* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download October, 1987 P/N 21-6100 DUAL SHOWMAN TOP AMPLIFIER P/N

Electric power system wikipedia , lookup

Electrical substation wikipedia , lookup

Vacuum tube wikipedia , lookup

History of electric power transmission wikipedia , lookup

Current source wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Solar micro-inverter wikipedia , lookup

Power inverter wikipedia , lookup

Voltage optimisation wikipedia , lookup

Power engineering wikipedia , lookup

Ground (electricity) wikipedia , lookup

Alternating current wikipedia , lookup

List of vacuum tubes wikipedia , lookup

Electrical ballast wikipedia , lookup

Two-port network wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Mains electricity wikipedia , lookup

Power electronics wikipedia , lookup

Audio power wikipedia , lookup

Surface-mount technology wikipedia , lookup

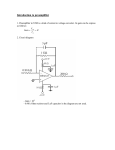

Opto-isolator wikipedia , lookup

October, 1987 P/N 21-6100 DUAL SHOWMAN TOP AMPLIFIER P/N 21-6102/3 DUAL SHOWMAN "WEDGE" ENCLOSURE P/N 21-6200 "THE TWIN" SERIES AMPLIFIER There are a few conditions relative to these amplifiers that you should know about: In early production, some defective rocker switches were not caught in time and got through the assembly process, into finished product. These switches are mechanically out of specified tolerances and may cause the rocker tab to pop out of its surrounding retainer. Whenever servicing any of the above amplifiers, carefuly check the output, standby, and power rocker switches for any evidence of excessive play. Replace with P/N 026479 (power, standby), or P/N 026480 (output) as appropriate. Another early trend was a higher than normal incidence of broken bias and balance adjustment trim pots. The cause: missing .048 inch shim washers between the body of the trim pots and the chassis, resulting in too much tension. Vibration during shipment translated the tension into broken trim pot wafers. When servicing one of these amplifiers, check to ensure that the shim washers are in place. If not, install P/N 026564 flat washers between the chassis and the body of the trim pots. A third (but normal) condition occurs when the output is switched from high to low, or vice versa. This causes loud clicks or bangs, depending on the settings of the various cintrols. You simply can't slam B+ (and bias) voltages around without hearing the results during normal operation. the correct way to switch power is to place the amplifier in the standby mode while selecting the power level. There is an additional (also normal) condition that you should be aware of: These amplifiers can be run at reduced power using only two output tubes instead of the usual four. This option is covered in the owners manual under the heading "impedance selector". In fact, it requires only two easy steps. 1. Remove the two inner 6L6-GC tubes, (counting from left to right, the 2nd and 3rd tubes). 2. Set the impedance selector switch to one-half of the total speaker load impedance, (with two 8 ohm speakers in series equal to a 16 ohm load set the switch to 8 ohms). In this configuration the output power is reduced to 60 watts R.M.S. in the high setting, and 15 watts R.M.S in the low setting, instead of 100 and 25 watts R.M.S. February, 1988 The Champ 12 The Champ 12 is so named because of its 2 inch speaker, not because of its power which is 10 watts R.M.S. into 8 ohms. This amplifier uses a single 6L6GC output tube. The output stage is rather unusual in that the screen voltage is only +242VDC, while the plate voltage is +496VDC. this was done in order to achieve the exact sound desired for both clean and overdrive modes while maintaining call "A" operation within the proper family of curves for a 6L6GC. A reasonable way to provide such a 2 to 1 B+ ratio is to use a voltage doubler in the power supply, and tap off one half of the doubler for the screen, and use the total output for the plate. The trade-off is a slight increase in hum. It puts 60Hz. ripple on the screen and 120Hz. ripple on the plate. Audible hum is noticeable only in a very queit enviroment, so the Chanmp 12 is better used as a guitar or practice amp, rather than in a recording studio application(editor note: a room or