* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download What is a Power Supply?

Ground (electricity) wikipedia , lookup

Electrical ballast wikipedia , lookup

Solar micro-inverter wikipedia , lookup

Power factor wikipedia , lookup

Power over Ethernet wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Current source wikipedia , lookup

Electric power system wikipedia , lookup

Electrification wikipedia , lookup

Audio power wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Electrical substation wikipedia , lookup

Three-phase electric power wikipedia , lookup

Power MOSFET wikipedia , lookup

Power inverter wikipedia , lookup

Stray voltage wikipedia , lookup

History of electric power transmission wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Power engineering wikipedia , lookup

Amtrak's 25 Hz traction power system wikipedia , lookup

Schmitt trigger wikipedia , lookup

Surge protector wikipedia , lookup

Voltage regulator wikipedia , lookup

Distribution management system wikipedia , lookup

Opto-isolator wikipedia , lookup

Alternating current wikipedia , lookup

Buck converter wikipedia , lookup

Voltage optimisation wikipedia , lookup

Power supply wikipedia , lookup

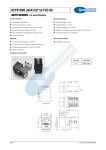

CONTENTS Selection Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . What is a Power Supply? . . . . . . . . . . . . . . . . . . . . . . . . . Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Technical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Discontinued Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . History of OMRON Power Supplies . . . . . . . . . . . . . . . . . Selection Guide Selection Guide Classification DIN track-mounting Power Supplies Model S82K Appearance 90 W, 100 W S82S 240 W H H H D D W D W Input voltage 100 or 200 VAC selectable Output capacity 90 W 100 W 240 W RuCW W 100 or 200 VAC selectable 100 to 230 VAC 12 to 24 VDC 90 W 240 W 3W 7.5 W 0.6 A at 5 V 1.5 A at 5 V S82S-7305 S82S-7705 0.25 A at 12 V 0.6 A at 12 V S82S-7312 S82S-7712 100 W Output current/voltage and model number RC 0.3 A, 0.2 A at ±12 V S82S7727 W H D (mm) Features Applications 3.75 A at 24 V 4.2 A at 24 V S82K-09024 S82K-10024 145 75 96 10 A at 24 V 10 A at 24 V S82K-24024 S82K24024T 280 130 138 3.75 A at 24 V 4.2 A at 24 V S82KP09024 S82KP10024 145 75 96 10 A at 24 V S82KP24024 280 138 130 0.2 A at 15 V 0.5 A at 15 V 0.2 A at ±15 V S82S-7315 S82S-7715 S82S7728 0.13 A at 24 V 0.3 A at 24 V 37.5 75 65 • Direct DIN track mounting • 12- to 24-VDC input • Plastic case • DC-DC converter • S82K-P09024, -P10024, -P24024 models incorporate PFC (90,100 and 240-W models) • Medium and small-scale control panels • PCB power supply • Control panels • Auxiliary power supply • Food processing and packing machines • Industrial machines Function Overvoltage protection (S82K-24024T model only ) Overcurrent protection Approved standards Class 2 (UL 1310)/class 2 (CSA C22.2 No. 950), UL 508 (Listing)/1950, CSA C22.2 No. 14/No. 950, EN 50178 (VDE 0160), EN60950, conforms to VDE 0106/P100 EMC EN50081-1 (90, 100 W models), EN50081-2 (240 W model), EN61000-3-2 (S82K-Pjjj24), EN50082-2 --- Cat. No. M048 M044 2 S82S-7724 S82S-7324 UL 508 (Listing)/1012, CSA C22.2 No. 14, CSA E.B. 1402C, EN50178 (VDE 0160), EN60950, conforms to VDE 0106/P100 Overcurrent protection Class 2 (UL 1310)/class 2 (CSA C22.2 No. 950), UL 508 (Listing)/1950, CSA C22.2 No. 14/No. 950, EN 50178 (VDE 0160), EN60950, conforms to VDE 0106/P100 UL 508 (Listing)/1012, CSA C22.2 No. 14, CSA E.B. 1402C, EN50178 (VDE 0160), EN60950, conforms to VDE 0106/ P100 UL508, CSA E.B.1402C Selection Guide Selection Guide Classification DIN track-mounting Power Supplies Model S8PS 50 W Appearance 100 W H 150 W H 600 W H H D D W 300 W H D D W D W W W RC W Input voltage 100 to 240 VAC 100 to 240 VAC Output capacity 50 W Output current/voltage and model number 10 A at 5 V 10 A at 5 V S8PS-05005j S8PS-05005Cj 4.2 A at 12 V 4.2 A at 12 V 100 W 150 W 50 W S8PS-05012j W H D (mm) Features Applications 100 W 150 W 300 W 600 W S8PS-05012Cj 2.1 A at 24 V 4.5 A at 24 V 6.5 A at 24 V 2.1 A at 24 V 4.5 A at 24 V 6.5 A at 24 V 14 A at 24 V 27 A at 24 V S8PS-05024j S8PS-10024j S8PS-15024j S8PS-05024Cj S8PS-10024Cj S8PS-15024Cj S8PS-30024Cj S8PS-60024C 40 50 50 40 50 50 110 170 85 127 92 145 92 163 • Compact DIN-track-mounting power supply • Models with Front-mounting Bracket available • PFC • Molding machines • Machine tools • Food processing and packing machines 85 127 92 145 92 163 Function Overvoltage protection, Overheat protection (600-W model only), Protection-ON alarm indicator (300-/600-W models) Approved standards UL508, UL1012, CSA C22.2 No. 950, CSA C22.2 No. 14, EN60950, VDE0160, conforms to UL1950 and CSA E.B. 1402C EMC EN50081-1, EN50082-2, EN61000-3-2 Cat. No. T021 92 175 92 179 3 Selection Guide Selection Guide Classification General-purpose Power Supplies Model S82J Appearance H H D D W W RuCW RuCW Input voltage 100 VAC 100 VAC Output capacity 10 W 25 W 50 W 100 W 10 W 25 W 50 W 100W Output current/ voltage and model number 2 A at 5 V 5 A at 5 V 10 A at 5 V 20 A at 5 V 2 A at 5 V 5 A at 5 V 10 A at 5 V 20 A at 5 V S82J-0105 S82J-0205 S82J-0505 S82J-10005A1 S82J-5105 S82J-5205 S82J-5505 S82J-10005D1 1 A at 12 V 2.1 A at 12 V 4.2 A at 12 V 8.5 A at 12 V 1 A at 12 V 2.1 A at 12 V 4.2 A at 12 V 8.5 A at 12 V S82J-0112 S82J-0212 S82J-0512 S82J-10012A1 S82J-5112 S82J-5212 S82J-5512 S82J-10012D1 0.7 A at 15 V 1.7 A at 15 V 7 A at 15 V 0.7 A at 15 V 1.7 A at 15 V 7 A at 15 V S82J-0115 S82J-0215 S82J-10015A1 S82J-5115 S82J-5215 S82J-10015D1 0.5 A at 24 V 1.1 A at 24 V 0.5 A at 24 V 1.1 A at 24 V S82J-5124 S82J-5224 35 x 97 x 90 40 x 97 x 124 S82J-0124 S82J-0224 WxHxD (mm) 35 x 97 x 90 40 x 97 x 124 Features • Each model provided with a mounting bracket for mounting to a control panel 40 x 97 x 161 50 x 97 x 198 • DIN track mounting brackets available (sold separately) Applications • Medium- and small-scale control panels Function Overvoltage protection (5-V of 100-W models only) Overcurrent protection Approved standards UL508, 1012 (10, 25, 50 W models), CSA C22.2 No. 14 EN50178 (VDE0160), EN60950 EMC EN50081-2, EN50082-2 Cat No. M047 4 40 x 97 x 161 50 x 97 x 198 Selection Guide Selection Guide Classification General-purpose Power Supplies Model S82J Appearance H H D D W W RuCW RuCW Input voltage 200 VAC 200 VAC Output capacity 10 W 25 W 50 W 100 W 10 W 25 W 50 W 100W Output current/ voltage and model number 2 A at 5 V 5 A at 5 V 10 A at 5 V 20 A at 5 V 2 A at 5 V 5 A at 5 V 10 A at 5 V 20 A at 5 V S82J-2105 S82J-2205 S82J-2505 S82J-10005A2 S82J-6105 S82J-6205 S82J-6505 S82J-10005D2 1 A at 12 V 2.1 A at 12 V 4.2 A at 12 V 8.5 A at 12 V 1 A at 12 V 2.1 A at 12 V 4.2 A at 12 V 8.5 A at 12 V S82J-2112 S82J-2212 S82J-2512 S82J-10012A2 S82J-6112 S82J-6212 S82J-6512 S82J-10012D2 0.7 A at 15 V 1.7 A at 15 V 7 A at 15 V 0.7 A at 15 V 1.7 A at 15 V 7 A at 15 V S82J-2115 S82J-2215 S82J-10015A2 S82J-6115 S82J-6215 S82J-10015D2 0.5 A at 24 V 1.1 A at 24 V 0.5 A at 24 V 1.1 A at 24 V S82J-6124 S82J-6224 35 x 97 x 90 40 x 97 x 124 S82J-2124 S82J-2224 WxHxD (mm) 35 x 97 x 90 40 x 97 x 124 Features • Each model provided with a mounting bracket for mounting to a control panel 40 x 97 x 161 50 x 97 x 198 40 x 97 x 161 50 x 97 x 198 • DIN track mounting brackets available (sold separately) Applications • Medium- and small-scale control panels Function Overvoltage protection (5-V of 100-W models only) Overcurrent protection Approved standards UL508, 1012 (10, 25, 50 W models), CSA C22.2 No. 14 EN50178 (VDE0160), EN60950 EMC EN50081-2, EN50082-2 Cat No. M047 5 Selection Guide Selection Guide Classification General-purpose Power Supplies Model S82J Appearance H H H D W D D W RuCW W RuCW Input voltage 100 to 240 VAC input Output capacity 50 W 100 W 150 W 2.1 A at 24 V 4.5 A at 24 V 6.5 A at 24 V S82J-05024D S82J-10024D S82J-15024D 40 50 50 Output current/voltage t/ lt and d model number W H D (mm) Features 97 161 • Compact DIN-track-mounting power supply 97 170 97 198 • Models with Front-mounting Bracket available Applications • Medium-and small-scale control panels Function Overvoltage protection (100-W model only) Overcurrent protection Approved standards Class 2 (50 W), UL508 (Listing)/1012/1950, CSA C22.2 No. 14/No. 950 (100, 150 W models), EN50178 (VDE0160), EN60950 EMC EN50081-2, EN50082-2 Cat. No. M047 6 RuCW 100 or 200 VAC (selected automatically) Selection Guide Selection Guide Classification General-purpose Power Supplies Model S82J Appearance H H D W D W RuCW RuCW Input voltage 100 or 200 VAC (selectable) 100 or 200 VAC (selectable) Output capacity 300 W 600 W Output current/voltage and model number 14 A at 24 V S82J-30024j 27 A at 24 V S82J-60024j W x H x D (mm) 120 x 92 x 181 170 x 92 x 169 Features • Each model provided with a mounting bracket for mounting to a control panel • Compact and low-cost Applications Control panels Function Overvoltage protection Overcurrent protection Over heat protection (600-W model only) Approved standards UL508/1012, CSA E.B. 1402C, EN50178 (VDE0160), EN60950 EMC EN50081-2, EN50082-2, EN50081-1 (with noise filter) Cat. No. M047 7 Selection Guide Selection Guide Classification General-purpose Power Supplies Model S82F S82F-P Appearance H H D D W W RCW RCW Input voltage 100 or 200 VAC (automatically selectable) 100 or 200 VAC (automatically selectable) Output capacity 150 W 120 W (240 W) 240 W (480 W) Output current/voltage and model number 13.5 A at 12 V 5 A (a peak current of 10 A) at 24 V 10 A (a peak current of 20 A) at 24 V S82F 1224P S82F-1224P S82F 2424P S82F-2424P 