* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

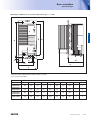

Download Lenze - Inverter Drive Supermarket

MIL-STD-1553 wikipedia , lookup

Surge protector wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Superheterodyne receiver wikipedia , lookup

Phase-locked loop wikipedia , lookup

Distributed element filter wikipedia , lookup

Mathematics of radio engineering wikipedia , lookup

Equalization (audio) wikipedia , lookup

Valve RF amplifier wikipedia , lookup

Opto-isolator wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Index of electronics articles wikipedia , lookup

Radio transmitter design wikipedia , lookup

Power electronics wikipedia , lookup