distance microphone would work). We don't want you chasing ghosts, so if someone complains about hum on a Champ 12, measure the ripple on the output tube with a scope. You should see about 1Vp-p ripple on the screen (pin 4), and 15Vp-p on the plate (pin 3). Ripple of 15Vp-p translates to 5.3Vrms riding on +490DVC, or about 1%. If you scope acroos the speaker, you should see 50 or 60 millivolts peak-to-peak. That is what you hear and is normal for this amplifier. You may have to remind certain purists that this is a guitar amp. After all, when you play a guitar through it, you can get a wide variety of sounds. The Strat Plus Rattling at the roller nut. A certain amount of this acoustic "rattle" is the nature of the roller nut, but it should not be audible through the amplifier. In some cases, this rattling is extreme enough to be heard when the instrument is amplified. The first problem to check for is nut misalignment. the string should go straight through the center of the string slot, and directly back to the tuning machine post. If the nut is off center, the string can be to close to either side of the string slot. This can be easily corrected by loosening the mounting screws slightly and pushing the nut to either side to properly center the string in the groove. While holding the nut in position, the screws should be slowly tightened. The second problem is that the nut was not properly shimmed. If the action is below specs at the first fret, the nut can be shimmed up which will correct the angle of the string over the nut, allowing enough downward pressure to eliminate any rattling that may happen in the rollers. If this is the case, you may request additional shims from Fender which are easy to install (thin stainless steel of the kind used in feeler guages can be used for shims). Investigate for this problem only if proper alignment of the roller nut fails to correct the rattling. June, 1988 On Hum In Fender Amps: As you already know, open or defective filter caps in the B+ power supply are the cause of excessive hum in many an amp. This is especially evedent to the user as too much hum if the open capacitor happens to be filtering a high gain preamp tube where the ripple gets amplified through a number of stages. So you put the chassis on the bench, fire it up and it hums. Now you try shunting a known good electrolytic capacitor across each filter in turn to no avail. Next you think of heater to cathode leakage in a bad tube, so you start changing tubes. Good! that's a valid move but now you have to change them all, and the amplifier still hums. Remember that those heaters are referenced close to ground, and if they are instead left to float, may very well introduce hum into the audio stream. Check with the power off, using an ohmmeter to see whether the ground reference is present. In many Fender amps, the heater winding of the power transformer is center tapped. this center tap (coded green with yellow tracers) should go directly to ground. Measuring between each solid green heater winding to ground dhould give you a low reading. An alternate method uses fixed resistors from each side of the heater winding to ground. These amplifiers have a power transformer with only the two solid green leads and no center tap. On Fender amplifiers, the resistors used to keep the filaments close to ground are usually rated at 100 ohms, 2 watts. They are mounted on each terminal of the power on indicator socket to ground. Some Fender amps have a hum balance control instead of the fixed resistors. These are usually 100 ohms with two fixed terminals across the heater winding (some have 4.7 ohms or so in series with one side), and the wiper terminal grounded. If the wiper opens, you lose the ground reference and get hum. Having your scope ready, it's a simple matter to determine which way to go. Set the horizontal time base at 2 milliseconds per division, and measue the period of the ripple. Since most Fender amps use full wave or gridge supplies, power supply ripple equals 120 hertz while heater induced hum equals 60 hertz. If you read 8.3 lilliseconds, check the filter capacitors, but if you measure 16.6 lilliseconds, go after the heaters. Unwanted Oscillations Audible frequencies other than hum due to unwanted oscillations