74 x 120 x 230 146 x 120 x 230 300 W S82F-1512 7 A at 24 V 14 A at 24 V S82F-1524 S82F-3024 WxHxD (mm) 74 x 120 x 230 146 x 120 x 230 Features • Natural air cooling • Ideal for peak loads • Automatic input selection • Automatic input selection • Large-scale control panels • Robots • Molding machines • Molding machines • Factory machines • Lab system Applications • Robots • Large-scale LED indicators Function Overvoltage protection Overvoltage protection Overcurrent protection Overcurrent protection Remote sensing Remote sensing Remote control Remote control Approved standards UL1012, CSA E.B. 1402C, VDE0160, VDE0805, EN60950 UL1012, CSA E.B. 1402C, VDE0160, VDE0805, EN60950 EMC EN50081-2, EN50082-2 EN50081-2, EN50082-2 Cat No. T001 T001 8 Selection Guide Selection Guide Classifica tion General-purpose Power Supplies S82H-3 Model PFC S82H S82H-P Appearance H H H D D W Input voltage 100 or 200 VAC (selectable) Output capacity 15 W 30 W Output current/ voltage and model number 3 A at 5 V S82H-3105 RC D RC W RC W 100 or 200 VAC (automatically selectable) 100 to 240 VAC 50 W 100 W 150 W 100 W 150 W 300 W 600 W 6 A at 5 V 10 A at 5 V 20 A at 5 V 30 A at 5 V 20 A at 5 V 30 A at 5 V 60 A at 5 V 120 A at 5 V S82H-3305 S82H-3505 S82H-10005 S82H-15005 S82HP10005 S82HP15005 S82HP30005 S82HP60005 1.2 A at 12 V 2.5 A at 12 V 4.5 A at 12 V 9 A at 12 V 13.5 A at 12 V 9 A at 12 V 53 A at 12 V S82H-10012 S82H-15012 S82H-3112 S82H-3312 S82HP10012 13.5 A at 12 V 27 A at 12 V S82H-3512 S82HP30012 S82HP60012 1 A at 15 V 2 A at 15 V 3.4 A at 15 V 7.2 A at 15 V 10 A at 15 V 7.2 A at 15 V 20 A at 15 V 40 A at 15 V S82H-3115 S82H-3315 S82H-3515 S82H-10015 S82H-15015 S82HP10015 S82HP30015 S82HP60015 S82HP15012 10 A at 15 V S82HP15015 0.6 A at 24 V 1.3 A at 24 V 2.3 A at 24 V 4.6 A at 24 V 7 A at 24 V 4.6 A at 24 V 7 A at 24 V 14 A at 24 V 27 A at 24 V S82H-3524 S82H-10024 S82H-15024 S82HP10024 S82HP15024 S82HP30024 S82H-3124 S82H-3324 S82HP60024 WxHxD (mm) 35 x 90 x 100 40 x 90 x 130 45 x 90 x 150 60 x 110 x 200 74 x 120 x 230 60 x 110 x 200 74 x 110 x 200 120 x 92 x 190 190 x 92 x 200 Feature • DIN track mounting brackets available (sold separately) • 3-year guarantee Applications • Medium-and small-scale control panels • Medium-and small-scale control panels • Suitable for exporting to Europe • Control panels • Control panels • Control panels Function Remote control Remote voltage adjustment Fan alarm function Remote sensing Remote control Remote voltage adjustment Overvoltage protection Remote sensing Remote control Overcurrent protection Overvoltage protection Remote sensing Overcurrent protection Overvoltage protection • 3-year guarantee • PFC Overcurrent protection Approved standards UL1012, CSA E.B. 1402C UL1012, CSA E.B. 1402C, VDE0160, EN60950 UL1012, CSA E.B. 1402C, VDE0160, EN60950 EMC --- EN50081-1, EN50082-2 EN50081-2, EN50082-2, EN61000-3-2 Cat No. T003 T020 T020 9 Selection Guide Selection Guide Classification Built-in Power Supplies Model S8E1 Appearance W D H RC Input voltage 100 VAC Output capacity 10 W 15 W 25 W 50 W Output current/voltage and model number 2 A at 5 V 3 A at 5 V 5 A at 5 V 10 A at 5 V S8E1-01005j S8E1-01505j S8E1-02505j S8E1-05005j 1 A at 12 V 1.3 A at 12 V 2.1 A at 12 V 4.2 A at 12 V S8E1-01012j S8E1-01512j S8E1-02512j S8E1-05012j 0.7 A at 15 V 1 A at 15 V 1.7 A at 15 V 3.4 A at 15 V S8E1-01015j S8E1-01515j S8E1-02515j S8E1-05015j 0.5 A at 24 V 0.7 A at 24 V 1.1 A at 24 V 2.2 A at 24 V S8E1-01024j S8E1-01524j S8E1-02524j S8E1-05024j WxHxD (mm) 24 x 69 x 85 34 x 69 x 94 35 x 69 x 123 37 x 69 x 161 Features • Twice as compact as the S82J • A total of 128 models available for a variety of applications Applications • Measuring equipment • Chemical equipment • Automobile parking systems • Home security systems • Built-in power supplies for electronic devices Function Overvoltage protection (5-V output models only) Overcurrent protection Approved standards UL1950 D3, CSA E.B. 1402C EMC Conforms to FCC class A standards Cat No. M046 10 What is a Power Supply? What is a Power Supply? What is a Power Supply? Commercial AC power distributed from power plants cannot be supplied directly to the ICs and other electronic components built into electronic devices in automated office and factory equipment without destroying the components due to the high voltage of commercial AC power. Devices, called power supplies (specifically, regulated DC power supplies) are thus required to convert commercial AC power into regulated DC power to drive ICs and other electronic components. This section will introduce you so some basic information about power supplies in general. Regulated DC Power Supplies There are three kinds of regulated DC power supplies: switching power supplies, linear power supplies, and CVT (constant voltage transformer) power supplies. Of these, switching power supplies and linear power supplies are generally referred to as power supplies. CVT power supplies, though reliable and limited in the number of internal parts, are large and heavy, and are usually treated separately from power supplies in general. Switching Power Supplies Regulated DC Power Supplies Linear Power Supplies Constant Voltage Transformers Switching Power Supplies Switching power supplies convert commercial AC power into high-frequency DC power using the high-speed switching of semiconductors built into the switching power supply. Switching power supplies are so compact, light, and efficient that they are used as power supplies by most electronic devices. Converts AC into DC by rectifying and smoothing AC. Steps down the voltage with a high-frequency (40 to 200 kHz) transformer. The primary and secondary sides are insulated from each other. + + DC OUT + – AC IN Controls the highfrequency switching pulse width and frequency to stabilize the output. PWM Detection circuit Advantages • Highly efficient, compact, and light. • A wide input voltage range is available. • The output is maintained for a certain period after input power is turned off. Disadvantages • Switching noise is generated. Market Share 90% or more of power supplies are switching power supplies. 11 What is a Power Supply? What is a Power Supply? Linear Power Supplies Linear power supplies convert commercial AC into DC power via a step-down transformer (50 or 60 Hz) and a variable resistor. Linear power supplies are so large and heavy that they are used only in special applications. Converts AC into DC by rectifying and smoothing AC. Steps down the voltage with a linear control circuit and stabilizes the output voltage. + + + DC OUT AC IN Reference voltage – Steps down the voltage with a transformer (50 or 60 Hz). The primary and secondary sides are insulated from each other. Advantages • Output voltage is very stable. • No noise is generated. Disadvantages • The transformer is heavy. • Excessive heat is generated by the power transistor for linear control. Linear Power Supplies vs. Switching Power Supplies Electric Characteristics Characteristic Meaning Linear power supplies Switching power supplies Input fluctuation Output voltage fluctuation resulting from input voltage fluctuation Good (0.1 %) Fair (0.5 %) Load fluctuation Output voltage fluctuation resulting from load current fluctuation Good (0.3 %) Fair (1 %) Ripple noise Output ripple and noise Excellent (0.04%) Fair (1%) Due to high-frequency switching Input voltage range Efficiency Permissible input voltage range Output power Input power 100 (%) Fair (±10%) Excellent (+32%/–15%) Fair (40%) Excellent (75%) • The transformer and transistors built into a linear power supply are so large that the heat generated by the power supply is twice as great as that for switching power supplies. • A switching power supply is nearly twice as efficient as a linear power supply. • The efficiency of a linear power supply is 40% due to power lost through transformer coils and magnetic cores. Output holding time Time between power supply input turning off and a drop in power supply output Fair (2 ms) Good (20 ms) Weight --- • Very heavy due to the transformer built into the linear power supply. • A switching power supply is five times lighter than a linear power supply. 12 Glossary Glossary Glossary Item Definition Constant voltage accuracy The fluctuation of the output voltage due to a change in input, load, or temperature. Efficiency Inrush current Output power 100 (%) Input power There will be an inrush current at the moment AC power is input to the power supply. The inrush current is caused by the charge current flowing into the high-capacity electrode capacitors of the power supply when the power supply is turned on. Leakage current The current leaking to the ground from the input lines through the casing of the power supply. Efficiency x Input Power supply Ammeter Capacitor The leakage current is checked as shown in the above diagram. A bypass capacitor is used in accordance with the UL standards. Life expectancy The life expectancy indicates average operating hours under the ambient temperature of 40°C and a load rate of 50%. Normally this is determined by the life expectancy of the built-in aluminum electrolytic capacitor. Noise terminal voltage A kind of electromagnetic interference. The high-frequency noise voltage generated from the input terminals of the power supply. Output hold time The period the power supply keeps outputting at its rated output voltage after the input has turned off. Usually a period of 20 ms minimum is required so that computer data will not be corrupted at the time of power failure. Input power Power supply’s output Rated voltage accuracy Output hold time Overload protection Turns off the output so that the output current will not be more than the value that has been specified to protect the power supply from damage when the load is short-circuited. Overvoltage protection Turns off the output to protect the load when the power supply output is excessive. Usually, the output is turned off if the output voltage reaches approx. 