-8.2 Pumps in fluid systems The driving force causing the fluid motion was explicitly stated as either a pressure difference or as an elevation difference. The energy per unit mass added by the pump is calculated p V p V W pump m gz gz discharg e 2 suction 2 W pump p V p V h pump gz gz m 2 discharg e 2 suction (8.47) p1 p2 V1 2 V22 1 gz1 2 gz2 hpump hlT 2 2 (8.48) Part C Flow measurement 8-9 direct methods For determine flow rate (volume or mass of liquid collected) 8-10 Restriction flow meters for internal flows Restriction flow meter are based on acceleration of a fluid stream through some form of nozzle. Flow separation at the sharp edge of the nozzle throat causes a recirculation zone to form , as shown by the dashed line lines downstream from the nozzle. The mainstream flow continues to acceleration from the nozzle throat to form a vena contracta at section (2) and then decelerates again to fill the duct. At the vena contracta, the flow area is minimum, the flow streamlines are essentially straight, and the pressure is uniform across the channel section Assumption: steady, incompressible, flow along a streamline, no friction, uniform velocity at section,pressure is uniform across sections and z1=z2 dV V dA 0 cs t CV (4.13) 2 p1 2 V1 p2 V2 gz1 gz 2 2 2 (6.9) 2 V1 2 V2 2 1 p1 p2 (V2 V1 ) 2 2 V2 0 V1 A1 V2 A2 2 2 V1 A2 V2 A1 2 2 A2 V 1 p1 p2 2 A1 2 2 V2 2 p1 p2 [1 ( A2 / A1 ) 2 ] (8.49) The theoretical mass flow rate is then given by A2 m theoretical V2 A2 1 ( A2 / A1 ) 2 2 ( p1 p2 ) (8.50) The above formulation is adjusted for Reynolds number and diameter ratio by defining an empirical discharge coefficient such that m actual CAt 1 ( At / A1 ) 2 2 (p 1 p 2 ) (8.51) Dt / D1 4 ( At / A1 ) 2 m actual CAt 1 4 2 (p 1 p 2 ) (8.52) The velocity-of-approach factor and The discharge coefficient are combined into a single flow coefficient K C (8.53) 1 4 m actual KAt 2 ( p1 p2 ) (8.54) For the turbulent flow regime, the discharge coefficient b C C n Re D1 (8.55) The corresponding form for the flow-coefficient equation is K K 1 b n 1 4 Re D1 (8.56) 8-10.1 The Orifice Plate The thin plate , the pressure gaps for orifices may be placed in several locations, the location of the pressure taps influences the empirically determined flow coefficient, you need select handbook values of C or K consistent with the location of pressure gaps 2.5 91 . 71 C 0.5959 0.0312 2.1 0.184 8 Re 0D.175 0.2 0.75 10 4 Re D1 107 (8.57) 8-10.2 The flow Nozzle 6.53 0.5 C 0.9975 Re 0D.15 (8.53) 0.25 0.75 10 4 Re D1 107 a. Pipe installation (K is function of and Re D ) 1 b. Plenum installation 0.95<K<0.99 8-10.3 The Venturi Venturi meters are heavy,bulky,and expensive. The conical diffuser section downstream from the throat gives excellent pressure recovery; overall head loss is low. The discharge coefficients for venturi meters range from 0.980 to 0.995 at Re >2x10e+5. C=0.99