can sometimes be troublesome, especially if the source is in, or before a high gain stage. In such a case, the oscillation may be small and in the noise where it is virtually impossible to see on some scopes. In these cases, try using a coupling capacitor - say 0.2 microfarad/600 volt mylar, with one end strapped to ground. You can sytematically ground each tube socket terminal working back to the preamps, and when you have gone too far, the oscillation will come back. This will localize the stage which you can "shotgun" or further analyze. Sometime just adding a small capacitor from plate to cathode will neutralize the interelectrode capacitance of the tube long enough to stop the oscillation. Try a 220 picofarad 1000 volt disc ceramic. Check Those Bypass Caps Most Fender tube amps use 25 microfarad/25 volt (or 22uF/16V) capacitors bypassing the cathode resistor to provide a good A.C. ground in the preamp stages. These electrolytics may deteriorate with age changing value, or even becoming open. This is not an uncommon problem and may cause severe signal degeneration with excessive rolloff, or lack of gain. Replace them in older amps, and at least check them when any tube type amp is on the bench. Vibrato Ticking The vibrato assembly consists of a photo-cell and a neon lamp held together by a piece of 0.025 inch thick black heat shrink tubing. One side of the photo-cell or LDR, goes to a control potentiometer and the other side goes to ground. One side of the NE-2 neon lamp goes to a 100K resistor, and the other side goes to a 10M resistor (also tied to the plate of the 12AX7 vibrato tube). The solution calls for adding one capacitor and dressing the leads: Connect a 0.01 microfarad/600 volt mylar capacitor from the junction of the 10 megohm resistor (where it connects to the neon lamp on the eyelet board) to ground (where the LDR connects to ground also on the eyelet board). Dress the leads to the vibrato speed and intensity controls away from the tone controls, and filter leads. Bunch together the leads connecting the components on the eyelet board to the tube socket of the 12AX7 vibrato tube. Incidentally, the vibrato oscillator is a phase shift type oscillator that uses three capacitors between the plate and control grid of the first triode to shift the phase approximately 60 degrees each, or 180 degrees in all to provide regenerative feedback for sustaining oscillation. These capacitors (usually one 0.02uF and two 0.01uF) have a higher incidence of failure than most of the other components in the vibrato circuit (outside of the tube). They should be checked or replaced right away if the circuit is not oscillating. A Common Reverb Question: Many of you are aware that the input transducer (part #071423) of most reverb pans used in Fender amps has an input impedance of 8 ohms, and the output transducer (part #071415) an output impedance of 2250 ohms, at 1000 hertz. These correspond to a D.C. resistance of 0.87 ohms (input) and 180 ohms (output). That's fine, the pan checks good, the tubes have been replaced, the circuit board components have been checked including the 500 picofarad coupling capacitor into the 12AT7 reverb driver (an open 500pF is a common fault), but the reverb is still dead. This leads to the common question: "What readings should I get when checking the reverb driver transformer?" This driver transformer (part #022921) is an output transformer matching at 25K ohms in the primary to 8 ohms in the secondary at 1000 hertz. the primary D.C. resistance should measure 2100 ohms, the secondary 1 ohm. For those wishing to sugject it to dynamic testing, the turns ratio is 53 to 1. Early Production "Twins" During the early phase of production on the new tube type "Twin", the wave flow soldering operation was not fine tuned well enough to avoid a couple of potential problems. This was especially true of the flux used at the time. Most of the Twin amplifiers were caught before shipment and reworked, but dome did get out into the field. The first problem is too little solder adhesion in the various solder joints throughout the P.C. board. To correct this in the field, carefully examine the four P.C. boards under a magnifying glass, and solder any that look suspect. Two of the four boards need to be turned