120% of the rated output voltage. Parallel operation More than one power supply can be connected in parallel. In which case, the total output current is obtained by adding the output current of each power supply connected in parallel. Input Power factor Power factor x Effective power Effective power x Apparent power Root mean square of voltage x root mean square of current 13 Glossary Glossary Item Definition Rated I/O conditions The conditions required to operate the power supply at its rated AC input (50/60 Hz), rated output voltage, and rated output current at an ambient temperature of 23°C ±2°C and an ambient humidity of 65% ±5% are called rated I/O conditions. Rated input voltage Nominal input voltage such as 100, 110, or 120 VAC Rated output voltage Nominal output voltage such as 5, 12, or 24 VDC Reliability (MTBF) MTBF stands for Mean Time Between Failures, which is calculated according to the probability of accidental device failures, and indicates reliability of devices. Therefore, it does not necessarily represent a life of the product. Remote control Remote control function turns the output of the power supply on or off from a distance. Load Power supply Remote sensing The remote sensing function compensates for voltage drop caused by the lead wires between the output terminals and load. Output DC Load Power supply Terminals for voltage sensing The voltage drop is fed back to the voltage sensing terminal of the power supply to increase the supply voltage by calculating the difference between the set value and the actual voltage supplied to the load. Remote voltage adjustment Remote voltage adjustment function is used to adjust the output voltage externally. Load Power supply Variable resistor 14 Glossary Glossary Item Ripple noise Definition The combined value of ripple noise added to the output voltage. High frequency noise Ripple voltage * Rated output voltage 0V *The ripple voltages mentioned in specification sheets include high-frequency noise. Serial operation More than one power supply can be connected in series. In which case, the total output voltage is obtained by adding the output voltage of each power supply connected in series. Input L 15 Technical Information Technical Information Technical Information Basic Selection Points The input voltage and output capacity (voltage x current) are the most important factors for selecting the most suitable Power Supply for any application. These and other basic selection points are shown in the following illustration. Confirm all points before selecting a Power Supply. Output Capacity (voltage x current) The maximum load capacity must be less than the maximum output capacity of the Power Supply. Input Voltage Each Power Supply has an input voltage range. Select the Power Supply according to the available input voltage. PS Load Safety Standards UL-, CSA-, or VDE-approved Power Supplies are available. Shape and Mounting Method Power Supplies of various shapes are available. Use the most suitable Power Supply according to the application. Various mounting brackets are also available. Main Selection Points: 1) Input Voltage 2) Output Capacity (voltage x current) Input Voltages Permissible Input Voltage Range The voltage of commercial AC power varies between different regions of the world as shown in the following diagram. 230 V 100 V/200 V 120 V 220 V 230 V 220 V 220 V AC Voltages Used Around the World 16 240 V Technical Information Technical Information Precautions Switching Power Supplies rectify the full waves of AC input to output DC using a circuit like the one shown below. VDC + AC 0V VDC is obtained by multiplying the AC input by √2 (approximately 1.414). If the input is DC, VDC will be obtained in the same way by inputting VDC. Rectangular pulses are output from uninterruptive Power Supplies or inverters, and they thus cannot be connected to linear Power Supplies. Before connecting an uninterruptive Power Supply or inverter to a switching Power Supply, check the input voltage. Inverters generate regenerative voltage, which must be taken into consideration. Output Capacities Rated Output Currents The rated output current of a Power Supply is computed as follows: Load current I0 = I1 + I2 + I3...+In Select a Power Supply with a sufficient rated output current for the required load current I0. +V I0 I 1 Power Supply Load –V I 2 Load I 3 Load 17 Technical Information Technical Information Mounting Methods There are various mounting brackets available for OMRON Power Supplies, including panel-mounting and DIN-track mounting. Model Mounting Bracket S82K-series models Not required S82S-series models Not required S82V-series models S82JJ S8 S82H-3 S8 3 S8E1 S8 Not required 10 W S82Y-01N 25 W S82Y-03N 50 W S82Y-05N 100/150 W S82Y-10N 15 W S82Y-01N 30 W S82Y-03N 50 W S82Y-05N 10 W S82Y-01N 15 W S82Y-01N 25 W S82Y-03N 50 W S82Y-05N Mounting Brackets F models Item e Rear mounting S models B models ode s Front mounting Left-side mounting Purpose u pose Right-side mounting Panel-mounting a e ou g S82J-series models Provided with Supply. None None S82J (100 W (24 V) only) S82Y-J01F None None S82H-3 S8 3 15 W S82Y-H01F S82Y-H01B S82Y-H01S 30 W S82Y-H03F S82Y-H03B S82Y-H03S 50 W S82Y-H05F S82Y-H05B S82Y-H05S 100 W S82Y-H10F S82Y-H10B S82Y-H10S 150 W None Provided with Supply. Provided with Supply. 100 W S82Y-H10F S82Y-H10B S82Y-H10S 150 W None Provided with Supply. Provided with Supply. 300 W None S82Y-D30B S82Y-D30S 600 W None S82Y-D60B S82Y-D60S S82F (150/300 W) None Provided with Supply. Provided with Supply. S82D S8 300 W None S82Y-D30B S82Y-D30S 600 W None S82Y-D60B S82Y-D60S S8E1-series models except PCB models None None None Built-in S82F-P (120/240 W) None Provided with Supply. Provided with Supply. Peak loads S82H S8 S82H-P S8 In order to obtain the full capability of the Power Supply, The “technical information” mentioned in this section must be followed. This section consists of five sections: Input, Output, Function, Testing, and Mounting/Wiring. Frequently used terms are explained in each section. 18 Technical Information Technical Information Precautions Operating Environments • Be sure to use or store the Unit in places satisfying the specified permissible operating ranges including the operating ambient temperature, ambient operating humidity, and storage temperature ranges. • • • Be sure to use the Unit in places that satisfy the specified enclosure rating and where the Unit is free from vibration or shock exceeding the specified vibration or shock range. Use the Unit in places that are free from excessive dust or corrosive gas. Be sure to separate the Unit from equipment that generates excessive high-frequency noise. Mounting The Unit has mounting holes, each of which is 4 mm deep. Be sure that the length of each mounting screw does not exceed 4 mm. Prevention of Metal Dust Penetration Machining work performed above the Unit may drop metal dust or chips onto the PCB of the Unit and short-circuit the internal circuitry, therefore damaging the Unit. Regardless of whether the Unit has a cover or not, before performing machining above the Unit, protect the Unit with a sheet so that the Unit will be free from such metal dust or chips. Be sure to remove the sheet used for the protection of the Unit before turning on the Unit to properly ventilate it. Input Input Voltage Inrush current prevention circuit Input fuse Under the datasheet heading “input voltage”, voltage and frequency values at which the rated operations and characteristics of the Power Supply are guaranteed are shown. The AC input voltages shown are effective values. Models S82V, S82H-3, S82D, S82K (100 W, 240 W), and S82J (300 W, 600 W) can operate at 100 to 120 or 200 to 240 VAC depending on whether the power terminals are short- or open-circuited. When the power terminals are shorted, the Power Supplies operate at 100 to 120 VAC, and operate at 200 to 240 VAC when the power terminals are open. 100 to 120 VAC Attach the short-circuit bar to short-circuit + Input smoothing capacitor Input Terminals Do not connect the input line to any terminal other than the input terminal, otherwise the Unit will be damaged. Pay the utmost attention when wiring the Unit. If the Unit is a DC input model, be sure not to make mistakes in polarity (i.e., positive and negative terminal connections) in order to protect the Unit from damage. Internal Fuse 100 to 120 VAC If the internal fuse has blown, the problem has most probably resulted from damage to the internal circuits of the Power Supply, which cannot be corrected by changing the fuse alone. If the fuse has blown, consult your OMRON representative. AC 1 AC 2 Inrush Current 200 to 240 VAC 200 to 240 VAC AC 1 Leave the terminals open When a Switching Power Supply is turned on, a surge of current flows into the input smoothing capacitor to charge the capacitor. This current surge is called the “inrush current”. The inrush current varies depending on the application timing and the presence of an inrush current prevention circuit, but is usually an order of magnitude greater than the steady-state current. AC 2 Input voltage Input Current Standard Switching Power Supplies rectify AC input current. Usually, rectification is done