over to accomplish this (editor note: I would advise hitting every joint while the amp is apart). The second problem is caused by contamination residue from the flux itself. the resulting leakage between traces causes a ticking sound not always evident because it depends on the configuration of the channel switching circuits. The fix for this id to install a 100K ohm resistor from the cathode side of LDR1 to ground. This cleans up a little noise from the LDR1 supply which tends to bleed through on some of these P.C. boards. the tolerance is not critical, try a 10% 1/4W carbon film resistor. The third problem may exist where the leadsbetween the tube sockets and the P.C. board need to be dressed properly. Improperly dressed leads cause excessive noise. These leads should be pulled away from the chassis and spread apart from each other. Sunn Controllers Internal changes have caused recent versions of the PLC816 to draw less power. This led to the belief that only one dimmer pack would be needed to provide power. It turns out that this is not true. Using only one dimmer pack puts the system into a marginal condition where most PLC816 controllers will malfunction. So always use two or more dimmer packs, or the optional A.C. power supply (part #027158). A PLC3200 does not derive power from dimmer packs. Always use the included A.C. power adaptor (part #29316), and follow the power supply instructions to ensure correct positive tip polarity. March, 1989 Sunn PS-1200 low Level Flickering: A problem came to light in an installation using multiple PS-1200 dimmer packs. The symptom was random low intensity turn on/off with some of the channels. the solution calls for providing a slight amount of D.C. voltage offset (on the order of 50 millivolts or so), to the reference (inverting) inputs of I.C. #6. This will ensure that they shut off fully and stay off whenever the controlling (non-inverting) inputs are sitting at zero volts. This is easily accomplished by ading a 5.6 megohm 1/4 watt resistor from the +15VDC source, to the input of each of the two ramp generators. Two 5.6 megohm resistors are required but tolerance need not be tight, any value around 5.6 megohms will do fine. This pertains to the PS-1200 only, and should be done to all PS-1200 dimmer packs in for service. Refer to the partial schematic below for electrical orientation of the two resistors designated R59 and R60: Fender 85 and 185 Channel Switching during early production of the 85 and 185 series amplifiers, some 1N4148 diodes were accidently mixed with diodes in the bin holding type 1N4448 diodes. When the P.C. boards were stuffed, some of the 1N4148 diiodes were put into circuits requiring the 1N4448. the result of this mix-up causes the channel switching feature to malfunction after 15 minutes or so od operation from a cold state. On the Deluxe 85, CR21 through CR26 must be 1N4448 diodes. Channel switching on the Deluxe 85 may be further improved by changing a zener diode and two resistors. Change R90 from 1.5K ohms to 1.8K ohms, amd R92 from 10K ohms to 2.2K ohms. Check R89 to make certain it is 10K ohms. On the 185 series, CR25 through CR29 must be type 1N4448 diodes. Be sure R113 is 2.2K ohms. CR24 must be a 1N5236B 7.5V zener diode. Resistor R108 must be 10K ohms, and R109 1.8K ohms. The R108/R109 ratio is important. R109 was originally 1.5K ohms and was changed to 1.8K ohms. Ultrasonic Oscillations One condition sometimes encountered in powerful audio amplifiers is unwanted high frequency oscillation. The Dual Showman Top is one of these amps. It has been observed on the bench producing a 20kHz oscillaltion in the power amplifier. this happened with nothing plugged into the preamp, and only when both the loop level, and the damping switch were in their center, medium positions. The following modification was designed to eleminate this condition. As shown in the partial schematic of the Dual Showman top below, the output of the preamp is taken from cathode follower VB3, and coupled by C201 through rear mounted effects loop jacks, and selectable voltage dividers with summing resistors to the grid of voltage amplifier V3A. WHOO! What a mouth-full. Part of this signal path is made up of P.C. traces on the bias P.C. board, and part is made up with a shielded cable going from the bias board to pin 2 of V3A (the control grid of the voltage amplifier). The input to this control grid is very sensative and the leads dressing play an important part in overall amplifier stability. If the shielded cable is tied against the cable harness, it should be pulled away from the harness and routed up in the air by itself. Relocate the shield ground and center conductor to the new position on the bias P.C. board, and cut one trace to physically shorten the signal path as shown on the partial diagram below. Shut Down Noise While we're reviewing unwanted ocsillations, the early production 60 Series amplifiers sometimes generate noise best explained as a sudden increase, or swell in overall volume when turned off. A Super 60 or S60 head can break into oscillation when turned shut down and squeal until the rails drop. the fix for the is the following: Two capacitors need to be changed, C126 and C127. Change C126 from 47ufd/50V to 100ufd/100V, and C127 from 100ufd/100V to 470ufd/50V. That's it! April, 1989 Watch Out For The Unexpected! The thermistor TH-1, in the 185 Series amplifiers was designed to limit initial turn on surge, improving the life span of the other components. This is a problem in some of the amps (editor note: most that I have serviced). The vendor that Fender purchased these thermistors from purposely introduced small half bends in the leads during the manufacturing process. These semi-circle bends are there to stop the component from being inserted to far during stuffing of the P.C. board. Without these bends, the component leads may go in so far that the ceramic covering of the thermistor (and a 1/4 inch or more of the leads) may enter the hole and insulate the leads from the pad. These thermistors were damaged during the bending process causing the leads to crystalize and become very brittle. Subsequent vibration from shipment added to the problem by causing the leads to fracture completely, resulting in a dead or intermittent amplifier. Replace the thermistor with a known good one and use a little RTV cement between the thermistor and the P.C. board after the solder cools (editor note: I have found that goop and electronics grade silicon work well for this application). Thermistors vs. MOVs On completeed warranty forms to Fender, thermistors are sometimes referred to as MOVs. This is understandable as both thermistors and MOVs are used in the primary wiring of transformer powered equipment, and they are virtually identical in physical appearance. Take a close look and you will see definite differences in the circuit configuration. Thermistors are wired in one side of the A.C. line, in series with the primary winding of the power transformer (which is why the amp goes dead when a lead breaks open), and are used to limit the in-rush current when the amp is turned on cold. As the thermistor warms up, its internal resistance goes down gradually increasing current flow in the primary of the power transformer. Small changes of resistance in the 120VAC primary circuit are significant. Typically a thermistors value in ohms, ranges in the single numbers just as good surge resistors would. In the 185 series, TH-1 varies from about 2.5 ohms cold to about 0.06 ohms warm, and is rated at 8 amperes. These thermistors are wired into the phase side rather than the neutral side of the A.C. line, and also provide a second benefit in reducing noise getting back onto the A.C. line from the amplifier. This can be a welcome benefit when you have lots of equipment connected to the A.C. line on stage, and you operate the 185 without without causing sudden transients over the high powered P.A. system. Unlike thermistors, metal oxide varistors are wired in parallel, or across the primary winding (sometime the secondary) of the power transformer. Varistors are voltage dependent symetrical resistors which act in a manner similar to back-to-back zener diodes in circuit protection functions. When exposed to high energy voltage transients, the varistor impedance changes from a very high standby value to a very low conducting value, clamping hte transient voltage to a safe level. January/February 1990 Proper Controls (Power Chorus) The revised footswitch can not be used with the non-revised (early production) amplifiers, or vice versa. If you have a Power Chorus with problems in the switching circuit, it may be in the footswitch or the amp. For these situations you need the proper controls. One key to this control is the serial number cut-over used when the change went into production. The serial number cut-over is . . L099109, that is, the revision starts with serial number L099109. Serial number below L099109 do not have the upgrade. Most Power Chorus amps will have a higher serial number and will therfore have the upgrade. A second key to maintaining proper control is to have a list of the revisions, or the proper schematic for the amp in service. the schematics distributed to dealers reflect the upgrade. Both revisions of the schematics for the footswitch and amp are shown below. Refer to the serial number and choose the proper schematic. REF CR1 CR2 CR3 LD1 LD2 LD3 LD4 LD5 PART# 006260 006260 027327 028039 028039 028039 028039 9902202281 TYPE 1N4448 1N4448 1N5234B LED RED LED RED LED RED LED RED LED RED REF CR1 CR2 CR3 CR4 LD1 LD2 LD3 LD4 PART# 006260 006260 027327 031017 028039 028039 036588 036588 Amplifier (footswitch decoding) ONLY PARTS CHANGED FOR THE UPGRADE ARE LISTED: (These are the parts used before the upgrade) REF C63 C65 PART# TYPE 027278 CAPRF 63V, .1uF, 10% 028459 CAPRE 50V, 2.2uF, 20% TYPE 1N4448 1N4448 1N5234B 1N5223B LED RED LED RED LED ORANGE LED ORANGE CR21 CR23 CR42 R132 R133 R138 R139 R141 031017 006260 027327 015582 036200 036202 036201 024998 ZENER DIODE ZENER RESMF RESMF RESMF RESMF RESCF 2.7V, 1N5223B, 5% SIG., 1N4448 6.2V, 1N5234B, 5% 10K, 1/4W, 1% 9.31K, 1/4W, 1% 118K, 1/4W, 1% 34.8K, 1/4W, 1% 120K, 1/4W, 5% (These are the parts used after the upgrade) REF C63 C65 CR21 CR42 R132 R133 R138 R139 R141 PART# 027281 028460 027329 029898 024981 024983 036587 036586 025059 TYPE CAPRF CAPRE ZENER ZENER RESCF RESMF RESMF RESCF RESCF 63V, .22uF, 10% 50V, 4.7uF, 20% 3.9V, 1N5228B, 5% 7.5V, 1N5236B, 5% 10K, 1/4W, 5% 12K, 1/4W, 5% 158K, 1/4W, 1% 52.3K, 1/4W, 1% 220K, 1/4W, 5% Power Chorus spatial Effect For more depth or space in the chorus effect, simply change C114 from 22uF/25V to 4.7uF/25V (or 50V). July/August, 1990 Channel Switching In The Princeton Chorus After a warm-up period of 15 minutes or so, the channel switching function in some of these amps will not switch into the overdrive mode, even though the LED indicates that it has. Look at I.C. U11. If it is a Samsung 4558, change it to a Texas Instruments or Motorola 4558. A TL0-72 will also work here. Take A Close Look at Those Power Resistors When you are servicing an amplifier, take a close look at the power resistors to see if the compound is badly cracked or falling out. If so, replace the bad part(s) but do not use any with CB in the code. Resistors with the codes such as PW or CP are preferred over the CB coded resistors. November/December, 1990 BXR Spectrum Crossover Changes The change involves revising the printed circuit board bringing it up to revision "C". The drawings that follow show an earlier revision "B" printed circuit board (figure 1), and the latest revision "C" board (figure 2). The original P.C. board and the revision "A", are nearly the same as revision "B", so they are not shown here. FIGURE 1 FIGURE 2 The change applicable to field service involves replacing the 126uF/100V capacitor with a 120uF/100V capacitor, and the 2.0mH/3amp inductor witha 2.2mH/5.5amp inductor. Changing the capacitor does not require p.c. board modification, but changing the inductor does. Two new holes designated "H" in figure 3, with a diameter of 0.55 of an inch (1/16 inch is close enough) must be drilled 1-1/8 inches apart, slightly offset from the existing traces for the electrical leads of the inductor. Additionally, the mounting hole designated "M" in figure 3, must be enlarged to 0.175 of an inch (3/16 inch is close enough). FIGURE 3 Note that the holes are drilled offset from the printed traces. DO NOT drill directly through the printed traces as this will remove to much of the current carrying capability of the trace material. Use a 8-32 x 2 inch machine screw with an 8 x 1/2 inch neoprene washer, and 8-32 hex nut to mount the replacement inductor. the washer and nut should be mounted on top of the inductor. After