by a smoothing capacitor through which an effective current is allowed to flow. Therefore, the input current depends on the output power, input voltage, power factor, and efficiency, as follows: Output power Input current = Input voltage x Power factor x Efficiency The power factor of a Switching Power Supply is usually between 0.4 and 0.6. Input current Inrush current When two or more Switching Power Supplies are connected to the same input, the total current is the sum of the currents for each supply. Therefore, check that the external fuses and circuit breakers used in the input lines have sufficient current ratings. The pulse width can be considered to be about 5 ms. 19 Technical Information Technical Information Technical Information Technical Information Output Voltage Adjustment The range over which the output voltage can be changed while maintaining specific output characteristics. Ripple and Noise Since Switching Power Supplies operate at high frequencies (i.e., as high as 20 kHz or more), the DC output will contain ripple and noise. The following figure shows a representative waveform for ripple and noise. Line Regulation The change in the output voltage occurring when only the input voltage is changed slowly over the input range while maintaining constant output conditions. Switching cycle Ripple Noise Load Regulation The change in the output voltage occurring when the output current is changed slowly over a specified range while maintaining constant input conditions. Ripple and noise Input cycle of commercial power source Temperature Coefficient The change in the output voltage occurring when only the ambient operating temperature is changed. Since ripple and noise contain high-frequency components, the ground line of the oscilloscope must be shortened when making measurements. If the ground line is too long, it acts as an antenna which is influenced by radian waves and, consequently, the correct values of ripple and noise cannot be measured. Special Functions Overvoltage Protection Output voltage (V) This function protects the load circuit from damage by cutting off the Power Supply output when the output voltage rises to above 120% of the rated value. To cancel the effect of this function, turn off the power, wait for a specified time, then turn the power back on again. Note: When the overvoltage protection circuit operates, the Power Supply itself may be malfunctioning. When restarting the Power Supply after the overvoltage protection circuit has operated, turn the Power Supply ON with the load line disconnected and check the output voltage. Overvoltage protection operating Approx. 20% 10% Rated output voltage –10% Variable range Models with the Zener-diode clamp system do not restart after the protection circuit operates. Send the product for repair. S8E1-5V (10-W, 15-W models) S82J-D7 (10-W models) For further details, refer to the data for individual models. The overvoltage protection function is provided for the following models: S82F, S82F-P, S82D, S8E1 (5-V output), S82J (100-W/5-V, 24-V output, 300 W, 600 W), S82J-D7, S82W, S8E3 (V1 output only), S82H, and S82H-P, S8PS. Overcurrent Protection (All Models Except S8XA) The output voltage will return to the original value when the overcurrent is removed for “Voltage drop” and “Voltage/Current drop” models. For “Shutoff” models, the output voltage will return to the original value if the input power is turned off for at least 30 seconds and then turned on again. Item Voltage drop Voltage/Current drop Shutoff Voltage Voltage Voltage Characteristic Rating Current Features Easy recovery for loads that draw inrush current. Rating Current Both the voltage and current are reduced for overcurrents. Difficult recovery for loads that draw inrush current. Rating Current Output shut off for overcurrents lasting longer than a specific time. Higher safety for short circuits. 21 Technical Information Technical Information Note: 1. The output voltage will not necessarily drop to 0 V in actual operation for overcurrents, but will normally drop to and remain at a low voltage level. 2. If a Power Supply is used continuously under short-circuited or overcurrent condition, its internal elements may become deteriorated or damaged. Remote Sensing Function (Applicable models: S82F, S82D, S82H and S82H-P) Remote sensing can be used to compensate for a voltage drop on the load lines. More stable operation can be achieved by using thicker load lines and compensating the voltage drop using the Power Supply’s V.ADJ. To use remote sensing, remove the short bar from the remote sensing terminals (connected when shipped) and wire as shown in the diagram. Remote sensing connection (2-conductor shielded cable) Remove the short bars. +S Load +V –V Wire connecting to load Note: 22 –S 1. When the voltage drop in the load wiring is large, the overvoltage protection function might engage due to the increase in voltage to correct the voltage drop, so be sure to use high capacity wiring. 2. Be sure that VOUT x IOUT does not exceed the rating of the Power Supply. Technical Information Technical Information Remote Voltage Adjustment The output voltage of the Power Supply can be varied using an external variable resistor connected between terminals +V and +S. The output voltage variable range is ±10%. 23 Technical Information Technical Information Models for Series Output Operation Backup Operation Two Power Supplies can be wired in parallel even though each has a sufficient power rating. This can be done to ensure (back up) Power Supply even though one of the Power Supplies fails. A Model 24 VDC S8PS S8 S 50 W 5, 12, 24 VDC 100, 150, 300, 600 W 24 VDC 50 W 24 VDC 100 W 5, 12, 15, 24 VDC 150, 300, 600 W 24 VDC 150 W 12, 24 VDC 300 W 24 VDC S82F-P 120, 240 W 24 VDC S82D 300, 600 W 5, 12, 24 VDC S8E1 50 W 5, 12, 15, 24 VDC S82H 100, 150 W 5, 12, 15, 24 VDC S82H-P 100, 150, 300, 600 W 5, 12, 15, 24 VDC Load –V S82JJ S8 B D2 +V S82F S8 –V Use the same model of Power Supply for A and B. Select the Power Supplies A and B so that either has a sufficient power rating for the load. You must connect diodes to both Power Supplies as shown in the diagram to be sure that the faulty Power Supply will not affect the backup operation. Guidelines for the kind, dielectric strength, and forward current of the diodes are as follows: • • Kind: Schottky barrier diodes. Dielectric strength (VRRM): Higher than the rated output voltage of the Power Supply. • Forward current (IF): Higher than twice the rated output current of the Power Supply. Adjust the output voltage of Power Supplies A and B just enough to allow for the forward voltage drop (VF) on diodes D1 and D2. Also, make sure that the diodes are sufficiently cooled so that their temperatures remain below the catalog value. This is necessary so control the power loss resulting across the diodes (output current of Power Supply IOUT x diode forward voltage VF). Backup operation is possible for all Power Supplies with single outputs. There will be some power loss to the load due to diodes. Be sure to use Power Supplies with sufficient power ratings (rated output voltage x rated output current) to allow for this loss. Do not exceed the power rating of the Power Supply. Series Operation Connect the Power Supplies in series to increase the output voltage. +V V1 INPUT –V Load VL +V INPUT V2 –V VL =V1 +V2 Rated voltage 90, 100, 240 W D1 +V Power ratings S82K Series operation is possible only for the models shown in the table. If other models are used, one of the Power Supplies may not operate when the AC Power Supply is turned on, possibly damaging internal circuits over a period of time. If models with different power ratings or rated voltages are wired in series, keep the current flowing to the load below the rated output current for the Power Supply with the lowest power rating. Wiring Generating Outputs The use of a floating output (the primary and secondary circuits are separated) allows you to create ± outputs using two Power Supplies. To create ± outputs, connect two of the same model of Power Supply as shown in the diagram. +V +V –V Load +V Load INPUT 0V INPUT –V –V All models of Power Supply can be used to create ± outputs. If there is the possibility that another load is wired in series as shown in the diagram, connect diodes D1 and D2 as shown in the diagram. Without these diodes, the Power Supplies may not start when power is turned on, possibly damaging internal circuits over a period of time. Guidelines for the kind, dielectric strength, and forward current of the diodes are as follows: Kind: Schottky barrier diodes Dielectric strength (VRRM): Higher than twice the rated output voltage of the Power Supply Forward current (IF): Higher than twice the rated output current of the Power Supply +V D1 INPUT –V Load Load +V INPUT Load D2 –V • 24 No diodes are required for models that allow series operation. Technical Information Technical Information Mounting Operating Life The life of a Power Supply is determined by the life of the electrolytical capacitors used inside. Here, Arrhenius’ law applies, i.e., the life will be cut in half for each rise of 10_C or the life will be doubled for each drop of 10_C. The life of the Power Supply can thus be increased by reducing its internal temperature. For natural cooling: Temperature Reduction The temperature inside a Power Supply will remain constant when the heat generation is equal to the heat dissipated. The internal temperature will rise if not enough heat is dissipated, i.e., the Power Supply must be mounted to allow proper heat dissipation. 3. It is recommended that forced cooling be used as much as possible. • • 1. Provide air holes and an environment that allows air circulation 2. Heat will also transmit to metal mounting plates. Due consideration must be given so that the operating ambient temperature of the Power Supply falls within the range specified by the derating curves. The calorific (heating) value of the Power Supply can be expressed in the following equation. Calorific value (W)= Output voltage – Output voltage Efficiency Mounting Methods The standard mount methods should be used to ensure proper heat dissipation. If other mounting methods must be used, the ambient temperature must be lowered or the load rate must be reduced to prevent temperature increase inside the Power Supply caused by poor heat dissipation. Model Mounting direction A B C D E (Standard mounting) S8PS OK OK (See note 1) Conditional (See note 2) Conditional (See note 2) No S82J OK OK Conditional Conditional No S82H-3 OK OK Conditional Conditional No S82F, S82F-P OK Conditional Conditional Conditional No S82D OK OK OK OK No S8E1 OK OK Conditional Conditional No S82W OK Conditional Conditional Conditional No S82K OK No Conditional No No S82V OK No Conditional No No S82S OK No Conditional No No S8E3 OK OK Conditional Conditional No S82H, S82H-P (100, 150 W) OK OK Conditional Conditional No S82H-P (300, 600 W) OK OK OK OK No OK: Use possible; No: Use not possible; Conditional: Use possible at an ambient temperature of 50_C and a load rate of 50% max. Note: 1. The 300-W model is conditional. 2. The 600-W model is ok. 25 Technical Information Technical Information Spacing Required Between Power Supplies Spacing Model A A C B Dimension B Dimension C S82J 20 mm 20 mm (300 W, 600 W) 20 mm (300 W, 600 W) S82K 10 mm --- --- S82H-3 20 mm S82F, S82F-P 20 mm S8E1 15 mm S82V 10 mm S82S 10 mm 50 mm 40 mm 70 mm 50 mm 20 mm --- --- 20 0 mm 50 mm 40 mm 70 mm 50 mm S82W S82D S8 Fan S82D S82H S82H-P Dimension A 20 mm 300 W 10 0 mm 600 W S8E3 S82H-P S8 300 W 600 W C B S82H, S82H-P 100 W, 150 W 20 mm 20 mm 20 mm S8PS S8 S 50 W, 600 W 20 mm 20 mm 20 mm 100 W, 150 W, 300 W 30 mm 20 mm 20 mm S82J S8PS Testing Methods Dielectric Strength Insulation Resistance Applicable models: S82H-3, S82F, S82D, S82F-P, and S82H-P (300, 600 W) When a high voltage is applied between the input terminals and the housing (FG terminal), electric energy builds up across the inductor L and capacitor C of the internal noise filter. This energy may generate a voltage surge when a high voltage is applied to the Power Supply by a switch or timer, and as a result, the internal components of the Power Supply may be damaged. To prevent voltage impulses when testing, decrease the applied voltage using the variable resistor on the dielectric strength testing equipment, or apply the voltage so that it crosses the zero point when it rises or falls. Some models (S82H-3, S82F, S82D, S82F-P, and S82H-P (300, 600 W)) of OMRON Switching Power Supplies have surge absorbers between the input lines and between the input terminals and the ACG terminal. When testing the dielectric strength of these models, remove the short bar from the FG and ACG terminals. With the short bar attached to the terminals, the applied voltage may be cut off by the testing equipment. Applicable models: S82H-3, S82F, and S82D, S82F-P, S82H-P (300, 600 W) To protect the Power Supply from an input voltage surge, surge absorbers are inserted between the input lines and between the input terminals and the ACG terminal. When testing the insulation resistance of the Power Supply, remove the short-circuiting bar from the FG and ACG terminals; otherwise, the measured resistance will be lower than the actual value. (See following diagram.) Input side Input Output side +S Input +V PS M ACG –V FG –S (See following diagram.) Input side Output side (M: Insulation resistance meter) Input +S +V Input AC1 26 PS ACG –V FG –S Technical Information Technical Information Wiring to Prevent Noise Interference Separate input lines and output lines, and use twisted cables. Noise will be induced on the output lines if they are laid together with or close to input lines. +V –V L N OUT IN +V –V L N OUT IN Binding Use short, thick input lines. Input lines radiate noise, and must therefore be as short and thick as possible. +V –V L N +V –V L N 27 Technical Information Technical Information Mounting Precautions Mounting Metal Splinters (Filings, etc.) The depth (excess length) of screws screwed into the Power Supply can never be longer than 6 mm. The length of these mounting screws must be so that no more than 4 mm extends into the Power Supply. Metal splinters, filings, etc., produced when mounting can fall onto PCB of a Power Supply, causing shorting and possible failure of internal circuits. Always cover a Power Supply with a protective sheet or cloth whenever working above of it to prevent metal splinters from entering, regardless of whether or not the Power Supply is equipped with a cover. Always remove the protective sheet or cloth before applying power to the Power Supply to ensure proper heat dissipation. Before Applying Power Check to be sure the Power Supply is grounded. Check to be sure that all functions are set as desired (refer to information on individual models). Function Factory setting Input power voltage: 100 V or 200 V Open (200-V input voltage) Remote sensing function The following terminals are shorted with a short bar: +S to +V and –S to –V Remote control function –RC and –RC are shorted with a short bar. When you are checking functions, take the time to be sure that all terminals are properly tightened. 28 Standards Standards Standards Safety Standards Today, safety is required for all equipment including power supplies. Strict rules and regulations have been established for safety, such as the USA’s UL standards, Canada’s CSA standards, and Germany’s VDE standards. To protect people and property from electric shock, fire, and other accidents, these standards stipulate the construction and capabilities of individual products. The following table lists the main standards related to power supplies. Type of standard International Safety standards North America Europe IEC UL (USA) CSA (Canada) VDE (Germany) SEV (Switzerland) SEMKO (Sweden) NEMKO (Norway) DEMKO (Denmark) KEMA (Holland) BS (UK) USE (France) CEI (Italy) CEBEC (Belgium) CEE (Europe) Manufacturing standards (compatible) ISO ANSI (USA) DIN (Germany) Maritime standards --- ABS (USA) LR (UK) GL (Germany) BV (France) Radio interference CISPR FCC (USA) DOC (Canada) FTZ (Germany) Industrial standards --- NEMA (USA) ASTM (USA) --- North American: Protects human life and properly. European: Protects people from death caused by electric shock or prevents electrical fire. Others Terminology The following chart shows the relationship between the terms that are often found in approval reports on power supplies and safety standards, including the EMI standards. EMI standards, reflecting contemporary computer proliferation, were established to prevent radio interference. Prevention of electric shock Countermeasures against voltage SELV and ELV circuits Primary and secondary circuits Setting of devices Countermeasures against current Insulation of devices (Class Ι/Class ΙΙ/Class ΙΙΙ) Purpose Prevention of electric shock and fire Prevention of fire Selection of insulating materials Kind of insulation (function/basis/extra/double insulation/reinforced insulation) New standards established to prevent mutual interference between computers and external noise interference, reflecting extensive use of computers in contemporary society. EMI standards for preventing radio interference Applicable regions Insulationdi stance(space/di stancn) North Ar 17a: (USM FCC), CanadaM DOCn))TjÏÈ0 -1..575 TDÏÈ0 TwÏÈ(urope: GteranyM FTZn))TjÏÈ0 -1.748 TDÏÈ0.125 TwÏÈ(Ixternntioal: CISPR) 29 Standards Standards Insulation Example of Class-ΙΙ Equipment Molded case electrically insulated Reinforced insulation (3) Active side L Power supply Secondary circuit 1 Primary circuit Neutral side N Extra insulation (2) Basic insulation (1) (see note 2) Touchable metal parts ELV circuit Basic insulation Secondary circuit 2 I/O connectors SELV circuit Touchable secondary circuits DC printers Reinforced insulation (3) (see note 2) *Basic insulation (1) + extra insulation (2) = double insulation, the insulation distance of which is twice as large as that of basic insulation and equivalent to reinforced insulation (3). Note: 30 Basic insulation (1), double insulation, or reinforced insulation may be required of relays depending on how they are used. Relays from which double insulation or reinforced insulation are required are called class-ΙΙ relays. Standards Standards National Standards Note: For detailed information about applicable standards, refer to the relevant catalog. 