mounting the inductor (L1), the leads must be bent over and soldered to the existing pads. Below are the Fender part numbers. PART # 028658 028732 029467 029468 022004 DESCRIPTION Inductor, L1, 2.2 millihenries, 5.5 amperes Capacitor, C3, 120 microfarads, 100 volts NP Screw, Machine, 8-32 x 32" Washer, Neoprene, 8-32 x 1/2" Nut, Hex, 8-32 Dual Bass 400 Changes Replace the eight MJ15003 transistors with MJ15022 transistors to increase the safe operating area of the output stages. Use Motorola or equivalent parts only. the Fender part numer is: 025744 type MJ15022 NPN power output The Twin The Twin uses 1.0 ohm/1W resistors in the cathode circuit of each pair of 6L6GC output tubes to permit measuring and setting the bias from rear panel test points. Setting the bias control to produce 40 millivolts across the 1 ohm resistor equates to 40 milliamps of idle current, the proper biasing. There are certain conditions of 6L6GC tube failure that can cause excessive current through these 1 ohm resistors resulting in heat build-up enough to char the p.c. board even though they are flameproof type resistors. Adding diodes across the resistors will protect them in the event of tube failure. add a 1N4003 doide across R215 and one across R216. Refer to diodes D202 and D203 in figure 4: FIGURE 4 Position the diodes so that the cathode of the diode connects to the ground side of the resistor, and the anode of the diode connects to the side of the resistor that connects to the cathode of th 6L6GC tube. The 1N4003 are Fender part number 064089. October, 1991 PX2108, PX2112, PX2116 Powered Mixing Consoles To improve reliabilty and cooling of the power amp, a higher speed fan is required. After changing the fan, the low speed mode requires a modification to operate properly. R130 must be changed from a 100 ohm/2W metal oxide resistor to a 39 ohm/2W metal oxide resistor. THis resistor must also be mounted above the circuit board using 1/2 inch long fiberglass tubing over the leads. This allows air circulation for improved heat dissipation. The old fan may be identified by the green label attahed to the blade. The newer higher speed fan has a silver label. In either case, the label is visible from outside the unit looking through the grill. The part number is the same but the green labeled fan is obsolete. Part numbers: 1 1 1 036177 Fan, 24VDC, 3-1/8" Sq., 44CFM 037177 Resistor, 39 ohm/2W, metal oxide (R130) 029962 Tubing, Fiberglass #12, 1/2" long January/February, 1992 Fan Starting Torque A problem with the starting tiorque of the cooloing fan on an SPL7250 power amplifier. This 24VDC fan is set up to operate at two speeds, with a normally open thermal switch sensing temperature. When the temperature rises above 60 degrees Celsius, the switch closes, shorting across a 2 watt resistor. This resistor is in series with the fan motor, and shorting across it causes the fan to run at high speed. Originally the specified value for the resistor was 300 ohms, used in both the SPL7250 and the PX2100 series mixers. This has been changed, the new value for use in the SPL7250 is 39 ohms, 2 Watts. In the PX2100, the value is 100 ohms, 2 watts. Refer to R310 below: October, 1992 SKX-35R, SKX-65R, SKX-100R Bias Modification These solid state amps require two component changes. SKX-35R Remove R53 (1.6K) and replace it with a 1K, 1/4 watt carbon film resistor. Remove CR6 (diode) and replace it with a jumper wire. SKX-65R/100R Remove R82 (1.6K) and replace it with a 1.1K, 1/4 watt carbon film resistor. Remove CR14 (diode) and replace it with a jumper wire. The resistor change reduces the amount of idle current (bias) that flows through the output transistors. Replacing hte diode with a jumper will allow the bias transistor, mounted on the heatsink, to track the heatsink temperature more accurately. Novenber, 1992 Reissue '63 Vibroverb Bias modification During the summer of 1992, Fender began shipping all production tube amplifiers with 5881 output tubes as original equipment. The 5881 has slightly different specs than the standard 6L6GC. This combined with the lower plate vlotage of 435VDC used in the '63 Vibroverb, causes an increase in crossover distortion. Decreasing the negative bias voltage turns the tube on harder, reducing the crossover distortion. To