31 Standards Standards The Recognition Mark applies to the components used in a product, and therefore constitutes a more conditional approval of a product. Products display the Recognition Mark shown below. R RECOGNITION MARK The UL and CSA are unifying their standards with the adoption of a mutual approval system. Furthermore, they are adjusting their standards so that they will be in conformity with IEC standards. Since October 1992, UL has been approved as a CO (council organization) and TO (test organization) by the SCC (Standard Council of Canada). This authorizes UL to conduct safety tests and certify products conforming to Canadian standards. The above marks are UL marks for products certifying that the products meet Canadian standards. The designs of the listing marks and recognition marks have been revised as shown below. These marks have been effective since November 1998. The previous marks are valid until November 2007. LISTING MARKS Marks for US Marks for Canada Marks for US and Canada u Previous mark New mark RECOGNITION MARKS Marks for US Marks for Canada Marks for US and Canada Previous mark New mark CSA Standards (Canadian Standards Association) This association descended from a nonprofit, non-government standardization organization established in 1919. In addition to industrial standardization, the association now carries out safety testing on electrical products. CSA has closer ties to government agencies than UL, so that electrical products not approved by CSA cannot be sold in Canada. Non-approved goods being sold illegally may have to be withdrawn. CSA approval is known as “certification”, and consequently, CSA-approved equipment is referred to as “certified equipment”. Products display the mark shown below. For a conditional certification, products display component acceptance mark. The CSA is adjusting its standards so that they will be in conformity with UL and IEC standards. C CERTIFICATION MARK China GB (Guojia Biaozhun) Chinese National Standards The GB are established Chinese national standards based on IEC standards. Products such as home electronics appliances (e.g., televisions, washing machines, and microwave ovens), for which GB standards are obligatory, must be approved by CCIB (China Commodity Inspection Bureau) and CCEE (China Commission for Conformity Certification of Electrical Equipment). The marks shown below are respective marks of recognition. CCIB Mark 32 CCEE Mark Standards Standards Shipping Standards LR (Lloyd’s Register of Shipping) These are the standards of the Lloyd’s Register of Shipping, headquartered in London. All of the OMRON control components approved in LR are UMS ships, the unmanned engine-room ship classification in the Lloyd’s Register. Unlike the safety standards such as UL, the devices are checked to ensure that they can function sufficiently under the environmental conditions when they are used in ships. When a device is approved, Lloyd’s Register doesn’t apply the passing mark on the product, but includes it on the list of approved products that it publishes every year. NK (Nippon Kaiji Kyokai) Nippon Kaiji Kyokai (NK), which was established in 1899 under a different name for the purpose of ensuring the safety of vessels and the maintenance of maritime environmental conditions, has been using the present name since 1946. Automation equipment and devices receive tests and inspections based on the provisions of the steel-ship regulations and can be formally approved if the tests are passed. Testing at the production factory can be partially or entirely omitted when automation equipment and devices that have been formally approved are installed on ships. As a general rule, manufacturers of approved products indicate that the products being shipped have been approved. (It is also acceptable to affix a label to products which require it.) Japan Electrical Appliance and Material Control Law of Japan The EAMCL was substantially revised in July 1995 in conformity with IEC standards, such as IEC335. Consequently, the previously-used symbol for second-grade appliances was abolished while the symbol for first-grade appliances remained unchanged. Furthermore, the range of applicable products has been greatly revised. First-grade appliance Second-grade appliance Previous symbol 282 products 216 products Present symbol 165 products 333 products (no markings) J J O Europe EN (European Norm) Standards As part of EC unification, 18 European countries are going to integrate their national safety standards into EN standards. When EN standards come into effect, they shall apply to the unified standards in Europe in place of the current safety standards. EN standards related to electricity are based on IEC standards and include requirements relating to countermeasures against electric shocks. EN codes consist of the prefix “EN” followed by five figures beginning with the figure 6 (e.g., EN60204). Industrial products exported to Europe must satisfy IEC standards if the products do not fall under EN standards. Industrial products exported to European countries from Japan or North America or traded between European countries must satisfy EN standards. Furthermore, 12 types of industrial products, such as machines, low-voltage devices, and EMC equipment, must bear CE markings. CE markings on a product indicate that the product meets safety standards specified by all related EC directives. For example, an industrial machine must satisfy the EC Machinery Directive, Low-voltage Directive (LVD), and EMC requirements. CE MARKING The following marks of recognition are used in European countries in accordance with EN standards. 33 Standards Standards VDE (Verband Deutscher Electroechnischer e.v.) in Germany VDE (applicable to electrical appliances only) W X D VDE MARK MONITORING MARK TÜV (applicable to electrical appliances, machines, and automobiles) E TÜV Rheinland TÜV Product Service K DEMKO (Danmarks Elektriske Materielkontrol) KEMA (Keuring van Electrotechnische Materialen Nederland B. V.) NEMKO (Norges Elektriske Materiellkontroll) UTE (Union Technique De Electricite) FIMKO (Finlands Material Kontroll) IMQ (Istituto Italiano del Marchio di Qualita) BSI (British Standards Institution) Britain (applicable to industrial products) SEMKO (Svenska Elektriska Materielkontroll Anstalten) BEAB (British Electrotechnical Approvals Board) Britain (applicable to home electronics products) SEV (Schweizerischer Electrotechnischer Verein) F ASTA (ASTA Certification Services) Britain (applicable to general products) 34 S + Standards Standards Normative References EN50081-1 1992 Electromagnetic compatibility Emission standard Part 1: Residential, commercial and light industry IEC 1000-4-2 1995 Electromagnetic compatibility (EMC) Part 4: Testing and measurement techniques Section 2: Electrostatic discharge immunity test. EN50081-2 1993 Electromagnetic compatibility Emission standard Part 2: Industrial environment IEC 100-4-3 1996 Electromagnetic compatibility (EMC) Part 4: Testing and measurement techniques Section 3: Radiated, radio-frequency, electromagnetic field immunity test. EN50082-1 1992 Electromagnetic compatibility Immunity standard Part 1: Residential, commercial and light industry EN50082-2 1995 Electromagnetic compatibility Immunity standard Part 2: Industrial environment EN55011 1990 Limits and methods of measurement of radio disturbance characteristics of industrial, scientific and medial (ISM) radio-frequency equipment EN55022 1985 Limits and methods of measurement of radio disturbance characteristics of information technology equipment EN60204-1 1992 Safety of machinery Electrical equipment of machines Part 1: General requirements EN61000-4-8 1993 Electromagnetic compatibility Part 4: Testing and measurement techniques Section 8: Power frequency magnetic field immunity test ENV50140 1993 Electromagnetic compatibility Basic immunity standard Radiated, radio-frequency electromagnetic field Immunity test ENV50141 1993 Electromagnetic compatibility Basic immunity standard Conducted disturbances inducted by radio-frequency fields Immunity test IEC 1000-3-2 1995 Electromagnetic compatibility (EMC) Part 3: Limits Section 2: Limits for harmonic current emissions (Equipment input current x 16 A per phase). IEC 1000-4-4 1995 Electromagnetic compatibility (EMC) Part 4: Testing and measurement techniques Section 4: Electrical fast transient/burst immunity. IEC 1000-4-5 1995 Electromagnetic compatibility 8EMC) Part 4: Testing and measurement techniques Section 5: Surge immunity IEC 1000-4-6 1996 Electromagnetic compatibility (EMC) Part 4: Testing and measurement techniques Section 6: Immunity to conducted disturbances, induced by radiofrequency fields IEC68-2-2 1974 Environmental testing Tests B: Dry heat IEC68-2-30 1980 Environmental testing Test Db and guidance: Damp heat, cyclic (12 + 12 hour cycle) IEC68-2-36 1973 Environmental testing Test Fdb: Random vibration wide band Reproducibility Medium IEC529 1983 Degrees of protection provided by enclosures MIL-STD-810E 1989 Method 514.4: Vibration ASTM D 4728 1987 Standard test method for random vibration testing of shipping containers Note: Abbreviations EMC: Electromagnetic compatibility EMS: Electromagnetic susceptibility EMI: Electromagnetic interference RF: Radio frequency ISM: Industrial, scientific and medical equipment IEC 100-3-3 1994 Electromagnetic compatibility (EMC) Part 3: Limits Section 3: Limitation of voltage fluctuations and flicker in low-voltage supply systems for equipment with rated current t 16 A. 35 Standards Standards Harmonic Current What is Harmonic Current? Harmonic Current Control Most switching power supplies have input circuitry incorporating capacitors. As a result, input current that flows into the circuitry is transformed into a pulse wave as shown below. As an international standard, IEC555-2 was enacted for the limitation of harmonic current emission. IEC61000-3-2, as a revised standard replacing IEC555-2, was established in 1994. In conformance with the IEC61000-3-2, EN61000-3-2 was established and will come into effect in European countries in January 2001 covering 75-W-capacity power supplies and with a transition period lasting until January 2001. In Japan, the Ministry of International Trade and Industry provided some guidelines for the suppression of harmonics generated from electrical household appliances and electrical equipment. Japanese manufacturers have been voluntarily issuing and abiding by the guidelines. Input current Input voltage VC (∗) Power Supply The relationship between input current/voltage and VC is as shown in the following chart. Applicable Model as of September 2000 S82H-Pjjjjj S82K-Pjjj24 (200-V Series only for 90-W and 100-W models) S8PS Harmonic Current Suppression Input DC voltage (∗) Existing OMRON products that satisfy the harmonic current control standard are provided with active filters to suppress harmonic current. As shown in the following illustration, current waveforms are shaped into waveforms that are close to sine waves by switching in accordance with the voltage waveform. This suppresses generation of harmonic current. Input voltage Input current + Input current This current waveform includes a fundamental wave with a commercial frequency of 50/60 Hz and multiple frequencies (harmonic current). – Current Active filter circuit Power Supply Input voltage Input current Degree If this current is provided to the power receiving installations of factories or buildings, the installations will generate excessive heat that may damage the installations themselves while consuming unnecessary energy. This has become a problem in society as well. 36 Standards Standards Typical Safety Standards for Noise Item Applicable law Europe CISPR Pub. 14 (for office equipment) Permissie ss bl noise ble i ((noise terminal voltvolt age) U.S.A. VDE0871 (for high-frequency applied equipment) Class A Class A Voltage dB (µV) Frequency range (MHz) Voltage dB (µV) Frequency range (MHz) Voltage dB (µV) Frequency range (MHz) Voltage dB (µV) 0.525 to 1.605 65 0.15 to 0.5 66 0.01 to 0.15 91 to 69.5 0.45 to 1.6 60 0.5 to 5 60 0.15 to 5 66 1.6 to 30 69.5 5 to 30 66 0.5 to 30 60 Class B Class B Frequency range (MHz) Voltage dB (µV) Frequency range (MHz) Voltage dB (µV) 0.01 to 0.15 79 to 57.5 0.45 to 1.6 48 0.15 to 5 54 1.6 to 30 48 0.5 to 30 48 (max. value between one line and ground) Item Europe • Class I (stationary type) 3.5 mA max. General 5 mA max. Class I (portable type) 0.75 mA Double insulation 0.25 mA max. Class II 0.25 mA ( easu ed at (measured a resistance es s a ce of o 1 5 kΩ and 1.5 d att 0.15 0 15 µF) F) (input: 110%) Between current-carrying parts and surface of insulated part • • Between primary non-current-carrying parts and across-the-line capacitor terminals Japan Electric components regulations (Table 8) 1 mA max. (measured at resistance of 1 kΩ) • General Between current-carrying parts and non-current-carrying metal parts Class I Class II Up to 250 V 1,000 V Up to 150 V 1,000 V Function insulation 1,250 V --- Over 250 V 1,000 V + 2 V Over 150 V 1,500 V Reinforced insulation 3,750 V 3, 750 V (AC, for 1 min) (AC, for 1 min) • (max. value between one line and ground) UL114 (for office equipment) (measured at resistance of 1.5 kΩ and at 0.15 µF) (input: 106%) Dielectric strength (max. value between one line and g ground)) ( i t operating ti on (equipment 1 kW max.) U.S.A. IEC 380 (for office equipment) Leakage current Electric components regulation (Table 8) Frequency range (MHz) (max. value between one line and ground) Applicable law Japan FCC Part 15 (for computers) Between current-carrying parts: 1,250 V (AC, for 1 min) Ca acitor: (VDE0565) Capacitor: Evaporative Eva orative X capacitor: ca acitor: 4.3 x rated voltage (DC, for 1 min) File Y capacitor: 1,500 V (AC, for 1 min) U: maximum indicated voltage Between current-carrying parts (Table 4) 2.3 x rated voltage (AC, for 1 min) • Double insulation: between currentcarrying parts and non-current-carrying metal parts Up to 150 V Over 150 V Function insulation 1,000 V 1,500 V Protection insulation 1,500 V 2,500 V Reinforced insulation 2,500 V 4,000 V (AC, for 1 min) 37 Standards Standards Noise Terminal Voltage Values Stipulated in Each Country (1) (2) (3) (4) (5) (6) (7) (8) CISPR Pub. 14, VDE0875 FCC Part15-J (Class A) FCC Part15-J (Class B) VDE0871 (Class A) VDE0871 (Class B) Voltage dB (µV) VCCI (Class 1) VCCI (Class 2) Frequency range (MHz) Frequency range (MHz) CISPR: Applied to office equipment. FCC: Noise regulation in U.S.A. VDE: Noise regulation in Europe Class A: industrial equipment Class B: household appliance and information equipment including communications equipment. Japan Electric components regulations (J): regulations applied to household and industrial electric equipment in Japan VCCI: Applied to data processing devices in Japan. Voltage dB (µV) (1) 0.15 to 0.5, 0.5 to 5, 5 to 30 66, 60, 66 (2) 0.45 to 1.6, 1.6 to 30 60, 69.5 (3) 0.45 to 1.6, 1.6 to 30 48, 48 (4) 0.01 to 0.15, 0.15 to 0.5, 0.5 to 30 91 to 69.5, 66, 60 (5) 0.01 to 0.15, 0.15 to 0.5, 0.5 to 30 79 to 57.5, 54, 48 (6) 0.525 to 1.605 65 (7) 0.15 to 0.5, 0.5 to 30 79, 73 (8) 0.15 to 0.5, 0.5 to 5, 5 to 30 66, 56, 60 Selection of Wires Wires for the power supply should must be carefully selected. Refer to this table when selecting the wires. AWG No. Cross-sectional C oss sec o a a area ea 2) ( (mm Co gu a o Configuration ( (number b off conductors/mm) Recommended maximum current (A) Voltage o age d drop op pe per 1 A ( V/ t ) (mV/meter) UL1007 (300 V at 80°C) UL1015 (600 V at 105°C) 30 0.051 7/0.102 358 0.12 --- 28 0.081 7/0.127 222 0.15 0.2 26 0.129 7/0.16 140 0.35 0.5 24 0.205 11/0.16 88.9 0.7 1.0 22 0.326 17/0.16 57.5 1.4 2.0 20 0.517 26/0.16 37.6 2.8 4.0 18 0.823 43/0.16 22.8 4.2 6.0 16 1.309 54/0.18 14.9 5.6 8.0 14 2.081 41/0.26 9.5 --- 12.0 12 3.309 65/0.26 6.0 --- 22.0 10 5.262 104/0.26 3.8 --- 35.0 Recommended Maximum Current The table is applicable to wires with 1 to 4 conductors. Keep the current value to within 80% of the values shown in this table when using wires having 5 or more conductors. The following chart shows the voltage drop per meter in terms of the relationship between the current and conductor diameter. Make sure that the current value does not exceed the recommended maximum current value. 38 Standards Standards Voltage Drop per Meter (UL1015 Vinyl-sheathed Wires for Heat-resistant Equipment AWG28 AWG26 AWG24 AWG24 AWG22 AWG20 AWG18 AWG16 AWG12 Voltage drop (mV) AWG10 (See note) Current (A) Note: The current indicates the allowable current. In practice, application must be below the recommended current values. 39 Troubleshooting Troubleshooting Troubleshooting Troubleshooting Table Trouble Probable cause and possible remedy • An electric shock is felt when touching the power supply. • There is an AC voltage such as a 100-VAC input voltage between the casing or output terminal of the power supply and the ground. • The casing may not be properly grounded. Ground the FG or GR terminal properly. • The earth leakage breaker operates with the leakage current between the AC input and ground. • The length of mounting screws inside the power supply is limited. If this is the case, the mounting screws may be touching the internal circuits and the internal circuits may have been damaged. • The load malfunctions due to noise. • Input and output wires to the power supply may not be separated. • The output wires may be influenced by inductive noise. • The AC input source may have noise. If this is the case, connect a noise filter to the AC input wires near the AC input terminals. • The load may be influenced by common mode noise that may be generated between the output terminal of the power supply and the ground. If this is the case, connect a film capacitor with a capacitance of approximately 0.1 µF and a dielectric strength of 500 VDC minimum between the input terminal of the load and the ground. • The circuit breaker on the input side opens. • The circuit breaker on the input side may be opening due to inrush current. • The built-in fuse in the power supply is blown. In most cases, this happens because the circuit on the primary side is short-circuited due to the following reasons. If this happens, send the power supply to your OMRON representative for repairs. • A voltage of 200 VAC is being imposed on a power supply with a permissible input voltage of 100 VAC. • The AC input wires are not properly connected to the AC input terminals of the power supply. • The kind of load is not proper or the load current is not within the rated output current of the power supply. • The internal temperature of the power supply is improper or the ambient temperature is too high. • Shock has been imposed on the power supply or vibration has been imposed on the power supply for a long time. • The length of a mounting screws inside the power supply is more than 4 mm. • Metallic debris, water, or oil has penetrated into the power supply. • There has been condensation in the power supply due to a sudden ambient temperature change. • There has been an abnormality such as surge caused by lightning on an AC power supply. • The service life of the power supply has expired. • The output of the power supply is low or the output indicator flashes. • • • • • • • The output indicator lights but turns off soon. • The output voltage adjuster may be turned too far clockwise. • If the S82F, S82H, S82H-P, or S82D being used, the short bar for remote sensing may not be connected or properly secured. 40 The capacity of the load may be too large. The input voltage may be outside the rated input voltage range. The output voltage adjuster may be turned too far counterclockwise. Power supplies used in series cannot be connected in series. Power supplies used in parallel cannot be connected in parallel. The output wires may not be thick enough. Troubleshooting Troubleshooting Trouble There is no output voltage or the output voltage drops. Probable cause Possible remedy Remarks The input terminals for AC input voltage selection (VOLTAGE SELECT) may not be selected properly or the screws may not be secured properly. Example: An input of 100 VAC is used with 200 VAC range selected. 