perform the modification: Remove the knobs and nuts on the "SPEED" and "Intensity" controls. Gently remove the small circuit board. Locate R58 (1K, 1/2W, 5%) and desloder. Install a 3.9K, 1/2W, 5% carbon film resistor. With the above modification, 6L6GC and 5881 tubes will be biased correctly. February, 1993 Crossover Modifications SUNN - 1211, 1228, 1291C, SPL1225, SPL1226 FENDER - 2825 first determine if the crossover is the old version. The differences between the old and the new versions involve: the number of standoffs used to mount the circuit board the amperage rating of the inductor used at "L1" the capacitors used at "C1, C3", and the addition of "C5". OLD 6 mounting stand-offs L1 Inductor 1800uH 5.5Amp (028657) (033612) C1 Capacitor 33uF 100V (028724) (040272) C3 Capacitor 18uF 100V (028721) New 8 mounting stand-offs L1 Inductor 1800uH 7.2Amp C1,C3,C5 Cap 15uF 100V Ployfilm NOTE: C5 is parallel with C1 March, 1993 Overheating Solid State Guitar Amps In most cases the thermal switch will shut down the unit, and after cooling, it will turn on again. The problem is caused by poor heat transfer from the output transistors through the mounting bar to the diodes, leading to poor tracking of the bias circuit, and excessive bias current flow through the output transistors. In most cases the output transistors are not seated onto the mounting bar. Inspect the insulator used between the transsitors and the mounting bar. The overheating units all appear to be using Silicone insulators (Sill Pads). these are soft and flexible. A simple test will verify the overheating condition. Using a DC Volt Meter, attach the leads across one of the emitter resistors (.47 ohm/5watt). Turn the power on and let the amp idle with no input signal or output load. Obsrve the DC voltage drop across the emitter resistor. The measurement will climb up to a certain level and stabalize. This usually takes 3 to 5 minutes. An overheating amp will measure 80mVDC to 250mVDC. Modification procedure: Desolder and remove the transistors (TIP142/TIP147). Remove the Sill Pads (insulators). Install Mica Pads using a liberal amount of thermal grease to both side. Remount the transistors and tighten securely (6 to 8 lbs.), and solder the leads. Repeat the test. A good measurement is in the area of 40mVDC to 80mVDC The TIP142 and TIP147 Darlingtons have a wide gain range. In some cases the transistors may need to be replaced to obtain a lower idle (bias) current (editor note: It's been my experince that 50% of these amps will eat the replacement parts. Although more expensive, non-generic parts have worked well for me in keeping the call back ratio way down). April, 1993 Reissue '65 Twin - Intermittent Operation A problem with the control pots can cause intermittent operation. There are three leads which protrude from the bottom of the pots. One of the leads appears to have not been riveted securely to the phenolic material on the back of the pot. this problem was noarrowed down to the date code of (9208). To inspect the pots, remoce the circuit board they are mounted to, being careful not to damaga the flex jumpers. Inspect the back side of the pots. The date code is printed on the phenolic backing, just above the lead mounting rivets. the fender part number is printed above. remove the pot with the date code in question and attempt to wiggle the leads. A poorly secured lead will wiggle easily. Replace all pots as necessary. June, 1993 M-80, M-80 Chorus Bias Modification A resistor change is required in the power amp section to reduce the DC Bias current through the output transistors. The change will minimize the possibility of overheating. M-80 : Remove R74 & R76 (1K, 1/4W), and replace them with 2.2K, 1/4W carbon film resistors. M-80 Chorus : Remove R127, R129, R154, R156 (1K, 2W), and replace them with 2.2K, 2W carbon film, or metal film resistors. M-80 Bass Power Supply Modifications A resistor change is required in the power supply section to reduce the amount of current through the 16 volt zener diodes CR49 & CR50. This will minimize the possibility of the zeners overheating. Remove R144 & R145 (270 ohm, 7W), and replace them with 390 ohm, 7W wire wound resistors. Make sure to glue the resistors to the p.c. board using an RTV silicone compound.