41 Troubleshooting Troubleshooting Trouble There is no output voltage or the output voltage drops. (continued) Probable cause The remote control terminals (+RC and –RC terminals) may be open or the screws may not be secured properly. Possible remedy If the remote control terminals are not used: Remarks The power supply has output when the remote control terminals are short-circuited and no output when the remote control terminals are open. Short-circuit the +RC and –RC terminals with a short bar. Open If the remote control terminals are used: Applicable models: S82F, S82F-P, S82D, S82H (150 W), and S82H-P (150, 300, 600 W) There will be output when the switch is turned on. The V2 output of the multi-channel power supply drop. The V1 output may not be connected to a load. The V1 output must be connected to a load, the current consumption of which must be at least 10% of the rated current of the power supply output. Open Load The output of the multi-channel power supply is controlled by the V1 output. Therefore, if the load connected to the V1 output is not sufficient, the V2 output may drop. 10% min. of the rated current Load Load Applicable models: S82K 7.5-W dual output models, S82S 7.5-W dual output models Insulation resistance and dielectric strength test results are not satisfactory. The short bar may be connected to the ACG and FG terminals. Applicable models: S82F, S82F-P, S82D, S82H-3, and S82H-P (300, 600 W) 42 Remove the short bar from the ACG and FG terminals before performing an insulation resistance test or dielectric strength test. A varistor is connected between the AC input and ACG terminals. If an insulation resistance test or dielectric strength test are performed with the ACG and FG terminals short-circuited, a current flows into the varistor. Accessories Accessories Accessories Mounting Track PFP-100N/PFP-50N PFP-100N2 Track Mounting Bracket S82Y-01N/-03N/-05N/-10N Supporting model Model ode Model S82Y-01N S8 0 S82Y-03N S8 03 S82Y-05N S8 05 S82Y-10N S8 0 Power ratings S82H-3 15 W S82J 10 W S8E1 10, 15 W S82H-3 30 W S82J 25 W S8E1 25 W S82H-3 50 W S82J 50 W S82J 100, 150 W S8E1 50 W 43 Discontinued Models Discontinued Models Discontinued Models OMRON has been refraining from manufacturing products that have not been in demand for the past few years and has also been unifying models into a single model if the models were used for exactly the same applications. The following table lists products that OMRON is no longer manufacturing or will stop manufacturing shortly. Name Switching Power Supply Model Recommended alternative models Scheduled to be discontinued Remarks S82E S82J End of March 1993 Different in dimensions and mounting method. S82K-j1jj S82K-015jj End of March 1994 Different in input specifications and design. S82K-j3jj S82K-030jj End of March 1994 Different in input specifications and design. S82K-j524 S82K-05024 End of March 1994 Different in input specifications and design. S82K-j7jj S82S-07jj End of March 1994 Different in dimensions and mounting method. S82M S8E3 End of March 1998 Different in dimensions and mounting method. S82N S8E3 End of March 1998 Different in dimensions and mounting method. S82H-30jj S82H-100jj End of March 1998 Different in input specifications and design. S82A None End of March 2000 --- S82T None End of March 2000 --- S82J-jj24 S82J-jjj24j End of September 2000 Different in input specifications S82J-15024jj S82J-15024j End of September 2000 Different in input specifications DIN-track Mounting Bracket S82Y-JjjN/-RN S82Y-jjN End of September 1994 Different in external dimensions and enclosed-mounting method. Power Failure Detector S87A None End of March 1998 --- Note: 44 Products recommended as replacements may not be completely compatible with the previous products. Before replacing the products, be sure to compare their specifications. History of OMRON Power Supplies History of OMRON Power Supplies History of OMRON Power Supplies Switching Power Supplies Multiple-output Single-output DIN track General-purpose/Built-in NTLP Linear Power Supplies Standard/ High-reliability FS82B S82A FS82C FS82P FS82H FS82E FS82M S82T FS82N FS82F Upgraded FS82G FS82K S82J S82H-3 S82W S82S S82V S82D S82L S8E1 S82R S82S Upgraded S82F-P Upgraded S82K: 100 W S82J: 100/150 W S8XA Upgraded S82J-D7 S82K: 240 W NTLP: Graphic 46 S82H: 100/150 W S82H-P: 100 to 600 W S8E3 S82J: 300/600 W F: Production discontinued (as of March 1998) OMRON SALES OFFICES ASIA/OCEANIA OMRON Corporation Shiokoji Horikawa, Shimogyo-ku, Kyoto, 600-8530 Japan Tel: 81-75-344-7000/Fax: 81-75-344-7001 OMRON CHINA CO., LTD. BEIJING OFFICE Room 1028, Office Building, Beijing Capital Times Square, No. 88 West Chang’an Road, Beijing, 100031 China Tel: (86)10-8391-3005/Fax: (86)10-8391-3688 OMRON ELECTRONICS ASIA LTD. Unit 601-9, Tower 2, The Gateway, No. 25, Canton Road, Tsimshatsui, Kowloon Hong Kong Tel: 852-2375-3827/Fax: 852-2375-1475 OMRON ASIA PACIFIC PTE. LTD. INDIA LIAISON OFFICE No. 59 HemKunt, Opp. Nehru Place, New Delhi 110048 India Tel: 91-11-623-8431/Fax: 91-11-623-8434 OMRON ASIA PACIFIC PTE. LTD. INDONESIA REPRESENTATIVE OFFICE Danamon Aetna Lifetower Suite No: 1602 JL. Jend Sudirman Kav 45-46 Jakarta 12930 Indonesia Tel: 62-21-577-0838/Fax: 62-21-577-0840 OMRON KOREA CO., LTD. 3F, New Seoul Bldg., #618-3 Sin Sa-Dong, Kang Nam-Gu, Seoul Korea Tel: 82-2-512-0871/Fax: 82-2-517-9033 OMRON ELECTRONICS SALES AND SERVICE (M) SDN. BHD. 2.01 Level 2, Wisma Academy, 4A, Jalan 19/1, 46300 Petaling Jaya, Selangor Darul Ehsan, Malaysia Tel: 60-3-754-7323/Fax: 60-3-754-6618 OMRON ASIA PACIFIC PTE. LTD. MANILA REPRESENTATIVE OFFICE 2/FL, Kings Court II Bldg. 2129 Pasong Tamo St., 1231 Makati City, Metro Manila Philippines Tel: 63-2-811-2831 to 2839 Fax: 63-2-811-2582 OMRON ASIA PACIFIC PTE. LTD. 55 Ubi Arenwel #05-01 408935 Singapore Tel: (65)5476789/Fax: (65)5476766 OMRON TAIWAN ELECTRONICS INC. HEAD QUARTERS 6F, Home Young Bldg, No.363, Fu-Shing N. Road, Taipei Taiwan Tel: 886-2-715-3331/Fax: 886-2-712-6712 0 OMRON ELECTRONICS CO., LTD. Rasa Tower 20th Floor, 555 Phaholyothin Road, Ladyao, Chatuchak, Bangkok 10900 Thailand Tel: 66-2-937-0500/Fax: 66-2-937-0501 OMRON ELECTRONICS G.m.b.H. Elisabeth-Selbert-Strasse 17 D-40764 Langenfeld Germany Tel: 49-2173-6800-0/Fax: 49-2173-6800-400 OMRON ASIA PACIFIC PTE. LTD. HO CHI MINH REPRESENTATIVE OFFICE 99 Nguyen Thi Minh Khai, Dist. 1 Ho Chi Minh Vietnam Tel: 84-8-830-1105/839-6666 Fax: 84-8-830-1279 OMRON ELECTRONICS KFT. Kiss Erno u. 1-3, H-1046, Budapest Hungary Tel: 36-1-399-3050/Fax: 36-1-399-3060 OMRON ELECTRONICS PTY. LTD. 71 Epping Road, North Ryde, N.S.W 2113 Australia Tel: 61-2-9878-6377/Fax: 61-2-9878-6981 OMRON ELECTRONICS LTD. 65 Boston Road, Private Bag 92620, Symonds Street, Auckland New Zealand Tel: 64-9-358-4400/Fax: 64-9-358-4411 NORTH/SOUTH AMERICA OMRON ELECTRONICS, INC. 1 East Commerce Drive, Schaumburg, IL 60173 U.S.A. Tel: 1-847-843-7900/Fax: 1-847-843-7787 OMRON CANADA INC. 885 Milner Avenue, Scarborough, Ontario M1B 5V8 Canada Tel: 1-416-286-6465/Fax: 1-416-286-6648 OMRON ELETRONICA DO BRASIL LTDA. Av, Santa Catarina, 935/939 04378-300 São-Paulo-SP- Brazil Tel: 55-11-5564-6488 Fax: 55-11-5564-7751 EUROPE OMRON ELECTRONICS G.m.b.H. Altmannsdorfer Strasse 142, A-1231 Vienna Austria Tel: 43-1-801900/Fax: 43-1-8044846 OMRON ELECTRONICS N.V./S.A. Stationsstraat 24, B-1702 Groot Bijgaarden Belgium Tel: 32-2-4662480/Fax: 32-2-4660687 Telex: 62150 OMRON ELECTRONICS SPOL. S.R.O. Srobarova 6, CZ-100 10, Prague 10 Czech Tel: 42-2-67-31-1254/Fax: 42-2-74-03-33 OMRON ELECTRONICS A/S Odinsvej 15, DK-2600 Glostrup Denmark Tel: 45-43-440011/Fax: 45-43-440211 OMRON ELECTRONICS O.Y. Metsänpojankuja 5, FIN-02130 Espoo Finland Tel: 358-9-5495800/Fax: 358-9-54958150 OMRON ELECTRONICS S.a.r.l. 19, Rue Du Bois Galon/B.P.33 F-94121 Fontenay Sous Bois Cédex, Paris France Tel: 33-1-49747000/Fax: 33-1-48760930 OMRON ELECTRONICS S.r.l. Viale Certosa 49, I-20149 Milano Italy Tel: 39-2-32681/Fax: 39-2-325154 OMRON ELECTRONICS B.V. Wegalaan 61, NL-2132 JD Hoofddorp The Netherlands Tel: 31-2356-81-100/Fax: 31-2356-81-188 OMRON ELECTRONICS NORWAY A/S Ole Deviksvei Vei 4, N-0666 Oslo Norway Tel: 47-22-657500/Fax: 47-22-658300 OMRON ELECTRONICS SP. Z.O.O Ul Jana Sengera Cichegol, PL-02 790 Warsaw Poland Tel: 48-22-645-7860/Fax: 48-22-645-7863 OMRON ELECTRONICS LDA Edificio OMRON, Rua de Sao Tomé, Lote 131, P-2685 Prior Velho Portugal Tel: 351-1-942-9400/Fax: 351-1-941-7899 OMRON ELECTRONICS Brigadiersky Pereulok 6 R-107005 Moscow CIS (Russia) Tel: 7-501-258-6277/Fax: 7-501-258-6280 OMRON ELECTRONICS S.A. C/Arturo Soria 95, E-28027 Madrid Spain Tel: 34-1-377-9000/Fax: 34-1-377-9056 OMRON ELECTRONICS A.B. Norgegatan 1, S-164 29 Kista Sweden Tel: 46-8-632-3500/Fax: 46-8-632-3510 OMRON ELECTRONICS A.G. Sennweidstrasse 44 CH-6312 Steinhausen Switzerland Tel: 41-41-748-1313/Fax: 41-41-748-1345 OMRON ELECTRONICS LTD. Acibadem Caddesi Palmiye Sokak 12 TR-81020 Kadikoy-Istanbul Turkey Tel: 90-216-326-2980 to 2982 OMRON Corporation Industrial Automation Company Measuring and Supervisory Controls Department Shiokoji Horikawa, Shimogyo-ku, Kyoto, 600-8530 Japan Tel: (81)75-344-7108/Fax: (81)75-344-7189 In the interest of product improvement, specifications are subject to change without notice. Authorized Distributor: Cat. No. Y102-E1-2 Printed in Japan 0900-2M (0498) (A)